Design for 'X' and be prepared for anything

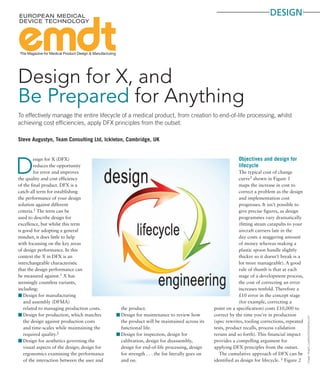

- 1. design The Magazine for Medical Product Design & Manufacturing Image:Yevgen_Lyashko/iStockphoto.com Steve Augustyn, Team Consulting Ltd, Ickleton, Cambridge, UK To effectively manage the entire lifecycle of a medical product, from creation to end-of-life processing, whilst achieving cost efficiencies, apply DFX principles from the outset. D esign for X (DFX) reduces the opportunity for error and improves the quality and cost efficiency of the final product. DFX is a catch-all term for establishing the performance of your design solution against different criteria.1 The term can be used to describe design for excellence, but whilst this term is good for adopting a general mindset, it does little to help with focussing on the key areas of design performance. In this context the X in DFX is an interchangeable characteristic that the design performance can be measured against.1 X has seemingly countless variants, including: 00 Design for manufacturing and assembly (DFMA) related to managing production costs. 00 Design for production, which matches the design against production costs and time-scales while maintaining the required quality.2 00 Design for aesthetics governing the visual aspects of the design; design for ergonomics examining the performance of the interaction between the user and the product. 00 Design for maintenance to review how the product will be maintained across its functional life. 00 Design for inspection, design for calibration, design for disassembly, design for end-of-life processing, design for strength . . . the list literally goes on and on. Objectives and design for lifecycle The typical cost of change curve3 shown in Figure 1 maps the increase in cost to correct a problem as the design and implementation cost progresses. It isn’t possible to give precise figures, as design programmes vary dramatically (fitting steam catapults to your aircraft carriers late in the day costs a staggering amount of money whereas making a plastic spoon handle slightly thicker so it doesn’t break is a lot more manageable). A good rule of thumb is that at each stage of a development process, the cost of correcting an error increases tenfold. Therefore a £10 error in the concept stage (for example, correcting a point on a specification) costs £10,000 to correct by the time you’re in production (spec rewrites, tooling corrections, repeated tests, product recalls, process validation reruns and so forth). This financial impact provides a compelling argument for applying DFX principles from the outset. The cumulative approach of DFX can be identified as design for lifecycle. 1 Figure 2 Design for X, and Be Prepared for Anything

- 2. design (adapted from BS 8887) shows how some of the different DFX approaches map onto the life of a product. This issue is too wide ranging to give definitive answers for any of the significant areas of impact in the space of a magazine article, but some of the references at the foot of this article should prove useful. If we consider the three main phases of a product’s life— creation, use and end-of-life processing— the implications of DFX become clearer. Creation and realisation DFMA is one of the better understood and applied aspects of DFX. Whilst the origins of design for manufacture, particularly from the context of standardised designs, can be traced back to Eli Whitney4 at the end of the 18th century, it is Hitachi’s Assembly Evaluation Method from the 1970s and the work of Peter Dewhurst and Geoffrey Boothroyd at the University of Massachusetts that really defined DFMA with a deep, analytical methodology. Originally based on a series of charts and lookup tables, the Boothroyd and Dewhurst DFMA approach is now available as a software package that can be used to analyse designs at any stage of development to obtain an estimated cost. This methodology will give you a predicted cost of different approaches, allowing the designer to choose the most cost-effective option. However, this process is limited by the knowledge built into the system and it will only report one piece of the puzzle. More specifically, it will allow the designer to compare two puzzle pieces that he is holding. A component assembly variability risk analysis review (CAVRA) can provide a numerical score to compare the relative assembly risks in different designs.5 Running a detailed analysis on a large piece of equipment would dramatically eat into the time and budget available, but by using the guidelines as a checklist as the design progresses, a lot of the benefit can be achieved for a fraction of the cost. For high-volume mass-produced parts, spending more time on the DFMA process can be easily justified, but sometimes a thorough review of the design with experienced production engineers can generate a lot of value (see the section titled Caveats and good practices). One equally crucial piece of the puzzle is design for production. This is distinct from DFMA, as it deals more with the logistics of manufacturing; in the area of medical device development, this can have an even bigger impact. For example, you run your DFMA analysis to compare a steel spring against an elastomeric one. With the number of features required, the elastomer comes out as the clear winner so you merrily proceed with the information neatly tucked away. Now you hit production planning and you find out that the minimum order quantity for your medical-grade elastomer is three metric tons (enough for five years’ production at full capacity) and the material is on a 12-week lead time, three weeks after the product is supposed to be in clinical trial. Use and implementation The use and implementation of the product crosses many boundaries and expertise including mechanical design, industrial design and ergonomics. The effects of mechanical design can be felt most keenly in areas such as design for reliability, design for service and design for wear. For example, when I worked on the design of photocopiers at Xerox, a lot of work was done to prevent paper jams in the machines. Jams are inevitable—you never know what sort of rubbish someone will feed into the machine. However, designing a paper path in the machine that is easily accessible to the user allows these failures to be recovered simply and quickly. By reducing the importance of design for service you can end up in the nightmare position known to many car owners, where replacing something as simple as a headlight bulb can necessitate a trip to the car dealership. Whether the decisions that led to this state of affairs were motivated by aesthetic or pecuniary concerns, I’ll leave to the reader to decide. Determining and measuring the benefits of industrial design and ergonomics can be more difficult. Poor design on a Figure 1: The cost of correcting a problem increases considerably at each stage of the product development process, as shown by the cost of change curve. Costofchange Specify Implement Verification Production By reducing the importance of design for service you can end up in the nightmare position known to many car owners, where replacing a headlight bulb can necessitate a trip to the car dealership.

- 3. design consumer product or a fatal flaw in the interaction could lead to an unappealing product or something that is inherently dangerous. An appealing or easy-to- use product may compensate for some lacklustre engineering, but a poorly conceived product will present a barrier that no amount of clever engineering will be able to balance out. What constitutes good industrial design is beyond the scope of this article, but good guidance is available for the definition of interaction design. Two resources I have found useful are the Principles of Universal Design6 and ISO/IEC Guide 71.7 Both of these guides are based on an inclusive design approach, but the principles hold up well for all types of product interaction. Design reviews, state space analysis and user trials all work well to match the performance of the product against identified performance characteristics. End-of-life processing Design for end-of-life processing is often low on a list of objectives for a designer. Working in the medical device space does come with its own requirements related to product safety, and it can be necessary to consider how to safely disable a single-use product. With issues of cross-contamination or dangerous, poorly controlled reprocessing, finding ways to permanently disable products after they have been used once can become very important. Single-use, auto-disable syringes such as the BD SoloShot8 show how such features can be easily engineered into products. It may be enough to ensure that products can be incinerated without producing harmful toxins or optimised to use the minimum amount of material. Beyond basic safety issues and avoiding toxic materials wherever possible, manufacturers and importers are coming under increasing pressure to consider the processing of their products at the end of life. With rapidly rising demand in developing countries, the pressure on limited resources such as rare earth metals is going to become ever more acute, and recycling and reprocessing will become ever more important as European guidelines such as WEEE and RoHS place responsibility on the postprocessing and construction of electronic products to minimise environmental impact. This is an area where car companies are leading the way, with BMW (among others) adopting thorough end-of-life strategies to recover and reprocess as much material as possible.9 Design Engineering magazine has an article that provides a very useful overview to the whole issue of sustainable product development and manufacturing.10 Caveats and good practices It costs time and money to analyse different designs against the various X criteria and to implement the resulting changes. These development costs will have to be annotated over the entire production run (or the projected payback period). Unfortunately, numerous papers and academic guides to DFX act as if the engineers’ time costs nothing and that all activity directly benefits the product. One of my favourite engineering quotes is attributed to Henry Ford: “An engineer can do for a nickel what any damn fool can do for a dollar.” Whilst this is a pretty clear rallying call for the benefits of applying DFX methodologies, it is important to keep DFX in the context of the whole development process. The crucial point is to make these methodologies as efficient as possible and understand that the outcome of a review is limited by the knowledge, experience and prejudices of the review panel or process. Going back to the cost of change graph (Figure 1), applying these principles early in the design process will reap the largest rewards. Applying “three yards of DFMA” once the prototype has been completed and tested probably will lead to compromise and frustration if the design is found to be Design of parts and manufacturing processes Piece part manufacture Assembly Design of parts and manufacturing processes Disassembly Piece part reprocessing Material recovery or disposal Design for disassemblyDesign for service Design for lifecycle Design for manufacture Design for manufacture and assembly Design for inspection Design for end-of-life processing Use Figure 2: How various DFX approaches map onto the life of a product. Diagram adapted from BS 8887. With rapidly rising demand in developing countries, the pressure on limited resources such as rare earth metals is going to become ever more acute, and recycling and reprocessing will become ever more important.

- 4. design deficient. Getting a good brief and defining a clear and considered specification to the product will help ensure that these features are built into the design from day one. Delivering a better product The job of the designer and engineer has never been more difficult, with so many competing demands and regulations to balance in a rapidly evolving market. However, taking responsibility for the whole lifecycle of the product and examining design decisions will always lead to a better product and a more considered execution. Catching errors—or recognising opportunities for optimisation—early in the design process will help to produce a stronger product in the most cost-efficient way possible. Some excellent tools are available to help with any of these analyses. They take time and effort to implement, however, and even then the results will only be as good as the questions asked. Remember, it is entirely possible to make five completely rational design decisions and end up in some completely irrational place. By applying the principles of DFX, it’s possible to get back to the right place and deliver a better, more capable product. References 1. ISO 8887-1:2006 Design for Manufacture, Assembly, Disassembly and End of Life Processing (DFMADE). 2. G. Pahl et al. as translated by Ken Wallace and Lucienne Blessing, “7.5.8 Design for Production,” in Engineering Design: A Systematic Approach, Third Edition, Springer Science and Business Media (2007). 3. M. Tarr, “The DFX Concept” (www.ami.ac.uk/ courses/topics/0248_dfx/index.html). 4. www.eliwhitney.org/new/museum/about-eli- whitney/inventor. 5. J. D. Booker, M. Raines and K. G. Swift, “2.4 Component Assembly Variability Risks Analysis” Designing Capable and Reliable Products, 63-66, Butterworth-Heinemann, Oxford, UK (2001). 6. The Principles of Universal Design, Version 2.0, The Centre for Universal Design, Raleigh, NC, USA (1997). 7. ISO IEC Guide 71 2001: Guidelines for Standards Developers to Address the Needs of Older Persons and Persons with Disabilities. 8. www.bd.com/immunization/products/ 9. www.bmw.co.uk/bmwuk/about/corp/recycling 10. A. Plant, D. Harrison and B Griffiths, “Raising the Standard: A review of standards and legislation in sustainable product design,” Journal of the Institution of Engineering Designers, January/February (2011). Guidelines for Running an Effective DFX Review 00 Gather at least three participants, including a facilitator and device expert. 00 Recruit at least one person who has nothing to do with the project activities other than to review. 00 Ensure that the reviewers have strong, and complimentary, manufacturing experience. 00 Keep the group small. 00 Limit sessions to no more than three hours. 00 Leave egos outside the room. 00 Have review in hand in time to imple- ment changes, not two hours before design freeze. Steve Augustyn is Head of Mechanical Engineering, Team Consulting Ltd, Abbey Barns, Duxford Road, Ickleton, Cambridge CB10 1SX, UK tel. +44 1799 532 700 e-mail: sea@team-consulting.com www.team-consulting.com Reprinted with permission from EMDT, January/February 2013. On the web at emdt.co.uk. © A UBM Canon Publication. All rights reserved. Foster Printing Service: 866-879-9144, www.marketingreprints.com.