Gdt tutorial

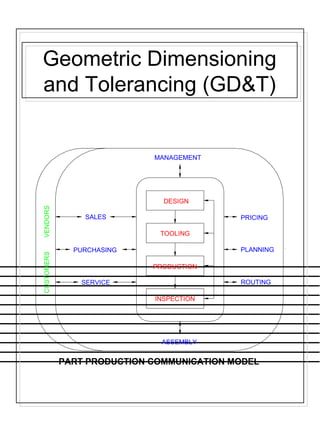

- 1. Geometric Dimensioning and Tolerancing (GD&T) MANAGEMENT DESIGN VENDORS SALES PRICING TOOLING PURCHASING PLANNING CUSTOMERS PRODUCTION SERVICE ROUTING INSPECTION ASSEMBLY PART PRODUCTION COMMUNICATION MODEL

- 2. Three Categories of Dimensioning Dimensioning can be divided into three categories: •general dimensioning, •geometric dimensioning, and •surface texture. The following provides information necessary to begin to understand geometric dimensioning and tolerancing (GD&T)

- 4. Limit Tolerancing Applied To An Angle Block

- 5. Geometric Tolerancing Applied To An Angle Block

- 6. Geometric Dimensioning & Tolerancing (GD&T) s GD&T is a means of dimensioning & tolerancing a drawing which considers the function of the part and how this part functions with related parts. – This allows a drawing to contain a more defined feature more accurately, without increasing tolerances.

- 7. GD&T cont’d s GD&T has increased in practice in last 15 years because of ISO 9000. – ISO 9000 requires not only that something be required, but how it is to be controlled. For example, how round does a round feature have to be? s GD&T is a system that uses standard symbols to indicate tolerances that are based on the feature’s geometry. – Sometimes called feature based dimensioning & tolerancing or true position dimensioning & tolerancing s GD&T practices are specified in ANSI Y14.5M-1994.

- 8. For Example s Given Table Height Assume all 4 legs will be cut to length at the same time. s However, all surfaces have a degree of waviness, or smoothness. For example, the surface of a 2 x 4 is much wavier (rough) than the surface of a piece of glass. – As the table height is dimensioned, the following table would pass inspection. or s If top must be flatter, you could tighten the tolerance to ± 1/32. – However, now the height is restricted to 26.97 to 27.03 meaning good tables would be rejected.

- 9. Example cont’d. s You can have both, by using GD&T. – The table height may any height between 26 and 28 inches. – The table top must be flat within 1/16. (±1/32) .06 .06 .06 28 27 26

- 10. WHY IS GD&T IMPORTANT s Saves money – For example, if large number of parts are being made – GD&T can reduce or eliminate inspection of some features. – Provides “bonus” tolerance s Ensures design, dimension, and tolerance requirements as they relate to the actual function s Ensures interchangeability of mating parts at the assembly s Provides uniformity s It is a universal understanding of the symbols instead of words

- 11. WHEN TO USE GD&T s When part features are critical to a function or interchangeability s When functional gaging is desirable s When datum references are desirable to insure consistency between design s When standard interpretation or tolerance is not already implied s When it allows a better choice of machining processes to be made for production of a part

- 12. TERMINOLOGY REVIEW s Maximum Material Condition (MMC): The condition where a size feature contains the maximum amount of material within the stated limits of size. I.e., largest shaft and smallest hole. s Least Material Condition (LMC): The condition where a size feature contains the least amount of material within the stated limits of size. I.e., smallest shaft and largest hole. s Tolerance: Difference between MMC and LMC limits of a single dimension. s Allowance: Difference between the MMC of two mating parts. (Minimum clearance and maximum interference) s Basic Dimension: Nominal dimension from which tolerances are derived.

- 13. LIMITS OF SIZE SIZE DIMENSION WHAT DOES THIS MEAN? 2.007 2.003

- 14. LIMITS OF SIZE A variation in form is allowed between the least material condition (LMC) and the maximum material condition (MMC). SIZE DIMENSION ENVELOPE PRINCIPLE MMC (2.007) LMC (2.003) ENVELOPE OF SIZE Envelop Principle defines the size and form relationships between mating parts.

- 15. LIMITS OF SIZE ENVELOPE PRINCIPLE LMC CLEARANCE MMC ALLOWANCE

- 16. LIMITS OF SIZE The actual size of the feature at any cross section must be within the size boundary. ØMMC ØLMC

- 17. LIMITS OF SIZE No portion of the feature may be outside a perfect form barrier at maximum material condition (MMC).

- 18. Other Factors I.e., Parallel Line Tolerance Zones GEOMETRIC DIMENSIONING TOLERANCE ZONES PARALLEL LINES PARALLEL LINES PARALLEL LINES PARALLEL PLANES PARALLEL PLANES PARALLEL PLANES PARALLEL PLANES PARALLEL PLANES CYLINDER ZONE

- 19. GEOMETRIC CHARACTERISTIC CONTROLS 14 characteristics that may be controlled TYPE OF TYPE OF CHARACTERISTIC SYMBOL FEATURE TOLERANCE FLATNESS INDIVIDUAL STRAIGHTNESS (No Datum FORM Reference) CIRCULARITY CYLINDRICITY INDIVIDUAL LINE PROFILE or RELATED PROFILE FEATURES SURFACE PROFILE PERPENDICULARITY ORIENTATION ANGULARITY PARALLELISM RELATED FEATURES CIRCULAR RUNOUT (Datum RUNOUT Reference TOTAL RUNOUT Required) CONCENTRICITY LOCATION POSITION SYMMETRY

- 20. Characteristics & Symbols cont’d. – Maximum Material Condition MMC – Regardless of Feature Size RFS – Least Material Condition LMC – Projected Tolerance Zone – Diametrical (Cylindrical) Tolerance Zone or Feature – Basic, or Exact, Dimension – Datum Feature Symbol – Feature Control Frame

- 21. Feature Control FRAME FEATURE CONTROL Frame GEOMETRIC SYMBOL TOLERANCE INFORMATION DATUM REFERENCES COMPARTMENT VARIABLES THE RELATIVE TO OF THE FEATURE MUST BE WITHIN CONNECTING WORDS

- 22. Feature Control Frame s Uses feature control frames to indicate tolerance s Reads as: The position of the feature must be within a .003 diametrical tolerance zone at maximum material condition relative to datums A, B, and C.

- 23. Feature Control Frame s Uses feature control frames to indicate tolerance s Reads as: The position of the feature must be within a .003 diametrical tolerance zone at maximum material condition relative to datums A at maximum material condition and B.

- 24. Reading Feature Control Frames s The of the feature must be within a tolerance zone. s The of the feature must be within a tolerance zone at relative to Datum . s The of the feature must be within a tolerance zone relative to Datum . s The of the feature must be within a zone at relative to Datum . s The of the feature must be within a tolerance zone relative to datums .

- 25. Placement of Feature Control Frames s May be attached to a side, end or corner of the symbol box to an extension line. s Applied to surface. s Applied to axis

- 26. Placement of Feature Control Frames Cont’d. s May be below or closely adjacent to the dimension or note pertaining to that feature. Ø .500±.005

- 27. Basic Dimension s A theoretically exact size, profile, orientation, or location of a feature or datum target, therefore, a basic dimension is untoleranced. s Most often used with position, angularity, and profile) s Basic dimensions have a rectangle surrounding it. 1.000

- 28. Basic Dimension cont’d.

- 29. Form Features s Individual Features s No Datum Reference Flatness Straightness Circularity Cylindricity

- 30. Form Features Examples Flatness as stated on drawing: The flatness of the feature must be within .06 tolerance zone. Straightness applied to a flat surface: The straightness of the feature must be within .003 tolerance zone. .003 0.500 ±.005 .003 0.500 ±.005

- 31. Form Features Examples Straightness applied to the surface of a diameter: The straightness of the feature must be within .003 tolerance zone. .003 ∅ 0.500 0.505 Straightness of an Axis at MMC: The derived median line straightness of the feature must be within a diametric zone of .030 at MMC. ∅ 0.500 0.505 ∅ .030 M 1.010 0.990

- 32. Dial Indicator DIAL INDICATOR BEZEL CASE 2 2 4 4 6 6 8 8 10 10 12 CLAMP PROBE

- 34. Activity 13 s Work on worksheets GD&T 1, GD&T 2 #1 only, and GD&T 3 – (for GD&T 3 completely dimension. ¼” grid.)

- 35. Features that Require Datum Reference s Orientation – Perpendicularity – Angularity – Parallelism s Runout – Circular Runout – Total Runout s Location – Position – Concentricity – Symmetry

- 36. Datum s Datums are features (points, axis, and planes) on the object that are used as reference surfaces from which other measurements are made. Used in designing, tooling, manufacturing, inspecting, and assembling components and sub- assemblies. – As you know, not every GD&T feature requires a datum, i.e., Flat 1.000

- 37. Datums cont’d. s Features are identified with respect to a datum. s Always start with the letter A s Do not use letters I, O, or Q s May use double letters AA, BB, etc. s This information is located in the feature control frame. s Datums on a drawing of a part are represented using the symbol shown below.

- 38. Datum Reference Symbols s The datum feature symbol identifies a surface or feature of size as a datum. A A A ANSI ASME ISO 1982 1994

- 39. Placement of Datums s Datums are generally placed on a feature, a centerline, or a plane depending on how dimensions need to be referenced. A OR A A ANSI 1982 ASME 1994 Line up with arrow only when the feature is a feature of size and is being defined as the datum

- 40. Placement of Datums s Feature sizes, such as holes A Ø .500±.005 s Sometimes a feature has a GD&T and is also a datum A Ø .500±.005 Ø .500±.005

- 41. TWELVE DEGREES OF FREEDOM UP LEFT BACK 6 LINEAR AND 6 ROTATIONAL DEGREES OF FREEDOM FRONT RIGHT DOWN UNRESTRICTED FREE MOVEMENT IN SPACE

- 42. Example Datums s Datums must be perpendicular to each other – Primary – Secondary – Tertiary Datum

- 43. Primary Datum s A primary datum is selected to provide functional relationships, accessibility, and repeatability. – Functional Relationships » A standardization of size is desired in the manufacturing of a part. » Consideration of how parts are orientated to each other is very important. – For example, legos are made in a standard size in order to lock into place. A primary datum is chosen to reference the location of the mating features. – Accessibility » Does anything, such as, shafts, get in the way?

- 44. Primary Datum cont’d. – Repeatability For example, castings, sheet metal, etc. » The primary datum chosen must insure precise measurements. The surface established must produce consistent » Measurements when producing many identical parts to meet requirements specified.

- 45. Primary Datum Restricts 6 degrees of freedom FIRST DATUM ESTABLISHED BY THREE POINTS (MIN) CONTACT WITH SIMULATED DATUM A

- 46. Secondary & Tertiary Datums s All dimension may not be capable to reference from the primary datum to ensure functional relationships, accessibility, and repeatability. – Secondary Datum » Secondary datums are produced perpendicular to the primary datum so measurements can be referenced from them. – Tertiary Datum » This datum is always perpendicular to both the primary and secondary datums ensuring a fixed position from three related parts.

- 47. Secondary Datum Restricts 10 degrees of freedom. SECOND DATUM PLANE ESTABLISHED BY TWO POINTS (MIN) CONTACT WITH SIMULATED DATUM B

- 48. Tertiary Datum Restricts 12 degrees of freedom. THIRD DATUM PLANE ESTABLISHED BY ONE POINT (MIN) 90° CONTACT WITH SIMULATED DATUM C MEASURING DIRECTIONS FOR RELATED DIMENSIONS

- 49. Coordinate Measuring Machine COORDINATE MEASURING MACHINE BRIDGE DESIGN PROBE GRANITE Z SURFACE PLATE DATUM REFERENCE FRAME

- 50. Size Datum (CIRCULAR) THIS ON THE DRAWING A MEANS THIS SIMULATED DATUM- SMALLEST PART CIRCUMSCRIBED CYLINDER DATUM AXIS

- 51. Size Datum (CIRCULAR) THIS ON THE DRAWING A MEANS THIS SIMULATED DATUM- LARGEST PART INSCRIBED DATUM AXIS A CYLINDER

- 52. Orientation Tolerances – Perpendicularity – Angularity – Parallelism s Controls the orientation of individual features s Datums are required s Shape of tolerance zone: 2 parallel lines, 2 parallel planes, and cylindrical

- 53. PERPENDICULARITY: s is the condition of a surface, center plane, or axis at a right angle (90°) to a datum plane or axis. Ex: The perpendicularity of this surface must be within a .005 tolerance zone relative to datum A. The tolerance zone is the space between the 2 parallel lines. They are perpendicular to the datum plane and spaced .005 apart.

- 54. Practice Problem s Plane 1 must be perpendicular within .005 tolerance zone to plane 2. BOTTOM SURFACE

- 55. Practice Problem s Plane 1 must be perpendicular within .005 tolerance zone to plane 2 BOTTOM PLANE

- 56. Practice Problem 2.00±.01 .02 Tolerance Without GD & T this would be acceptable 2.00±.01 .005 Tolerance Zone .02 Tolerance With GD & T the overall height may end anywhere between the two blue planes. But the bottom plane is restricted to the red tolerance zone.

- 57. PERPENDICULARITY Cont’d. s Location of hole (axis) This means ‘the hole (axis) must be perpendicular within a diametrical tolerance zone of .010 relative to datum A’

- 58. ANGULARITY: s is the condition of a surface, axis, or median plane which is at a specific angle (other than 90°) from a datum plane or axis. The surface is at a 45º angle with a . 005 tolerance zone relative to datum A. s Can be applied to an axis at MMC. s Typically must have a basic dimension.

- 59. PARALLELISM: s The condition of a surface or center plane equidistant at all points from a datum plane, or an axis. s The distance between the parallel lines, or surfaces, is specified by the geometric tolerance. ±0.01

- 60. Activity 13 Cont’d. s Complete worksheets GD&T-2, GD&T-4, and GD&T-5 – Completely dimension. – ¼” grid

- 61. Material Conditions s Maximum Material Condition (MMC) s Least Material Condition (LMC) s Regardless of Feature Size(RFS)

- 62. Maximum Material Condition s MMC s This is when part will weigh the most. – MMC for a shaft is the largest allowable size. » MMC of Ø0.240±.005? – MMC for a hole is the smallest allowable size. » MMC of Ø0.250±.005? s Permits greater possible tolerance as the part feature sizes vary from their calculated MMC s Ensures interchangeability s Used – With interrelated features with respect to location – Size, such as, hole, slot, pin, etc.

- 63. Least Material Condition s LMC s This is when part will weigh the least. – LMC for a shaft is the smallest allowable size. » LMC of Ø0.240±.005? – LMC for a hole is the largest allowable size. » LMC of Ø0.250±.005?

- 64. Regardless of Feature Size s RFS s Requires that the condition of the material NOT be considered. s This is used when the size feature does not affect the specified tolerance. s Valid only when applied to features of size, such as holes, slots, pins, etc., with an axis or center plane.

- 65. Location Tolerances – Position – Concentricity – Symmetry

- 66. Position Tolerance s A position tolerance is the total permissible variation in the location of a feature about its exact true position. s For cylindrical features, the position tolerance zone is typically a cylinder within which the axis of the feature must lie. s For other features, the center plane of the feature must fit in the space between two parallel planes. s The exact position of the feature is located with basic dimensions. s The position tolerance is typically associated with the size tolerance of the feature. s Datums are required.

- 67. Coordinate System Position s Consider the following hole dimensioned with coordinate dimensions: s The tolerance zone for the location of the hole is as follows: 2.000 .750 s Several Problems: – Two points, equidistant from true position may not be accepted. – Total tolerance diagonally is .014, which may be more than was intended.

- 68. Coordinate System Position s Consider the following hole dimensioned with coordinate dimensions: s The tolerance zone for the location (axis) of the hole is as follows: Center can be anywhere along the diagonal line. 2.000 .750 s Several Problems: – Two points, equidistant from true position may not be accepted. – Total tolerance diagonally is .014, which may be more than was intended. (1.4 Xs >, 1.4*.010=.014)

- 69. Position Tolerancing s Consider the same hole, but add GD&T: s Now, overall tolerance zone is: MMC = .500 - .003 = .497 s The actual center of the hole (axis) must lie in the round tolerance zone. The same tolerance is applied, regardless of the direction.

- 70. Bonus Tolerance s Here is the beauty of the system! The specified tolerance was: This means that the tolerance is .010 if the hole size is the MMC size, or .497. If the hole is bigger, we get a bonus tolerance equal to the difference between the MMC size and the actual size.

- 71. Bonus Tolerance Example This means that the tolerance is . 010 if the hole size is the MMC size, or .497. If the .503 hole is bigger, we get a bonus tolerance equal to the difference between the MMC size and the actual size. Actual Hole Size Bonus Tol. Φ of Tol. Zone Ø .497 (MMC) 0 .010 Ø .499 (.499 - .497 = .002) .002 (.010 + .002 = .012) .012 Ø .500 (.500 - .497 = .003) .003 (.010 + .003 = .013) .013 Ø .502 .005 .015 Ø .503 (LMC) .006 .016 Ø .504 ? ? s This system makes sense… the larger the hole is, the more it can deviate from true position and still fit in the mating condition!

- 72. .497 = BONUS 0 Hole TOL ZONE .010 Shaft .499 - .497 = BONUS .002 BONUS + TOL. ZONE = .012

- 73. .501 - .497 = BONUS .004 BONUS + TOL. ZONE = .014 .503 - .497 = BONUS .006 BONUS + TOL. ZONE = .016

- 74. s What if the tolerance had been specified as: Since there is NO material modifier, the tolerance is RFS, which stands for regardless of feature size. This means that the position tolerance is .010 at all times. There is no bonus tolerance associated with this specification. s VIRTUAL CONDITION: The worst case boundary generated by the collective effects of a size feature’s specified MMC or LMC material condition and the specified geometric tolerance. GT = GEOMETRIC TOLERANCE

- 75. PERPENDICULARITY Cont’d. Means “the hole (AXIS) must be perpendicular within a diametrical tolerance zone of .010 at MMC relative to datum A.” Actual Hole Bonus Ø of Tol. Size Tol. Zone 1.997 (MMC) 1.998 1.999 2.000 2.001 Vc = 2.002 2.003

- 76. Activity 13 Cont’d. s Worksheet GD&T 6

Notas del editor

- Pat McQuistion

- Quotes from Geo Metric III Foster

- Quotes from Geo Metric III Foster

- Quotes from Geo Metric III Foster Pat McQuistion

- Pat McQuistion

- Pat McQuistion

- Pat McQuistion

- Pat McQuistion

- Why symbols ? The symbol has uniform meaning. A note can be stated inconsistently, with a possibility of misunderstanding. Symbols are compact, quickly drawn, and can be placed on the drawing where the control applies Symbols can be made by computer or with a template & retain legibility when reproduced. Symbols provide international language. Notes may need to be translated if used in another country.

- Why symbols ? The symbol has uniform meaning. A note can be stated inconsistently, with a possibility of misunderstanding. Symbols are compact, quickly drawn, and can be placed on the drawing where the control applies Symbols can be made by computer or with a template & retain legibility when reproduced. Symbols provide international language. Notes may need to be translated if used in another country.

- Why symbols ? The symbol has uniform meaning. A note can be stated inconsistently, with a possibility of misunderstanding. Symbols are compact, quickly drawn, and can be placed on the drawing where the control applies Symbols can be made by computer or with a template & retain legibility when reproduced. Symbols provide international language. Notes may need to be translated if used in another country.

- Why symbols ? The symbol has uniform meaning. A note can be stated inconsistently, with a possibility of misunderstanding. Symbols are compact, quickly drawn, and can be placed on the drawing where the control applies Symbols can be made by computer or with a template & retain legibility when reproduced. Symbols provide international language. Notes may need to be translated if used in another country.

- Why symbols ? The symbol has uniform meaning. A note can be stated inconsistently, with a possibility of misunderstanding. Symbols are compact, quickly drawn, and can be placed on the drawing where the control applies Symbols can be made by computer or with a template & retain legibility when reproduced. Symbols provide international language. Notes may need to be translated if used in another country.

- Foster’s text

- Foster’s text

- Why symbols ? The symbol has uniform meaning. A note can be stated inconsistently, with a possibility of misunderstanding. Symbols are compact, quickly drawn, and can be placed on the drawing where the control applies Symbols can be made by computer or with a template & retain legibility when reproduced. Symbols provide international language. Notes may need to be translated if used in another country.