Slam Freezing For Electron Microscopy

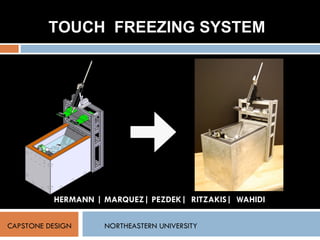

- 1. HERMANN | MARQUEZ| PEZDEK| RITZAKIS| WAHIDI CAPSTONE DESIGN NORTHEASTERN UNIVERSITY TOUCH FREEZING SYSTEM

- 8. Touch Freezing System Linear Motor Basin Mirror Module with Copper Mirrors in LN 2 Ribbon Laser Motor and Sensor Stand Sample Stack

- 10. Mirror Module: Material Selection Cooling Rates of Various Liquid Cryogen Echlin, Patrick. Low-Temp Microscopy and Analysis . New York: Plenum Press, 1992. Thermal Conductivity and Inertia of Various Materials Material Temperature [K] Specific Heat [J/(g∙K)] Thermal Conductivity [ J/(m∙s∙K)] Thermal Inertia [ Jm 2 /√K ] Aluminum 77 3.7 x 10 -1 410 1.9 20 8.4 x 10 -3 - 1.6 4 2.6 x 10 -4 15,000 0.3 Copper 77 2.1 x 10 -1 570 3.2 20 8.0 x 10 -3 10,500 2.6 4 9.1 x 10 -5 11,300 0.3 Gold 77 9.6 x 10 -2 252 2.6 20 1.6 x 10 -2 1,500 2.4 4 1.6 x 10 -4 1,710 2.3 Sapphire 77 6.3 x 10 -2 960 1.6 20 2.0 x 10 -2 15,700 0.6 4 8.0 x 10 -6 410 0.1 Silver 77 1.5 x 10 -1 471 2.9 20 1.3 x 10 -2 5,100 2.7 4 1.3 x 10 -4 14,700 0.4 Cryogen Temperature Mean Cooling Rate ( ° K) (10 3 ° K/s) Ethane 90 13-15 Liquid Helium 4.3 0.1 Liquid Nitrogen 77 0.5 Propane 88 10-12

- 11. Mirror Module: Design Iterations Revision 1 Manufacturability Locking & Thermal Mass Reduction FINAL DESIGN

- 12. Mirror Module: Components Base Unit Female Thermocouple Connector (4) Male Thermocouple Connector (4) Copper Mirror Ceramic Standoff Handle Shaft Gearing Teeth (4) Thermocouple Cover

- 15. Basin: Inner Basin Working Zone T-Type Thermocouple Mirror Module Sample Storage Inner Basin Handle Stand Working Zone Thermocouple Placement Stationary Support Exposed Copper Mirror Screws

- 16. Basin: Heat Transfer Analysis Energy Balance: Liters of LN 2 Required = 12.8654L Heat transfer rate per unit area through basin: q”= 181 [W/m 2 ] with EPS @ 1.5” AIR EXT BOX INNER BASIN INSULATION LIQUID NITROGEN

- 17. Basin: Insulation LN 2 FOAM FOAM Ceramic Standoffs Sample Storage Exposed Copper Mirror Handle Stand

- 18. Basin: Exterior Box Exterior Box LN 2 FOAM Sample Storage Exposed Copper Mirror Handle Stand

- 21. Linear Motor: Selection Slider Stator Connector LinMot Nippon Linear Motor

- 22. Linear Motor: Motion Profiles 5 m/s 4 m/s

- 23. Linear Motor: Motion Profiles 5 m/s 4 m/s

- 24. Linear Motor: Controlling Motor Ribbon Laser Sample Stack Attached at End of Slider Mirror Module LN 2 Ribbon Laser Sensor Copper Mirror LN 2 Sample Stack X s X r X m Linear Motor Sample

- 25. Touch Freezing System Process

- 26. System Cost Analysis COST ANALYSIS ITEM MANUFACTURER MODEL # SIZE QUANTITY COST ($) Linear Motor (stator/slider/power/controller/etc.) Linmot PS01-23x160F-HP-R PL01-12x480/440-HP E1100-GP-HC S01-72/300 * 1 2688.65 Ribbon Laser Keyence LV-H300 * 1 299 Laser Amplifier Keyence LV-51MP * 1 299 Mounting Brackets for LV-H300 Keyence LV-B302 * 1 13 Rod End Bearing, Male/Female Cooper Bearing Set * 1 55 Thermocouple T-Type Connector (male) Omega NHX-T-M * 4 36 Thermocouple T-Type Connector (female) Omega NHX-T-F * 1 7 Thermocouple T-Type for Working Zone Omega 5TC-TT-T24-36 * 1 33 Epoxy (Cryo-Bond) Valpac 877 * * * Polystyrene Insulation Foam ICA * * 35 Aluminum Alloy 6061 McMaster-Carr 1610T44 4-1/2"D X 6" 1 65.11 Aluminum Plates Admiral Metals * * * 250 Screws McMaster-Carr 6-32 Screws * 300 38 Brackets McMaster-Carr L-Brackets * 20 38 Machining for Mirror Module Nova Machine * * 1 1100 TOTAL COST 4956.76

- 29. Design Team Nicholas Hermann Gabriel Marquez Afjal Wahidi Jamison Pezdek Nector Ritzakis

- 30. FEA Analysis

- 31. Sample Stack

- 32. Material Selection: Aluminum T-6061 http://cryogenics.nist.gov/MPropsMAY/6061%20Aluminum/6061_T6Aluminum_rev.htm

- 33. Motor Selection Linear Motor Selection Brushless Linear Motor Selection Attribute Weight Factor Brushed Brushless Step Low Maintenance 1.5 1.5 7.5 4.5 High Velocity 1.9 5.7 9.5 5.7 High Acceleration 1.9 5.7 9.5 5.7 High Travel Length 1.1 5.5 1.1 5.5 Precise Position 1.9 9.5 9.5 5.7 Low Cost 1.7 8.5 5.1 5.1 TOTAL 36.4 42.2 32.2 Attribute Weight Factor Iron Core Ironless Slotless Direct Drive No Cogging 1.9 1.9 9.5 5.7 9.5 No Attractive Force 1.5 1.5 7.5 4.5 7.5 Force/Size 1.4 7 1.4 4.2 1.4 Thermal Characteristics 1.1 5.5 1.1 3.3 3.3 Least Forcer Weight 1.1 1.1 3.3 3.3 5.5 Forcer Strength 1.3 6.5 1.3 3.9 3.9 TOTAL 23.5 24.1 24.9 31.1