Watervliet Arsenal Newsletter: Salvo 31 July 2013

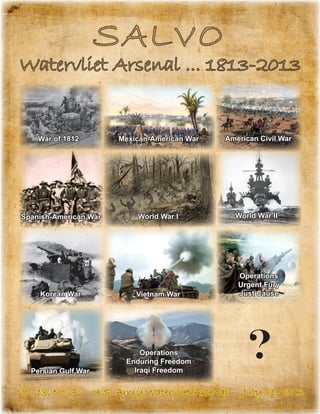

- 1. SALVO Watervliet Arsenal ... 1813-2013 Vol. 13, No. 7 U.S. Army Watervliet Arsenal July 31, 2013 War of 1812 Mexican-American War American Civil War Spanish-American War World War I World War II Korean War Vietnam War Persian Gulf War Operations Enduring Freedom Iraqi Freedom ? Operations Urgent Fury Just Cause

- 2. Page 2 Salvo July 31, 2013 The Arsenal Salvo is an authorized monthly publication for members of the Department of Defense. Contents of the Salvo are not necessarily the official views of, or an endorse- ment by the U.S. Government, the Department of Defense, the Department of the Army, or the Watervliet Arsenal. News may be submitted for publication by sending articles to Public Affairs Officer, 1 Buffington Street, Bldg. 10, Watervliet, NY 12189, or stop by office #102, Bldg. 10, Watervliet Arsenal. The editor may also be reached at (518) 266-5055 or by e-mail: john.b.snyder.civ@mail.mil. The editor reserves the right to edit all information submitted for publication. Commander, Col. Lee H. Schiller Jr. Public Affairs Officer, John B. Snyder Editor, John B. Snyder Photographer: John B. Snyder Photos provided by: Wikipedia U.S. Army & Air Force Defense Video & Imagery Distri- bution System Library of Congress Watervliet Arsenal Museum Lee H. Schiller Jr. Commanding Manufacturer 6 Let me begin by saying thank you to everyone who has extended a warm and friendly welcome to me and to my family. I look forward to getting out and meet- ing as many of you in my first 30 days of assuming command. Special thanks to those who helped make the change of command ceremony a very memorable one. In my short time here, I continue to be highly impressed by the dedication and commitment of our workforce, which is the arsenal’s greatest resource. PHILOSOPHY Because this is my first article I am writing for the Salvo, I thought it would be best to share with you my command philosophy for the Watervliet Arsenal. Our sole mission focus is to support our military servicemembers who defend our nation. They de- mand and deserve EXCELLENCE in our support and therefore, we will always strive to deliver high quality products, at cost, and on time. I truly believe that TEAMWORK is the success to any business. No one single person is greater than the team. We will strive for successful partnerships with management and labor, business partners, and our higher headquarters, TACOM and AMC. RESPECT is the very essence of what makes us an outstanding organization. It is a commitment to each other and a means of recognizing each person’s dig- nity and contribution to our mission. EXPECTATIONS My expectations are very simple: Be engaged; look for and solve problems; stay on schedule; have high expectations and insist that accountability occurs at every level; keep the chain of command informed; and adhere to policies, regulations, and guidance, whether those directives are verbal or written. Because people are our greatest asset, creating and maintaining a SAFE environment will remain one of the highest of priorities during my command. We will incorporate proactive safety measures into all of our programs and activities. I will consistently address this topic because it is important that we all keep it foremost in all that we do, on and off the job. We will strive to maintain a culture of safety that is rooted in training, awareness, and ac- countability. Through the next couple of years, I will use this column, as have past commanders, to communicate topics that I feel we need to discuss, things you need to know, and to recognize people who are doing a great job. In closing, it is truly an honor to be the commander of an arsenal where Dedication, Pride and Excellence are not just words. They are an icon that you have lived by and believed in since 1813. Commander’s Corner

- 3. Page 3 Salvo July 31, 2013 Top: An 1881 map of the arsenal shows its relation to the Hudson River and the Erie Canal. Bottom right: Built in 1841, the arsenal com- mander’s quarters was one of many new buildings constructed in the 1840s to replace deteriorated buildings from 1813 & 1814 as shown in this 1875 photo. Bottom left: Beginning with the Erie Canal, the arsenal has leveraged advanced technology to improve production. This 1913 photo shows just how much damage could be leveled against the arsenal whenever the Erie Canal flooded. That is Building 40 and the current Cannon Club in the water. Transformation begins Early years In the heat of our nation’s second war with Great Britain, a 12-acre plot of land was pur- chased on July 14, 1813, and construction of a manufacturing center begin immediately. Ad- ditional land purchases were made in 1826, 1828, 1833, 1859, 1862, 1867, 1869, 1918, 1920, and 1942. The location of the arsenal was the primary factor in the establishment of the arsenal at Watervliet. Being close to transportation routes, the Hudson and Mohawk Rivers, would allow the arsenal to quickly move supplies and trade. The existence of an underlying strata of shale also provided a sound foundation for manufacturing and the ability to tap into the skilled labor force of the area were all essential to the selection of the Watervliet location. Production during the war focused on the manufacture of ammunition, powder horns, cartridge boxes, and leather accoutrements. Once the war ended, the arsenal fell into a pe- riod of decline as it became a warehouse of sorts for military equipment. Maj. James Dalliba, the first commander, was challenged by the tyranny of distance be- cause he also commanded arsenals and depots at Buffalo, Batavia, and Rome, New York. He, therefore, assigned temporary command to Capt. Thomas Campbell who oversaw the construction of the first 10 buildings and two stables that became the foundation of the ar- senal’s war effort.

- 4. Page 4 Salvo July 31, 2013 Photos taken in 1865 show Building 40 after a major expansion, as well as the cast iron columns of the second floor that made this building fireproof, according to the plans. Although parts of Building 40, now home to Benét Laboratories, were constructed in 1828, a major expansion occurred to the building during the Civil War to accommodate the heavy volume of war-related material. This state-of-the-art structure in the 1860s housed the manufacturing of gun carriages and a foundry shop in a fireproof facility that received its power from the Erie Canal. During the Civil War period, the amount of business quadrupled as the workforce swelled to more than 2,000, of which one-quarter were children. Although the arsenal manufactured various articles of war, from saddles to carriages, the arsenal claimed its stake in ammunition production. Once again the arsenal turned to advanced technology in manufacturing. One of its foremen developed a bullet press that tripled bullet production. It was not uncom- mon for the arsenal to manufacture up to 30 million handmade ammunition cartridges a month. On any given day, millions of pounds of black powder were stored on the arsenal, much of it came from local manufacturers in Schaghticoke, N.Y. When the arsenal shipped ammunition cartridges, the quantities often exceeded 10 million rounds. Just as quickly as the arsenal transformed into a major supplier of war material at the beginning of the Civil War, it quickly moved from a production footing to a storehouse for military hardware once the war came to an end. Transformation to war ... Civil War

- 5. Page 5 Salvo July 31, 2013 Transformation from a maker of saddles to a maker of cannons Top: An 1889 print of a line drawing of Building 110. Bottom: The first 16-inch gun manufactured at the arsenal is being readied for transport in 1902. The post-Civil War years brought great decline to the arsenal. Faced with a severe recession in the 1870s, the arsenal was nearly closed by Congress. But world events in the 1880s ushered in a new era ... the United States would need to invest heavily in military technology and weaponry to compete as a world power. In 1887, a War Department board, which was charged with determining the best suited navy yard or army arsenal that could be modernized for modern warfare, selected the Watervliet location due to its proximity to skilled labor, supplies, and to centers of transportation. By October of that year, production of field and siege guns was underway. A two-story brick structure was converted for the manufacture of 3.2-, 8-, and 10-inch guns, as machinery and tools were transferred from other arse- nals. Congress appropriated funds in 1888 for the construction of a major shop that could produce the large seacoast guns...Building 110. It would not be until 1899, however, that the first 16-inch gun would begin production. The first 16-inch gun was completed in 1902. 1880s - 1900s

- 6. Page 6 Salvo July 31 2013 Transformation to war ... World War I Top: A typical World War I howitzer that was made at the Watervliet and Rock Island arsenals. This 1914 gun, and another just like it, reside at the Christian Brothers Academy, Albany, N.Y. Bottom right: A World War I poster. Bottom left: A 1919 victory celebration at the arsenal that had as many as 20,000 attend. After the turn of the century, the arsenal manufactured a very limited number of guns, but as it had done during the previous 100 years, it transformed itself using the latest in advanced technology. Beginning in 1906, the arsenal began to use a heat treatment process to support the re- lining of seacoast guns whose linings were well worn by usage. In 1910, the arsenal man- ufactured what may be the nation’s first air defense-type weapon, a “balloon gun,” that fired a 6-pound round through a 2.24-inch gun to down dirigibles (blimps) and airplanes. World War I brought a significant building boom to the arsenal as a new gun shop, Building 35, reached a daily production of four 240 mm howitzers and two 155 mm howit- zers. Building 25 was built and became a “mobile artillery shop.” New barracks, canteen and dining facility were also built to handle the large influx of workers. Employment in- creased from 670 in 1916 to more than 3,300 by 1917. As new technology was brought to the arsenal, old technology, such as the Erie Canal, was displaced. The Canal ended operations on the arsenal in 1922.

- 7. Page 7 Salvo July 31, 2013 Transformation to war ... World War II As the arsenal rediscovered, success on the battlefield does not mean continued suc- cess in regards to maintaining production levels and workforce size. After World War I, the arsenal went through a significant decline in production as orders were cancelled or greatly reduced. Production was reduced to just a single wing of the seacoast gun shop at which point, Col. Edwin Bricker, arsenal commander, complained to the Chief of Ordnance that any further decline in production would destroy gun-making in the Army. This slump continued for nearly 20 years. Arsenal Commander Col. Richard Somers took command one year before Germany in- vaded Poland. The year was 1938. When Somers took command there were only 350 em- ployees and the art of machining resided in just a few foremen and master machinists who survived the years of downsizing. But Somers began immediately preparing the arsenal for a war and saw its workforce grow to 1,000 by 1939 and to more than 1,700 by 1940. Production grew quickly and by the time Somers left the arsenal in 1940, the arsenal was manufacturing nearly 1,000 guns a year. Brig. Gen. Alexander Gillespie, took command in 1940 and saw the workforce grow to more than 9,300 at the peak of the war, of which near- ly 3,000 were women. From the time of the attack on Pearl Harbor to the landing at Normandy, the arsenal manufactured more than 23,000 guns with an on-time delivery rate exceeding 99 percent. Top: The arsenal produced hundreds of 16-inch guns for seacoast protection, as well as for battleships. Here, the USS Iowa is firing guns made at the arsenal as shown in this 1980s-era photo. Bottom right: Women made up nearly 30 percent of the workforce during World War II. Bottom left: A seacoast gun manufactured by the arsenal is being fired on a coast emplacement in the Philippines.

- 8. Page 8 Salvo July 31, 2013 Transformation to war ... Korean War From a peak of more than 9,300 employees in 1942, the arsenal had reduced its work- force to 940 by 1947. In 1947, the Army Chief of Ordnance said in a letter to a local con- gressman in regards to the current situation at the arsenal, “An economy-minded nation is not looking with favor on the expenditure of money for the purpose of sustaining an intelli- gent, well-trained crew of men ready to swing into the next war overnight.” After World War II, the arsenal returned to a familiar task that had perplexed the work- force since the end of the War of 1812 ... it once again became a warehouse for returned war material. By June 1950, a foreign military sale type of process was established as excess material was often shipped to Greece, Italy, France, China, Belgium, and the Netherlands. Production leading into the Korean War focused on small caliber weapon systems such as recoilless rifles and the 20 mm automatic cannon for aircraft and anti-aircraft use. But arsenal research and design also produced a 90 mm tank gun that was far more lethal to any U.S. cannon used during World War II, as well as a 120 mm heavy tank gun that used for the first time a deadly high-velocity armor piercing round. By 1952, the workforce expanded to nearly 4,800 workers as the arsenal manufactured small and large caliber weapons systems. The arsenal entered the atomic age in May 1953 when the world’s first nuclear shell was fired on Frenchmen’s Flat, Nev., from a 280 mm cannon manufactured at the arsenal. The Korean War came to an end about two months after that firing. From January 1950 to December 1954, the arsenal manufactured more than 20,000 guns, mortars, howitzers, and recoilless rifles. Top: Arsenal production on a 280 mm atomic gun system in the early 1950s. Bottom right, American artillery manufactured by the arse- nal being fired in Korea. Bottom left: The first atomic shell fired from a howitzer in 1953.

- 9. Page 9 Salvo July 31, 2013 Transformation to war ... Vietnam As defense budgets once again declined after the Korean War, the arsenal suffered through more reductions in force. But just like past post-war declines in military spending, the arsenal underwent several transformations that would assist in its long-term viability. In 1954, the arsenal became funded by a new process by what we know today as the Army Working Capital Fund. Prior to this new funding system, the arsenal had two sources of fund- ing and for command and control. The arsenal answered to the Army Chief of Ordnance for mission-related issues and to First Army Headquarters for repairs, maintenance, and other support services. To support the arsenal in this new effort to build the industrial base, Con- gress appropriated more than $6 million for future developments such as the modernization of Buildings 25 and 35, the building of a new boiler house, and the construction of Building 44 to house gage and products assurance operations. Prior to combat operations in Vietnam, the arsenal invested heavily in research and devel- opment. New 90 mm recoilless rifles, 105 mm tank guns, Honest John missiles, and a mortar system that could fire an atomic warhead were developed in just a few years. Even a new designed 175 mm howitzer made it into President John F. Kennedy’s inaugural parade in 1961. By 1962, arsenal research and development hit a milestone with the dedication of Building 40 as the home of the newly formed Benét Laboratories. The Army closed out the 1960s with a wide variety of artillery delivery systems such as the 175 mm M107 howitzer, the 155 mm M109 self-propelled howitzer; the 8-inch M110 howitzer; and the 105 mm M102 lightweight towed howitzer. Right: A self-propelled 175 mm howitzer at a fire base in Vietnam. Left: An Air Force gunship dropping flares while a 105 mm tube is showing out its left side.

- 10. Page 10 Salvo July 31, 2013 Transformation to war ... Grenada & Panama Top: A graphic of the invasion plan for Operation Urgent Fury into Grenada. Bottom right: The rotary forge was added to the arsenal in 1976 to wean the arsenal from outside vendors and to speed production. Bottom right: A 105 mm howitzer firing in Grenada. Prior to the 1983 Operation Urgent Fury in Grenada and the 1989 Operation Just Cause in Panama, the U.S. Congress invested heavily in new capability under a program called Project Renovation of Armament Manufacturing or REARM. Under this six-year program that began in 1979, nearly 700 pieces of equipment would be replaced or upgraded, as well as several build- ings renovated. The REARM program went beyond its original six-year plan and ended in 1992 after having attained $306 million in new capability. In addition to REARM, the arsenal invested to reduce reliance on outside vendors such as with the installation of the rotary forge in 1976. Despite this major revitalization, the arsenal still had a production mission to maintain. Although the Army moved from the jungle tactics of Vietnam to the Soviet-style type of force during the Reagan years, production shifted to the manufacture of guns and parts for a new lightweight 60 mm mortar system to a new 155 mm M198 towed howitzer to a new light- weight 105 mm M119 howitzer. These lightweight weapon systems were critical to the quick deployment of U.S. forces into Grenada and Panama. Just as in previous peacetime ebbs in defense budgets, the arsenal also turned to non- mission work to help fill the gaps. In 1989, the arsenal began to manufacture several parts for a new mine clearance system. During the Vietnam War, the arsenal manufactured scissor bridges.

- 11. Page 11 Salvo July 31, 2013 Transformation to war ... First Gulf War As the wall of the Cold War came tumbling down in the late 1980s, so too did the funding for military weapon systems. The first reductions in force notices began in August 1990 and would continue for another 11 years. Employment went from nearly 2,500 in 1989 to less than 500 by late 2001. Despite this outflow of critical skills and experience, the arsenal still had a mission to perform and in 1991, it once again proved its unique capability to respond to the urgent needs of the warfighter. As military planners designed the air campaign to support Operation Desert Storm that began on Jan. 17, 1991, they had concerns that current ordnance would be ineffective against Saddam Hussein’s hardened command and control bunkers. Their concerns proved to be true as 2,000 pound ordnance could not reach the underground bunkers. The Defense Department and Lockheed Missile and Space Co. turned to the arsenal on Jan. 25, 1991 to develop a 5,000 pound bomb because the 2,000 pound bombs were ineffective. With nothing more than a phone call initiating the request, the arsenal went to work and on Feb. 17, 1991, the arsenal delivered two bunker buster bombs. The first test, without ex- plosives, was dropped on a target and plunged more than 100 feet into the ground. After the testing of the two bombs, two more bombs, called GBU-28, were deployed to support the air campaign in Iraq. On Feb. 27, one of the two GBU-28s destroyed Saddam’s main command and control center just north of the Iraqi capital. On Feb. 28, Saddam Hussein agreed to a cease fire. Right: The first Bunker Buster bomb at Frenchmen’s Flat, Nev., goes more than 100 feet into the ground. Left: Abrams tanks in formation attacking Iraqi units.

- 12. Page 12 Salvo July 31, 2013 Transformation to war ... Operations Enduring Freedom & Iraqi Freedom Historically, after every major conflict there are many who believe that we will never fight that kind of war again. And so, absent of war, the need for military hardware dramatically declined after the first Gulf War, just as we have seen throughout the arsenal’s history. When America came under attack on Sept. 11, 2001, the arsenal was near its breaking point of main- taining a sufficient level of critical skill expertise to meet its core mission. But what has made the arsenal great for 200 years was once again thrust into national prominence as our nation soon found itself in two simultaneous combat operations, one in Af- ghanistan (Enduring Freedom) and the other in Iraq (Iraqi Freedom). A lot has changed on the arsenal since 1813 except one thing ... the ability of the workforce to meet the urgent needs of our nation’s servicemen and women. From ramping up production for its core manufac- turing requirements, such as tank and howitzer cannons, to non-mission production support for such things as armored kits for soft-skinned military vehicles, the arsenal workforce once again met the challenge supporting both conflicts. Today, as U.S. combat operations near an end in Afghanistan, the arsenal is assisting that transition by manufacturing hundreds of mortar systems for the Afghanistan National Army. The sooner the ANA is trained and armed, the sooner our troops may come home. Suffice it to say that for 200 years the arsenal has produced the materials that have helped hundreds of thousands of our military to safely come home. Top: Abrams tanks firing in Operation Iraqi Freedom. Bottom right: Afghanistan National Army soldiers firing a 60 mm mortar system that was manufactured by the arsenal. Bottom left: A M777 155 mm howitzer firing in Afghanistan.