Dana Farber Yawkey Center for Cancer Care wins ACEC Silver

- 1. SIMON DESIGN ENGINEERING 2011 YAWKEY CENTER for CANCER CARE DANA-FARBER CANCER INSTITUTE

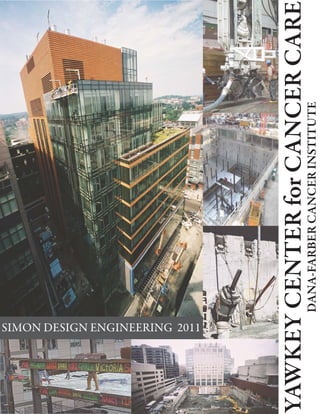

- 2. Y A W K E Y C E N T E R for C A N C E R C A R E Dana-Farber Cancer Institute Internationally known for its clinical excellence and cancer research, Dana-Farber Cancer Institute (DFCI) is consistently recognized as one of the leading cancer research institutes in the country. Between 2001 and 2008 alone, annual outpatient visits and infusions at DFCI increased from approximately 140,000 to more than 264,000 along with clinical trials increasing by nearly 80%. DFCI sought to provide ample, state-of-the-art facilities for leading-edge treatment of cancer and related diseases for the expanded patient population, and to create an enhanced healing environment with a strong patient and family centered focus, improved patient safety, and support for safe staff practices. Utilizing the last buildable site on the DFCI Longwood Campus in Boston, Massachusetts, the new Yawkey Center for Cancer Care (YCCC) is a 275,000 square foot building (198 ft x 186 ft plan) with seven stories of below-grade parking and fifteen above-grade stories. To help unite the DFCI campus, and to alleviate pedestrian and vehicular traffic, the design incorporates both below and above-grade connections to the adjacent Smith Fig. A: Site plan showing YCCC isolation slurry walls. Building and the Dana Building across the street. The facility represents the Institute’s forward-looking vision and according to Dr. Edward Benz, president of DFCI, “The new YCCC is Dana-Farber’s response to the need for the best 21st century cancer care and for new modes of clinical research designed to bring better treatments to patients more quickly and safely.” Working with the renowned ZGF Architects and Walsh Brothers construction team, Simon Design Engineering (SDE) provided site engineering master planning and served as Structural Engineer of Record for the superstructure and foundations. SDE brought over 20 years of experience on the DFCI campus, including the structural and isolation design of the abutting Smith Building. Intensive collaboration was demonstrated by the design and construction team, which ultimately resulted in the project being completed two months ahead of schedule and on budget. The logistical challenges of this project were extraordinary. With no lay-down area, the roof of the mechanical room was designed to provide a construction staging platform, tower crane support, and earth retention to avert the use of tiebacks at the upper levels. Proximity to the Medical Area Total Energy Plant (MATEP), which provides electricity, steam and chilled water to the Longwood area, also presented a host of issues. The low-frequency vibrations produced by its generators, if left unmitigated, would have a severe impact on DFCI’s sensitive operations. The solution, isolate the building from the surrounding soil with a three-foot thick reinforced concrete slurry wall that served as an excavation support system, groundwater cutoff, and a permanent isolation wall. With no physical connection to the slurry walls that surround the structure, the YCCC is literally a free-standing 22-story building that begins seven stories below grade and is supported on isolated piers founded on bedrock. ACEC 2011 SIMON DESIGN ENGINEERING page 1/2

- 3. Y A W K E Y C E N T E R for C A N C E R C A R E Dana-Farber Cancer Institute The slurry wall system is similar to the abutting 15 year old Smith Building, but significantly more complicated; DFCI utilized the same design team as the Smith Building, including GEI Consultants, Inc. for geotechnical services. The construction of the underground garage required the excavation and removal of 20,000 tons of soil to a depth of 80 feet beneath Brookline Avenue and 50 feet below the MATEP. Supporting the slurry walls are 286 permanent tie back anchors, composed of 140 foot-long bundles of steel cables (total of 75 miles of cable, weighing 148 tons). To ensure that there was no uncontrolled soil loss during the tieback installation, a specially designed rig was used to carefully manage the drilling process that occurred up to 60 feet below the groundwater table. Computer generated 3D survey technology was utilized to monitor the settlement of the MATEP during construction to insure its critical equipment incurred no impact. Due to potential construction related vibrations and noise, the team utilized an innovative hydro- mill drill rig to cut through the rock at the bottom of the slurry walls, without impacting the sensitive operations of neighboring facilities. The hydro-mill technology cut the bedrock at a rate 10-15 times faster than traditional methods, saving three weeks on the schedule and preventing shutdowns due to excessive vibrations. The superstructure foundations are offset ten feet from the slurry wall to preclude the need to expose the toe of the wall and reduce overall risk of vibration transmission. In some locations, it was essential that columns slope inward ten feet from the ground floor to the lower level, while avoiding large transfer girders at grade. For the deep foundations, SDE developed a vital “caisson-in-a-can” solution that provided a watertight seal, which allowed for the piers to be inspected and surrounded with a layer of isolation foam to reduce the transmission of ground vibrations. Protection of the public’s health during construction was a key initiative for the team. DFCI included an emissions control element into the construction management plan. Detailed specifications regarding standards for the idling of equipment and the reduction of hydrocarbons were imposed on all subcontractors. The result, the YCCC project became the model for Greater Boston Breathes Better and the team earned a Merit Award of Excellence from the Environmental Protection Agency (EPA) recognizing the incorporation of clean diesel strategies into the construction management plan. Volatile organic compound (VOC) pollutants were reduced by 42%, carbon monoxide by 31%, and particle matter by 20%. Nearly 100% of the site’s waste was recycled. The project is expected to receive a LEED Silver rating and is a pilot project in the Green Guide for Healthcare Initiative. A primary goal of this project was to achieve a park-like setting; green roof gardens with plantings have been incorporated on the roofs of the 4th, 11th, 12th, and 14th floors and a healing garden is provided as a place of calm for patients, families, and caregivers. Indoor air quality management plans to mitigate potential air quality hazards were also implemented and low-emitting adhesives/sealants, paints/coatings and carpet systems were used to reduce indoor air contaminants. SDE provides DFCI: Owner’s Agent Services, Conceptual Project Design, Project Programming, Value Engineering, Management, Parking Consulting, SER, Project Coordination, Material Evaluation, Quality Assurance, Project Closeout. ACEC 2011 SIMON DESIGN ENGINEERING page 2/2

- 5. Y A W K E Y C E N T E R for C A N C E R C A R E Dana-Farber Cancer Institute Raw Excavation: The view on the opposite side, looking south, has Brookline Avenue (and the mechanical space/staging area) to the right, the MATEP directly ahead, and the Smith Building to the left. This image displays the multiple construction operations and logistical issues that the team had to coordinate on a daily basis; from right to left: The reinforced concrete mechanical space roof, supported on steel columns is seen being used for construction staging and lay-down. To the right of this image is where the tower crane was located. Excavators and dozers inside the hole move soil to the southwest corner to be lifted up to the mechanical space roof for removal from the site. Tieback anchor installation proceeded level by level as the hole was excavated. The blue rig to the left is installing a P5-Level tieback under the MATEP; in order to minimize the water pressure and reduce the potential for soil loss, the anchor was installed from a ten-foot-high bench. Behind the plywood wall is the Smith garage. Portions of the Smith slurry walls were removed to make connections to the YCCC parking levels. The man on the scaffolding is cutting a pocket in the Smith slurry wall, which later supported the YCCC floor beams on slide bearings. Just below the scaffolding, the small black circles are the abandoned Smith tiebacks that were removed in a staged manner as excavation continued. Also below the scaffolding is a sump pit used to remove the water that was trapped in the hole after the slurry walls were complete. The slurry walls, which were toed into bedrock, acted to cut off any additional groundwater from entering the excavation. Simon Design Engineering Photo 1 Photography By: Krystal Layton

- 6. TOPPING OFF

- 7. Topping Off: The image on the opposite side, taken during the topping off ceremony, shows the continuation of the beloved tradition started during the Smith Building construction. Providing moments of joy to the pediatric patients, ironworkers spray painted the children’s names on the steel framing. The patients will forever be a part of the YCCC with their names emblazoned within the heart of the building; each name serving as an eternal tribute to the courageous children receiving cancer treatments, and the important work Dana-Farber will continue to do in the new Yawkey Center. The story of the bond between the craftsmen and young patients became known as “Steeling their Courage.” Initially local, it was not long before it was featured on ABC’s World News Tonight with host Charlie Gibson. The following links tell the story: http://abcnews.go.com/WN/PersonOfWeek/story?id=7024168&page=1 http://www.youtube.com/watch?v=17yvwYXEEZ8&feature=mfu_in_order&list=UL http://www.youtube.com/watch?v=87rKU7fg6DA http://www.youtube.com/watch?v=Fj4nHmV4DEY&NR=1 At the glass-enclosed stair tower, shown to the left, the names were left exposed for all to see.

- 8. FINAL TOUCHES OF COLOR

- 9. Y A W K E Y C E N T E R for C A N C E R C A R E Dana-Farber Cancer Institute Final Touches of Color: This view of the southwest corner of the building near construction completion displays one of the many design modifications that were required due to the constraints of the site. Working closely with the General Contractor, Simon Design Engineering designed temporary cantilevers that extended to the service elevators shown (note in the image to the right, the cantilevers have been removed and the cladding installation complete). Procured during the escalating construction market of 2006-2007, contingencies were incorporated into the budget to account for the potential inflationary effects. Design-assist partners were brought onto the team early to facilitate, design, and procure key elements of the project, including the curtainwall. This collaborative team approach produced a façade consistent with the design vision of a signature building while staying below budget through a blending of unitized curtainwall and rain screen design. Simon Design Engineering Photo 3 Photography By: Krystal Layton Photography By: Krystal Photography By: Krystal Layton

- 10. CORNER VIEW

- 11. Corner View: This corner perspective shows the third level, two-story “Healing Garden” which cantilevers out over the public entrance to the building. The elevated garden space is visible to the public from the street below and is being finished with materials sensitive to the patients’ health and emotional needs. The YCCC is designed to provide ample, state-of-the-art facilities for leading-edge treatment of cancer and related disease, but also focuses on providing an enhanced healing environment with a strong patient and family centered focus. This indoor sanctuary overlooking Joslin Park will consist of pathways with garden seating, natural stone walls, colorful flowers that change seasonally, and a canopy of tall greenery that envelopes visitors in a lush, serene environment. The healing garden will also contain a 20-by-28-foot glass conservatory without plants, so immune-compromised patients can enjoy the surrounding elements free of allergen or health concerns. "Our patients and families requested a living healing garden, but with a limited outdoor landscape, it wasn't realistic," says Wendy Gettleman, Dana-Farber's senior director of Planning, Design, and Construction. "So we did the next best thing and put it inside."

- 12. URBAN GREEN

- 13. Y A W K E Y C E N T E R for C A N C E R C A R E Dana-Farber Cancer Institute Urban Green: This image, taken from the YCCC-Smith connector bridge looking down on the fourth level roof garden adjacent to the Smith Building on the right, is just one of four roof gardens in the YCCC facility. The roofs at each building setback were utilized for providing as much green space as possible to achieve a park-like setting. The native shrubs and other plantings decrease storm water runoff, lower temperatures, improve air quality, and offer a green vista for onlookers in nearby buildings. This helped with attaining LEED points, but more importantly helped DFCI meet one if its primary goals of providing a healing environment by brining nature back into the dense, urban Longwood Medical Area. On the third floor, a healing garden also provides a place of calm for patients, families, and caregivers. DFCI incorporated soothing earth tones and the natural grain of eucalyptus and limestone throughout the building, infusing areas with floods of natural light and frosted glass speckled with delicate butterflies. “We’re trying to bring nature back to the site with a landscaped roof with trees and benches along Brookline Avenue, notes architect Margaret DeBolt and colleague Isabelle Arnold of ZGF. “It will be a small urban green space.” Other Earth-friendly options in the works include providing adequate bicycle storage and showering facilities. With the goal of minimizing patients’ exposure to toxins, everything from cleansers to refrigerants to construction materials are carefully chosen. DFCI insists on low levels of volatile organic compounds (VOCs) in carpeting adhesives and chemicals such as polyvinyl chloride (PVC) have been eliminated or reduced from all construction materials. Simon Design Engineering Photo 5 Photography by: Krystal Layton

- 14. NEW FACE OF DFCI

- 15. Y A W K E Y C E N T E R for C A N C E R C A R E Dana-Farber Cancer Institute New Face of DFCI: This view of the northwest corner of the Yawkey Center for Cancer Care at the intersection of Brookline Avenue and Jimmy Fund Way reorients the public face of DFCI to Brookline Avenue, away from the existing ineffectual entrance on Binney Street. It is the main entrance of the building and for the first time provides the Dana-Farber Cancer Institute with a major street presence serving as a signature image with access from both Brookline Avenue and Jimmy Fund Way. Some of the many cantilevers, setbacks, and interior atrium spaces of the building can be seen. The two-story lobby/atrium provides access to the third- level walkway system that links all of DFCI’s buildings and connects with Children’s and Brigham and Women’s Hospitals. A tunnel under the Jimmy Fund Way also connects the YCCC with clinical support facilities in the Dana Building and facilitates service access between the Dana Building, YCCC, Smith Laboratories Building, and the upgraded Smith loading dock. Simon Design Engineering Photo 6 Photography By: Krystal Layton