Temperature Measurement Guide: ITS-90, Thermometers, Conversions

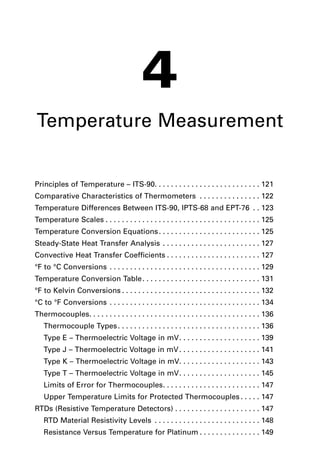

- 1. 4 Temperature Measurement Principles of Temperature – ITS-90. . . . . . . . . . . . . . . . . . . . . . . . . . 121 Comparative Characteristics of Thermometers . . . . . . . . . . . . . . . 122 Temperature Differences Between ITS-90, IPTS-68 and EPT-76 . . 123 Temperature Scales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125 Temperature Conversion Equations. . . . . . . . . . . . . . . . . . . . . . . . . 125 Steady-State Heat Transfer Analysis . . . . . . . . . . . . . . . . . . . . . . . . 127 Convective Heat Transfer Coefficients . . . . . . . . . . . . . . . . . . . . . . . 127 °F to °C Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129 Temperature Conversion Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131 °F to Kelvin Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132 °C to °F Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134 Thermocouples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136 Thermocouple Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136 Type E – Thermoelectric Voltage in mV. . . . . . . . . . . . . . . . . . . . 139 Type J – Thermoelectric Voltage in mV. . . . . . . . . . . . . . . . . . . . 141 Type K – Thermoelectric Voltage in mV. . . . . . . . . . . . . . . . . . . . 143 Type T – Thermoelectric Voltage in mV. . . . . . . . . . . . . . . . . . . . 145 Limits of Error for Thermocouples. . . . . . . . . . . . . . . . . . . . . . . . 147 Upper Temperature Limits for Protected Thermocouples . . . . . 147 RTDs (Resistive Temperature Detectors) . . . . . . . . . . . . . . . . . . . . . 147 RTD Material Resistivity Levels . . . . . . . . . . . . . . . . . . . . . . . . . . 148 Resistance Versus Temperature for Platinum . . . . . . . . . . . . . . . 149 new chap 4 temp.qxd 3/2/2006 8:56 AM Page 119

- 2. Wheatstone Bridge – Effect of Bridge Nonlinearities . . . . . . . . . . . 154 Wheatstone Bridge – 3-wire Measurement . . . . . . . . . . . . . . . . . . . 154 Thermistor Temperature-Resistance Relationship . . . . . . . . . . . . . 154 Resistance Tolerance Percent for Thermistors . . . . . . . . . . . . . . . . 155 Thermistor Voltage Drop Across a Wheatstone Bridge . . . . . . . . . 155 Stem Correction for a Total Immersion Thermometer . . . . . . . . . . . 155 Vapor Pressure Thermometers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156 Radiation Pyrometers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156 Planck’s Radiation Law . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156 Wien’s Radiation Law . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157 Stefan-Boltzmann Law . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157 Wien’s Displacement Law . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157 Total Emissivities of Metals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159 Total Radiation Pyrometer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160 Brightness Pyrometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160 Johnson Noise Thermometer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160 120 ISA Handbook of Measurement Equations and Tables new chap 4 temp.qxd 3/2/2006 8:56 AM Page 120

- 3. Principles of Temperature – ITS-90 Shortly after adoption of the Inter- national Practical Temperature Scale of 1968 (IPTS-68), it was real- ized the scale had many deficien- cies and limitations. Consequently, the Comité Consultatif de Ther- mométrie (CCT) – one of eight spe- cialized technical subcommittees of the Comité International des Poids et Mesures (CIPM) – undertook the development of a new scale. On 26- 28 September 1989, the CCT recom- mended ITS-90 be adopted. Follow- ing approval by CIPM, ITS-90 became the official international temperature scale on 1 January 1990, when it also was imple- mented at the U.S. National Insti- tute of Standards and Technology (NIST). According to a detailed report by B.W. Mangum, of NIST’s Center for Chemical Technology, National Measurement Laboratory, and NIST guest scientist G.T. Furukawa, ITS-90 – when compared to IPTS-68 – extends upward from 0.65 K. Also, temperatures on the newer scale are in much better agreement with thermodynamic values. In addition, ITS-90’s continuity, non- uniqueness and reproducibility throughout its ranges are much improved over previous scales. The most complete and authoritative document on ITS-90 from NIST is Technical Note 1265 by Mangum and Furukawa. It is available as a pdf from NIST’s web site: http://www.cstl.nist.gov/div836/836.0 5/papers/magnum90ITS90guide.pdf Temperature Defining Points – IPTS-68 vs. ITS-90 Temperature Defining Point IPTS-68 Kelvin ITPS-68°C ITS-90 Kelvin ITS-90°C Triple Point of Hydrogen 13.81 -259.34 13.8033 -259.3467 Boiling (Vapor Pressure) Point of Hydrogen at 25/75 Standard Atmosphere 17.042 -256.108 ~17.0 ~ -256.15 Boiling Point of Hydrogen 20.28 -252.87 ~20.3 ~ -252.85 Boiling Point of Neon 27.102 -246.048 — — Triple Point of Neon — — 24.5561 -248.5939 Triple Point of Oxygen 54.361 -218.789 54.3584 -218.7916 Boiling Point of Oxygen 90.188 -182.962 — — Triple Point of Water 273.16 0.01 273.16 0.01 Boiling Point of Water 373.15 100.00 — — Freezing Point of Zinc 692.73 419.58 692.677 419.527 Freezing Point of Silver 1235.08 961.93 1234.93 961.78 Freezing Point of Gold 1337.58 1064.43 1337.77 1064.18 Chapter 4/Temperature 121 new chap 4 temp.qxd 3/2/2006 8:56 AM Page 121

- 4. Comparative Characteristics of Thermometers Thermometer Range °C Resolution °C Accuracy of Absolute, % Drift in 20 khr, % Thermocouples, Sheathed 0-250 >0.1 0.3-0.8 1.3@650°C Sheathed type K (C/A) 250-850 >0.1 1-1.5 Sheathed type S(Pt-Rh) 0-1600 >0.1 0.1 1.7@ 1300°C Platinum Resistance Thermometers Industrial -200 to 650 0.01 0.5-0.1 0.02@ 650°C Standard -183 to 631 <0.01 0.0001-0.003 0.02@ 1063°C Thermistors -200 to 600 0.0005 0.03-1 0.02-0.03 Mercury-in-Glass -38 to 400 0.01 0.002-0.25 0.05 Optical Pyrometer 700-3000 0.20 0.10 0 Johnson Noise Thermometer -272 to 1500 0.10 0.01-1.30 0 Transistor Absolute Thermometer -200 to 123 0.04 0.50 Nuclear Quadrupole Resonance Thermometer -183 to 125 0.0002 0.0004 <0.01@ 100°C Ultrasonic Pulse Echo Thermometer 0-2000 1-2 1 Fluidic Thermometers 0-1200 0.00001 105 Quartz Crystal Thermometer -40 to 230 0.0001 <0.005 0.003@ 100°C Eddy Current Thermometer (sodium) 150-600 0.05 1-10 Microwave Resonator 1370 0.05 1 122 ISA Handbook of Measurement Equations and Tables new chap 4 temp.qxd 3/2/2006 8:56 AM Page 122

- 5. Differences Between ITS-90, IPTS-68 and EPT-76 where ITS or or E -90 = T t IPTS-68 = T t PT-76 = T 90 90 68 68 76 (T90 – T68)/K T90/K 0 1 2 3 4 5 6 7 8 9 10 -0.006 -0.003 -0.004 -0.006 -0.008 -0.008 20 -0.009 -0.008 -0.007 -0.007 -0.006 -0.005 -0.004 -0.004 -0.005 -0.006 30 -0.006 -0.007 -0.008 -0.008 -0.008 -0.007 -0.007 -0.007 -0.006 -0.006 40 -0.006 -0.006 -0.006 -0.006 -0.006 -0.007 -0.007 -0.007 -0.006 -0.006 50 -0.006 -0.005 -0.005 -0.004 -0.003 -0.002 -0.001 0.000 0.001 0.002 60 0.003 0.003 0.004 0.004 0.005 0.005 0.006 0.006 0.007 0.007 70 0.007 0.007 0.007 0.007 0.007 0.008 0.008 0.008 0.008 0.008 80 0.008 0.008 0.008 0.008 0.008 0.008 0.008 0.008 0.008 0.008 90 0.008 0.008 0.008 0.008 0.008 0.008 0.008 0.009 0.009 0.009 T90/K 0 10 20 30 40 50 60 70 80 90 100 0.009 0.011 0.013 0.014 0.014 0.014 0.014 0.013 0.012 0.012 200 0.011 0.010 0.009 0.008 0.007 0.005 0.003 0.001 (T90 – T76)/mK T90/K 0 1 2 3 4 5 6 7 8 9 0 -0.1 -0.2 -0.3 -0.4 -0.5 10 -0.6 -0.7 -0.8 -1.0 -1.1 -1.3 -1.4 -1.5 -1.8 -2.0 20 -2.2 -2.5 -2.7 -3.0 -3.2 -3.5 -3.8 -4.1 Chapter 4/Temperature 123 new chap 4 temp.qxd 3/2/2006 8:56 AM Page 123

- 6. (T90 – T68)/°C T90/°C 0 -10 -20 -30 -40 -50 -60 -70 -80 -90 -100 0.013 0.013 0.014 0.014 0.014 0.013 0.012 0.010 0.008 0.008 0 0.000 0.002 0.004 0.006 0.008 0.009 0.010 0.011 0.012 0.012 T90/°C 0 10 20 30 40 50 60 70 80 90 0 0.000 -0.002 -0.005 -0.007 -0.010 -0.013 -0.016 -0.018 -0.021 -0.024 100 -0.026 -0.028 -0.030 -0.032 -0.034 -0.036 -0.037 -0.038 -0.039 -0.039 200 -0.040 -0.040 -0.040 -0.040 -0.040 -0.040 -0.040 -0.039 -0.039 -0.039 300 -0.039 -0.039 -0.039 -0.040 -0.040 -0.041 -0.042 -0.043 -0.045 -0.046 400 -0.048 -0.051 -0.053 -0.056 -0.059 -0.062 -0.065 -0.068 -0.072 -0.075 500 -0.079 -0.083 -0.087 -0.090 -0.094 -0.098 -0.101 -0.105 -0.108 -0.112 600 -0.115 -0.118 -0.122 -0.125 -0.08 -0.03 0.02 0.06 0.11 0.16 700 0.20 0.24 0.28 0.31 0.33 0.35 0.36 0.36 0.36 0.35 800 0.34 0.32 0.29 0.25 0.22 0.18 0.14 0.10 0.06 0.03 900 -0.01 -0.03 -0.06 -0.08 -0.10 -0.12 -0.14 -0.16 -0.17 -0.18 1000 -0.19 -0.20 -0.21 -0.22 -0.23 -0.24 -0.25 -0.25 -0.26 -0.26 T90/°C 0 100 200 300 400 500 600 700 800 900 1000 -0.26 -0.30 -0.35 -0.39 -0.44 -0.49 -0.54 -0.60 -0.66 2000 -0.72 -0.79 -0.85 -0.93 -1.00 -1.07 -1.15 -1.24 -1.32 -1.41 3000 -1.50 -1.59 -1.69 -1.78 -1.89 -1.99 -2.10 -2.21 -2.32 -2.43 124 ISA Handbook of Measurement Equations and Tables new chap 4 temp.qxd 3/2/2006 8:56 AM Page 124

- 7. Temperature Conversion Equations °Celsius to °Fahrenheit Degree F = (Degree C x 1.8) + 32 °Celsius to °Rankine Degree R = (Degree C + 273.15) x 1.8 °Celsius to Kelvin Kelvin = Degree C + 273.15 °Fahrenheit to °Celsius °Fahrenheit to °Rankine Degree R = Degree F + 459.67 °Fahrenheit to Kelvin °Rankine to °Fahrenheit Degree F = Degree R - 459.67 Degree C = Degree F - 32 1.8 273.1+ Degree C = Degree F - 32 1.8 Chapter 4/Temperature 125 17 80100 21 -40 0273 0 ˚C = ˚F 460 70 32 -40 0 212 500 960 533 260 208 ˚Rea ˚F ˚R K ˚C 1000 538 1340 1800 1000 727 ˚F = 2(˚C) Approx. Water Boils Room Temp Water Freezes Absolute Zero Temperature -460 -273 -2180 0 Fahrenheit Rankin Kelvin Celsius Reaumur Relation of Temperature Scales new chap 4 temp.qxd 3/2/2006 8:56 AM Page 125

- 8. °Rankine to Kelvin Kelvin to °Celsius Degree C = Kelvin - 273.15 Kelvin to °Rankine Degree R = Kelvin x 1.8 Interpolation Values To interpolate for accurate temper- atures between the various incre- mental changes in the following temperature conversion tables, the interpolation table below provides the values to add to the conversion table values. Note that these values are to four decimal places. To use these add-on values correctly, cal- culate the add-on value, and then round to two decimal places. Kelvin Degree R = 1 8. °Fahrenheit Add to °Celsius 1 0.5556 2 1.1111 3 1.6667 4 2.2222 5 2.7778 6 3.3334 7 3.8889 8 4.4445 9 5.0000 10 5.5556 20 11.1112 30 16.6668 40 22.2224 50 27.7780 60 33.3336 70 38.8892 80 44.4448 90 50.0004 126 ISA Handbook of Measurement Equations and Tables new chap 4 temp.qxd 3/2/2006 8:56 AM Page 126

- 9. Steady-State Heat Transfer Analysis The performance of temperature sensors can depend on all the modes of heat transfer – conduc- tion, convection, and radiation. The steady-state heat conduction equation is: where ∇ = geometry-dependent differential operator k = thermal conductivity For constant thermal conductivity, the conduction equation is: The differential operators for three geometries are: x,y,z (Cartesian) r,z, θ (cylindrical) r, θ, φ (spherical) In many applications, heat transfer along all the coordinate axes is not significant. In these cases the equa- tions are: Cartesian (one-dimensional) Cylinder (r only) Cylinder (r,z) Sphere (r only) Convective Heat Transfer Coefficients Dimensionless Quantities for Sensors of Single Cylinders or Spheres Nusselt number (Nu) = Reynolds number (Re) = Prandtl number (Pr) = ∇ = ∂ ∂ ∂ ∂ = ∂ ∂ + ∂ ∂ 2 2 2 2 2 1 2 T r r r T r T r r T r ∂ ∂ + ∂ ∂ + ∂ ∂ = 2 2 2 2 1 0 T r r T r T z ∂ ∂ + ∂ ∂ = 2 2 1 0 T r r T r ∂ ∂ = 2 2 0 T x ∇ = ∂ ∂ ∂ ∂ + ∂ ∂ ∂ ∂ + ∂ 2 2 2 2 2 2 2 1 1 1 T r r r T r r T r sin sin sin θ θ θ θ θ TT ∂φ2 ∇ = ∂ ∂ + ∂ ∂ + ∂ ∂ + ∂ ∂ 2 2 2 2 2 2 2 2 1 1 T T r r T r r T T zθ ∇ = ∂ ∂ + ∂ ∂ + ∂ ∂ 2 2 2 2 2 2 2 T T x T y T z ∇ =2 0T ∇ ⋅ =kVT 0 Chapter 4/Temperature 127 hD k Du ρ µ c k µ new chap 4 temp.qxd 3/2/2006 8:56 AM Page 127

- 10. where h = film heat transfer coefficient D = diameter of sensor k = thermal conductivity of fluid ρ = fluid density u = fluid velocity µ = fluid viscosity c = fluid specific heat capacity General Form of the Correlations where a = experimental data Nonmetals Flowing Normal to a Single Cylinder Nu = (0.35 + 0.47 Re0.52) Pr0.3 for 0.1 <Re <1000 Nu = 0.26 Re0.6 Pr0.3 for 1000 < Re <50,000 Nonmetals Flowing Across a Single Sphere Nu = 2.0 + 0.60 Re1/2 Pr1/2 Metals Flowing Normal to a Single Cylinder Nu = 0.8 Re0.5 Pr0.5 Metals Flowing Across a Single Sphere Nu = 2.0 + 0.386 Re0.5 Pr0.5 Nu a a a a = +1 2 3 4Re Pr 128 ISA Handbook of Measurement Equations and Tables new chap 4 temp.qxd 3/2/2006 8:56 AM Page 128

- 11. Conversion Tables, °F to °C °F °C °F °C °F °C -500 -295.556 0 -17.778 70 21.111 -480 -284.444 1 -17.222 80 26.667 -460 -273.333 2 -16.667 90 32.222 -440 -262.222 3 -16.111 100 37.778 -420 -251.111 4 -15.556 110 43.333 -400 -240.000 5 -15.000 120 48.889 -380 -228.889 6 -14.444 130 54.444 -360 -217.778 7 -13.889 140 60.000 -340 -206.667 8 -13.333 150 65.556 -320 -195.556 9 -12.778 160 71.111 -300 -184.444 10 -12.222 170 76.667 -280 -173.333 11 -11.667 180 82.222 -260 -162.222 12 -11.111 190 87.778 -240 -151.111 13 -10.556 200 93.333 -220 -140.000 14 -10.000 210 98.889 -200 -128.889 15 -9.444 220 104.444 -180 -117.778 16 -8.889 230 110.000 -160 -106.667 17 -8.333 240 115.556 -140 -95.556 18 -7.778 250 121.111 -120 -84.444 19 -7.222 260 126.667 -100 -73.333 20 -6.667 270 132.222 -80 -62.222 30 -1.111 280 137.778 -60 -51.111 40 4.444 290 143.333 -40 -40.000 50 10.000 300 148.889 -20 -28.889 60 15.556 310 154.444 Chapter 4/Temperature 129 new chap 4 temp.qxd 3/2/2006 8:56 AM Page 129

- 12. Conversion Tables, °F to °C (cont.) °F °C °F °C °F °C 320 160.000 570 298.889 900 482.222 330 165.556 580 304.444 950 510.000 340 171.111 590 310.000 1000 537.778 350 176.667 600 315.556 1050 565.556 360 182.222 610 321.111 1100 593.333 370 187.778 620 326.667 1150 621.111 380 193.333 630 332.222 1200 648.889 390 198.889 640 337.778 1250 676.667 400 204.444 650 343.333 1300 704.444 410 210.000 660 348.889 1350 732.222 420 215.556 670 354.444 1400 760.000 430 221.111 680 360.000 1450 787.778 440 226.667 690 365.556 1500 815.556 450 232.222 700 371.111 1550 843.333 460 237.778 710 376.667 1600 871.111 470 243.333 720 382.222 1650 898.889 480 248.889 730 387.778 1700 926.667 490 254.444 740 393.333 1750 954.444 500 260.000 750 398.889 1800 982.222 510 265.556 760 404.444 1850 1010.000 520 271.111 770 410.000 1900 1037.778 530 276.667 780 415.556 1950 1065.556 540 282.222 790 421.111 2000 1093.333 550 287.778 800 426.667 2050 1121.111 560 293.333 850 454.444 2100 1148.889 130 ISA Handbook of Measurement Equations and Tables new chap 4 temp.qxd 3/2/2006 8:56 AM Page 130

- 13. Temperature Conversion Table To Convert From To Multiply by: °C heat unit Btu 1.8 °C heat unit Calorie 453.592 °C heat unit Joule 1899.10 °C/hr-kilocalorie °C / watt 0.859845 ft/°F m/°C 0.548640 in/°F mm/°C 45.72 Joule Calorie 0.238846 Joule/°C Btu/°F 0.000526565 kilocalorie Btu 3.968320 kilocalorie Joule 4186.80 liter-bar Joule 100.0 °C-temperature interval °F 1.8 °C-temperature interval °Rankine 1.8 °F-temperature interval °C 0.5555556 °F-temperature interval °Rankine 1.0 °F-temperature interval Kelvin 0.5555556 Chapter 4/Temperature 131 new chap 4 temp.qxd 3/2/2006 8:56 AM Page 131

- 14. 1 Conversion Tables, °F to Kelvin °F K °F K °F K -500 -22.406 0 255.372 70 294.261 -480 -11.294 1 255.928 80 299.817 -460 -0.183 2 256.483 90 305.372 -440 10.928 3 257.039 100 310.928 -420 22.039 4 257.794 110 316.483 -400 33.150 5 258.150 120 322.039 -380 44.261 6 258.706 130 327.594 -360 55.372 7 259.261 140 333.150 -340 66.483 8 259.817 150 338.706 -320 77.594 9 260.372 160 344.261 -300 88.706 10 260.928 170 349.817 -280 99.817 11 261.483 180 355.372 -260 110.928 12 262.039 190 360.928 -240 122.039 13 262.594 200 366.483 -220 133.150 14 263.150 210 372.039 -200 144.261 15 263.706 220 377.594 -180 155.372 16 264.261 230 383.150 -160 166.483 17 264.871 240 388.706 -140 177.594 18 265.372 250 394.261 -120 188.706 19 265.928 260 399.817 -100 199.817 20 266.483 270 405.372 -80 210.928 30 272.039 280 410.928 -60 222.039 40 277.594 290 416.483 -40 233.150 50 283.150 300 422.039 -20 244.261 60 288.706 310 427.594 132 ISA Handbook of Measurement Equations and Tables new chap 4 temp.qxd 3/2/2006 8:56 AM Page 132

- 15. Conversion Tables, °F to Kelvin (cont.) °F K °F K °F K 320 433.150 570 572.709 900 755.372 330 438.706 580 577.594 950 783.150 340 444.261 590 583.150 1000 810.928 350 449.817 600 588.706 1050 838.706 360 455.372 610 594.261 1100 866.483 370 460.928 620 599.817 1150 894.261 380 466.483 630 605.372 1200 922.039 390 472.039 640 610.928 1250 949.817 400 477.594 650 616.483 1300 977.594 410 483.150 660 622.039 1350 1005.372 420 488.706 670 627.594 1400 1033.150 430 494.261 680 633.150 1450 1060.928 440 499.817 690 638.706 1500 1088.706 450 505.372 700 644.261 1550 1116.483 460 510.928 710 649.817 1600 1144.261 470 516.483 720 655.372 1650 1172.039 480 522.039 730 660.928 1700 1199.817 490 527.594 740 666.438 1750 1227.594 500 533.150 750 672.039 1800 1255.372 510 538.706 760 677.594 1850 1283.150 520 544.261 770 683.150 1900 1310.928 530 549.817 780 688.706 1950 1338.706 540 555.372 790 694.261 2000 1366.483 550 560.928 800 699.817 2050 1394.261 560 566.483 850 727.594 2100 1422.039 Chapter 4/Temperature 133 new chap 4 temp.qxd 3/2/2006 8:56 AM Page 133

- 16. Conversion Tables, °C to °F °C °F °C °F °C °F -300 -508.0 -50 -58.0 20 68.0 -290 -490.0 -40 -40.0 25 77.0 -280 -472.0 -30 -22.0 30 86.0 -270 -454.0 -20 -4.0 40 104.0 -260 -436.0 -10 14.0 50 122.0 -250 -418.0 0 32.0 60 140.0 -240 -400.0 1 33.8 70 158.0 -230 -382.0 2 35.6 80 176.0 -220 -364.0 3 37.4 90 194.0 -210 -346.0 4 39.2 100 212.0 -200 -328.0 5 41.0 110 230.0 -190 -310.0 6 42.8 120 248.0 -180 -292.0 7 44.6 130 266.0 -170 -274.0 8 46.4 140 284.0 -160 -256.0 9 48.2 150 302.0 -150 -238.0 10 50.0 160 320.0 -140 -220.0 11 51.8 170 338.0 -130 -202.0 12 53.6 180 356.0 -120 -184.0 13 55.4 190 374.0 -110 -166.0 14 57.2 200 392.0 -100 -148.0 15 59.0 210 410.0 -90 -130.0 16 60.8 220 428.0 -80 -112.0 17 62.6 230 446.0 -70 -94.0 18 64.4 240 464.0 -60 -76.0 19 66.2 250 482.0 134 ISA Handbook of Measurement Equations and Tables new chap 4 temp.qxd 3/2/2006 8:56 AM Page 134

- 17. Conversion Tables, °C to °F (cont.) °C °F °C °F °C °F 260 500.0 510 950.0 760 1400.0 270 518.0 520 968.0 770 1418.0 280 536.0 530 986.0 780 1436.0 290 554.0 540 1004.0 790 1454.0 300 572.0 550 1022.0 800 1472.0 310 590.0 560 1040.0 810 1490.0 320 608.0 570 1058.0 820 1508.0 330 626.0 580 1076.0 830 1526.0 340 644.0 590 1094.0 840 1544.0 350 662.0 600 1112.0 850 1562.0 360 680.0 610 1130.0 860 1580.0 370 698.0 620 1148.0 870 1598.0 380 716.0 630 1166.0 880 1616.0 390 734.0 640 1184.0 890 1634.0 400 752.0 650 1202.0 900 1652.0 410 770.0 660 1220.0 910 1670.0 420 788.0 670 1238.0 920 1688.0 430 806.0 680 1256.0 930 1706.0 440 824.0 690 1274.0 940 1724.0 450 842.0 700 1292.0 950 1742.0 460 860.0 710 1310.0 960 1760.0 470 878.0 720 1328.0 970 1778.0 480 896.0 730 1346.0 980 1796.0 490 914.0 740 1364.0 990 1814.0 500 932.0 750 1382.0 1000 1832.0 Chapter 4/Temperature 135 new chap 4 temp.qxd 3/2/2006 8:56 AM Page 135

- 18. Thermocouples The thermocouple is the most pop- ular type of sensor. Thermocouples are based on the principle that two wires made of dissimilar materials connected at either end will gener- ate a potential between the two ends that is a function of the mate- rials and temperature difference between the two ends. A number of material choices are in common use. Base metal thermo- couples are useful for measuring temperatures under 1000 degrees C. This class includes iron/constan- tan (Type J), Chromel/Alumel (Type K) and a number of others. Nobel metal thermocouples are useful to about 2000 degrees C. This class includes tungsten-rhenium alloy thermocouples and others. The potential generated is in milli- volts and is a nonlinear function of temperature. In practice, one end is placed near the material to be measured and the other end is con- nected to the instrument. Since the thermocouple materials are not typically good materials for trans- mission, wires with similar charac- teristics are used when the trans- mitting instrument is remote. Thermocouple Types Thermocouples come in different combinations of metals and cali- brations. Types J, K, T and E are the four most common calibrations. Types R, S, C and GB are high tem- perature calibrations. Each calibra- tion has a different temperature range and environment. However, the maximum temperature varies with the diameter of the wire used in the thermocouple. The letter type, e.g., type J, identi- fies a specific temperature-voltage relationship, not a particular chem- ical composition. Thermocouples of a given type may have variations in composition as long as their Thermocouples Type Composition Temperature range, °C B Pt-30% Rh versus Pt-6% Rh 0 to 1820 E Ni-Cr alloy versus a Cu-Ni alloy -270 to 1000 J Fe versus a Cu-Ni alloy -210 to 1200 K Ni-Cr alloy versus Ni-Al alloy -270 to 1372 N Ni-Cr-Si alloy versus Ni-Si-Mg alloy -270 to 1300 R Pt-13% Rh versus Pt -50 to 1768 S Pt-10% Rh versus Pt -50 to 1768 T Cu versus a Cu-Ni alloy -270 to 400 136 ISA Handbook of Measurement Equations and Tables Courtesy: National Institute of Standards and Technology (NIST) ©1995 copyright by the U.S. Secretary of Commerce on behalf of the United States of America. All rights reserved. new chap 4 temp.qxd 3/2/2006 8:56 AM Page 136

- 19. resultant temperature-voltage rela- tionships remain within specified tolerances. All materials manufac- tured in compliance with the estab- lished thermoelectric voltage stan- dards are equally acceptable. Thermocouple Circuit Analysis Thermocouple Circuit Analysis where: V = open-circuit voltage T1 = Temperature at one end of wires T2 = temperature at other end of wires Sa = absolute Seebeck coefficient for material Sb = absolute Seebeck coefficient for material T = temperature where Sab = relative Seebeck coefficient for materials a and b The Relation Between Temperature Difference and Voltage where V = voltage T = temperature The Basic Thermoelectric Voltage Element A Simple Thermocouple Circuit S V T = ∆ ∆ ∆ = −V S T T( )2 1 S S S S S S S S S S S a b ab ab ba ac ab cb ac ab bc − = = − = − = + V S S dTT T a b= −∫ 1 2( ) Chapter 4/Temperature 137 The Basic Thermoelectric Voltage Element ∆V T1 S T2 A Simple Thermocouple Circuit T1 Sa Sb T1 T2V new chap 4 temp.qxd 3/2/2006 8:56 AM Page 137

- 20. Solutions also require specification of boundary conditions at inter- faces. Interfaces occur between regions containing different materi- als or surfaces. Since notation becomes cumbersome if all geome- tries are considered, only the com- mon boundary conditions for cylin- drical (r only) geometry are given. Internal; Continuity of Temperature Tr- = Tr+ Internal; Continuity of Heat Flux Internal; Finiteness of Temperature Surface; Convection Surface: Fixed Surface Temperature TR = TF Surface: Insulated Surface Surface: Radiation where Tr- = temperature at r as approached from the interior Tr+ = temperature at r as approached from the exterior k = thermal conductivity k1 = thermal conductivity of material interior to the interface at r k2 = thermal conductivity of material exterior to the interface at r R = radius at the surface h = film heat transfer coefficient θ = temperature of fluid around sensor θR = temperature of medium exchanging radiative energy with the sensor TF = fixed temperature specified for surface ∈ = emissivity σ = Stefan-Boltzmann constant − ∂ ∂ =∈ −k T r TR R Rσ θ( )4 4 ∂ ∂ = T r R 0 − ∂ ∂ = −k T r h TR R( )θ T r( ) ≠ ∞ k T r k T r r r1 2 ∂ ∂ = ∂ ∂ − + 138 ISA Handbook of Measurement Equations and Tables new chap 4 temp.qxd 3/2/2006 8:56 AM Page 138

- 21. 110 6.998 120 7.685 130 8.379 140 9.081 150 9.789 160 10.503 170 11.224 180 11.951 190 12.684 200 13.421 210 14.164 220 14.912 230 15.664 240 16.420 250 17.181 260 17.945 270 18.713 280 19.484 290 20.259 300 21.036 310 21.817 320 22.600 330 23.386 340 24.174 350 24.964 360 25.757 370 26.552 380 27.348 390 28.146 400 28.946 410 29.747 420 30.550 430 31.354 440 32.159 450 32.965 460 33.772 470 34.579 480 35.387 Type E - Thermoelectric Voltage in mV °C mV 270 -9.835 -260 -9.797 -250 -9.718 -240 -9.604 -230 -9.455 -220 -9.274 -210 -9.063 -200 -8.825 -190 -8.561 -180 -8.273 -170 -7.963 -160 -7.632 -150 -7.279 -140 -6.907 -130 -6.516 -120 -6.107 -110 -5.681 -100 -5.237 -90 -4.777 -80 -4.302 -70 -3.811 -60 -3.306 -50 -2.787 -40 -2.255 -30 -1.709 -20 -1.152 -10 -0.582 0 0.000 10 0.591 20 1.192 30 1.801 40 2.420 50 3.048 60 3.685 70 4.330 80 4.985 90 5.648 100 6.319 Chapter 4/Temperature 139 new chap 4 temp.qxd 3/2/2006 8:56 AM Page 139

- 22. 860 65.698 870 66.473 880 67.246 890 68.017 900 68.787 910 69.554 920 70.319 930 71.082 940 71.844 950 72.603 960 73.360 970 74.115 980 74.869 990 75.621 1000 76.373 Type E - Thermoelectric Voltage in mV (cont’d.) °C mV 490 36.196 500 37.005 510 37.815 520 38.624 530 39.434 540 40.243 550 41.053 560 41.862 570 42.671 580 43.479 590 44.286 600 45.093 610 45.900 620 46.705 630 47.509 640 48.313 650 49.116 660 49.917 670 50.718 680 51.517 690 52.315 700 53.112 710 53.908 720 54.703 730 55.497 740 56.289 750 57.080 760 57.870 770 58.659 780 59.446 790 60.232 800 61.017 810 61.801 820 62.583 830 63.364 840 64.144 850 64.922 140 ISA Handbook of Measurement Equations and Tables new chap 4 temp.qxd 3/2/2006 8:56 AM Page 140

- 23. 110 5.814 120 6.360 130 6.909 140 7.459 150 8.010 160 8.562 170 9.115 180 9.669 190 10.224 200 10.779 210 11.334 220 11.889 230 12.445 240 13.000 250 13.555 260 14.110 270 14.665 280 15.219 290 15.773 300 16.327 310 16.881 320 17.434 330 17.986 340 18.538 350 19.090 360 19.642 370 20.194 380 20.745 390 21.297 400 21.848 410 22.400 420 22.952 430 23.504 440 24.057 450 24.610 460 25.164 470 25.720 480 26.276 Type J - Thermoelectric Voltage in mV °C mV -210 -8.095 -200 -7.890 -190 -7.659 -180 -7.403 -170 -7.123 -160 -6.821 -150 -6.500 -140 -6.159 -130 -5.801 -120 -5.426 -110 -5.037 -100 -4.633 -90 -4.215 -80 -3.786 -70 -3.344 -60 -2.893 -50 -2.431 -40 -1.961 -30 -1.482 -20 -0.995 -10 -0.501 0 0.000 10 0.507 20 1.019 30 1.537 40 2.059 50 2.585 60 3.116 70 3.650 80 4.187 90 4.726 100 5.269 Chapter 4/Temperature 141 new chap 4 temp.qxd 3/2/2006 8:56 AM Page 141

- 24. 830 47.431 840 48.074 850 48.715 860 49.353 870 49.989 880 50.622 890 51.251 900 51.877 910 52.500 920 53.119 930 53.735 940 54.347 950 54.956 960 55.561 970 56.164 980 56.763 990 57.360 1000 57.953 1010 58.545 1020 59.134 1030 59.721 1040 60.307 1050 60.890 1060 61.473 1070 62.054 1080 62.634 1090 63.214 1100 63.792 1110 64.370 1120 64.948 1130 65.525 1140 66.102 1150 66.679 1160 67.255 1170 67.831 1180 68.406 1190 68.980 1200 69.553 Type J - Thermoelectric Voltage in mV (cont’d.) °C mV 490 26.834 500 27.393 510 27.953 520 28.516 530 29.080 540 29.647 550 30.216 560 30.788 570 31.362 580 31.939 590 32.519 600 33.102 610 33.689 620 34.279 630 34.873 640 35.470 650 36.071 660 36.675 670 37.284 680 37.896 690 38.512 700 39.132 710 39.755 720 40.382 730 41.012 740 41.645 750 42.281 760 42.919 770 43.559 780 44.203 790 44.848 800 45.494 810 46.141 820 46.786 142 ISA Handbook of Measurement Equations and Tables new chap 4 temp.qxd 3/2/2006 8:56 AM Page 142

- 25. 70 2.851 80 3.267 90 3.682 100 4.096 110 4.509 120 4.920 130 5.328 140 5.735 150 6.138 160 6.540 170 6.941 180 7.340 190 7.739 200 8.138 210 8.539 220 8.940 230 9.343 240 9.747 250 10.153 260 10.561 270 10.971 280 11.382 290 11.795 300 12.209 310 12.624 320 13.040 330 13.457 340 13.874 350 14.293 360 14.713 370 15.133 380 15.554 390 15.975 400 16.397 410 16.820 420 17.243 430 17.667 440 18.091 Type K - Thermoelectric Voltage in mV °C mV -270 -6.458 -260 -6.441 -250 -6.404 -240 -6.344 -230 -6.262 -220 -6.158 -210 -6.035 -200 -5.891 -190 -5.730 -180 -5.550 -170 -5.354 -160 -5.141 -150 -4.913 -140 -4.669 -130 -4.411 -120 -4.138 -110 -3.852 -100 -3.554 -90 -3.243 -80 -2.920 -70 -2.587 -60 -2.243 -50 -1.889 -40 -1.527 -30 -1.156 -20 -0.778 -10 -0.392 0 0.000 10 0.397 20 0.798 30 1.203 40 1.612 50 2.023 60 2.436 Chapter 4/Temperature 143 new chap 4 temp.qxd 3/2/2006 8:56 AM Page 143

- 26. 830 34.501 840 34.908 850 35.313 860 35.718 870 36.121 880 36.524 890 36.925 900 37.326 910 37.725 920 38.124 930 38.522 940 38.918 950 39.314 960 39.708 970 40.101 980 40.494 990 40.885 1000 41.276 1010 41.665 1020 42.053 1030 42.440 1040 42.826 1050 43.211 1060 43.595 1070 43.978 1080 44.359 1090 44.740 1100 45.119 1110 45.497 1120 45.873 1130 46.249 1140 46.623 1150 46.995 1160 47.367 1170 47.737 1180 48.105 1190 48.473 1200 48.838 1210 49.202 Type K - Thermoelectric Voltage in mV (cont.) °C mV 450 18.516 460 18.941 470 19.366 480 19.792 490 20.218 500 20.644 510 21.071 520 21.497 530 21.924 540 22.350 550 22.776 560 23.203 570 23.629 580 24.055 590 24.480 600 24.905 610 25.330 620 25.755 630 26.179 640 26.602 650 27.025 660 27.447 670 27.869 680 28.289 690 28.710 700 29.129 710 29.548 720 29.965 730 30.382 740 30.798 750 31.213 760 31.628 770 32.041 780 32.453 790 32.865 800 33.275 810 33.685 820 34.093 144 ISA Handbook of Measurement Equations and Tables new chap 4 temp.qxd 3/2/2006 8:56 AM Page 144

- 27. Type T - Thermoelectric Voltage in mV °C mV -270 -6.258 -260 -6.232 -250 -6.180 -240 -6.105 -230 -6.007 -220 -5.888 -210 -5.753 -200 -5.603 -190 -5.439 -180 -5.261 -170 -5.070 -160 -4.865 -150 -4.648 -140 -4.419 -130 -4.177 -120 -3.923 -110 -3.657 -100 -3.379 -90 -3.089 -80 -2.788 -70 -2.476 -60 -2.153 -50 -1.819 -40 -1.475 -30 -1.121 -20 -0.757 -10 -0.383 0 0.000 10 0.391 20 0.790 30 1.196 40 1.612 50 2.036 60 2.468 70 2.909 80 3.358 90 3.814 1220 49.565 1230 49.926 1240 50.286 1250 50.644 1260 51.000 1270 51.355 1280 51.708 1290 52.060 1300 52.410 1310 52.759 1320 53.106 1330 53.451 1340 53.795 1350 54.138 1360 54.479 1370 54.819 Chapter 4/Temperature 145 new chap 4 temp.qxd 3/2/2006 8:56 AM Page 145

- 28. Type T - Thermoelectric Voltage in mV °C mV 100 4.279 110 4.750 120 5.228 130 5.714 140 6.206 150 6.704 160 7.209 170 7.720 180 8.237 190 8.759 200 9.288 210 9.822 220 10.362 230 10.907 240 11.458 250 12.013 260 12.574 270 13.139 280 13.709 290 14.283 300 14.862 310 15.445 320 16.032 330 16.624 340 17.219 350 17.819 360 18.422 370 19.030 380 19.641 390 20.255 400 20.872 146 ISA Handbook of Measurement Equations and Tables Source: NIST ITS-90 Database new chap 4 temp.qxd 3/2/2006 8:56 AM Page 146

- 29. aLimits of error are expressed in percentage of Celsius temperature. Limits of error are material tolerances, not accuracies. RTDs (Resistive Temperature Detectors) RTDs are made of metal wire, fiber, or semiconductor material that responds to temperature change by changing its resistance. Platinum, nickel, tungsten and other metals are used that have high resistivity, good temperature coefficient of resistance, good ductile or tensile strength, and chemical inertness with packaging and insulation materials. When the material is a semiconductor, the sensor is called a thermistor. Recommended Upper Temperature Limits for Protected Thermocouples, °C (°F) Type 8 Gauge 14 Gauge 20 Gauge 24 Gauge 28 Gauge T 370 (770) 260 (500) 200 (400) 200 (400) J 760 (1400) 590 (1100) 480 (900) 370 (700) 370 (700) E 870 (1600) 650 (1200) 540 (1100) 430 (800) 430 (800) K 1260 (2300) 1090 (2000) 980 (1800) 870 (1600) 870 (1600) R or S 1480 (2700) B 1700 (3100) Limits of Error for Thermocouples Thermocouple Type Temperature Range °C Standarda Error Limit Speciala Error Limit T -59 to 93 1.0°C 0.5°C 93 to 371 J 0 to 277 2.2°C 1.1°C 277 to 1260 E 0 to 316 1.7°C 1.0°C 316 to 817 K 0 to 277 2.2°C 1.1°C 277 to 1260 R or S 0 to 538 1.5°C 0.6°C 538 to 1482 B 871 to 1705 0.50% n.a. Chapter 4/Temperature 147 new chap 4 temp.qxd 3/2/2006 8:56 AM Page 147

- 30. Change in resistance can be deter- mined using a bridge circuit. Since resistance changes in the connec- tion wire due to ambient tempera- ture changes can also affect the resistance reading, a third wire is used from another leg in the bridge to balance that change. RTDs are generally more accurate than thermocouples, but are less rugged and cannot be used at as high temperatures. All types of temperature measuring devices suffer from slow response, since it is necessary for heat to con- duct through the protective sheath, and through any installed well. Locating the well (or unprotected sensor) so it sees as high a veloc- ity of process material as possible helps reduce this lag, as does hav- ing the sensor contact the well. A bare thermocouple touching the sheath and/or well, however, gen- erates a ground and requires an isolated amplifier. The resistivity (r) is proportional to the length (L) and inversely propor- tional to the cross-section area (A). where R = resistance, ohms r = resistivity, ohm cm L = length, cm A = cross-section area, cm2 R r L A = ( ) RTD Material Resistivity Levels Metal Resistivity (Ohm/CMF) CMF = Circular Mil Foot) Copper 9.26 Gold 13.00 Nickel 36.00 Platinum 59.00 Silver 8.8 Tungsten 30.00 148 ISA Handbook of Measurement Equations and Tables new chap 4 temp.qxd 3/2/2006 8:56 AM Page 148

- 31. Chapter 4/Temperature 149 -200 -100 0 100 200 300 400 500 600 4.0 3.8 3.6 3.4 3.2 3.0 2.8 2.6 2.4 2.2 2.0 1.8 1.6 1.4 1.2 1.0 0.8 0.6 0.4 0.2 0.0 Basis: German Standard DIN 43760 Linear approximation for -200 to 600˚C Resistance/resistance˚C Temperature ˚C Resistance vs. Temperature for Platinum new chap 4 temp.qxd 3/2/2006 8:56 AM Page 149

- 32. Resistance Versus Temperature and Tolerance for 100 Ohm Platinum RTDs According to DIN 43760 T°C R Ohm °C Temp. Tolerance T°C R Ohm °C Temp. Tolerance -220 10.41 1.8 30 111.67 -210 14.36 40 115.54 -200 18.53 1.2 50 119.40 -190 22.78 60 123.40 -180 27.05 70 127.07 -170 31.28 80 130.89 -160 35.48 90 134.70 -150 39.65 100 138.50 0.6 -140 43.80 110 142.28 -130 47.93 120 146.06 -120 52.04 130 149.82 -110 56.13 140 153.57 -100 60.20 0.7 150 157.32 -90 64.25 160 161.04 -80 68.28 170 164.76 -70 72.29 180 168.47 -60 76.28 190 172.16 -50 80.25 200 175.84 1.2 -40 84.21 210 179.51 -30 88.17 220 183.17 -20 92.13 230 186.82 -10 96.07 240 190.46 0 100.00 0.3 250 194.08 10 103.90 260 197.70 20 107.79 270 201.30 150 ISA Handbook of Measurement Equations and Tables new chap 4 temp.qxd 3/2/2006 8:56 AM Page 150

- 33. Resistance Versus Temperature and Tolerance for 100 Ohm Platinum RTDs According to DIN 43760 (cont.) T°C R Ohm °C Temp. Tolerance T°C R Ohm ° Temp. Tolerance 280 204.88 530 290.87 290 208.46 540 294.16 300 212.03 1.8 550 297.43 310 215.58 560 300.70 320 219.13 570 303.95 330 222.66 580 307.20 340 226.18 590 310.43 350 229.69 600 313.65 3.6 360 233.19 610 316.86 370 236.67 620 320.05 380 240.15 630 323.24 390 243.61 640 326.41 400 247.06 2.4 650 329.57 410 250.50 660 332.72 420 253.93 670 335.86 430 257.34 680 338.99 440 260.75 690 342.10 450 264.14 700 345.21 4.2 460 267.52 710 348.30 470 270.89 720 351.38 480 274.25 730 354.45 490 277.60 740 357.51 500 280.93 3.0 750 360.55 510 284.26 800 375.61 4.8 520 287.57 850 390.38 5.1 Chapter 4/Temperature 151 new chap 4 temp.qxd 3/2/2006 8:56 AM Page 151

- 34. Resistance Versus Temperature for 100 Ohm (Nominal) Platinum RTD According to SAMA RC21-4-1966 T °C R Ohm T °C R Ohm -200 16.666 20 105.920 -190 20.972 30 109.799 -180 25.244 40 113.665 -170 29.483 50 117.521 -160 33.691 60 121.365 -150 37.871 70 125.197 -140 42.023 80 129.018 -130 46.151 90 132.827 -120 50.255 100 136.625 -110 54.337 110 140.412 -100 58.399 120 144.187 -90 62.441 130 147.950 -80 66.466 140 151.702 -70 70.474 150 155.442 -60 74.465 160 159.171 -50 78.442 170 162.889 -40 82.405 180 166.595 -30 86.355 190 170.289 -20 90.292 200 173.972 -10 94.216 210 177.644 0 98.129 220 181.304 10 102.030 230 184.953 152 ISA Handbook of Measurement Equations and Tables new chap 4 temp.qxd 3/2/2006 8:56 AM Page 152

- 35. Resistance Versus Temperature for 100 Ohm (Nominal) Platinum RTD According to SAMA RC21-4-1966 (cont.) T °C R Ohm T °C R Ohm 240 188.581 430 255.512 250 192.215 440 258.919 260 195.829 450 262.315 270 199.432 460 265.699 280 203.023 470 269.072 290 206.603 480 272.434 300 210.171 490 275.784 310 213.728 500 279.122 320 217.273 510 282.449 330 220.807 520 285.784 340 224.329 530 289.068 350 227.840 540 292.361 360 231.339 550 295.642 370 234.827 560 298.911 380 238.303 570 302.169 390 241.768 580 305.416 400 245.221 590 308.651 410 248.663 600 311.875 420 252.093 Chapter 4/Temperature 153 new chap 4 temp.qxd 3/2/2006 8:56 AM Page 153

- 36. Wheatstone Bridge – Effect of Bridge Nonlinearities where E = voltage drop Eo = output voltage RT = fixed resistor RS = adjustable resistor Wheatstone Bridge 3-Wire Measurement Thermistor Temperature- Resistance Relationship where R = unknown resistance Ro = known resistance β = Kelvins T = unknown temperature To = known temperature The Steinhart and Hart Equation for NTC Thermistors where T = temperature R = resistance ao = 1.1252 x 10-3 K-1 a1 = 2.3476x10-4 K-1 a3 = 8.5262 x 10-8 K-1 Thermistor Temperature Error Due to Self-Heating where ∆T = temperature measurement error, °C I = sensing current, mA R = thermistor resistance, Ω DC = dissipation constant, mW/°C ∆ =T I R DC 2 1000( ) 1 1 11 3 3 T a a n R a n Ro= + +( ) ( ) R R T To o = − β 1 1 E E R R R R R R o T T S S = + − + E E R R R R R R o T T S S = + − + 154 ISA Handbook of Measurement Equations and Tables E RT Eo Rs R R Basic Wheatstone Bridge (2-wire) Lead 3 Lead 2 Lead 1 RL RL RT Rs Eo R R E Wheatstone Bridge for 3-Wire Measurements new chap 4 temp.qxd 3/2/2006 8:56 AM Page 154

- 37. Thermistor Voltage Drop Across a Wheatstone Bridge where Stem Correction for a Total Immersion Thermometer where ∆T = temperature correction K = temperature correction factor n = number of degrees on scale between surface of fluid and end of fluid column in the capillary TB = bulb temperature T = average temperature of the portion of the thermometer between the fluid surface and end of fluid column in the capillary ∆ = −T Kn T TB( ) K R R R F T R R R R R s T T T T o o o = − + = + = ( ) 1 1 resistance at a reference temperature E E K F T o = + ( ) Resistance Tolerance Percent for Thermistors (MIL-T-23648A) Temperature °C Type F + or -1% Type G + or -2% Type J + or -5% Type K + or -10% -55 10 12 15 20 -15 5 6 9 14 0 3 4 7 12 25 1 2 5 10 50 3 4 7 12 75 5 6 9 14 100 7 9 12 17 125 10 12 15 20 200° 15 18 25 30 275° 20 25 35 40 Chapter 4/Temperature 155 aThe percent tolerance indicated with each thermistor type is the resistance at 25°C. new chap 4 temp.qxd 3/2/2006 8:56 AM Page 155

- 38. Vapor Pressure Thermometers Cross Ambient Effect where PG = pressure on the Bourdon tube PB = pressure in the bulb PC = pressure in the capillary Radiation Pyrometers Planck’s Radiation Law where H(λT) = radiant power density λ = wavelength, cm T = temperature, K C1 = 3.74 x 10-12, Wcm2 C2 = 1.44, cmK H T C ec T ( ) ( ) λ λ λ = − 1 5 2 1 P P PG B C= + ∆ 156 ISA Handbook of Measurement Equations and Tables Rs Eo E R R T Wheatstone Bridge for Thermistor Readout Vapor Vapor Volatile Liquid Volatile Liquid Vapor Pressure Thermometers new chap 4 temp.qxd 3/2/2006 8:56 AM Page 156

- 39. Wien’s Radiation Law (lower temperatures) Stefan-Boltzmann Law (total radiation power) where H(T) = total radiation power per unit area σ = 5.669 x 10-12, W/cm2 K4 T = temperature, K Wien’s Displacement Law where T = temperature, K λm = wavelength where maximum radiation power density occurs T m = 0 2898. λ H T T( ) = σ 4 H T C e C T ( ) / λ λ λ = − 1 5 2 Chapter 4/Temperature 157 new chap 4 temp.qxd 3/2/2006 8:56 AM Page 157

- 40. Radiation Power Density as a Function of Wavelength and Temperature (Plank’s Law for a Blackbody) 158 ISA Handbook of Measurement Equations and Tables 6543210 0.15 0.14 0.13 0.12 0.11 0.10 0.09 0.08 0.07 0.06 0.05 0.04 0.03 0.02 0.01 0.00 Wavelength λ, microns RelativeSpectralRadiantPower Location of Peak (see Wien's Displacement Law) 1300 K, 1880˚F 1200 K, 1700˚F 1100 K, 1520˚F 1000 K, 1340˚F 900 K, 1160˚F 800 K, 960˚F 700 K, 800˚F new chap 4 temp.qxd 3/2/2006 8:56 AM Page 158

- 41. Total Emissivities of Metals, Surface Unoxidized Material 25°C 100°C 500°C 1000°C 1500°C 2000°C Aluminum 0.022 0.028 0.060 Bismuth 0.048 0.061 Carbon 0.81 0.81 0.79 Chromium 0.08 Cobalt 0.13 0.23 Columbium 0.19 0.24 Copper 0.02 0.15 Liquid Gold 0.02 0.03 Iron 0.06 Lead 0.05 Mercury 0.10 0.12 Molybdenum 0.13 0.19 0.24 Nickel 0.045 0.06 0.12 0.19 Platinum 0.037 0.047 0.095 0.152 0.191 Silver 0.02 0.035 Tantalum 0.21 0.26 Tin 0.043 0.05 Tungsten 0.024 0.032 0.071 0.15 0.23 0.28 Brass 0.035 0.035 Cast Iron 0.21 0.29 Liquid Steel 0.08 0.28 Liquid Chapter 4/Temperature 159 new chap 4 temp.qxd 3/2/2006 8:56 AM Page 159

- 42. Total Radiation Pyrometer True Temperature vs. Indicated Temperature where T = true temperature TI = indicated temperature ∈ = material radiation emissivity Brightness Pyrometer True Temperature vs. Brightness Temperature where T = true temperature TB = brightness temperature Johnson Noise Thermometer Relationship Between Noise Volt- age and Absolute Temperature where V = noise voltage k = Boltzmann’s constant T = absolute temperature R = electrical resistance of sensor ∆f = frequency band-width over which the noise voltage is measured V kTR f2 4= ∆ T T T n B B = + ∈1 1 44 1 λ λ . ( ) T TI= ∈( ) /1 4 160 ISA Handbook of Measurement Equations and Tables new chap 4 temp.qxd 3/2/2006 8:56 AM Page 160