A project report on the inventory management at ranna sugar ltd

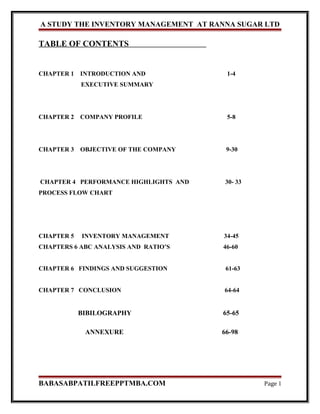

- 1. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD TABLE OF CONTENTS CHAPTER 1 INTRODUCTION AND 1-4 EXECUTIVE SUMMARY CHAPTER 2 COMPANY PROFILE 5-8 CHAPTER 3 OBJECTIVE OF THE COMPANY 9-30 CHAPTER 4 PERFORMANCE HIGHLIGHTS AND 30- 33 PROCESS FLOW CHART CHAPTER 5 INVENTORY MANAGEMENT 34-45 CHAPTERS 6 ABC ANALYSIS AND RATIO’S 46-60 CHAPTER 6 FINDINGS AND SUGGESTION 61-63 CHAPTER 7 CONCLUSION 64-64 BIBILOGRAPHY 65-65 ANNEXURE 66-98 BABASABPATILFREEPPTMBA.COM Page 1

- 2. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD INTRODUCTION TO SUGAR INDUSTRY The sugar industry occupies a prominent place among the organized industries in India. Sugar industry hold second rank next to cotton textiles industry in importance. It provides employment to nearly 5 lakhs of people directly. Sugar is essential product in India. Considerable quantity of sugar is produced since old days. India produces white sugar, Khandasari, and Jaggery.There are about 450 industries working through out the country. Among them 120 are in private sector 235 in cooperative sector and 95 are in public sector. In Karnataka state there are about 40 sugar industries established. Out of 40, 20 are in private sector, 18 are in cooperative sector, and remaining 2 are in public sector. The sugar industries are located in rural areas and have an in intrinsic symbiotic relationship with rural masses. Some units are also in position to supply surplus power to the grid thru Bagass based co-generation system. Type of sectors In India In Karnataka Cooperative sector 235 18 Private sector 120 20 Public sector 95 02 Total 450 40 EXECUTIVE SUMMARY Inventory control is the process whereby investment in materials and parts carried in stock is regulated within predetermined limits set in accordance with inventory policy established by the management. In modern competitive one of the burning problem of every business and industries that of cost control and cost reduction. An all pervasive effort for cost control and cost reduction is of paramount, importance for survival and growth of every industrial enterprises. This is why inventory management as a scientific device for controlling inventory cost and eliminating wastage, is now regarded as an integral part of industrial management. Inventory management does not involve any human factor, as it concerns itself not with men but with inventory. BABASABPATILFREEPPTMBA.COM Page 2

- 3. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD It is one the widely used techniques for the control of inventory. Objective of ABC control is to vary the expenses associated with maintaining appropriate control according to the potential savings associated with the proper level of such a control. A may account for more than half the total value usage in the inventory. These items required very careful management and special careful estimates of future usually class C items which in total account for only a few percent of the total value of usage very little effort should be devoted to forecast the requirement of items. The inter mediate class B items justify a reasonable but routine effort in forecasting demands and managing inventory. The basis for my study is the theory related to inventory. The theory collected is as follows, Meaning and definition of inventory, objectives & significant of inventory and techniques of inventory and also what are the Benefits derived to Company by holding inventory. FINDINGS: * The A items carry nearly about 7 to 8% of the total items similarly B items 11% and C items 81% * In the inventory A items very strict control because having high volume of the inventory management B items are moderate. SUGGESTION: From the study Ranna sugar found that is non professional in approach to be made to professional the systems in ranna sugars. Methodology: • primary source • secondary source BABASABPATILFREEPPTMBA.COM Page 3

- 4. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD BACKGROUND AND INCEPTION OF THE RSSK RANNANAGAR Chairman of factory is Mr. R. S. TALEWAD. Company is situated in Timmapur village near by Lokapur, Mudhol taluka, Bagalkot district and its registered office is in Factory sight The Factory has more than 500 employees on its roll including some officers and technical experts. Human resources being the most important assets of the company all the efforts are made to enhance the motivational level and efficiency of the employees. NATURE OF BUSINESS CARRIED SUGAR PRODUCTION (RANN SUGAR) The plant is capable of crushing about 2,500 Tons Cane per Day (T.C.D.) and would be producing export quality crystal white sugar using the latest techniques in the country. The factory one of the most advanced in India. Robust and reliable equipment of latest design, high efficiency, and low power consumption have been installed continuous operation all around the year. Due to abundant cane available in the area of operation, a minimum duration of season of 7 to 8 months is assured i.e. to say about 5 lacs tones of sugarcane will be crushed during the season to produce around 6.2 lacs quintals of sugar. When this is done, the turnover of the company right from beginning would be Rs.100 corers and after meeting all the obligations, there will be sizable surplus per year. POWER GENERATION (RSSK POWER) The company has undertaken to establish a mega project to generate power using non conventional energy fuel i.e. bagasse which is a byproduct coming out of sugarcane and available in plenty at the location employing very high pressure (67ata) and high efficiency boilers and turbo generator sets. Out of 12.5 megawatts of power generated, 4.2 mgt will be used for captive consumption, living a balance of 8.5 mgt to be sold to Karnataka Power Transmission Corporation Ltd, K.P.T.C.L (Formerly Karnataka Electricity Board) all around the year. BABASABPATILFREEPPTMBA.COM Page 4

- 5. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD Under the 10 year power purchase agreement entered into between the factory and KPTCL. The power to be exported to grid at 110kv would be paid for through an assured letter of credit at Rs.3.02per unit initially with an escalation of 5%. Every year i.e. to say 8.5 MW of exported power will generate a revenue of about Rs.16 crores per year and after meeting incidental expenses for generation, there will be a sizable surplus per year, which makes it a highly attractive preposition. M/s. Indian Renewable Energy Development Agency Ltd.(IREDA), New Delhi, the Govt. of India undertaking has rightly considered this project as a “ First Co-generation Plant in Co-op sector” in Karnataka and has financed the project in a big way towards establishment of this project BY-PRODUCTS The company has ambitious plans to utilize various by-products in a systematic way as fallows. BAGASSE 1. Power Generation 2. Paper production 3. Particle Board 4. Cattle Feed & Furfural MOLASSES: 1. Butanol 2. Yeast 3. Industrial Alcohol 4. High Protein Molasses FILTER CAKE: 1. Manure 2. Refined Wax BABASABPATILFREEPPTMBA.COM Page 5

- 6. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD PRODUCT PROFILE SUGAR PRODUCTION (RANN SUGAR) The plant is capable of crushing about 2,500 Tons Cane per Day (T.C.D.) and would be producing export quality crystal white sugar using the latest techniques in the country. The factory one of the most advanced in India. Robust and reliable equipment of latest design, high efficiency, and low power consumption have been installed continuous operation all around the year. Due to abundant cane available in the area of operation, a minimum duration of season of 7 to 8 months is assured i.e. to say about 5 lacs tones of sugarcane will be crushed during the season to produce around 6.2 lacs quintals of sugar. When this is done, the turnover of the company right from beginning would be Rs.100 corers and after meeting all the obligations, there will be sizable surplus per year. POWER GENERATION (RSSK POWER) The company has undertaken to establish a mega project to generate power using non conventional energy fuel i.e. bagase which is a byproduct coming out of sugarcane and available in plenty at the location employing very high pressure (67ata) and high efficiency boilers and turbo generator sets. Out of 12.5 megawatts of power generated, 4.2 mgt will be used for captive consumption, living a balance of 8.5 mgt to be sold to Karnataka Power Transmission Corporation Ltd, K.P.T.C.L (Formerly Karnataka Electricity Board) all around the year. Under the 10 year power purchase agreement entered into between the factory and KPTCL. The power to be exported to grid at 110kv would be paid for through an assured letter of credit at Rs.3.02per unit initially with an escalation of 5%. Every year i.e. to say 8.5 MW of exported power will generate a revenue of about Rs.16 cr per year and after meeting incidental expenses for generation, there will be a sizable surplus per year, which makes it a highly attractive preposition. M/s. Indian Renewable Energy Development Agency Ltd.(IREDA), New Delhi, the Govt. of India undertaking has rightly considered this project as a “ First Co-generation Plant in BABASABPATILFREEPPTMBA.COM Page 6

- 7. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD Co-op sector” in Karnataka and has financed the project in a big way towards establishment of this project. 2. COMPANY PROFILE: LOCATION : The RAYATAR SAHAKARI SAKKRE KARKHANE NYIYAMIT (R.S.S.K.N) Factory: Timmapur Mudhol, Tq: Mudhol District: Bagalkot ESTABLISHED IN : 25/11/1999 REGESTERED NO : DSK/REG/182-83 WEEKLY HOLIDAY : SUNDAY WORKING SHIFT : 4 am to 12 pm, 12 pm to 8 pm, 8 pm to 4 am CHAIRMAN : R.S.Talewad M.D : S.S. Pujari FINANCIAL : The Karnataka State Co-operative sugar Factories INSTITUTION Ltd, Bangalore OF THE COMPANY BABASABPATILFREEPPTMBA.COM Page 7

- 8. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD Shri Ryatar Sahakari Sakkare Karakhane N, Rannanagar Timmapur Tq: Mudhol. Board of Directors Shri. Ramann .S. Talewad Chairman Shri. A.B.Gorphade Vice Chairman Shri. S.S.pujari Managing Director Shri. D.S.Patil Director Shri. R.A.Tungal Director Shri. K .N. Paraddi Director Shri. U.V.Sarawad Director Shri. A.M.Patil Director Shri. G.P.Patil Director Shri. A.P.Patil Director Shri. R.T.Patil Director At every Annual General Meeting one third of the total number of Directors, whose period of office is liable to retire by rotation shall retire in accordance with the provisions of section 255 and 256 of the company Act. 1956 and they are eligible for reappointment. BABASABPATILFREEPPTMBA.COM Page 8

- 9. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD Financial Institutions HUDCO New Delhi BDCC Bank Bagalkot BDCC Bank Bijapur. SKDCC Bank SIRSI. CANARA Bank Lokapur. Auditors M/s. Biradar Assistant Co-op Audit Jamakhandi Management Team Shri R. N. Patil, Chief Engineer Shri M. M. Shendri, Chief Chemist Shri M. T. Patil, Cane Manager Shri V.V. Tulasigeri, Off Suptd Shri S. K. Kulkarni Accounts officer Engineers and Consultants M/s. Amminabhavi and Hegde Architects & Engineers (P) Ltd., Dharwad M/s. Avant Grade Engineers & Consultants (P) Ltd., Chennai M/s. Walachandanagar Industrial Ltd, Pune BABASABPATILFREEPPTMBA.COM Page 9

- 10. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD Objective of the Company 1. To carry on the business of manufacturers, refiners, producers, importers, exporters and dealers in cane sugar, bet Sugar, starch sugar, khandasari sugar and jaggery of all kinds and varieties and their bye products. 2. To carry on the business of manufacturers refiners, producers, importers, exporters and dealers in all kinds of sugars products, molasses, combustible fuel, Yeast and other fermentation, organic and inorganic chemicals, starch, syrups all alcoholic substances, acetone, spirits, sugar candy, glucose, confectionery and canned fruits. 3. To carry on the business of distillers. Brewers molesters, compound, rectifiers and dealers in all kinds of spirits and alcohol, liquors, like rum, gin, whisky, brandy and beer, special syrups, aerated waters, tinctures, essences, pharmaceutical and other chemical preparations, chemical fertilizers, manures, boot polish, wax, power alcohol and the like. 4. To carry on the business of manufacturers and dealers in melada, bagasse, bagasse boards, papers, paper pulp carbon dioxide, hydrogen, potash cane wax, fertilizers and cattle feed. 5. To carry on the business of agriculturist’s horticulturists and planters of all kinds and description. 6. To employ or pay experts, foreign consultants and other in connection with the prospecting planning, execution and development of all or any of the business which the company is entitled to carry on. 7. To carry on the business of transport operators of all kinds and description. BABASABPATILFREEPPTMBA.COM Page 10

- 11. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD 8. To set-up an Institute for training people in sugar technology sugar plants power generation, paper plants etc. and give implant training to the successful personal India and Abroad. 9. To carry on the business of cultivating growing, buying, selling, manufacturing or otherwise dealing in agriculture and its products including sugar cane, bagasse products, beet sugar, raw sugar and to acquire purchase sell manufacture construct, sugar mills, and khandasari mills, distillery and laboratory mills, paper mills co-generation of power, particle boards etc. 10. To buy sell, import, export prepare and to carry on the business of canners, preservers and dealers in fruits, honey-fresh and per servable products and generally to carry on the manufacture and trading in jams, jelly, pickles, chutney, vinegar, ketchup, juices, squashes, syrups, drinks, beverages, essences, ice-creams, milk preparations and other preparation where the sugar is used . Administration Department Administration department is the main department in the organization. They are total number of 38 employees working in this department. is divided into 6 sections and they are as below : 1. Share section. 2. Purchase section. 3. Stores section. 4. Sales Section. 5. Time office section. 6. Computer section. BABASABPATILFREEPPTMBA.COM Page 11

- 12. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD 7. Security section. 8. Telephone operating section. SHARE SECTION : The Share section is one of the important sections because more than half of the total authorized capital is collected from shareholders. In this factory the share are class 1.Grower shares A class 2.Non Grower Shares D class 3. Society share B Class 4. Out of Area Share E class 5. Govt share C Class The person who wants to become a member has to follow the procedure / rules. He has to fulfill appropriate application given by the share section authority. If the board of directors approve the application in body meeting, then only he is treated as shareholder of the factory. After the approval he has to pay the amount equivalent to face value of the share. There is no transferability of share. If at all he wants to transfer his shares, he has to transfer to such a person who is the member of the factory. If he transfer to another person it is not valid and such shares get cancelled. For the identification of its members, the factory issues share certificate and identity cards to such share holders. PURCHASE SECTION : Purchase officer BABASABPATILFREEPPTMBA.COM Page 12

- 13. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD Clarks Attainders Hear this section will get the requisitions from different departments of company. According to the requirements it arranges to purchase materials and supplies to each and every departments required materials in time. Steps involved in purchasing the materials: A. Raising requisition : It is the first step and necessity for particular can be used only by the user of the material. B. Scrutinizing requisition : The manager scrutinizes the demand of materials. He examines whether the item mentioned in the requisition note is necessary or not. C. Vendor selection : After scrutinizing, if a material is necessary then tender advertisement is given or if they have permanent vendors. The manager chooses the power vendor. The BOD does selection of vendors. D. Enquiry : After selecting a proper vendor enquiry is sent to the vendor. E.Receiving Quotation : BABASABPATILFREEPPTMBA.COM Page 13

- 14. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD The purchase manager receives the quotations from vendors to whom the enquiries are sent. Through there quotations a right vendor is choosen. E. Sending purchase order : Lastly the purchase order is placed to the selected venders. In this way purchase of material takes place. STORES SECTION Stores keeper Clarks Tool room Clark Diesel room Clark Attainders Tool room attainders Clarks Daily wage labours Attainders Store section is also important section in the administrative department. All types of materials are kept in this section. Which are required for the factory smooth running. The section works day and night. Shift is changing every 8 hours. This section is maintained by the stores keeper. The main work of this section is providing the materials to the required departments. Those stores section maintains some books like : a. Transport. b. Bin card c. Daily issued. d. Monthly issued. BABASABPATILFREEPPTMBA.COM Page 14

- 15. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD It is also one of the section under Administration department, there are total of 7 employees working in this section. PROCEDURE OF WORKING AT PRESENT: STORES: Handling of materials: First, they receive the stores purchase indents from concerned section heads for requisition to purchase item needed for the crushing or off season work. Then they mention the present stock of item in the purchase indents, after verifying the stores. Then only they forward the purchase indents. After receiving the materials from suppliers they seek the quality approval of the same materials. After getting the approval materials are placed to the respective to the racks they issue the materials by adapting FIFO method. They issue the materials to the workers of the factory on loan and retainable basis on daily loan or personal loan. STORES ACCOUNT: After receiving the materials from suppliers quantity will be verified. The details of the materials will be entered in to transport registered and approved memo will be sent to the concerned departments for getting quality approval. They keep bin cards for each different items receipt from the suppliers with details. DIESEL BANK: They issue diesel to the party against indents brought by the parties and issued is entered in the daily issue register. BABASABPATILFREEPPTMBA.COM Page 15

- 16. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD TOOL ROOM: Tool room is personnel issue the materials to the workers on temporary loan and retainable basis entering in the register. List of the registers: 1. Transport register. 2. Approval memo book. 3. Bin card files. 4. Purchase order. 5. Stores purchase indent TIME OFFICE : Supendent Clerks Time office is one of the important sections of administration department. There are 5 employees working in this department. Functions: 1. Showing the absent report to the HOD’s 2. To receive the attendance cards from the workers 3. To put attendance of the workers in the master role 4. It arranges the duty to the workers, maintains working bell BABASABPATILFREEPPTMBA.COM Page 16

- 17. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD 5. It maintains salary register book. Types of Leaves: 1. Sick leaves : Sick leave provided to employees 15 days Per year 2. Casual leaves : Casual leave provided to employees 12 days Per year 3. Earn leaves : Shift Time I 4 am to 12 pm II 12 pm to 8 pm III 8 pm to 4 am General Shift 8-30 am to 5-30 pm If employee attends 30 days in a month then he is eligible for 3 days Earn leave Shift working : In a shift of 8 hours the factory is providing 4 types of shifts. TELEPHONE OPERATING SECTION: BABASABPATILFREEPPTMBA.COM Page 17

- 18. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD In this section EPABX system is i.e. “Electronic Private Automotive Branch Exchange”. Hear only one person is operating in this section. He is the person who connects the incoming calls to different departments of the factory and also out going calls. SALES SECTION: Sales officer Godoun clerk Consultant Clarks In this section sales of the following products produced takes place are sugar, molasses, bagasses and power. This factory is producing three types of sugars they are M-30, S1-30 and S2-30 grades. And also it producing by products like molasses, bagasses, pressmud. These are used by factory it self only like molasses and press mud are used in distillery / Ethanol production, and bagasses is used in production of power. And power is exported to KPTCL . This section will take care of all the sales transactions. The sale of sugar is done according to the notification by the central government and has such factories follows certain government rules in sales of sugar. Accordingly, Karnataka state federation of co- operative sugar factories limited will give figures of bags to sell within a month. PROCEDURE FOR SALE: The organization undertakes selling activities in three methods; 1. Free sale: Free sale is done within the country. Hear company will invite tenders from different buyers at a 10 days notice. The sugar is sold to that buyer who quotes or bids highest price. Tenders are called periodically. If the rate is not satisfactory the tender will BABASABPATILFREEPPTMBA.COM Page 18

- 19. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD be cancelled. In free sale sugar is being done to bulk purchases on the bases of tenders, these bulk purchases then sell the purchased sugar to retailers. 2. Levy sale: It is also done within the state of Karnataka and being sold to the government of Karnataka on levy bases. The government then distributes outlets at predetermined, reasonable pric 3. Export: Sugar is sold outside the country on the contract bases. According to the rules and regulation of the contract it will be done. MARKATING DEPARTMENT The marketing department is also comes under sales section. The factory does not have separate marketing department but it is controlled by the sales section. INTRODUCTION ABOUT THE MARKETING: The term marketing has been derived from the word market. Market is generally understood as a place or geographical area where buyers and sellers meet and enter in to transactions involving transfer of ownership of goods, services and securities. “ Marketing ” is a social and managerial process by which individual and group obtain what they need and want through creating, offers and exchanging the products of values with others. FEATURES OF MARKETING: It is consumer oriented. BABASABPATILFREEPPTMBA.COM Page 19

- 20. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD It starts and ends with consumer. Marketing is a system. It is goal oriented. It is a continue process. It is a guiding element of business. COMPUTER SECTION: The total number of employees working in this department is 4. This section is to maintain all types of records that are very important for the organization and the following departments are computerized in the factory, a) Weigh bridge department b) Cane accounts department c) Time office department d) Laboratory department e) Stores department f) Sales department g) Purchase department h) General accounts department i) Sales accounts section BABASABPATILFREEPPTMBA.COM Page 20

- 21. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD SECURITY SECTION: Security officer Assistant security officer Security guard The security section is operating under the administrative department. It is also working in three shifts as mentioned under time office section. Hear in this department the employees are recruited on the yearly contract basis. There are total 42 guards working in this section. The main works of this section are as follows: • They are maintaining peace and discipline within the factory area. • Time maintenance of worker. • They check the incoming materials as per the vouchers, if they are right, they will records inwards and seal the bill and leave inside. • If outgoing material from the industry that person must and should have gate pass and it will be entered in outwards. FINANCE DEPARTMENT Accounts of finance department are the main and the hart of every department of the company or industry. Hear in this factory, the accounts section maintains all the transactions BABASABPATILFREEPPTMBA.COM Page 21

- 22. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD related to the factory dealings. The sale accounts, purchase accounts, etc are maintained and this department prepares P&L account, Balance sheet, etc. In RSSK is divided finance department or accounts department in two sections. General account section Cane account section In the above chart 50% of the labour is working in the general account section and 50% are in the cane accounts section. 1. GENERAL ACCOUNTS SECTION: In general accounts section book keeping is followed. General account transactions like receipts and payments registers are maintained. Receipts include sales process of sugar, molasses, share amount, etc. Payments include salary, tax, etc. maintaining audit and audit rectification is done, annual account and monthly account are prepared and maintained. Some other types of registers are maintained by this section are : a. Advance register b. Contractors register c. Contra register d. Fixed assets register e. Bank register f. Expense register 2. CANE ACCOUNTS SECTION: BABASABPATILFREEPPTMBA.COM Page 22

- 23. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD This section maintains the cane accounts and cane bills. This section purchases the cane on daily basis and prepares accounts of forthrightly basis. In addition, will take care of all cane suppliers accounts and department manager separates accounts for cane suppliers. The section will provide cane bill once in a month desired by the higher authority. While giving cane bill, department will debut all the expenses and advances which is given to the cane suppliers in terms of seeds, fertilizers and transportation facilities and also harvesting of the cane that all the expenses are given by the factory. The registers maintained in this section are : a) Self harvesting payment register b) Harvesting bills c) Cultivator payment register Finance: Our company was able to get working capital finance to the extent of Rs. 42.52 crores. The bankers of the company have extended their fullest co-operation in sanctioning and releasing working requirement, which enabled our company to make payments of cane bills of the farmers. The company has paid Rs. 1000 per MT as first installment for the cane supplied during the year. CANE DEVELOPMENT DEPARTMENT Cane Manager Office manager Cane Cane Procurement Manager Cane Dev Manager Cane Officers Cane Officers BABASABPATILFREEPPTMBA.COM Page 23

- 24. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD Field Assisnants Field Assisnants Objectives of the CDD: • To get best quality of cane at a right time • To improve the variety of the cane • To provide all facilities like seeds, fertilizers, unloading and loading charges • Main objectives are to receiving exactly 2500 TCD • To undertake seeds development program Varieties of Sugar cane: 1.COC671 {Early Maturity} 2.CO8011 {Middle Maturity} 3.CO86032 {Early Maturity} 4.CO8021 {Early Maturity} 5.CO94012 {Early Maturity} PRODUCTION DEPARTMENT The production department is one of the core parts in every process based industry. In addition, it plays a vital role in the organization for smooth going in every sugar industries; Production department is divided in to two sections. 1. Engineering department 2. Manufacturing department BABASABPATILFREEPPTMBA.COM Page 24

- 25. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD Chief Engineer Mechanical Electrical section Workshop Stores Section section Cane Boiler Weighment section Cane unloading Power Arrangements generatio 1.Mechanical section : This includes all the mechanical process that is right from the cane weighment till milling ( obtaining of sugar juice ) for further processing. This section includes 4 main steps they are….. a. Cane unloading arrangement b. Cane preparation c. Milling Cane weighment arrangements : Cane weighment is totally computerized process. Hear the cane weightment is carried through electronic platform called “ weigh bridge ”. This electronic platform is of two types. One with the capacity of 40 tons for lorry and tractors and other with a capacity of 10 tones for only cart. Hear after weighing the cane a slip is provided so that particular farmer which has the details of total weight of the cane, total trips, timing, vehicle number, variety of sugarcane and BABASABPATILFREEPPTMBA.COM Page 25

- 26. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD other details. And after this when the vehicle comes back after unloading the sugar cane, empty vehicle weight all their data stored in the computer and final copies listed for further actions. Cane unloading arrangements : Hear the weighed sugar cane is unloaded and sent further for cane preparation. Further unloading cane there are 2 unloaders with the help of sling attached instruments cane is loading on the feeding table. Cane preparation : After feeding the sugar cane on feeding tables with the help of levelers which avoid overloading of sugar cane is sent to primary cutter, which cut the sugar canes in to small pieces, further fine fibers are obtained from there process by passing them in the fibrizer. Milling : After fibrizering the cane passing the prepared fiber cane through a set of mills carries on milling weighted hot water is also added in the course of crushing for better extraction of juice. After crushing the juice is sent for further processing. Electrical section : This section has two other sub sections. They are … i) Boiler section ii) Power section Boiler section : 40 tons / hrs capacity 2 boilers of 66 kg / cm2 pressure mainly use fuel as waste of cane called bagasses. This waste of cane (bagasses) is used in generation steam for production of electricity. Power generation : BABASABPATILFREEPPTMBA.COM Page 26

- 27. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD Process chart of Co-generation Water treatement Make up water Feed water tank Deareator tank Pumping Stream drum Turbine Generator [ electricity ] Functions of power generation department are given below. • To generate power at high quantity. • To distribute it to different areas, as KPTCL. • To provide better working conditions to their workers for safety. • 4 MW, 11 KV turbo alternator using for home consumption. • Around 8.5 MW is exported to KPTCL. • Power production 12.5 MW per hour. 3. Workshop : In this workshop machinery work is done. The spares, materials are fabricated using lathe machines in the workshop shaping like square cutting and other etc. are also done in the workshop. Following machines are used in the workshops. • Lathe machines for round job. BABASABPATILFREEPPTMBA.COM Page 27

- 28. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD • Radial drilling machine for drilling work. • One Hacksaw machine for cutting. • One grinding machine for tool grindings. Workshop is the main section in the engineering section. Stores : Various section spare parts are stored in stall system and all the units are computerized and given a code number. Bin card and other system are followed hear. These stores materials are normally required for preventive maintenance during seasons and off seasons for servicing and overalling. MANUFACTURING DEPARTMENT Manufacturing section is again divided in to 3 sub sections. • Laboratory • Manufacturing process • Godown Laboratory : BABASABPATILFREEPPTMBA.COM Page 28

- 29. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD The factory is having well equipped lab, and the main activity of the lab is to check the content of sugar in the sugar cane and fixing the correct shape and size of the sugar. The lab prepares hourly reports which advise on the addition of the other chemicals in production. Other concerned activities of the laboratory : • It determines the percentage of water contents in the dilution of the juice. • It determines as well as managing the temperature of boiling juice. • Choices of colors and size of sugar. • To manage time and quality. • It decides the percentage and contents of chemicals to be added during production. • It finds the pH of water through universal indicator. • Chemicals used in the production of sugar. • Burnt-lime bleaching agent and pH controls (juice clarification) • Sulphur major bleaching agent. • Orthophosphoric acid-bleaching agent. • Flocculent - setting aid. • Caustic soda - clearing. • Washing soda - clearing. • Phosphoric acid - setting. • Hydros a pan bleaching agent ( color ). • Ammonium biflouride formalin-quality maintain and preservative. • Mill sanitation chemical to prevent generation of bacteria and increases the rate of boiling. BABASABPATILFREEPPTMBA.COM Page 29

- 30. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD • Mesopropile alcohol. • Commercial HCL. Bleaching powder – for cleaning purpose. PRODUCTS : Finished products : The finished product is sugar, which is produced from the sugar cane. There are 3 varieties of sugar produced. They are, S1-30 S2-30 M2-30 By products : There are three types of by products produced during the manufacturing of sugar from sugar cane. They are, • Molasses • Bagasses • Fresh mud • Power Molasses is used as major content in production of wines and other alcoholic products. So it is sold to liquor industry of income 0.50 crores is earned per month. Bagasses is also used as one of the by product obtained during the process. It is used as fuel for boilers to produce steam through which electricity is obtained. The electricity obtained is used for the factory itself and surplus is sold to KPTCL. Fresh mud is yet another by product produced during the process. It is sold to farmer during the process. Which they in turn use it as fertilizer to grow sugar cane. It is also sold to fertilizer units and also feed to the cattle. BABASABPATILFREEPPTMBA.COM Page 30

- 31. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD PERFORMANCE OF THE FACTORY : Sl. No. Details 2003- 2004-2005 2005- 2006- 2007-2008 2004 2006 2007 1 Starting date of 5-11-2003 21-10-2004 02-11- 28-10- 20-11- crushing 2005 2006 2007 2 Closing date of 13-1-2004 18-1-2005 21-4-2006 9-6-2007 26-5-2008 crushing 3 Total crushing 1,15,321 1,05,687 3,51,953 5,20,288 3,79,020 ( MT ) 4 Total sugar 1,27,300 1,15,850 4,00,150 6,08,549 4,46,699 produced (Qts) 5 Recovery (%) 10.68% 10.88% 11.39% 11.69% 11.65% BABASABPATILFREEPPTMBA.COM Page 31

- 32. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD PROCESS FLOW CHART BABASABPATILFREEPPTMBA.COM Page 32

- 33. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD Cane Yard Unloading Feeder Table Cane Carrier Process Flow Chart Cane Kicker Leveller Fibrizer Meceration water/Imbibition Bagasse Mills Juice Boiler No 1 Boiler No2 Excess Bagasse Juice weighing scale PRD Station Weighed Juice Distributed to SO2 Gas Lime Steam power various J H PRI Heaters Turbine stations Juice sulphiter Exhaust steam for process Clarrifier or JH sec Heaters Settler Clear Juice Disposal filter cake Muddy Juice Oliver Evaporator SO2 Gas filters Super heated wash water/Steam syrup Syrup Sulphitor A mols B m/c Syrup Tanks Crystllizer Vaccum pan B Centrifugal A Boiling A m/c Crystilliser B Sugar B Mols A Centrifugal C m/c White sugar Crystallizer Grading To Tanks C- Sugar Final Mols Weighing & Godown packing B and C sugar melted & used to Boil A m/c FUTURE GROWTH AND PROSPECTUS BABASABPATILFREEPPTMBA.COM Page 33

- 34. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD 1. Expansion of company’s business 2. Distillery and Ethanol project 1. Expansion of company’s business Our directors are pleased to inform that the company has been permitted for the enhancement in cane crushing capacity from 2500 T.C.D. to 3500 T.C.D. From govt. of Karnataka in its global investors meeting held during Sept 2006. Distillery/Ethanol Project: Our board of directors has received a letter of intent from Govt. of Karnataka to take up distillery unit. Further our decision and approval given in the 9th annual general meeting to establish a distillery/ethanol project, implementation of distillery project commenced by appointing M/s. Vasantdada Sugar Institute, Pune, as a consultant for the said project. However this decision had to be dropped as no financial institutions/bankers come forwarding for financing the project, due to loss is incurred by the company during 2002-03 and depressing sugar scenario. SWOT Analysis of the company BABASABPATILFREEPPTMBA.COM Page 34

- 35. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD 1. STRENGTH a. It is located in the place where good infrastructure is available. b. The company’s concentration towards the quality of the product. c. The technological standard of the company. d. Modern equipments. e. High production efficiency. f. Good sources of raw material. g. Power generation. 2. WEAKNESS a. The company needs improvements and should concentrate on timely customer Service. b. The company must improve labour payments c. Labors turnover. d. The promotion procedure in the organization is too rigid. e. No specific dept. such as HRD. f. Large number of sugar factories within 25-30 kilometers. g. No scheme offers are given. 3. OPPORTUNITIES a. Expansion of projects like paper unit, ethanol production, bio-fertilizers, and power generation. b. All these above projects will give the company maximum profits. 4. THREATS Stiff competition by brands like Prabhu sugars, Nandi, Godhavari sugars, Nirani sugars and other. IMPORTANCE OF INVENTORY MANAGEMENT:- BABASABPATILFREEPPTMBA.COM Page 35

- 36. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD Investment in inventory normally accounts for about 1/3 value of the total assets and for an average manufacturing concern, cost of inventory represents about one half of the product cost. Because inventory constitutes such a significant part of product cost since the cost is controllable, proper planning, purchasing, handling, accounting and control of inventories is of great significance. Inventory management is now great significance in a view of imperative need for productivity growth. Optimal utilization of all available resources and avoidance of all types of waste especially in case of raw materials is required for an ambitious programmer of economic growth. The importance of inventory management lies in the fact that many significant effort for the reducing the materials cost will go along way in improving the profitability and rate return on investment. Following are the benefits of optimum inventory management: It provides a check against the loss of materials through carelessness or pilferage. Inventory management ensures an adequate supply of materials, stores, spares etc. Minimizes the stock out and shortages an avoids a costly interruption in operations. It reduce length of manufacturing cycle to the minimum. It enables the management make cost and consumption between operations and periods. SCOPE OF THE STUDY :- Inventory management being a very important concept in all the company’s having a void coverage often calls for the managerial attention. In the modern times inventory management has become the integral part of the all companies. So all the firm give special importance for inventory management. The major objective of the study is to examine the effectiveness of inventory management system adopted by R .S. S. K.N. The study mainly focuses on the techniques used by this company to control the inventory. BABASABPATILFREEPPTMBA.COM Page 36

- 37. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD INVENTORY MANAGEMENT: In modern competitive one of the burning problem of every business and industries that of cost control and cost reduction. An all pervasive effort for cost control and cost reduction is of paramount, importance for survival and growth of every industrial enterprises. This is why inventory management as a scientific device for controlling inventory cost and eliminating wastage, is now regarded as an integral part of industrial management. Inventory management does not involve any human factor, as it concerns itself not with men but with inventory. Meaning of Inventory: The dictionary meaning of inventory is stock of goods, of a list of goods; various authors understand the word inventory differently. In accounting language it may mean stock of initial goods only. In a manufacturing concern, it may include raw materials; work in process and stores etc. To understand the exact meaning of the word ‘inventory’ we May study it from the usage side or from the side point of entry in the operations. Inventory includes the following things. 1. RAW MATERIALS Raw material form a major input into the organization. They are required to carry out production activities uninterruptedly. The liquidity of raw materials required will be determined by the rate of consumption and the time required for replenishing the supplies. The factors like the availability of our materials and the government regulations, etc. to affect the stock of raw materials. 2.WORK IN PROGRESS The work in progress is that stage of stocks, which are in between the materials and initial goods. The raw materials enter the process of manufacture but them yet party in a final shape of initial goods. The quantum of work in progress depends upon the time taken in the manufacturing process. The greater the time taken in a manufacturing the more will be the amount of work in progress. BABASABPATILFREEPPTMBA.COM Page 37

- 38. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD 3.CONSUMABLES: These are the materials, which are needed to smoothen the process of production. These materials were not directly enter production but they act as catalysts etc.. Consumables may be classified according to their consumption and criticality. Generally, consumables stores to not create any supply problem and form a small part of production costs. They can instances where these materials may account for much value than the materials. The fuel oil may form a substantial part of cost. 4.FINISHED GOODS There are the goods, which are ready for the consumers. The stock of initial goods provides a buffer between production and market. The purpose of maintaining inventories to ensure proper supply of goods to customers. In some concerns the production is undertaken on order basis, in these concerns they will not be need for finished goods the need for finished goods inventory will be more when production is undertaken in general without waiting for specific orders. 5.SPARES Spares also form of part of inventory. The consumption pattern from materials, consumables, finished goods are different from that of spares. The stocking policies of spares for different from industry to industry. Some industries like transport will require more space than the other concerns. The costly spare parts like engines, maintenance spares etc. are not discarded after use, rather they are kept in ready position for further use. All decisions about spares are based on the financial cost of inventory on such and the cast that may arise due to their non-availability. PURPOSE-BENEFITS OF HOLDING INVENTORIES: Although holding inventories involves blocking of firms funds and the cost of storage and handling, every business enterprise has to maintain a certain level of inventories to facilitate uninterrupted production and smooth running of business. In the absence of inventories a firm will have to make purchases as soon as it receives orders. It will mean loss of time and delays BABASABPATILFREEPPTMBA.COM Page 38

- 39. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD in execution of orders, which sometimes may cause loss of customers and business (stock out). Therefore also needs to maintain inventories to reduce ordering costs and avail liquidity discounts etc.. Generally speaking, there are three main purposes or motives of holding inventories. 1. THE TRANSACTION MOTIVE: Which facilitates continuous production and timely execution of sales orders. 2. THE PRECAUTIONARY MOTIVE : Which necessitates the holding of inventories for meeting the unpredictable changes in demand and supplies of materials. 3. THE SPECULATIVE MOTIVE: Which induces to keep inventories for taking advantage of price fluctuations, saving in the ordering costs and quantity discounts etc. RISK AND COST OF HOLDING INVENTORIES: The holding of inventories involves blocking of a firm’s funds and incurrence of capital and other costs. It also exposes the firm to certain risks; the various parts risks involved in holding inventories are as below 1. CAPITAL COSTS Maintaining of inventories result in blocking of the firm's financial resources. The firm has therefore to arrange for add both the cases the firm incurs a cost. In the former case, there is an opportunity cost of investment while in the latter case; the firm has to interest to the outsiders. 2. STORAGE AND HANDLING COSTS Holding of inventory is also involves costs on storage as well as handling of materials. The storage costs include the rental of the godown, insurance initial funds to meet the cost of inventories. The funds may be arranged from own resources or from outsider. But in charges etc BABASABPATILFREEPPTMBA.COM Page 39

- 40. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD 3. RISK OF PRICE DECLINE There is always a risk of reduction in the prices of inventories by the suppliers in holding inventories. This may be due to increased market supplies, competition or general depression in the market. 4. RISK OF OBSOLESCENCE The inventories may become obsolete due to improve technology, changes in requirements, change in customers taste etc. 5. RISK DETERIORATION IN QUALITY The quality of the materials may also deteriorate while in the inventories are kept in stores. INVENTORY MANAGEMENT: The investment in inventory is very high in most of the undertakings increased in a manufacturing wholesale and retail trade. The amount of investment is sometimes more in inventory than in other assets. In India, a study of 29 major industries has revealed that the average cost of materials is 64 paise and the cost of labour and overhead is 36 paise in a rupee. In industries like Sugar, the materials cost is as high as 68.75% of the total cost. About 90% of part of working capital is invested in inventories. It is necessary for every management to give proper attention to inventory management. The proper planning of purchasing handling, storing and accounting should form a part of inventory management. An efficient system of inventory management will determine (a) what to purchase (b) how much to purchase (c) from where to purchase (d) where to store etc. There are conflicting interests of different departmental heads over the issue of inventory. The finance manager will try to invest less in inventory because for him it is an idle investment, whereas production manager will emphasis to acquire more and more inventories as he does not want any interruption in production due to shortage of inventory. The purpose of inventory management is to keep the stocks in such that neither there is over stocking nor under-stocking. The over stocking will mean a reduction of liquidity and targeting off other production processed: under stocking on the other hand will result in stoppage of work on the investment in inventory should be kept in reasonable limits. BABASABPATILFREEPPTMBA.COM Page 40

- 41. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD OBJECTS OF INVENTORY MANAGEMENT: The main objectives of inventory management or operational and finances the operational objectives mean that the materials and the spares should be Honorable in the sufficient liquidity is so that work is not disrupted for want of infantry. The finance object means that investments in inventories should be remain idle and minimum working capital should be locked in it the following are the objectives of inventory management. 1. To ensure continuous supply of materials spares and finished goods so that production should not suffered at any time and the customers demand should also be met. 2. To avoid both over stocking and under-stocking inventory. 3. To maintain investments in inventory is at the optimum level as required by the operational and sales activities. 4. To keep material cost and control so that they contribute in reducing cost of production and overall costs. 5. To eliminate duplication in ordering or replenishing stocks. This is possible with the help of centralizing purchases. 6. To minimize losses through deterioration, pilferage, wastages and damages. 1. To design proper organization for inventory management. A clear-cut accountability 2. should be fixed at various levels of the organization. 8. To ensure perpetually inventory control so that materials shown in stock ledgers should be actually lying in the stores. Responsibility of inventory specialists: Controlling and authorizing finding for material so that the proper kind, quality and quantity is available at the correct time and place. Maintaining records and controls over material in stock, planned for distribution system. BABASABPATILFREEPPTMBA.COM Page 41

- 42. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD They decide upon inventory level Kinds and fixation of inventory level: The various levels fixed for effective inventory control are as follows MINIMUM LEVEL: It represents the quantity below which the inventory of any item should not be allow to fall, in other words an enterprise must maintain minimum quantity of stocks. The following factors should be considered in order to fix minimum stock level • Reorder level • Lead time • Average rate of consumption of material Where, Minimun level =Reordr level-Aerage consumption*lead time Maximum level It represents the level beyond, which the stock in hand is not allowed to exceed .This is because of the cost involved in holding more than required stock. RE ORDER LEVEL: When the quantity of materials reaches at a certain figure the fresh order is tended to get materials again. The order is sent before the materials reaches minimum stock level. The reordering level or ordering level is fixed at between the minimum level and maximum level. The rate of consumption, number of days required replacing the stocks and maximum quantity of materials required on any day are taken into account while fixing the reordering level. The ordering level is fixed with the following formula. Re order level = maximum consumption X maximum Re-order period. BABASABPATILFREEPPTMBA.COM Page 42

- 43. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD MAXIMUM LEVEL: It is the quantity of materials beyond which the firm should not exceed its stocks if the quantity exceeds maximum level limit then it will be over stocking. Your firm should avoid over stocking because it will result in high material costs. Over stocking will mean blockading of more working capital, more space for storing the materials, more wastages of materials and more chances of losses from obsolescence. Maximum stock level will depend upon the following factors. 1. The availability of capital for the purchase of materials. 2. The maximum requirements of materials at any point of time. 3. The availability of space for storing the materials. 4. The rate of consumption of materials storing lead-time. 5. The cast of maintaining the store. 6. The possibility of fluctuation in prices. 7. The nature of materials. If the materials or perishable in nature then they cannot miss told for long. 8. Availability of materials. If the materials are available only during seasons then they will have two bestowed for the rest of the period. Maximum stock level = reordering level + reordering quantity - (minimum consumption X minimum reordering period) SAFETY LEVEL: The consumption rate of materials and lead time don’t remain constant and therefore to guard against the uncertainty, an extra stock is always maintained which is known as safety stock. A safety stock of materials is maintained as insurance against stock depletion due to increase usage or unusually long delivery times, which cause the stock to fall below minimum level. The main objective behind keeping safety stock is minimizing stock out cost. BABASABPATILFREEPPTMBA.COM Page 43

- 44. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD OBJECTIVES OF THE STUDY: • To study the inventory management in the organization. • To identify the loop holes if any in the inventory management system. • To apply the modern inventory management techniques like • ABC • HML • VED • SDE • EOQ • JIT Based on the above to give suggestion INVENTORY CONTROL TECHNIQUES: Inventory control techniques are employed by the inventory control. Organization within the frame work of one of the basic inventory model, viz., fixed order quantity systems or fixed order period system. Inventory techniques represent the operations aspects of inventory management and help to realize the objective of inventory management and its control. Several techniques of inventory control are in use and it depends on the policy of the firm product, the techniques most commonly used are 1. Always Better Control (ABC) Classification 2. High, Medium and Low (HML) Classification 3. Vital, Essential and Desirable (VED) Classification 4. Scare, Difficult and Easy to obtain (SDE) BABASABPATILFREEPPTMBA.COM Page 44

- 45. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD 5. Fast moving, Slow moving, and Non moving (FSN) 6. Economic Order Quantity (EOQ) 7. Max – minimum System 8. Two bin System 9. Material Requirement Planning (MRP) 10. Just In Time (JIT) 11. Distribution Logistics (DL) a) ABC Analysis: It is one the widely used techniques for the control of inventory. Objective of ABC control is to vary the expenses associated with maintaining appropriate control according to the potential savings associated with the proper level of such a control. A may account for more than half the total value usage in the inventory. These items required very careful management and special careful estimates of future usually class C items which in total account for only a few percent of the total value of usage very little effort should be devoted to forecast the requirement of items. The inter mediate class B items justify a reasonable but routine effort in forecasting demands and managing inventory. b) HML Analysis: Since the total annual usage is considered in case of ABC Analysis, quite a few items which fall in B category although the unit cost (cost per unit) is quite high. If controls are exercised on the basis of ABC only, the importance of these items will be much less than A or B items even though the inventory or transaction of one unit of these items will mean quite a lot money. Therefore, it is necessary that the unit cost is also considered in order to find out the importance of items on the basis of unit cost. Limits of units costs are fixed for high costs items (H), medium costs items (M) and low cost units (L) and all items are segregated into H, M and L categories depending on there unit cost. This analysis is quite useful in deciding the safety stock in relation to the availability of the material. c) VED Analysis: BABASABPATILFREEPPTMBA.COM Page 45

- 46. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD The materials classification on the items is called VED analysis. VED stands for vita, Essential and Desirable. Vital items which render the requirement or the whole line operation in the process totally and immediately inoperative, unsafe and if these items go out of stock or not readily available, results in losses of whole production of whole period. E-Essential items which reduce the equipment’s, performance but not render it inoperative, results or unsafe, non-availability of items may result in temporary loss of production or dislocation of production work replacement can be done without any delayed, without affecting the equipment’s performance seriously, temporary repairs sometime possible. D-Desirable items which are mostly non –functional and don’t effect the performance of the equipment. d) FSN Classification : Materials can be classified on the basis of movement as fast moving slow moving and non moving –FSN according to their consumption patterns. FSN analysis is specially useful to combat obsolete items whether spare parts, raw material or component. Cut –off points of three classes are usually in items of number of issues in previous few years depends on the peculiarities of an individual concern. e) SDE Analysis: SDE stands for scarce, difficult and easily available items in the local market. Scarce items are generally in short supply; usually these are raw material, spare parts and imported items. Difficult items are not available in local markets, and have to be produced from for off cities or items for which there are a limited a number of supplies or items for which quantity suppliers are difficult to get. The SDE analysis proves to be very useful, in industrial situations where certain materials are in scare supply, and gives proper guidelines for deciding inventory policies. f) XYZ Analysis: BABASABPATILFREEPPTMBA.COM Page 46

- 47. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD For the effective management of stores, the stock can be split as high valued, middle value or low valued – XYZ classification. This technique helps in identifying the items, which are being extensively stocked. ‘X’ items are those whose inventory values are high while ‘Z’ items are those whose values are low. Understandably ‘Y’ items fall in between these tow categories. XYZ classification may be used in the conjunction for the better results. g) Minimum-Maximum Techniques : The Minimum –maximum system is often used in connation with manual inventory control system. The minimum quantities is established in the same way as any re-order point. The effectiveness of minimum-maximum system is determined by the method and precision with which the minimum. h) Two Bin Technique: One of the oldest system of inventory control is the two bin system, stock of each item is separated into two bins. One bin contains stock, just enough to last from the data a new order is placed until it is received in inventors. The other bin contains quantities of stock, enough to satisfy probable demand during the period of replenishment i) Material Requirement Planning (MRP): MRP is a new solution to an old problem having stock of materials a lowers on hand when heeded without carrying excess inventory. j) E.O.Q. Model : There are two basic questions relating to inventory management 1. What should be the size of the order 2. At what level should the order be placed. To answer this question the economic order quantity model is helpful. General E.O.Q. includes 3 types of costs, that are carrying cost, ordering cost & shortage cost. BABASABPATILFREEPPTMBA.COM Page 47

- 48. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD i) Just in Time : The management of inventory has become very sophisticated in recent years. In certain industry the production process it self lends to just in time (J I T) inventory control. As the name implies, the idea is that the inventories are acquired and inserted in the production at the exact time they are needed. This requires efficient purchasing, very reliable and an efficient purchasing, very reliable and an efficient inventory handling system. One thing that has made this possible is advent of instant information through sophisticated computer networks. The coordination of varies suppliers in an efficient manner is known as supply chain management. j) Distribution Logistics: An exciting and profit promising way of using systems logistics in planning and control is the expansion of inventory control to include other factors. This system is referred to here as distribution logistics. In its advance form. It treats the entire logistics of business – ranging from sales forecasting through purchasing and processing materials and inventorying to shipping the finished goods as a single system. The goal is usually to optimize the total cost of the system in operation while furnishing a desire to level of customer service meeting certain constrains such as financially limited inventory levels. ABC Analysis : These important items usually designated as class A may account for more than half the total value usage in the inventory. These items require very careful management and special careful estimates of future usually class C items which in total account for only a few percent of the total value of usage very little effort should be devoted to forecast the requirement of items. The inter mediate class B items justify a reasonable but routine effort in forecasting demands and managing inventory. The ABC approach means of category inventory items into three class, A, B and C according to potential amount to be controlled. A - Items, which are the 10% BABASABPATILFREEPPTMBA.COM Page 48

- 49. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD B - Items, which are the 20% C - Items, which are the 70% A.B.C. Analysis A.B.C. analysis is a selective technique of controlling different items of inventory. In actual practice, thousands of items are included in business as inventories. But all these items are not equally important. According to this technique, only those items of inventory are paid more attention which are significant for business. According to this technique, all items are classified into 3 categories A.B. and C. In ‘A’ category those items are taken which are very precious and their quantity . ABC ANALYSIS - 1 One of the most important considerations of control is the value of annual consumption of inventory items in a year. Only a small number of inventory items consume a very large share of inventory consumption during the year. A little larger number of inventory items covers a moderate share of annual inventory consumption. A very large number of items just cover a very small share of annual inventory consumption. These facts gave birth to the concept of ABC analysis. ABC ANALYSIS – 2 It has been observed that in an industrial unit only 10% of items have 70% of the annual inventory consumption. 20% of the items have 20% of annual inventory consumption, and 70% of the items have only 10% of the annual inventory consumption. BABASABPATILFREEPPTMBA.COM Page 49

- 50. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD Since 70% of the annual consumption of inventory is covered by only 10% of the items in the inventory, these items deserve highest attention and are classified as ‘A’ items Similarly 20% of the items covering 20 % of the inventory investment are B class items. Balance 70% of the inventory items are termed as C class items. STEPS IN ABC ANALYSIS: The steps in computing ABC analysis are: a .Determine the annual usage in units for each item for the past one-year. b. Multiply the annual usage quantity with the average unit price of each item to calculate the annual usage in for each item. c. Item with highest volume usage annually is ranked first. Then the next lower annual usage item is listed till the lowest item is listed in the last. Arrange the items in the inventory by cumulative annual usage and by cumulative percentage. Categorize the items in A, B , and C categories.. BABASABPATILFREEPPTMBA.COM Page 50

- 51. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD 1. Current Ratio Current ratio may be defined as the relationship between quick or liquid asset and current liabilities. This is a measure of general liquidity & is most widely used to make analysis of short-turn financial position or liquidity of firm. It is calculated by dividing the total current assets by total current liabilities. Current Ratio = Current Assets Current Liabilities TABLE-1.1 Current Ratio (in lakhs) Year Current Current Ratio Assets Liabilities 2006-2007 3363.89326 8028.62101 0.42 2007-2008 4178.11267 8685.3814 0.48 2008-2009 349.34576 7745.30918 0.45 CURRENT RATIO 0.6 0.5 0.4 RATIO 0.3 Ratio 0.48 0.45 0.2 0.42 0.1 0 2006-2007 2007-2008 2008-2009 YEAR BABASABPATILFREEPPTMBA.COM Page 51

- 52. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD INTERPRETATION An arbitrary standard of current ratio is 2:1 indicates that for every one rupee of current liability two rupee of current assets is available. From the graph it is below the standard this shows that there is no short term solvency of the company . Quick Ratio/Acid Test Ratio Quick ratio establishes relationship between quick or liquid assets & current liabilities. It is also known as acid test ratio. An asset is said to be liquid if it can be converted into case within short period of time without loss of value. The prepaid expenses and stock were excluded. Quick ratio = Quick asset Current Liabilities Year Quick Current Ratio Assets Liabilities 2006-2007 1383.13276 8028.62101 0.17 2007-2008 1278.13793 8685.3814 0.15 2008-2009 1707.11841 7745.30918 0.22 QUICK RATIO 0.25 0.2 0.15 RATIO Ratio 0.22 0.1 0.17 0.15 0.05 BABASABPATILFREEPPTMBA.COM 0 Page 52 2006-2007 2007-2008 2008-2009 YEAR

- 53. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD INTERPRETATION Table 1.2 reveals that quick ratio of the company is not higher than standard 1:1. This shows that the firm liquidity position is not so good. Absolute Quick Ratio/cash Ratio Cash ratio is the strongest measurement of liquidity. Since cash is the most liquid assets, a financial analyze may examine cash ratio & its equivalent to current liabilities. Trade investments or marketable securities are equivalent of cash therefore they may be included in computation of cash ratio. To calculate absolute quick ratio we consider cash in hand, cash at bank & marketable securities. Cash Ratio = Cash + Marketable securities Current Liabilities year quick asset current liablities Ratio 2006-07 228.30326 8028.62101 0.028 2007-08 67.86987 8685.3814 0.0078 2008-09 679.05859 7745.30918 0.087 BABASABPATILFREEPPTMBA.COM Page 53

- 54. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD CASH RATIO 0.1 0.08 RATIO 0.06 0.087 Ratio 0.04 0.02 0.028 0 0.0078 2006-07 2007-08 2008-09 YEAR INTERPRETATION Table 1.3 reveals that absolute quick ratio is below the standard ratio i.e. 0.5:1 indicates that 50 paisa worth of absolute liquidity assets are sufficient to meet one rupee worth of current liabilities. In all 3 years it indicates that there is no sufficient liquidity in a firm. Leverage Ratios Leverage ratios are also known as capital structure ratio. These ratios indicate mix of funds provided by owners & lenders. As a general rule these should be appropriate mix debt & owners equity in financing the firm’s assets. Leverage ratios are calculated to judge the long long-term financial position of the company. Some of the popular leverage ratios are: a. Total Debt Ratio Debt ratio may be used to analyze the debt ratio by dividing Total debt (T.D) by dividing Capital employed (C.E) or net assets (N.A). The total debt include short and long term borrowing from financial institutions, debentures, bounds, deferred payments, arrangements for buying capital equipment’s bank borrowings, public deposits etc. Debt Ratio = Total Debt Capital Employed BABASABPATILFREEPPTMBA.COM Page 54

- 55. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD DEBT RATIO 2.85 2.8 2.75 2.7 RATIO 2.65 Ratio 2.8 2.6 2.55 2.61 2.59 2.5 2.45 2006-2007 2007-2008 2008-2009 YEAR Year Total Debt Capital Ratio Employed 2006-2007 5671.68647 2175.3 2.61 2007-2008 5650.92766 2180.18495 2.59 2008-2009 6273.97167 2239.83274 2.8 BABASABPATILFREEPPTMBA.COM Page 55

- 56. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD INTERPRETATION Table reveals that ratio is decreasing in the year 2008 .this shows that debt capital is less than own capital.in the year 2009 increasing. Fixed Assets to Net Worth This ratio establishes the relationship between fixed assets & Shareholders fund i.e. Share Capital plus reserves & Surplus & retained earnings. The ratio can be calculated as follows. Fixed Assets to Net worth Ratio = Fixed Assets (After Depreciation) X100 Shareholder’s fund Shareholder Year Fixed Assets Fund Ratio 2006-07 5688.28076 2175.3 2.61 2007-08 5701.88858 2180.18495 2.62 2008-09 5712.66087 2239.83274 2.55 FIXED ASSETS TO NETWOTH RATIO 2.65 2.6 RATIO Ratio 2.61 2.62 2.55 2.55 2.5 2006-07 2007-08 2008-09 YEAR BABASABPATILFREEPPTMBA.COM Page 56

- 57. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD INTREPRETATION Table reveals that percentage of fixed assets value contributed by its owners is decreasing in the year2007-2008 . .in the year 2009 fixed assets value contributed by its owners is increasing It implies that funds are not sufficient to finance the fixed assets & the firm has to depends upon outside to finance fixed assets . Current Assets to Proprietor’s funds ratio This ratio is calculated by dividing total current assets by shareholders funds. It indicates the extent to which proprietor funds are invested in current assets. There is no rule of thumb for this ratio & depending upon the nature of the business there may be different ratios for different firms. CA to PF ratio = Current Assets Proprietors Fund Proprietors Year Current Assets Fund Ratio 2006-07 3363.89326 2175.3 1.55 2007-08 4178.11264 2180.18495 1.92 2008-09 3493.45761 2239.83274 1.56 C/A TO PROPRIETORS FUND 2.5 2 1.5 RATIO Ratio 1 1.92 1.55 1.56 0.5 0 2006-07 2007-08 2008-09 YEAR BABASABPATILFREEPPTMBA.COM Page 57

- 58. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD INTREPRETATION Table reveals that proprietors fund & investments are increasing. & Current assets are decreasing .It was 1.56 in the year 2008-09. Profitable Ratios The primary objective of a business undertaking is to earn profits. Profit is the difference between revenue & expenses over a period of time. Profit is output of a company & company will have no further if it fails to make sufficient profit Profits are thus a useful measure of overall efficiency of a firm. These ratios are calculated to measure the operating efficiency of the company. Beside management, creditors, owners are also interested in the profitability of the company. Generally profitability ratios are calculated either in relation to sales or in relation to investment. The various profitable ratios are: 1. In Relation to Sales a. Gross Profit Ratio G.P.Ratio measures the relationship between gross profits & sales; it is usually represented in percentage. Thus Gross profit margin highlights the production efficiency at a concern G.P.Ratio = Gross Profit X 100 Sales G.P.Ratio indicate the extent to which selling price of goods per unit may decline without resulting in losses on operations of firm. It reflect efficiency with which firm produces the product. Year Gross Profit Sales Ratio 2006-07 817.51169 5925.32689 13.8 2007-08 981.56497 4534.35123 21.65 2008-09 795.31898 7362.06987 10.8 BABASABPATILFREEPPTMBA.COM Page 58

- 59. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD GROSS PROFIT RATIO 25 20 RATIO 15 21.65 Ratio 10 13.8 10.8 5 0 2006-07 2007-08 2008-09 YERR INRTEPRETATION Table reveals that gross profit of the company has increasing in 2006-07 gross profit was 13.8, which was increased to 21.65 in 2007-08 but further gross profit was decreased 10.8 in 2008-09. The efficiency of firm is not satisfactory Net profit ratio Net profit ratio establishes the relationship between net profit & sales & indicates efficiency of management in manufacturing. Selling, administrative & other activities of the firm. This ratio is used as a measure of overall profitability & it helps in determining the efficiency of the firm to carry on its business. Net Profit Ratio= Net Profit after tax X 100 Sales Year Net Profit Sales Ratio 2006-07 152.45938 5925.32689 2.57 2007-08 510.45764 4534.35123 11.26 2008-09 0.91423 7362.06987 0.01242 BABASABPATILFREEPPTMBA.COM Page 59

- 60. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD NET PROFIT RATIO 12 10 8 RATIO 6 11.26 Ratio 4 2 2.57 0 0.01242 2006-07 2007-08 2008-09 YEAR Year Operating Cost Sales Ratio 2006-07 5929.97583 5925.32689 100.8 2007-08 4472.00049 4534.35123 98.62 2008-09 5453.11535 7362.06987 74.04 INRTEPRETATION This ratio indicates firms capacity to face the economic conditions, higher the ratio better the profitability. From the table it is clear that in 2006-07,2007-08, profit was increasing year by year marginally and in the 2008-2009 decreasing the profit. . Operating Ratio It is the relation between cost of goods sold & operating expenses on one hand & the sales on the other hand. It measures the cost of operations per rupee of sales. Operating Ratio = Operating Cost X 100 Sales BABASABPATILFREEPPTMBA.COM Page 60

- 61. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD OPERATING RATIO 120 100 80 RATIO 60 Ratio 100.8 98.62 40 74.04 20 0 2006-07 2007-08 2008-09 YEAR INTREPRETATION Table reveals that the operating ratio shows decreasing trend for the 3 years which means there is an increase in the profit. Expenses Ratio It indicates the relationship of various expenses to net sales. Expenses ratio are calculating by dividing each item of expenses or group of expenses with net sales to analyze the causes for variation in operating ratio. Administration, office, selling & other Expense Ratio: This ratio indicates the relationship at administrative, selling & other Expenses to the sales of the company. Here normally lower the expenses higher the profitability. Administration, office, selling & other Expenses = Expenses X 100 BABASABPATILFREEPPTMBA.COM Page 61

- 62. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD Sales EXPENSES RATIO 25.00% 20.00% RATIO 15.00% Ratio 10.00% 20.39% 14.71% 5.00% 11.53% 0.00% 2006-07 2007-08 2008-09 Year Expenses Sales Ratio 2006-07 683.21455 YEAR 5925.32689 11.53% 2007-08 924.74395 4534.35123 20.39% 2008-09 1082.76722 7362.06987 14.71% INTREPRETATION There is no role of thumb for this ratio, as it may differ from firm to firm depending upon nature of business. Table shows the comparative expenses ratio is in fluctuating trend. Profitability in relation to Investment Return on shareholders Investment: Return on shareholders investments, popularly known as ROI. It is the relationship between net profit after tax & shareholders funds. Thus this ratio is considered as affective BABASABPATILFREEPPTMBA.COM Page 62

- 63. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD indicator of the company’s profitability because it reflects the success of management in the efficient utilization of the owner’s investment. ROI=. Net Profit after Tax X 100 Shareholders fund ROI 30.00% 20.00% Shareholder RATIO Year 10.00% Net Profit Fund 23.41% Ratio Ratio 2006-07 7.01% 152.45938 2175.3 7.01% 2007-08 0.00% 510.45767 0.04% 2180.18495 23.41% 2006-07 2007-08 2008-09 2008-09 0.91423 2239.83274 0.04% YEAR INTREPRETATION The table reveals how were the resources of a firm were being used. So higher the ratio better will be the result The ratio of ROI has increased to 23.41% when compared to 2006-07 . There is no return on shareholders fund because the company shows the profit Activity Ratios: Funds are invested in various assets in business to make sales & earn profit. The efficiency with which assets are managed directly affects the volume of sales. The better the BABASABPATILFREEPPTMBA.COM Page 63

- 64. A STUDY THE INVENTORY MANAGEMENT AT RANNA SUGAR LTD management of assets, the larger is the amount of sales & the profit. Activity ratio measures the efficiency or effectiveness with which a firm manages its resources or assets. These ratios are also called turnover ratio because they indicate the speed with which assets are converted or turned over into sales. a. Inventory Turnover Ratio: Inventory turnover ratio indicates the number of times stock has been turned over during the period & evaluates efficiency with which a firm is able manage inventory. The ratio is calculated by dividing the net sales divided by average inventory at cost. ITR= Net Sales . Average Inventory at Cost Average inventory should be taken for calculating stock turnover ratio. Adding the stock in the beginning & at the end of period & dividing it by 2 to calculate average inventory. INTREPRETATION Inventory Turnover ratio has decreased to 1.9 to.94 in the year 2007-08, in the year 2008-09 incresing the ratio to1.94..which signifies the firms efficiency in producing and selling is improving. Average Year Net Sales Inventory Ratio 2006-07 5925.32689 3126.4008 1.9 2007-08 4534.35123 4846.23044 0.94 2008-09 7362.06987 3793.14434 1.94 FINDINGS: * The A items carry nearly about 7 to 8% of the total items similarly B items 11% and C items 81%. * In the inventory A items very strict control because having high volume of the inventory management B items are moderate. BABASABPATILFREEPPTMBA.COM Page 64