Denunciar

Compartir

Recomendados

Recomendados

Más contenido relacionado

Destacado

Destacado (20)

Product Design Trends in 2024 | Teenage Engineerings

Product Design Trends in 2024 | Teenage Engineerings

How Race, Age and Gender Shape Attitudes Towards Mental Health

How Race, Age and Gender Shape Attitudes Towards Mental Health

AI Trends in Creative Operations 2024 by Artwork Flow.pdf

AI Trends in Creative Operations 2024 by Artwork Flow.pdf

Content Methodology: A Best Practices Report (Webinar)

Content Methodology: A Best Practices Report (Webinar)

How to Prepare For a Successful Job Search for 2024

How to Prepare For a Successful Job Search for 2024

Social Media Marketing Trends 2024 // The Global Indie Insights

Social Media Marketing Trends 2024 // The Global Indie Insights

Trends In Paid Search: Navigating The Digital Landscape In 2024

Trends In Paid Search: Navigating The Digital Landscape In 2024

5 Public speaking tips from TED - Visualized summary

5 Public speaking tips from TED - Visualized summary

Google's Just Not That Into You: Understanding Core Updates & Search Intent

Google's Just Not That Into You: Understanding Core Updates & Search Intent

The six step guide to practical project management

The six step guide to practical project management

Beginners Guide to TikTok for Search - Rachel Pearson - We are Tilt __ Bright...

Beginners Guide to TikTok for Search - Rachel Pearson - We are Tilt __ Bright...

Unlocking the Power of ChatGPT and AI in Testing - A Real-World Look, present...

Unlocking the Power of ChatGPT and AI in Testing - A Real-World Look, present...

Jigging_2014

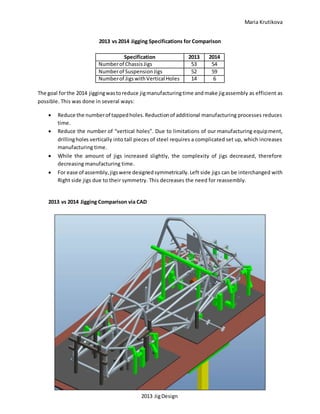

- 1. Maria Krutikova 2013 vs 2014 Jigging Specifications for Comparison Specification 2013 2014 Number of Chassis Jigs 53 54 Number of Suspension Jigs 52 59 Number of Jigs with Vertical Holes 14 6 The goal for the 2014 jigging was to reduce jig manufacturing time and make jig assembly as efficient as possible. This was done in several ways: Reduce the number of tapped holes. Reduction of additional manufacturing processes reduces time. Reduce the number of “vertical holes”. Due to limitations of our manufacturing equipment, drilling holes vertically into tall pieces of steel requires a complicated set up, which increases manufacturing time. While the amount of jigs increased slightly, the complexity of jigs decreased, therefore decreasing manufacturing time. For ease of assembly, jigs were designed symmetrically. Left side jigs can be interchanged with Right side jigs due to their symmetry. This decreases the need for reassembly. 2013 vs 2014 Jigging Comparison via CAD 2013 Jig Design

- 2. Maria Krutikova 2014 Jig Design Complexity of Jigging Assembly Simplified for 2014 2013 Jig Design 2014 Jig Design Note the suspension jig structures shown in green in both models. The 2013 design contains jig assemblies of up to 7 jigs. Almost all suspension jig assemblies in the 2014 model consist of 2 jigs.

- 3. Maria Krutikova Reduction of Vertical Holes 2014 2013 Jig Design Jig Design Due to limitations of the mills in our machine shop, drilling vertical holes takes more set up and therefore more time. Rather than drilling holes vertically into tall jigs as seen in the 2013 design, the same structure can be achieved with holes being drilled into the short part of the jig rather than the tall part. Optimize Jig Location for Welding Ease 2013 Jig Design 2014 Jig Design The purpose of jigging the chassis is to provide accurate tube placement for welding. The 2014 Jig Design allows for unobstructed access to joints, allowing a welding torch to pass through with ease. The 2013 Jig Design has jigs placed near joints, so jigs have to be taken off in order to access the joint for welding. This defeats the purpose of jigging since the chassis is no longer securely fixtured. The 2014 design allows for ergonomic welding and more precise tube placement. No jigs need to be removed for welding and then replaced, which saves chassis assembly time.