Checklist

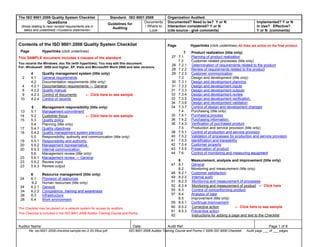

- 1. The ISO 9001:2008 Quality System Checklist Standard: ISO 9001:2008 Organization Audited: Questions (those relating to new/ revised requirements are in italics and underlined) <Guideline statements> Guidelines for Auditing Documents / Where to Look Documented? Need to be? Y or N Interaction considered? Y or N (cite source - give comments) Implemented? Y or N In Use? Effective? Y or N (comments) Auditor Name: Date: Audit Ref. Page 1 of 8 file: iso-9001-2008-checklist-sample-rev-2-20-09us.pdf ISO 9001:2008 Auditor Training Course and Forms© 2009 ISO 9000 Checklist Audit page ___ of ___ pages Contents of the ISO 9001:2008 Quality System Checklist Page Hyperlinks (click underlines) This SAMPLE document includes 4 clauses of the standard. You receive the Windows .doc file (with hyperlinks). You may edit this document. For: Windows® 2000 and higher, XP, Vista and Microsoft® Word 2000 and later versions. 4 Quality management system (title only) 2 4.1 General requirements 4.2 Documentation requirements (title only) 4 4.2.1 Documentation requirements — General 8 4.2.2 Quality manual 9 4.2.3 Control of documents ← Click here to see sample 10 4.2.4 Control of records 5 Management responsibility (title only) 13 5.1 Management commitment 14 5.2 Customer focus ← Click here to see sample 15 5.3 Quality policy 5.4 Planning (title only) 17 5.4.1 Quality objectives 18 5.4.2 Quality management system planning 5.5 Responsibility, authority and communication (title only) 19 5.5.1 Responsibility and authority 20 5.5.2 Management representative 20 5.5.3 Internal communication 5.6 Management review (title only) 23 5.6.1 Management review — General 23 5.6.2 Review input 23 5.6.3 Review output 6 Resource management (title only) 24 6.1 Provision of resources 6.2 Human resources (title only) 24 6.2.1 General 24 6.2.2 Competence, training and awareness 26 6.3 Infrastructure 26 6.4 Work environment The Checklist may be placed on a network system for access by auditors. This Checklist is included in the ISO 9001:2008 Auditor Training Course and Forms. Page Hyperlinks (click underlines) All links are active on the final product. 7 Product realization (title only) 27 7.1 Planning of product realization 7.2 Customer-related processes (title only) 28 7.2.1 Determination of requirements related to the product 28 7.2.2 Review of requirements related to the product 29 7.2.3 Customer communication 7.3 Design and development (title only) 30 7.3.1 Design and development planning 31 7.3.2 Design and development inputs 31 7.3.3 Design and development outputs 33 7.3.4 Design and development review 33 7.3.5 Design and development verification 34 7.3.6 Design and development validation 34 7.3.7 Control of design and development changes 7.4 Purchasing (title only) 35 7.4.1 Purchasing process 36 7.4.2 Purchasing information 36 7.4.3 Verification of purchased product 7.5 Production and service provision (title only) 38 7.5.1 Control of production and service provision 40 7.5.2 Validation of processes for production and service provision 41 7.5.3 Identification and traceability 42 7.5.4 Customer property 43 7.5.5 Preservation of product 44 7.6 Control of monitoring and measuring equipment 8 Measurement, analysis and improvement (title only) 47 8.1 General 8.2 Monitoring and measurement (title only) 48 8.2.1 Customer satisfaction 49 8.2.2 Internal audit 51 8.2.3 Monitoring and measurement of processes 52 8.2.4 Monitoring and measurement of product ← Click here 55 8.3 Control of nonconforming product 57 8.4 Analysis of data 8.5 Improvement (title only) 59 8.5.1 Continual improvement 60 8.5.2 Corrective action ← Click here to see sample 61 8.5.3 Preventive action 62 Instructions for adding a page and text to the Checklist

- 2. The ISO 9001:2008 Quality System Checklist Standard: ISO 9001:2008 Organization Audited: Questions (those relating to new/ revised requirements are in italics and underlined) <Guideline statements> Guidelines for Auditing Documents / Where to Look Documented? Need to be? Y or N Interaction considered? Y or N (cite source - give comments) Implemented? Y or N In Use? Effective? Y or N (comments) Auditor Name: Date: Audit Ref. Page 2 of 8 file: iso-9001-2008-checklist-sample-rev-2-20-09us.pdf ISO 9001:2008 Auditor Training Course and Forms© 2009 ISO 9000 Checklist Audit page ___ of ___ pages 4.2.3 Quality management system — Documentation requirements — Control of documents Clause 4.2.3 4.2.3 Control of documents ____ Is there a documented procedure for document control? Does the procedure define the controls needed to: __ a) approve documents for adequacy before they are issued __ b) review, update and re-approve documents, as necessary, __ c) ensure that the current revision status of documents and document changes are identified __ d) ensure that relevant versions of documents are made available at points of use <The relevant version of a document is the version that should be used for a task. The current revision of the document may not be the right one for the task.> __ e) ensure that documents remain legible and easy to identify __ f) ensure that documents that originate from out- side the organization are identified and the distribution of these documents is controlled (applies to documents necessary for the planning and operation of the quality management system) __ g) prevent the unintentional use of obsolete documents, and to clearly mark them with suitable identification if they are kept for any purpose? Verify that the documented Document Control procedure contains the requirements a-g for controlling: __ Quality Manual __ Documented Procedures __ Work Instructions __ Product documentation (including drawings, specifications, bills of material, parts lists, production plans, control plans, etc.) __ External documents __ Other required QMS documents Document Control procedure Evidence: Document #, Title, Rev / Person's Name, Title, Dept. /or other source ID. The Instructions Sample explains how to enter audit evidence on the Checklist. 4.2.3. ___ Are required QMS documents controlled as defined in the document control procedure? a) and b): Are new and revised documents: ___ reviewed for adequacy, and ___ approved by authorized personnel prior to issue? ___ Review a sampling of new and revised documents for evidence that the requirements for the review and approval of documents are followed as defined in the procedure. All new and revised documents. 4.2.3 Are documents: __ c) identified by their current revision status, __ d) the relevant version for the task and available at locations where they are needed __ e) legible, readily identifiable and retrievable? (continued) ___ Ask a sampling of employees how they know they are using the right document for the task. ___ Test the document distribution system at several locations: Ask for a document used in the department and check if it is the current revision, is retrievable and available. All controlled documents, Master lists, Distribution lists, etc. Return to Contents page.

- 3. The ISO 9001:2008 Quality System Checklist Standard: ISO 9001:2008 Organization Audited: Questions (those relating to new/ revised requirements are in italics and underlined) <Guideline statements> Guidelines for Auditing Documents / Where to Look Documented? Need to be? Y or N Interaction considered? Y or N (cite source - give comments) Implemented? Y or N In Use? Effective? Y or N (comments) Auditor Name: Date: Audit Ref. Page 3 of 8 file: iso-9001-2008-checklist-sample-rev-2-20-09us.pdf ISO 9001:2008 Auditor Training Course and Forms© 2009 ISO 9000 Checklist Audit page ___ of ___ pages 4.2.3 Quality management system — Documentation requirements — Control of documents Clause 4.2.3 (continued) 4.2.3 Control of documents (continued) 4.2.3 f) Are external documents ____ identified, and their ____ distribution controlled? (applies only to external documents that the organization determines are necessary for the planning and operation of the quality mgt. system) (External documents are those that originate from outside the organization.) ___ Review external documents (identified in clause 4.2.1.d) for proper identification and control. __ Do a sampling to determine that documents of external origin are current at multiple distribution points. All standards, customer documents,& statutory/ regulatory documents Evidence: Document #, Title, Rev / Person's Name, Title, Dept. /or other source ID. 4.2.3 g) Are obsolete documents: ____ identified and removed from places of use to prevent their use ____ identified to prevent their use, if they are kept for any purpose? ___ Verify g) ___ Review retained obsolete documents for proper identification. Identify any obsolete documents not removed from place of use. All obsolete documents Return to Contents page.

- 4. The ISO 9001:2008 Quality System Checklist Standard: ISO 9001:2008 Organization Audited: Questions (those relating to new/ revised requirements are in italics and underlined) <Guideline statements> Guidelines for Auditing Documents / Where to Look Documented? Need to be? Y or N Interaction considered? Y or N (cite source - give comments) Implemented? Y or N In Use? Effective? Y or N (comments) Auditor Name: Date: Audit Ref. Page 4 of 8 file: iso-9001-2008-checklist-sample-rev-2-20-09us.pdf ISO 9001:2008 Auditor Training Course and Forms© 2009 ISO 9000 Checklist Audit page ___ of ___ pages 5.2 Management responsibility — Customer focus Clause 5.2 5.2 Customer focus __ Does top management ensure that customer requirements are determined and met with the aim of enhancing customer satisfaction? (see 7.2.1 and 8.2.1) <7.2.1 and 8.2.1 are listed below for reference: > 7.2.1 Determination of requirements related to the product. The organization shall determine: a) customer-specified requirements, including requirements for delivery and post-delivery activities Person(s) responsible for this activity: ___________________________________ b) requirements not stated by the customer but necessary for stated use or known and intended use Person(s) responsible for activity: __________________________________ c) statutory and regulatory requirements related to the product Person(s) responsible for activity: ___________________________________ d) any additional requirements determined by the organization? Person(s) responsible for activity ___________________________________ 8.2.1 Customer satisfaction Does the organization monitor information relating to customer perception as to whether the organization has met customer requirements? Person(s) responsible for activity ___________________________________ ___ What methods has management determined for obtaining information related to customer perception as to whether product requirements have been met and how this information will be used? Person(s) responsible for activity ______________ ___ Are those who are assigned responsibilities (listed in 7.2.1 and 8.2.1) provided with adequate resources to accomplish the assigned tasks? (Resources means people, time and money.) ___ Interview those responsible for managing customer-related process- es to access the organiza- tion's strategy for determin- ing customer requirements and that they are met with the aim of enhancing customer satisfaction. Are strategies used getting the needed information? Examples of customer- related processes are: Sales_________________ Marketing _____________ Contract Admin. ________ Customer Service_______ Product Repair ________ ___ Is data concerning customer needs and expectations collected and analyzed? Collect customer satisfaction analysis reports. By interview, or other means, determine: __ if action was taken to resolve problems __ improvements or changes have been made and are now part of the product or service __ improvements or changes are planned for incorporation into the product or service Review any evidence of customer dissatisfaction to determine if customer requirements are unknown or not being met. ← Is this done? __Do Mgt. Review minutes discuss how to improve products and/or services? Product information brochures, customer information, contracts, quality plans Note to Lead Auditor: This clause can be audited with 7.2.1 & 8.2.1 They use same information. Customer complaints and/or satisfaction survey results. Internal customer complaints. Results of management reviews. Evidence: Document #, Title, Rev / Person's Name, Title, Dept. /or other source ID. Return to Contents page.

- 5. The ISO 9001:2008 Quality System Checklist Standard: ISO 9001:2008 Organization Audited: Questions (those relating to new/ revised requirements are in italics and underlined) <Guideline statements> Guidelines for Auditing Documents / Where to Look Documented? Need to be? Y or N Interaction considered? Y or N (cite source - give comments) Implemented? Y or N In Use? Effective? Y or N (comments) Auditor Name: Date: Audit Ref. Page 5 of 8 file: iso-9001-2008-checklist-sample-rev-2-20-09us.pdf ISO 9001:2008 Auditor Training Course and Forms© 2009 ISO 9000 Checklist Audit page ___ of ___ pages 8.2 Measurement, analysis and improvement — Monitoring and measurement — 8.2.4 Monitoring and measurement of product Clause 8.2.4 8.2.4 Monitoring and measurement of product product characteristics — the distinguishing features of the product or service ___ Are product characteristics monitored and measured at appropriate stages of product realization to verify that requirements for the product are met in accordance with the quality plan (traveler/work order)? (see clause 7.1) ____ Are records of product conformity with acceptance criteria maintained, and customer – the person or organization that receives a product. internal customer – the next process that will perform a work or service activity ____ do records indicate the person(s) who authorized the release of product for delivery to the customer? (see clause 4.2.4) <Guideline: When auditing any process, you check to see that defined monitoring and measurement activities are taking place, and that records with authorized release signatures are present.> Note: Monitoring and measurement activities required to determine product or service conformance to require- ments are identified during planning activities. (a requirement of 7.1 c.) Review several quality plans for work in progress and their associated test / inspection instructions. __ Does the quality plan indicate where monitoring and measuring should take place? __ Is acceptance criteria clearly defined? __ Are the required inspection and tests performed and the results recorded? ___ Do records indicate who released the product? __ Is the product or service monitored and measured at the stages indicated in the quality plan? Quality plan for product, Traveler Inspection and Test procedures and instructions Quality control plans and related records Get a list of who is qualified to perform audit monitoring, inspection and measuring activities in all process areas. Evidence: Document #, Title, Rev / Person's Name, Title, Dept. /or other source ID. Verify as applies to in-process inspection → (continued) Observe in-process inspection operations. ____ Is uninspected or nonconforming product prevented from being used in the next processing stage? ___ Is the inspection status of the product maintained throughout all stages of production? ___ Are inspection personnel trained? ___ Are inspection procedures available and followed? Quality plans, checklists, or traveler In-process inspection process, procedures and/or relevant work instructions Qualified inspector list Return to Contents page.

- 6. The ISO 9001:2008 Quality System Checklist Standard: ISO 9001:2008 Organization Audited: Questions (those relating to new/ revised requirements are in italics and underlined) <Guideline statements> Guidelines for Auditing Documents / Where to Look Documented? Need to be? Y or N Interaction considered? Y or N (cite source - give comments) Implemented? Y or N In Use? Effective? Y or N (comments) Auditor Name: Date: Audit Ref. Page 6 of 8 file: iso-9001-2008-checklist-sample-rev-2-20-09us.pdf ISO 9001:2008 Auditor Training Course and Forms© 2009 ISO 9000 Checklist Audit page ___ of ___ pages 8.2.4 Measurement, analysis and improvement — Monitoring and measurement of product Clause 8.2.4 (continued) 8.2.4 Monitoring and measurement of product (continued) All questions on this page apply to final inspection area → ___ Is the release of product and delivery of service to the customer held until the planned arrangements (including inspections, tests, and measurements) have been satisfactorily completed, unless otherwise approved by an appropriate authority and, where applies, by the customer? objective evidence — information based on facts acquired through measurement, test, observation, or some other means that can be proven to be true. RE: Final inspection Observe final inspection ___ Are instructions for final inspection available? ___ Are all activities in the final inspection instructions completed before product is released? ___ Is there is objective evidence that all the acceptance criteria for the product have been met before release? ___ Do records show the person(s) who authorized the release of product or delivery of service to the customer? ___ Verify that inspectors in the final inspection area are qualified. Review a sample of completed order records. ____ Do the completed orders/records show that all final inspection activities stated in the quality plan / procedures were completed and that the requirements for the product were met? ___ Do the records show the person(s) who authorized release of the product? ___ If records show a situation where all specified activities were not performed before release of product or service delivery, did a relevant authority (or, as appropriate, the customer) approve the product release? Quality plans, final audit checklists, or traveler Final inspection process, procedures and/or relevant work instructions Employee records or list of qualified inspectors Records of completed work. Evidence: Document #, Title, Rev / Person's Name, Title, Dept. /or other source ID. Return to Contents page.

- 7. The ISO 9001:2008 Quality System Checklist Standard: ISO 9001:2008 Organization Audited: Questions (those relating to new/ revised requirements are in italics and underlined) <Guideline statements> Guidelines for Auditing Documents / Where to Look Documented? Need to be? Y or N Interaction considered? Y or N (cite source - give comments) Implemented? Y or N In Use? Effective? Y or N (comments) Auditor Name: Date: Audit Ref. Page 7 of 8 file: iso-9001-2008-checklist-sample-rev-2-20-09us.pdf ISO 9001:2008 Auditor Training Course and Forms© 2009 ISO 9000 Checklist Audit page ___ of ___ pages 8.2.4 Measurement, analysis and improvement — Monitoring and measurement of product Clause 8.2.4 (continued) 8.2.4 Monitoring and measurement of product (continued) Verify as applies to service organizations → Verify as applies to product servicing and repair inspection → ___ Is the release of product and delivery of service to the customer held until the planned arrangements (including inspections, tests, and measurements) have been satisfactorily completed, unless otherwise approved by an appropriate authority and, where applies, by the customer? verification activities — checks to make sure all requirements for the product were met. objective evidence — information based on facts acquired through measurement, test, observation, or some other means that can be proven to be true. For services and repair: Observe services/repair: ___ Are all verification activities specified in the quality plan / procedures completed before the service or product is released? ___ Is there is objective evidence that all product (or service) acceptance criteria have been met? ___ Do records show the person(s) who authorized the release of the product / or delivery of the service to the customer? ___ Verify that inspectors involved in service / repair are qualified. Review a sample of service or repair completed orders and: ____ Verify that all activities specified in the quality plan / procedures were completed and requirements for service/repair were met. ___ Do final inspection records indicate the person(s) who authorized release of service/repair? ___ If records show a situation where all specified activities were not performed before release of product or service delivery, did a relevant authority (or as appropriate, the customer) approve the product/ service release? Quality plans, final audit checklists, or traveler Employee records or list of qualified inspectors Service repair inspection and final inspection process, procedures and/or relevant work instructions Records of completed work. Return to Contents page.

- 8. The ISO 9001:2008 Quality System Checklist Standard: ISO 9001:2008 Organization Audited: Questions (those relating to new/ revised requirements are in italics and underlined) <Guideline statements> Guidelines for Auditing Documents / Where to Look Documented? Need to be? Y or N Interaction considered? Y or N (cite source - give comments) Implemented? Y or N In Use? Effective? Y or N (comments) Auditor Name: Date: Audit Ref. Page 8 of 8 file: iso-9001-2008-checklist-sample-rev-2-20-09us.pdf ISO 9001:2008 Auditor Training Course and Forms© 2009 ISO 9000 Checklist Audit page ___ of ___ pages 8.5.2 Measurement, analysis and improvement — Improvement — Corrective action Clause 8.5.2 8.5.2 Corrective action ___ Is there a documented corrective action procedure that defines the requirements for: ___ a) reviewing nonconformities (including customer complaints) ___ b) determining the root cause(s) of nonconformities ___ c) evaluating the need for action to prevent recurrence of the nonconformities ___ d) determining the action needed and implementing the action ___ e) recording the results of action taken (see clause 4.2.4) ___ f) reviewing the corrective actions taken to verify their effectiveness ____ Does the procedure require that the action taken on nonconformities must be appropriate to the effects of the nonconformities found? ____ Does the organization take corrective action to eliminate the causes of nonconformities in order to prevent their recurrence? <The following is a guidance note and not included in the text of the standard. Note: When the nonconformity is minor and isolated, the risks or cost associated with taking corrective action may not be justified.> Verify that the documented procedure clearly defines ___ requirements for (a through f). ___ a) Is there evidence that the types of nonconformities in the far right column are reviewed and evaluated to determine if action is needed to prevent the specific problems found from occurring again? __ Do plans for corrective action include considera- ation of: __ action to remove the nonconformity and prevent recurrence in the short term __ action to determine if other product (or similar product) is affected that is in production, in stock or being designed __ action to determine if the nonconformity applies to product or service delivered in the past, and is action needed to minimize the impact of the defect on these customers __ action to prevent the problem in the future. ___ e) Are there records of the results of the corrective action taken? ___ f) Are corrective actions taken reviewed to verify effectiveness? Documented Corrective Action procedure Customer complaints, Internal audit reports, data analysis, minutes of management reviews Corrective action records Management review action records/ minutes of management reviews Completed Corrective Action Request Forms CPAR Log Evidence: Document #, Title, Rev / Person's Name, Title, Dept. /or other source ID. a) Does the documented procedure state who is responsible for reviewing nonconformities that originate from the sources listed here? The procedure may make reference to other procedures or documents with this information. (as applies) __ incoming materials __ incoming subcontracted product __ in-process/final inspection or test __ nonconforming material review __ sales or service concessions __ audit nonconformity __ customer complaints __ product returns __ warranty repairs __ process related nonconformities __ system related nonconformities Also see the instructions sample of how to enter audit evidence on the Checklist. Return to Contents page. Click Browser back button (in top left corner) to Return