Green foundations for wind turbines

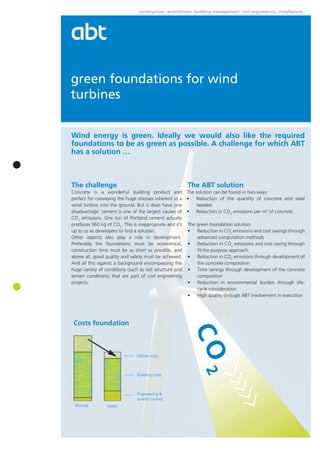

- 1. construction architecture building management civil engineering installations green foundations for wind turbines Wind energy is green. Ideally we would also like the required foundations to be as green as possible. A challenge for which ABT has a solution … The challenge The ABT solution Concrete is a wonderful building product and The solution can be found in two ways: perfect for conveying the huge stresses inherent in a • Reduction of the quantity of concrete and steel wind turbine into the ground. But it does have one needed disadvantage: cement is one of the largest causes of • Reduction in CO2 emissions per m3 of concrete. CO2 emissions. One ton of Portland cement actually produces 960 kg of CO2. This is inappropriate and it’s The green foundation solution. up to us as developers to find a solution. • Reduction in CO2 emissions and cost savings through Other aspects also play a role in development. advanced computation methods Preferably the foundations must be economical, • Reduction in CO2 emissions and cost saving through construction time must be as short as possible, and fit-for-purpose approach above all, good quality and safety must be achieved. • Reduction in CO2 emissions through development of And all this against a background encompassing the the concrete composition huge variety of conditions (such as soil structure and • Time savings through development of the concrete terrain conditions) that are part of civil engineering composition projects. • Reduction in environmental burden through life- cycle consideration • High quality through ABT involvement in execution Costs foundation Failure costs Building costs Engineering & quality control Normal Green

- 2. construction architecture building management civil engineering installations Green foundations for wind turbines Reduction in CO2 emissions and cost Reduction in CO2 emissions and reductions through fit-for-purpose cost reductions through advanced approach computation methods Investment costs in the foundation of a wind turbine will ABT has not stood still. Huge advances in wind turbine vary depending on the ground conditions. A choice is often foundations have taken place. By integrating practical made for a standard foundation per wind turbine type. experience acquired into new development, it has been Often the only variation that can then occur per location, possible to optimise foundation design still further. for example, consists of the length and dimensions of the The increase in turbine capacity and axis heights has also foundation piling. But choosing this approach actually forced designers to take a new look at foundation designs. means by definition that no cost-optimised foundation You cannot extrapolate a design for a small turbine to a is constructed. The standard foundation always has to large one without considering the risks entailed in such suffice across all locations, and thus by definition it is over a scaling-up. Reason enough for ABT to apply advanced dimensioned. This is why ABT has advocated a per-project computing methods and finite element sums in order approach for years. This also means that a fit-for-purpose to further develop the design. This puts us in a better foundation (and sometimes even per wind turbine location) position to assess risks while above all discovering the is designed per project. Experience has taught that this opportunities for optimisation. The three-dimensional extra investment in engineering always pays for itself in a computing models approach reality far better than the more economical foundation design simpler calculation models of the past. In summary, it can be concluded that, on the one hand, advanced computation is a necessity because of the increase in scale of wind turbine types, while on the other, it offers the advantage of savings in the design. It offers us a better insight, which enables safe optimisations in concrete and reinforcement steel to be achieved. Reduction in CO2 emissions through development of the concrete composition In contrast to normal practice, as a designer ABT also involves itself in the composition of the concrete mixture. The usual state of affairs is that the designer stipulates a concrete strength and the contractor ultimately determines the actual composition. But we believe this ignores a Time savings through development number of vital issues: • To a considerable extent it is the concrete that is of the concrete composition responsible for the CO2 emissions in foundations. Normally the choice of a concrete strength is made on the There are in fact possibilities for limiting this CO2 basis of the concrete compressive stress under maximum emission by the smart selection of a concrete load. Here it is assumed that this strength must be achieved mixture. after 28 days of hardening. But this actually ignores the • In bulk concrete (a foundation is generally thick), a fact that maximum stresses will only occur at a much later quantity of heat is released during the setting process. stage. Even more significantly, as long as the turbine is not If this is too much it can have a negative effect on the rotating the load is still only a fraction of this maximum quality of the concrete construction. It is therefore stress. This provides the opportunity to assemble the important to take this into account when choosing turbine just days after pouring the cement. the concrete mixture.

- 3. construction architecture building management civil engineering installations Green foundations for wind turbines Reduction in environmental High quality through ABT burden through life-cycle involvement in execution consideration Designing a wind turbine foundation is just one side of the What happens to the foundation once the wind turbine coin. Carrying out the work correctly is the other, and as is disassembled? Our experience with older wind the designer we believe we should continue to be closely turbines that have already been disassembled is that the involved. You might say that the design work doesn’t stop old foundation is barely usable or not at all. Just the in drawing a foundation and stipulating the specifications. speed alone with which new wind turbine development We have two important reasons for this: occurs, dictates that any new and more efficient wind 1. The quality of the work will only actually be achieved turbine with a high capacity will not be suited for the during execution. It is important that the quality ABT existing foundation. The only option that remains in envisages as the designer is also expressed in the 99% of cases is to demolish the existing foundations. construction execution. And that’s a pity. 2. We can only continue to innovate if we learn from Even more so given that most foundations still have years practice through ongoing feedback. Things that of life left in them. In construction design Dutch building don’t go as planned or practical solutions can only rules generally assume a 50-year lifespan. In practice the be incorporated into new designs if ABT is involved lifespan is much longer. However, current developments closely in the execution. in wind energy rather require an economic lifespan of 10 years. We are building too durably and too strongly! As designers we regard it as our responsibility to contribute If an existing foundation cannot be easily recycled (or acquired knowledge to the construction team during even upcycled), we are thus wasting effort. In designing execution. Alongside the checking role there is thus also foundations we already take into account the end of a supervisory one, where we support the contractor with that foundation’s functional life. the ultimate aim being a optimal result in quality and time At the same time when designing the foundation we … and thus reducing the risks for the principal. also make use of recycled materials. Here we take a more reduced lifespan into account (durability) and we take a balanced view of the required safety levels (strength).

- 4. construction architecture building management civil engineering installations Green foundations for wind turbines The company ABT has been closely involved in wind energy since the early 1980s. As a civil engineering consultant for wind energy projects, we might also label ourselves as pioneers. Through our involvement in a range of projects for a variety of principals, a large number of the problems that can occur during the preparation and construction of wind farms, have already been reviewed. And ABT has devised just as many solutions for these problems. With good results. All the services under one banner ABT is a multidisciplinary bureau. Alongside civil engineering we also have specialists in building management, construction, architecture and technical installations. This means ABT can offer you a complete package of services. Tasks and roles ABT can fulfil in your project: • Designing foundations • Designing mast anchorage • Designing masts • Designing the (civil) infrastructure for wind farms • Drawing up specifications • Supervising tendering and awarding • Producing cost estimations • Supervising execution • Carrying out quality inspections • Exercising management • Carrying out feasibility studies • Carrying out loss investigations • Carrying out quick-scan location studies Further information? Then please contact Adviesgroep Civiele Techniek (Civil Engineering Advice Group) Telephone: +31 (0)26 368 35 00 Fax: +31 (0)26 368 35 10 E-mail: windenergie@abt.eu Internet: www.abt.eu ABT bv Arnhemsestraatweg 358, Velp PO Box 82, 6800 AB Arnhem (Netherlands) Telephone: +31 (0)26 368 31 11 Delftechpark 12, Delft PO Box 458, 2600 AL Delft (Netherlands) Telephone: +31 (0)15 270 36 11 Kammenstraat 18 B-2000 Antwerp Telephone: +32 (0)3 205 37 11 Articles may be reproduced stating their source, following ABT permission.