Microencapsulation methods

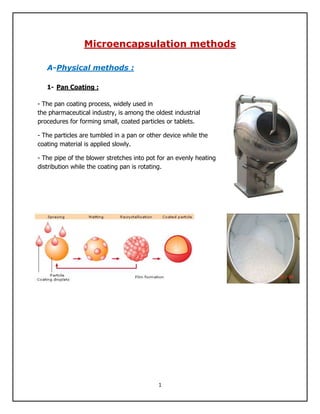

- 1. Microencapsulation methods A-Physical methods : 1- Pan Coating : - The pan coating process, widely used in the pharmaceutical industry, is among the oldest industrial procedures for forming small, coated particles or tablets. - The particles are tumbled in a pan or other device while the coating material is applied slowly. - The pipe of the blower stretches into pot for an evenly heating distribution while the coating pan is rotating. 1

- 2. 2- Air suspension method : - In the air suspension coating , the fine solid core materials are suspended by a vertical current of air and sprayed with the wall material solution . - After the evaporation of the solvent, a layer of the encapsulating material is deposited onto the core material. - The process can be repeated to achieve the desired film thickness. - The size of the core particle for this technique is usually large - Micro-encapsulation by air suspension is a technique that gives improved control and flexibility compared to pan coating Figure 1.1: Scheme showing microencapsulation by air suspension coating. 2

- 3. 3- Spray Drying : - In spray drying the liquid feed is atomized to droplets and contacted with a hot gas which causes the solvent of the droplets to evaporate, leaving dried particles. - The particles are subsequently separated from the drying gas in a cyclone or a bag filter. - Spray drying is the most widely used industrial process for particle formation and drying. It is extremely well suited to the continuous production of dry solids as either powder, granulates or agglomerates from liquid feeds. Feeds include solutions, emulsions and pumpable suspensions. - Spray drying is a versatile process and therefore it provides good control over the final powder properties such as flowability, particle size, redissolution rate, bulk density and mechanical strength. 4- Centrifugal Extrusion : - The centrifugal extrusion process is a liquid co- extrusion process utilising nozzles consisting of concentric orifices located on the outer circumference of a rotating cylinder. - A liquid core material is pumped through the inner orifice and a liquid wall material through the outer orifice forming a co-extruded rod of core material surrounded by the wall material. - As the device rotates, the extruded rod breaks into droplets which form capsules. - The rotational speed affects the capsule size which can be a little as 150microns in diameter and the active ingredients can be encapsulated to up to 80% per weight. - Typical wall materials include gelatin, alginate, carageenan, starch, cellulose derivatives, gum arabic, fats and waxes or polyethylene glycol. Flavour oils for example are easily encapsulated using this methodology. 3

- 4. 5- Vibrational nozzle : - Core-Shell encapsulation or Microgranulation (matrix-encapsulation) can be done using a laminar flow through a nozzle and an additional vibration of the nozzle or the liquid. - The vibration has to be done in resonance of the Rayleigh instability and leads to very uniform droplets. - The liquid can consists of any liquids with limited viscosities (0-10,000 mPa·s have been shown to work), e.g. solutions, emulsions, suspensions, melts etc. - The soldification can be done according to the used gelation system with an internal gelation (e.g. sol-gel processing, melt) or an external (additional binder system, e.g. in a slurry). - The process works very well for generating droplets between 100–5,000 µm (3.9– 200 mils), applications for smaller and larger droplets are known. - The units are deployed in industries and research mostly with capacities of 1– 10,000 kg per hour (2–22,000 lb/h) at working temperatures of 20–1500 °C (68– 2732 °F) (room temperature up to molten silicon). - Nozzles heads are available from one up to several hundred thousand are available. 4

- 5. B- Physico-chemical methods : 1- Coacervation : there are two methods for coacervation are available, namely simple and complex processes. The mechanism of microcapsule formation for both processes is identical, except for the way in which the phase separation is carried out. -In simple coacervation : a desolvation agent is added for phase separation. whereas complex coacervation involves complexation between two oppositely charged polymers. The three basic steps in complex coacervation are: (i) formation of three immiscible phases. (ii) deposition of the coating. (iii) rigidization of the coating. First step : include formation of three immiscible phases; liquid manufacturing vehicle, core material, coating material. The core material is dispersed in a solution of the coating polymer. The coating material phase, an immiscible polymer in liquid state is formed by (i) changing temperature of polymer solution. (ii) addition of salt. (iii) addition of nonsolvent. (iv) addition of incompatible polymer to the polymer solution. (v) inducing polymer – polymer interaction. Second step: includes deposition of liquid polymer upon the core material. Finally : the prepared microcapsules are stabilized by crosslinking, desolvation or thermal treatment. figure 1: Schematic representation of the coacervation process. (a) Core material dispersion in solution of shell polymer; (b) separation of coacervate from solution; (c) coating of core material by microdroplets of coacervate; (d) coalescence of coacervate to form continuous shell around core particles. 5

- 6. 3- supercritical carbon dioxide assisted microencapsulation : - Compressed carbon dioxide in the liquid or supercritical state is attractive as a solvent in microencapsulation processes. . - Carbon dioxide is non-toxic, non-flammable, and inexpensive. - The high volatility of carbon dioxide allows it to be easily separated from polymeric materials by lowering pressure. - The supercritical fluid state is reached when the temperature and pressure of a substance are above its critical temperature and pressure. For carbon dioxide, the critical temperature is 31 °C and the critical pressure is 74 bar. Phase diagram of CO2. -Generally there are three steps in the impregnation : First, the polymer materials are exposed to supercritical CO2 for a while; then the solution of additives in CO2 is introduced and the solute is transferred from CO2 to polymer - Last, CO2 is released and the solute is trapped in the polymer material. - When suspensions of polymer particles in water are exposed to supercritical CO2 with the presence of additives in water, the transport of the additive into polymer particles can also be enhanced. After releasing CO2, additives can be trapped in colloidal polymer particles. Figure : Scheme showing the encapsulation of additives into polymer colloids with the help of compressed CO2. 6

- 7. 3-Sol-Gel Encapsulation : - Sol-gel encapsulation allows trapping lipophylic components inside the spherical shell of amorphous silicon dioxide . - The process can be run, for example, in the oil-in-water (O/W) emulsion with an active material solubilized in the silicon phases such as tetraethoxysilane (TEOS) or tetramethoxysilane (TMOS). - Hydrolysis of the silicon droplets and condensation of the hydrolyzed species to silica occurs at the oil-water interface and leads to formation of the hard silica shell. . 7