Resume-Murugan

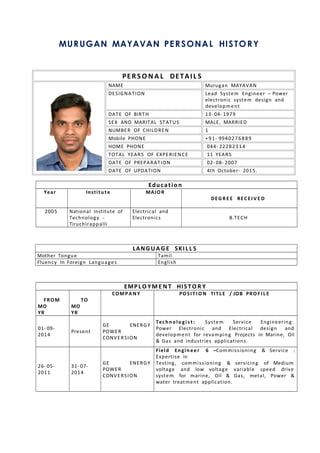

- 1. MURUGAN MAYAVAN PERSONAL HISTORY PER S O N A L DETAIL S NAME Murugan MAYAVAN DESIGNATION Lead System Engineer – Power electronic system design and development DATE OF BIRTH 13- 04- 1979 SEX AND MARITAL STATUS MALE, MARRIED NUMBER OF CHILDREN 1 Mobile PHONE +91- 9940276889 HOME PHONE 044- 22282314 TOTAL YEARS OF EXPERIENCE 11 YEARS DATE OF PREPARATION 02- 08- 2007 DATE OF UPDATION 4th October- 2015. Educatio n Year Institute MAJOR DEG R E E RECEI V E D 2005 National Institute of Technology - Tiruchirappalli Electrical and Electronics B.TECH LANGUA G E SKIL L S Mother Tongue Tamil Fluency In Foreign Languages English EMPL O YM E N T HISTO R Y FROM MO YR TO MO YR COMPA N Y POSITI O N TITL E / JOB PRO F I L E 01- 09- 2014 Present GE ENERGY POWER CONVERSION Technolo gi s t: System Service Engineering: Power Electronic and Electrical design and development for revamping Projects in Marine, Oil & Gas and industries applications. 26- 05- 2011 31- 07- 2014 GE ENERGY POWER CONVERSION Field Engin eer 6 –Commissioning & Service : Expertise in Testing, commissioning & servicing of Medium voltage and low voltage variable speed drive system for marine, Oil & Gas, metal, Power & water treatment application.

- 2. MURUGAN MAYAVAN PERSONAL HISTORY 01- 08- 2007 25.05.20 11 CONVERTEAM Technic al Lead –Commissioning & Service : Expertise in Testing, commissioning & servicing of Medium voltage and low voltage variable speed drive system for marine, Oil & Gas, metal, Power & water treatment application. 02- 01- 2006 25.07.20 07 M/s ISPAT INDUSTRIES LTD, Senior Engin eer: -Worked as Shift In-charge in Sinter Plant Electrical & Automation Dept. Carrying out Maintenance (Preventive, Predictive and Shutdown), Troubleshooting and Condition Monitoring of Electrical Equipments / Automation system. 04- 06- 2005 01- 01- 2006 M/s ISPAT INDUSTRIES LTD, Project Engin eer : -Worked as a project Engineer for sinter plant Erection and commissioning. SKIL L SET S Power Electronics design and developments. Power electronic Design & development (both hardware and software) for upgrade Projects which includes DC Drives upgrade, AC Low Voltage Drives upgrades, Thyristor based LCI Drives upgrades, Thyristor based Cyclo converters upgrades and AC Medium Voltage Drives upgrades for all application. MV Drives Commissioning & Testing of Medium Voltage MV7000 drives. Voltage & power range from 3.3KV & (4MW, 6MW,8MW )to 6.6KV & (12MW, 16MW). LV Drives Commissioning of, MV3000, DC Drives, MD2000, LV7000, Siemens AC MASTER drives, MD2000 & LV7000, Plant Network Profibus, Modbus (RTU, TCP/IP), Fieldbus &Ethercat Communication. Soft Starter system SIMADYN D2 Operation / Maintenance of Siemens Soft starter SIMADYN D2 system (6.6KV / 6.5 MVA ) PLC P80i, Isograph, Logic CAD, Siemens (Step 7), OMRAN PLC & GE Fanuc PLC SCADA Significant exposure in Siemens WINCC & GE FANUC CIMPLICITY Maintenance Predictive, Preventive and Shutdown Maintenance of Electrical Equipments, DRIVE system & PLC System. Troubleshooting Troubleshooting of Electrical Equipments/Drives Systems & PLC System. Process Knowledge Sinter Plant Operations. SAP - PM Module Knowledge of the PM Module Implementation & usage. Six Sigma Knowledge of Six sigma T.P.M (Total Productivity Maintenance) Knowledge of T.P.M. Software programming Significant Exposure in C, C+ + , MS OFFICE Package Usage. TOTAL PROJEC T S EXEC U T E D

- 3. MURUGAN MAYAVAN PERSONAL HISTORY 1. No. Of Projects Executed from 2007 to 2015 in Present Employer 18 2 No, of Green field Projects executed from 2005 to 2007 in Previous Employer 1 Project Execute d - 18 Date Custo m er Name & Addres s Application Augu s t 2015 to In progr e s s Thrybergh Tata steel, UK. Thryb er g h Dc Drive upgr ad e: Six No’s of Old Dc Drives upgr ad e with PECe control syste m s for mill application. Produ ct Name - Thrybergh Dc Drive Upgrades with PECe control systems. Roles & Respo n s i bili ty - FDS Preparation - PECe control system software preparation for thyristor based dc drive - Hardware design and schematic preparation for DC drives upgrades. - BOM Identification - FAT Validation for new PECe control system for Dc Drives. - Documents which include preparation of testing procedure, commissioning procedure & maintenance manual etc. Project Execute d - 17 Date Custo m er Name & Addres s Application April 2015 to May 2015 Trostre Cold Rolling Mill UK. Trostre Stand Three Dc Drive upgr ad e: PECe Control system upgrade for the replacement of Old analogue drive control system for cold rolling mil Stands application in Trostre steel plant UK. Project and Produ ct name - Trostre Stand Three Dc Drive Upgrade: 5 MW. Roles & Respo n s i bili ty - FDS Preparation, - Software Preparation for PECe control system upgrade. - Hardware Design - BOM Identification, - FAT – PECe control system validation. - Documentation which include preparation of Testing procedure, commissioning procedure. Project Execute d - 16

- 4. MURUGAN MAYAVAN PERSONAL HISTORY Date Custo m er Name & Addres s Application April 2015 to July 2015 Alvhiem Drives Upgrade, UK. Alvhiem Drives upgr ad e Project: Propulsion, Thruster & Cargo pump analogue drive upgrade to PECe control systems. Produ ct Name - Alvhiem projects: Dc, LCI & AC drives upgrade Roles & Respo n s i bili ty - FDS Preparation - PECe control system Software Preparation for LCI Drive Upgrade for propulsion, thruster application. - PECe control system software preparation for thyristor based front end converter to supply the dc fed inverter drives for ballest and cargo pumps. - Hardware design and schematic preparation for LCI and DC drives upgrades. - BOM Identification - FAT Validation for new PECe control system for LCI & Dc Drive front end converters. - Documents which include preparation of testing procedure, commissioning procedure & maintenance manual etc. Project Execute d - 15 Date Custo m er Name & Addres s Application Augu s t Febru ar y 2015 to April 2015 TATA STEEL UK. Cold Rollin g Mill Dc Drive upgra d e: PECe Control syste m upgra d e for the replac e m e n t of Old analo g u e drive control syste m for cold rolling mil application in Tata steel UK. Project and Produ ct name - Tata Steel thyristor based Dc Drive upgrade for Cold rolling mill in UK. Roles & Respo n s i bili ty - Site servey to understand the existing control system. - FDS Preparation to describe how to upgrade the old analogue drives. - Software Preparation - Control system design. - BOM Identification. - Hardware schematic preparation. - FAT Validation for PECe control systems. - Commissioning - Documentation which include preparation of testing procedure, commissioning & maintenance manual. etc Project Execute d - 14 Date Custo m er Name & Addres s Application Septe m b e r 2014 to Febru ar y 2015 GE ENERGY, Swansea, UK. NPI: New produ ct implem e n t a tio n : DC Drive upgrade: Power electronic Design and implementation of PECe based NPI product for replacement of very old dc analogue drives control

- 5. MURUGAN MAYAVAN PERSONAL HISTORY system upgrade for all application including Oil & Gas, Marine and Industries. Produ ct Name - NPI Project execution: PECe DC Control system design and development and standardization for Old analogue DC drive upgrades Roles & Respo n s i bili ty - Software development and standardization for thyristor based Dc Drive upgrade which includes 6 pulse configurations, 12 pulse drive configuration. - Hardware Design for PECe DC Control systems to replace very old analogue drive control systems. - BOM Identification, - FDS Preparation. - Engineering on power electronic schematic preparation. - Application code development, Fault class, I/o’ schedule standardization. - Communication interface standardization. - Documentation. Project Execute d - 13 Date Custo m er Name & Addres s Application Febru ar y 2014 to Septe m b e r 2014 STEEL AUTHORITY OF INDIA, RSP, Rourkela, India 4.3 M Hot Strip Plate Mill: Complete Electrical & Automation System supplied for 4.3 M HSPM. Syste m supplied - Complete Electrical & Automation system supplied: Which include Medium voltage Drives, UPS, Soft starters, Electrical Switch gear panels and Automation Roles & Respo n s i bili ty - Site Execution plan preparation - Commissioning of Medium voltage drives, UPS, Soft starters & its auxiliary cooling system (Application program modification if changes needed, drawing correction & updation, Tuning of system as per process requirement, Site acceptance test & reports). - Site management & customer co ordination. - Training to the customer. - Site Documentation - Follow up of spare parts, Verification & handing over to the customer. - Punch list completion (Material follow up, rectification, reports). Project Execute d - 12 Date Custo m er Name & Addres s Application

- 6. MURUGAN MAYAVAN PERSONAL HISTORY Augu s t 2013 to Nove m b e r 2013 TOTAL, OFON2 Nigeria Ltd, Hyundai Heavy Industries, Ulsan, South Korea OFF S H O R E GAS PRO C E S S I N G PLAT F O R M : VSDS Supplied for compressor application to separate the wastage from natural gas and transport the gas to storage offshore platform with required pressure. Syste m supplied - 2no’s x MV7616 Medium Voltage Variable speed drives (16MW, 6.6 KV each) - 2 no’s x (15 MW, 6 KV) Water cooled Motor. - 4 no’s x (9.7 MVA, 6.6KV/(4x1750V)) ONAN Transformers. Roles & Respo n s i bili ty - Site Execution plan preparation - Commissioning of system supplied & its auxiliary cooling system (Application program modification if changes needed, drawing correction & updation, Tuning of system as per process requirement, Site acceptance test & reports). - Site management & customer co ordination. - Training to the customer. - Site Documentation - Follow up of spare parts, Verification & handing over to the customer. - Punch list completion ( Material follow up, rectification, reports). Project Execute d - 11 Date Custo m er Name & Addres s Application Augu s t 2012 to March 2013 RACTEBEL ENGINEERING S.A., Wilhelmshaven Kraftwerk, Niedersachsendam m 10, 26388 Wilhelmshaven, German y COLE FIRE D THE RM A L POWE R PLAN T : 912MVA, 22KV rating. VSDS supplied to cool the main reactor & plant auxiliary system from the sea water. Syste m supplied - 2no’s x MV7308 Medium Voltage Variable speed drives (8 MW, 3.3 KV). - 2 no’s x (5.2 MW, 2.2KV) Water cooled Motor. - 4 no’s x (2.95 MVA, 15KV/(4x745V)) AN Dry type Transformers. Roles & Respo n s i bili ty - Site Execution plan preparation - Commissioning of system supplied & its auxiliary cooling system (Application program modification if changes needed, drawing correction & updation, Tuning of system as per process requirement, Site acceptance test & reports). - Site management & customer co ordination. - Training to the customer. - Site Documentation - Follow up of spare parts, Verification & handing over to the customer. - Punch list completion ( Material follow up, rectification, reports). Project Execute d - 10 Date Custo m er Name & Addres s Application

- 7. MURUGAN MAYAVAN PERSONAL HISTORY February 2012 to July 2012 ETZEL3 Gas storage, Twölv Grasen, 24664 Freideburg, Germa n y E- ON Gas Stora g e & Trans p o r t Plant: VSDS Supplied for compressor application in order to store the Natural gas under high pressure in Cavern walls under the ground and ensure the reliable gas supply when the irregularities occurs in supply chain. System supplied - 3no’s x MV7616 Medium Voltage Variable speed drives (16 MW, 6.6 KV). - 3 no’s x (15 MW, 6.6 KV) Air pressurized Water cooled Motors. - 3 no’s x (19.4 MVA, 10KV/(4x1650V)) ONAN Transformers. Roles & Responsibility - Site Execution plan preparation. - Commissioning of system supplied & its auxiliary cooling system (Application program modification if changes needed, drawing correction & updation, Tuning of system as per process requirement, Site acceptance test & reports). - Site management & customer co ordination. - Customer Training for the supplied systems. - Site Documentation. - Follow up of spare parts, Verification. - Punch list completion( Material follow up, rectification, reports). Project Execute d- 9 Date Custo m er & Addres s Application Septe m b e r 2011 to Febru ar y 2012 Essent Energy Gasspeicher GmBH, 48599 Gronau (Westfalen) Epe, Germa n y Essen t Ener gi e s Gas Stora g e & Trans p o r t Plant: VSDS Supplied for compressor application in order to store the Natural gas under high pressure in Cavern walls capacity of 200 million cubic metres under the ground and ensure the reliable gas supply when the irregularities occurs in supply chain. Syste m supplied - 1no x MV7616 Medium Voltage Variable speed drive (16 MW, 6.6 KV), - 1 no x (15 MW, 6 KV) Air pressurized water cooled Motors - 2 no’s x (9.4 MVA, 10KV/(2x1650V)) AN Dry type Transformers. - Auxiliary Water cooled system ( Air forced water cooled system) Roles & Respo n s i bility - Site Execution plan preparation. - Commissioning of system supplied & its auxiliary cooling system (Application program modification if changes needed, drawing correction & updation, Tuning of system as per process requirement, Site acceptance test & reports). - Site management & customer co ordination. - Customer Training for the supplied systems. - Site Documentation. - Follow up of spare parts, Verification & handing over to the customer.

- 8. MURUGAN MAYAVAN PERSONAL HISTORY - Punch list completion ( Material follow up, rectification, reports). Project Execute d- 8 Date Custo m er Name & Addres s Application May 2011 to Augu s t 2011 TATA PALLET, Tata Nagar, Jamshedpur – 831002 , INDIA TATA PAL L E T Plant VSDS Supplied for Fan Application for Pallet production systems to produce the Iron Pallet from the raw materials. Syste m supplied - 7no’s x MV306 Medium Voltage Variable speed drive (4 MW to 8 MW, 3 KV), - 7no’s x (3 MW MW to 7.2 MW, 2.2 KV to 3.3KV) - 7 no’s x (3.5 MVA to 9.4 MVA) ONAN Transformers. Roles & Respo n s i bility - Site Execution plan preparation. - Commissioning of system supplied & its auxiliary cooling system (Application program modification if changes needed, drawing correction & updation, Tuning of system as per process requirement, Site acceptance test & reports). - Site Documentation. - Follow up of spare parts, Verification & handing over to the customer. - Punch list completion (Material follow up, rectification, reports). Project Execute d- 7 Date Custo m er Name & Addres s Application Dece m b e r 2010 to March 2011 Samsung Heavy Industries Ship Yard, Geoje Island, South Korea. GAZ F L O T - 2 Semi sub mer si ble drillin g rig: VSDS Supplied for Thruster application for semi submersible Rig. The Rig is designed for drilling upto 7500 meters deep wells at sea depth upto 500 meters. The Rig is builded to operate in Russia northeast sea. Syste m supplied - 4 no’s x MV7306 Medium Voltage Variable speed drive (6 MW, 3.3 KV), - 4 no’s x (3.2 MW, 3 KV) water cooled Motors - 4 no’s x (4.5 MVA, 6.6KV/(2x1650V)) AFWF Dry type Transformers. - Complete automation systems Rig operation - DP systems - Drive systems for Drilling

- 9. MURUGAN MAYAVAN PERSONAL HISTORY Roles & Respo n s i bility - Site Execution plan preparation. - Commissioning of system supplied & its auxiliary cooling system (Application program modification if changes needed, drawing correction & updation, Tuning of system as per process requirement, Site acceptance test & reports). - Site Documentation. - Follow up of spare parts, Verification & handing over to the customer. - Punch list completion (Material follow up, rectification, reports). - Sea Trial. Project Execute d- 6 Date Custo m er Name & Addres s Application July 2010 to October 2010 Samsung Heavy Industries Ship Yard, Geoje Island, South Korea. GAZ F L O T - 1 Semi sub mer si ble drillin g rig: VSDS Supplied for Thruster application for semi submersible Rig. The Rig is designed for drilling upto 7500 meters deep wells at sea depth upto 500 meters. The rig is build to operate in Russia north east sea. Syste m supplied - 4 no’s x MV7306 Medium Voltage Variable speed drive (6 MW, 3.3 KV), - 4 no’s x (3.2 MW, 3 KV) water cooled Motors - 4 no’s x (4.5 MVA, 6.6KV/(2x1650V)) AFWF Dry type Transformers. - Complete automation systems - DP systems - Drive systems for Drilling Roles & Respo n s i bility - Site Execution plan preparation. - Commissioning of system supplied (Application program modification if changes needed, drawing correction & updation, Tuning of system as per process requirement, Site acceptance test & reports). - Site Documentation. - Follow up of spare parts, Verification & handing over to the customer. - Punch list completion (Material follow up, rectification, reports). - Sea Trial. Project Execute d- 5 Date Custo m er Name & Addres s Application

- 10. MURUGAN MAYAVAN PERSONAL HISTORY Augu s t 2010 to October 2010 Samsung Heavy Industries Ship Yard, Geoje Island, South Korea. BP SKA R V FPS O (Floatin g Produ ction, Stora g e and Offloadin g vessel): VSDS Supplied for Thruster & Propulsion application for FBSO Vessel. It has ability to process third party gas, Storage, transport & Offloading. It is builded to operate in Norwegian region. Syste m supplied - 5 no’s x MV7306 Medium Voltage Variable speed drive (6 MW, 3.3 KV), - 5 no’s x (3.4 MW, 3 KV) water cooled Motors - 5 no’s x (4.5 MVA, 6.6KV/(2x1650V)) AFWF Dry type Transformers. Roles & Respo n s i bility - Site Execution plan preparation. - Commissioning of system supplied (Application program modification if changes needed, drawing correction & updation, Tuning of system as per process requirement, Site acceptance test & reports). - Site Documentation. - Follow up of spare parts, Verification & handing over to the customer. - Punch list completion (Material follow up, rectification, reports). - Sea Trial. Project Execute d- 4 Date Custo m er Name & Addres s Application May 2010 to July 2010 DSME Ship Yard, Geoje Island, South Korea Group- R1: Semi subm er s i ble Drillin g Rig: VSDS Supplied for Thruster application for semi submersible Rig. It is build to operate in Norwegian sea. Syste m supplied - 8 no’s x MV7306 Medium Voltage Variable speed drive (6 MW, 3.3 KV), - 8 no’s x (3.4 MW, 3 KV) water cooled Motors - 8 no’s x (4.5 MVA, 6.6KV/(2x1650V)) AFWF Dry type Transformers. Roles & Respo n s i bility - Site Execution plan preparation. - Commissioning of system supplied (Application program modification if changes needed, drawing correction & updation, Tuning of system as per process requirement, Site acceptance test & reports). - Site Documentation. - Follow up of spare parts, Verification & handing over to the customer. - Punch list completion (Material follow up, rectification, reports). - Sea Trial.

- 11. MURUGAN MAYAVAN PERSONAL HISTORY Project Execute d - 3 Date Custo m er Name & Addres s Application Febru ar y 2010 to May 2010 DSME Ship Yard, Geoje Island, South Korea Mega Passio n –Semi sub mer si ble Heavy lift ship : VSDS Supplied for Propulsion system of the vessel. The propulsion system is designed to operate 21.Knotes speed of vessel with lifting capacity of 41.986 Ktones. Syste m supplied - 2 no’s x MV7306 Medium Voltage Variable speed drive (6 MW, 3.3 KV), - 2 no’s x (3.5 MW, 3 KV) water cooled Motors - 2 no’s x (4.75 MVA, 6.6KV/(2x1650V)) AFWF Dry type Transformers. - DP Systems - Propulsion field Station. Roles & Respo n s i bility - Site Execution plan preparation. - Commissioning of system supplied (Application program modification if changes needed, drawing correction & updation, Tuning of system as per process requirement, Site acceptance test & reports). - Site Documentation. - Follow up of spare parts, Verification & handing over to the customer. - Punch list completion (Material follow up, rectification, reports). - Sea Trial. Project Execute d : 2 Date Custo m er Name & Addres s Application October 2009 to January 2010 Nexen Buzzard Oil & Gas, Hartlepool, UK OFF S H O R E GAS PRO C E S S I N G PLAT F O R M : VSDS Supplied for compressor application to separate the wastage from natural gas and transport the gas to storage offshore platform with required pressure. Syste m supplied - 2no’s x MV306 Medium Voltage Variable speed drives (6 MW, 3.3 KV). - 2 no’s x (5 MW, 3.KV) Air pressurized Water cooled Motors. - 2 no’s x (4.75 MVA, 6.6KV/(4x 850V)) AFWF Oil type Transformers.

- 12. MURUGAN MAYAVAN PERSONAL HISTORY Roles & Respo n s i bility - Site Execution plan preparation. - Commissioning of system supplied & its auxiliary cooling system (Application program modification if changes needed, drawing correction & updation, Tuning of system as per process requirement, Site acceptance test & reports). - Site management & customer co ordination. - Customer Training for the supplied systems. - Site Documentation. - Follow up of spare parts, Verification & handing over to the customer. - Punch list completion (Material follow up, rectification, reports). Project Execute d :1 Date Custo m er Name & Addres s Application March 2008 to September 2009 Converteam SEMEA, PCM, Massy. Fran c e Factory Accept an c e Testin g: MV70 0 0 Medium Voltage Variable Speed Drive Testing for Different configuration (Active front end, Stand alone Drive, Machine Bridge) from 6 MW to 18 MW. System supplied - Total 62 Mv7000 Medium Voltage Variable speed Drives has been tested in 1 year period for different configuration ( Active front end, Machine Bridge, Stand alone upto 24 pulse configuration). - Roles & Responsibility - Factory acceptance Testing - Specific functional Testing - Test Report preparation Project Executed- in ISPAT Date Compa n y Name & Addres s Application May 2005 to July 2007 ISPAT Industries Ltd. Panvel, Navy Mumbai, INDIA Sinter Plant Project : New Sinter Plant installation, Commissioning & Operation, , Maintenance Roles & Respo n s i bility - Supervision of Subcontractor for sinter plant Electrical system installation & Commissioning. - Shift in charge for Electrical maintenance for sinter plant operation.

- 13. MURUGAN MAYAVAN PERSONAL HISTORY - Commissioning of Sieme n s - SIMOV E R T AC MAST E R DRIVE S (5.5kw, 7.5 KW, 11KW and 22 KW) for Sinter Plant Belt weighing System. - As per customer requirements Program modification done in Sieme n s S7- 400 PLC ,WINC C SCA D A , GE Fanu c PLC, Simplicity SCA D A and OMRAN PLC . Projects done for Conveyor Systems & Sector gate with Siemen s Drives & S7- 400 redun d a n c y PLC syste m In ISPA T. - Installation & Commissioning support for synchronous motor (6.6KV / 6.5MVA) and Siemens make soft starter SIMADYN D2 systems. - Support in energy saver Installation & commissioning for power saving in sinter plant. - Support for reliability of critical systems during power failure, as well as efficiency of DG by implementing dual power scheme- powering critical systems through dual power sources- DG & EB power. - Involved SAP PM Module Implementation for Sinter Plant. - Commissioning done for water tank level control for utility syste m in sinter plant Trainin g Receiv e d GE Energy Power Conversion 1. Safety Training - National Safety council of India 2. First Aid 3. HPCi & P80i 4. Crane Technology – Berlin Unit 5. Communication Development 6. French Spoken language 7. German Spoken language 8. BOSIET –OPITO approved. 9. VCA –Belgium( Basic element of safety SCC) ISPAT Industries 1. siemens S7- 300/400 PLC by Siemens 2. WINCC SCADA by ISPAT 3. AC Drives by Siemens 4. GE Fanuc Versa Max ,90- 30 series PLC and Simplicity SCADA by GEFanuc. 5. SAP PM by ISPAT. 6. Sinter plant Operations - XinYu iron & Steel Stock co. Ltd in china 7. Six sigma Green Belt Training and TPM by ISPAT. CONTA C T DETAI L S : Murugan MAYAVAN,

- 14. MURUGAN MAYAVAN PERSONAL HISTORY Plot No.83B, Sudharsan Nagar, Madambakkam, Chennai- 600073 Phone No:+ 9 1 ( 0 ) 44- 2228 2 3 1 4 Mobile No:+ 9 1 ( 0 ) 9940 2 7 6 8 8 9 E- Mail: murug a n . y@ g m a il.co m