Conmed Lsvt Brochure 4 09

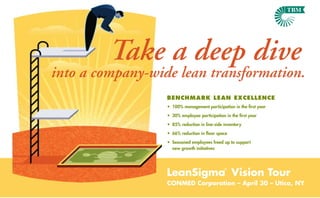

- 1. PRESORTED FIRST CLASS MAIL US POSTAGE PAID RALEIGH, NC PERMIT #2483 LeanSigma Vision Tour Come experience how CONMED achieved impressive results and developed a highly-committed culture of continuous improvement. Registration or More Information Contact Beth Ann Hunt 800-438-5535 x824 or bhunt@tbmcg.com Online details and registration at www.tbmcg.com/lsvt • 100% management participation in the first year • 30% employee participation in the first year • 85% reduction in line-side inventory • 66% reduction in floor space • Seasoned employees freed up to support new growth initiatives Benchmark Lean Excellence Take a deep dive into a company-wide lean transformation. LeanSigma Vision Tour ® CONMED Corporation – April 30 – Utica, NY What You’ll Learn Learn from the best and see what CONMED has done to create a culture committed to continuous improvement. See how they leverage lean to generate dramatic operations results that drive profitable growth while remaining focused on the highest levels of customer responsiveness. Take a deep dive into an enterprise-wide lean transformation, understand how they drive accountability, discipline, standard operations, standard work, visually identify abnormality and track performance for improvements and sustainability. Who Should Attend CEOs, President, COOs, CFOs, Controllers, General Managers, Plant Managers, Vice Presidents or Directors of Operations, Engineering, Continuous Improvement, Quality, Materials and Human Resources. CONMED was the 2008 Perfect Engine Site Award Winner “We presented the award to CONMED’s French Road facility because of their adaptability to the lean discipline and rapid business improvement. They were able to quickly implement and leverage the lean culture that has helped them achieve continuous business growth.” – Anand Sharma Founder and CEO TBM Consulting Group, Inc. ® TBM LeanSigma® Institute 4400 Ben Franklin Blvd. Durham, NC 27704 www.tbminstitute.com 02/09 LeanSigma® and the TBM Consulting Group logo are registered trademarks of TBM Consulting Group, Inc.

- 2. PRESORTED FIRST CLASS MAIL US POSTAGE PAID RALEIGH, NC PERMIT #2483 LeanSigma Vision Tour Come experience how CONMED achieved impressive results and developed a highly-committed culture of continuous improvement. Registration or More Information Contact Beth Ann Hunt 800-438-5535 x824 or bhunt@tbmcg.com Online details and registration at www.tbmcg.com/lsvt • 100% management participation in the first year • 30% employee participation in the first year • 85% reduction in line-side inventory • 66% reduction in floor space • Seasoned employees freed up to support new growth initiatives Benchmark Lean Excellence Take a deep dive into a company-wide lean transformation. LeanSigma Vision Tour ® CONMED Corporation – April 30 – Utica, NY What You’ll Learn Learn from the best and see what CONMED has done to create a culture committed to continuous improvement. See how they leverage lean to generate dramatic operations results that drive profitable growth while remaining focused on the highest levels of customer responsiveness. Take a deep dive into an enterprise-wide lean transformation, understand how they drive accountability, discipline, standard operations, standard work, visually identify abnormality and track performance for improvements and sustainability. Who Should Attend CEOs, President, COOs, CFOs, Controllers, General Managers, Plant Managers, Vice Presidents or Directors of Operations, Engineering, Continuous Improvement, Quality, Materials and Human Resources. CONMED was the 2008 Perfect Engine Site Award Winner “We presented the award to CONMED’s French Road facility because of their adaptability to the lean discipline and rapid business improvement. They were able to quickly implement and leverage the lean culture that has helped them achieve continuous business growth.” – Anand Sharma Founder and CEO TBM Consulting Group, Inc. ® TBM LeanSigma® Institute 4400 Ben Franklin Blvd. Durham, NC 27704 www.tbminstitute.com 02/09 LeanSigma® and the TBM Consulting Group logo are registered trademarks of TBM Consulting Group, Inc.

- 3. LeanSigma Vision Tour - April 30, 2009 ® Tour Highlights You’ll spend at least 20 minutes at each location where you’ll have the opportunity to take a deep dive and understand how lean helped drive sustainable improvement in each area. Some highlights are featured below: • Efficient U-shaped cells with single-piece flow. In these cells you will learn how CONMED used kaizen to improve productivity and quality with smaller footprints, less WIP and line-side inventory. All cells maintain standard work, improved safety, and ergonomics. • Experience their unique approach to abnormality response through its use of Andon lights. Andon lights are displayed in the main hallway along with the impressive use of technology to track performance of each product line including touch-screen monitors with SQDC metrics visible to everyone in the plant. • See how CONMED uses email and Blackberry® accounts to monitor real-time line status. Color-coded lights signal appropriate personnel to respond to the production line as problems develop minimizing downtime and facilitating solutions to technical issues. Rapid communication and visual management enabled them to maintain a 94% production uptime through 2008. • Set-up times for mold changeovers have been reduced by 70-75% helping to improve the efficiency and quality of the injection molding department. CONMED has now created an infrastructure focused on effective planning, scheduling and timely execution. Results include a cumulative capacity improvement with reduced overtime needs and the ability to in-source additional molded components. • Don’t miss the Continuous Improvement office and meeting center. Furthering its commitment to the lean journey, CONMED employs six full-time personnel including an office manager, four continuous improvement implementation analysts and one quality engineer. The new center boasts state-of-the-art media technology and a presentation room with high-definition wide screen presentation capabilities and seats for over 150 attendees. Visit our website at www.tbmcg.com/lsvt for for more information. About ConMed CONMED is a global medical technology company that specializes in the development and sale of products and services that allow physicians to deliver high-quality care and enhanced clinical outcomes for their patients. Their products are recognized as technological leaders by the specialties they serve. Caregivers within a vast array of specialized medical markets have come to value the CONMED name across the globe. In 2007, CONMED made the decision to adopt LeanSigma as a strategy to support the successful and profitable integration of growth initiatives. They launched their lean journey to transform their organization significantly in one short year. CONMED attributes its success to strong committed leadership, a robust continuous improvement cycle, an extremely aggressive implementation, a modern, technologically-advanced visual management system, and an army of dedicated employees. In just one year, CONMED achieved impressive results and developed a highly- committed culture of continuous improvement. They received the TBM Perfect Engine award in 2008 recognizing its outstanding achievement for a company-wide lean transformation. Agenda 7:45am Bus from hotel to plant 8:30am Welcome, introduction event objectives 9:30am 11:00am Tour begins 12:30pm Lunch break 1:30pm Tour resumes 3:00pm Tour summary and learning points 4:00pm Adjourn, bus transfer to hotel Event Details $800 per person for individuals $650 per person for groups of three or more Sponsored by TBM Consulting Group Hosted by CONMED Corporation April 30, 2009 - Utica, NY 7:45 am – 4:00 pm Recommended Accommodations Radisson - Utica Centre 200 Genesee St # 1 Utica, NY 13502 888-201-1718 Special rates of $104 for Vision Tour Attendees. Attendees pay hotel separately. Event price includes transportation from hotel to plant and back to hotel at end of day. Registration or More Information Contact Beth Ann Hunt 800-438-5535 x824 or bhunt@tbmcg.com Online details and registration at www.tbmcg.com/lsvt