MY CV AB - Lng-2014

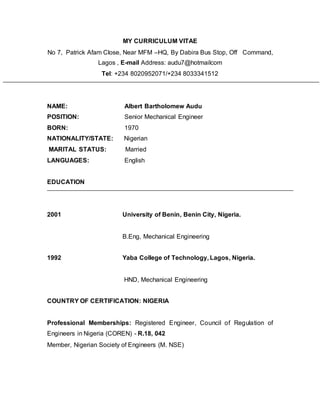

- 1. MY CURRICULUM VITAE No 7, Patrick Afam Close, Near MFM –HQ, By Dabira Bus Stop, Off Command, Lagos , E-mail Address: audu7@hotmailcom Tel: +234 8020952071/+234 8033341512 NAME: Albert Bartholomew Audu POSITION: Senior Mechanical Engineer BORN: 1970 NATIONALITY/STATE: Nigerian MARITAL STATUS: Married LANGUAGES: English EDUCATION 2001 University of Benin, Benin City, Nigeria. B.Eng, Mechanical Engineering 1992 Yaba College of Technology, Lagos, Nigeria. HND, Mechanical Engineering COUNTRY OF CERTIFICATION: NIGERIA Professional Memberships: Registered Engineer, Council of Regulation of Engineers in Nigeria (COREN) - R.18, 042 Member, Nigerian Society of Engineers (M. NSE)

- 2. CAREER SUMMARY: A mechanical engineer, with over 15 years of diversified experienced in engineering design of Oil and Gas Facilities such as mechanical -rotating equipment, Reliability and hardware maintenance, including Conceptual Studies, Front End Engineering Design (FEED),Detailed Engineering Design (DED) and Upgrades/Modifications of existing facilities relating to Onshore, Offshore, LNG and Refineries hydrocarbon plant installations. Currently, I work with “CresTech Engineering Company, Victoria Island, Lagos,” in the capacity of Lead/Sr. mechanical engineer responsible for delivering mechanical Engineering scope for TOTAL EGINA BUOY Project. COMPANY OF EMPLOYMENT: CresTech Engineering CO. Ltd, Lagos, Nigeria 4/6 Ajose Adegun Street, Victory Island, Lagos. PROJECTWORK HISTORY 1: (TOTAL –EGINA Buoy Project) Period: First Dec 2013 to Date Location: 4/6, Adjose Adeogu Street, VI, Lagos Position: Lead Mechanical Engineer Roles and Responsibility: Work with team of engineers and designers in carrying out DED designs, detailed engineering works, project modifications/upgrades works, including support for necessary technical procurement in compliance with tender specifications/data sheets within budgeted man-hour and project schedules.

- 3. Review contract requirements for project execution, the preparation of the Technical Document Register (TDR), identify requirements and scope of work; review specifications Process Data Sheets (PDS), Piping Material Specifications (PMS), Piping & Instrumentation Diagrams (P&ID’s), Plot plans, General Arrangement (GA) drawings, Review Philosophies, Area Classification Drawings, Fire and Gas Detector Layout Drawings and other relevant documents. Developed package Specification of Quick Release Hook assembly, Emergency Shutdown Valve (ESDV) for FPSO‘s tanker and the shuttle tanker, including interconnecting piping and other associated equipment. Carried out review and approval of vendor document as per Wind turbine power plant for ‘’EGINA Buoy’’ topsides, including basic design calculations and drawings. Review and approval of vibration isolation systems for wind turbine power plant in offshore applications. Company of Employment: CresTech Engineering CO. Ltd, Victoria Island, Lagos, Nigeria PROJECT HISTORY 2: ExxonMobil Unlimited Nigeria’s Eraha North Phase2 (DED and Modifications/Upgrades Offshore Project s) Period: Oct.1st, 2012 to Nov. 2013 Location: 4/6Adjose Adeogu Street, VI, Lagos Position: Senior /Lead Mechanical Engineer Roles and Responsibility: Work with team of engineers and designers in carrying out DED detailed engineering works project , including modifications/upgrades works, support for technical procurement in compliance with tender specifications/data sheets within budgeted man-hour and project schedules.

- 4. Provides support and expertise in the area of rotating equipment for offshore oil/DED projects throughout all of the engineering phases of the project, including front-end engineering, detailed design, construction, pre-commissioning, commissioning and start up. Review contract requirements for project execution, the preparation of the Technical Document Register (TDR), identify requirements and scope of work; review specifications Process Data Sheets (PDS), Piping Material Specifications (PMS), Piping & Instrumentation Diagrams (P&ID’s), Plot plans, General Arrangement (GA) drawings, Review material handling Philosophies, Area Classification Drawings, Fire and Gas Detector Layout Drawings and other relevant documents. Supervise and participate in the development and preparation of equipment sizing, specifications and interface i.e. compressors, pumps, turbines, controls, power supply, utility requirements, environmental regulation requirements and other assessments. Define metallurgy specifications in accordance to process requirements, administer the development of Mechanical Datasheets. Provide inputs for the preparation of plot plans; organize the issuance of engineering drawings and technical documents for Inter-Discipline Checks (IDC’s) coordinate with other engineering discipline in the integration of data inputs. Provides support for maintenance activities in areas of materials QA/QC, compliance, HSE Compliance, and Int’l codes & standards, including interchangeability, failures analysis and preventive maintenance. Demonstrated a sound understanding of associated engineering discipline interfaces as relates to process such as, UFDs/PFDs/P &IDs and the application of relevant industry standards. Work with design Contractor's Interface Engineers to ensure that interfaces activities are well controlled. Preparation of engineering deliverables, including Master Equipment List for Eraha North phase 2 Project

- 5. Check, review and approves contractor’s design calculations and Drawings. Participated in design reviews and HAZOP for compliance to required quality and constructability purpose. Carried out material handling philosophy/ study for Erah North phase 2. Carried out preparation, selection of rotating equipment important components, including checking their mechanical datasheets. COMPANY OF EMPLOYMENT: NETCO (National Engineering Technical Co. Ltd, Lagos, Nigerian.) 47, Ayorinde Close Victoria Island, Lagos. PROJECH HISTORY 1: Chevron- Nigeria. (Utonana, FEED Development Projects- Offshore) Position: Discipline Lead –Mechanical Engineer Period: March 2012- Sept 2012 Roles and Responsibility: Review ITB (Invi tation to Bid) documents submitted in the proposals stage, issue inquiry requisitions, review techno-commercial vendor offers, prepared project execution plan and man-hour estimates. Review of existing data and engineering design studies. Provides inputs to Electrical & structural discipline engineers as per equipment and machinery’s weights. Carried basic sizing and selection calculations for firewater system package, including jockey pumps, main pump and redundant pumps, consistent with project approved design codes and standards (NFPA). Accomplished mechanical scope of works under approved project schedule, budget and approved quality plan. Carried out review of process document, including process PFD & P & IDs.in order to verify compliance with project specifications. Participated in HAZARD and Operability Studies (HAZOP) to verify compliance to project specs, QQA/QC/ and constructability. Responsible for the design, specification, selection, drawing reviews, and testing services relating to oil and gas equipment including mechanical

- 6. packages, such as gas compressors and gas turbines for mechanical drives application for export crude oil pumps and gas export compressors. Participate in the engineering design reviews, for purpose of compliance to project design specifications, reliability, maintainability and operational safety. Company of Employment: NETCO, Lagos, Nigeria PROJECT HISTORY 2: ExxonMobil Major Integrity Projects (Detailed Engineering Design, Upgrade /Modifications FPSO -Offshore projects) For Gas compressors trains 4 Expansion Projects - Period: December 2009 to March 2012 Position: Lead, Mechanical Engineer Roles and Responsibility Review contract requirements for project execution, the preparation of the Technical Document Register (TDR), identify requirements and scope of work; review specifications Process Data Sheets (PDS), Piping Material Specifications (PMS), Piping & Instrumentation Diagrams (P&ID’s), Plot plans, General Arrangement (GA) drawings, Review Philosophies, Area Classification Drawings, Fire and Gas Detector Layout Drawings and other relevant documents. Monitor and review the works of young engineers for achievement of required project quality plan and approved budget. Verify contract technical specifications, scope of work, budgeted man hours, budgeted quantities, total of deliverables, and format of delivery, time schedules and project specifications for execution of the work. Identify equipment parameters including capacity, controls, power supply, and material of construction, required fatigue resistance/strength, and material performance at elevated temperatures, cyclic operations, pressure requirements, limitations of operating environment and others.

- 7. Supervise and participate in the development and preparation of fit for purpose technical specifications and basic sizing calculations, for process equipment, including compressors, pumps, turbines, controls, power supply, utility requirements, environmental regulation requirements and other assessments. Define metallurgy specifications in accordance to process requirements and administer the development of Mechanical Datasheets. Provide inputs for the preparation of plot plans; organize the issuance of engineering drawings and technical documents for Inter-Discipline Checks (IDC’s) and coordinate with other engineering discipline in the integration of data inputs. Supervise the preparation of technical inquiry requests (Inquiry Requisitions) to vendors; participate in the technical evaluation of vendor bid offers. Direct and provide guidance in the Technical Bid Evaluations (TBE), review vendor drawings and documents. Supervise the review of design calculations, ensure vendor equipment specifications meet with client equipment specifications and are within budgeted costs. Administer the preparation of Purchase Requisitions for the procurement of equipment and materials. Review vendor quality plans, ensure vendor equipment’s compatibility and compliance with the scope of client’s specifications. Coordinate with procurement to ascertain current & detailed specification for materials and or spares to be purchased. Interface and regularly meet with client and vendor representatives, conduct internal staff meetings, ensure the progress of project is in accordance to schedule, allotted man hours and budgeted costs. Coordinate with projects and planning departments on schedule related issues. Review and approves rotating equipment flex coupling to verify with project specifications, international codes and standards and applicable process loads.

- 8. Undertake Site Survey and Investigation to verify and confirm AS –Built Status of rotating equipment, including study/ inspection of equipment for obsolescing, requiring repair and or replacement. Assessing rotating possibility of failure due to equipment failures due to fatigue, looseness, instrumentation /control , high speed shaft misalignment, bearing/seal or component failures, etc. Carried out review and approvals of Vendor design /manufacturing design documentation, including equipment datasheets, drawings and basic design calculations Evaluate TBE for vendor offer, taking into consideration, vendor QA/QC, contractor HSE, delivery period and budgeted cost, Providing support for installation and machinery alignment for rotating equipment Carried out a study on equipment failure and troubleshooting for root cause analysis. Carried out technical clarifications with other discipline, including resolution of technical queries (TQs), as interface engineering among the Clients/contractor/vendors, ensuring timely closed out of pending Issues. Developed request for quotations (RFQs) and purchase requisitions and evaluate technical offers from bidders. Attends clarifications and construct- ability/quality assurance meetings on issues relating to design and construction. Carried out field mechanical completion verifications to design compliance as per approved P&IDs and GA Drawings. Provides support to mechanical Completions and commissioning Activities, including: Interface and technical clarification and guidance to construction sites, reviews and approvals of mechanical and commissioning plans. Company of Employment: NETCO, Lagos, Nigeria PROJECT HISTORY 2: Nigerian Petroleum Development Company (NPDC), FEED Development Project Lagos. PERIOD; Jan. 2008 to Nov. 2009.

- 9. Position: Senior Mechanical Engineer Roles Responsibility: Work with team of engineers and designers in carrying out FEED designs, engineering works, including support for necessary fit for purpose technical specifications in compliance with tender specifications/data sheets within budgeted man-hour and project schedules. Carried out coordination of the project mechanical scope and deliverables for the FEED project. Carried out for preparation of mechanical scope and execution plan for the FEED project. Carried out preparation of mechanical deliverables, including specifications, Basic sizing calculations, datasheets, for gas engines and emergency diesel generator, etc. Apportion work among engineering staff according to specialized training, monitor man-hour costs and team schedules. Recommend cost effective measures to reduce the overall package costs Assignment of responsibility young engineers. Providing timely inputs to structural and electrical disciplines engineers. Liaising with project manager and client representative engineer for timely project completion. Interfaces with Clients for timely information. Prepared project closed out report. Company of Employment: NETCO, Lagos, Nigeria PROJECT HISTORY 3: Nigerian Liquefied Natural Gas (N-LNG) Detailed Engineering Design /Construction Projects for Trains 3, 4, & 6 Period: June 2002- August 2007 Position: Mechanical Engineer/Field Support Engineer Roles & Responsibility:

- 10. Review and approval of vendor documents, including Monitoring of vendor manufacture progress and fabrications procedures, Participate in mechanical coupling alignment’s test of critical equipment items, including gas turbines compressor driven systems and generator drives (GTG) systems applications. Participate in Design reviews and HAZOP meetings with the client and representatives of other engineering disciplines, to ensure compliance to project HSE, project specifications ,design reliability and constructability, Interact with Quality Assurance for quality issues; Assisting with training of young engineers by providing instruction on new technologies. Participated in installation and functionality testing of vibration monitory & protection equipment (vibration sensors) for NLNG’s process plant, including high speed rotating shafts-bearings systems for centrifugal compressors. Participated in machinery alignment for GE - gas turbines driven power plant, pumps and compressors. Review of Conceptual design studies for N- LNG plant, including the design codes for the LNG storage tanks , LPG cargo tanks/systems, cargo heaters , HAZOP studies and design and fabrications of IMO type C cargo tanks. Provides technical assistance to engineering department on matters relating to operational safety, including equipment operational reliability, equipment/ machinery lubrications systems, equipment support structures, power transmission coupling performance, bearing performance, performance indicators of rotating machinery, alarm systems and shutdown of rotating machinery, members, Machinery structural defects, failure and mechanical stresses, including rotors, blades and bearing systems. . Review contractors design, drawings, and flow calculations of various mechanical systems, including Heaters, process compressors, and cooling fans Air systems.

- 11. Participated in mechanical completion and testing of all aspects of mechanical systems, equipment, and machinery. Participated in dropped object handling study over pressurized hydrocarbon equipment and their applicable risk mitigation. Provided Support for planning engineers with preparation of long term preventive maintenance and critical spares. Company of Employment: Sapele Power Plant, Delta State, Nigeria Period: Nov. 1992- August 1997 Position: Service Engineer Roles and Responsibility Conducts Engineering Analysis Conducts preventive maintenance & troubleshooting Responds to Service Maintenance Issues Prepares Service Reports & Technical Reports Provides findings & recommendations based on units checked Monitoring and inspection of rotating equipment performance, including inspection and monitoring of pumps, gas turbines, steam turbines, gearboxes, performance of cooling towers, lubrication systems and associated controls and instrumentations systems. Familiar with measuring tools ,such as vernier caliper, micrometers and dial gauges Carried out preventive maintenance program for rotating equipment to ensure maximum plant availability, safety integrity and long term plant reliability. Participate in rotating equipment installations, punched listings, mechanical completions and commissioning activities.

- 12. Carried out regular presentation on pump operations, maintenance, efficiency and performance, including other oil and gas associated equipment. Good experience of power generation enhancement through combined co- generation of gas turbines and gas turbines systems. Carried out routine preventive maintenance for bearings, lubrications pumps, fans, heaters, mechanical seals, coalesscer filters, cooling towers, cleaning and replacement and machinery lubrication activities. Carried out Installation, mechanical completion testing of new equipment Monitor Daily Operations Report for rated plant capacity for design and operating loads. Provides support during mechanical completion and commissioning activities, including punched listing, adjustment, system flow controls Participate in machinery alignment, including cold and hot alignment Carried inspection for plant/equipment vibrations of rotating machinery equipment Review applicable maintenance/operations OEM manuals and international standards for machinery modification and overhaul Policy. Liaise with OEM's and vendors on all technical matters relating to in service issues and product enhancement pertaining to reliability and defect troubleshooting as required. Provides technical assistance to the company on all matters effecting operational safety, criticality, reliability or the cost effectiveness of the maintenance of the power plant Prepare bill of materials/spares SKILLS AND COMPETENCIES Honesty, Integrity & organized. Special ability in mechanical/rotating equipment design Excellent communication skills both verbal and written.

- 13. Excellent in Interface issues, including design, scope changes, project modifications, tele -conference meetings and vendor issues. Exceptional analytical and problem solving abilities Perseverance and hardworking nature Proficient in Microsoft Windows/Microsoft Office (Word & Excel )and power points. Short Term Courses/Training PV Elite software for process vessel sizing and selection. Nigeria Mechanical soft wears for Fans for Design Quality Assurance training on mechanical rotating equipment installations for Chevron Agbami FPSO -topsides in South Korea. Sound Knowledge in the application of design codes and Standards, such as API, BS, ASME, ASTM, ISO and ABS Offshore Rules. REFEREES: 1. Engineer Madaki Mohammed, Project Engineering Manager, NETCO, Nigeria Ltd, Lagos. Tel: 08033033183, e- mail: mmadaki@netco.com.ng 2. Engineer David Okoye, Facilities Engineer, chevron Nigeria Ltd, Excravous Base, Warri ,.Delta State Tel; 08034880476, e-mail:DavidOkoye@chevron.com 3. Engineer, Anthony O. Bamwa, Lead Civil/Structural Engineer, NETCO Ltd, Lagos. Tel: 08035262791, e-mail: tonybamwa@yahoo.com