Pillar design

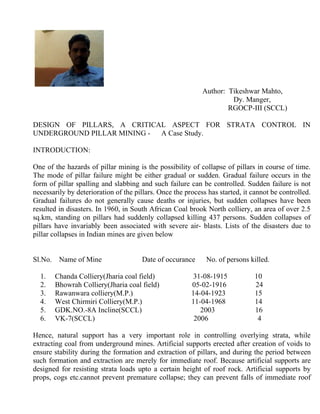

- 1. Author: Tikeshwar Mahto, Dy. Manger, RGOCP-III (SCCL) DESIGN OF PILLARS, A CRITICAL ASPECT FOR STRATA CONTROL IN UNDERGROUND PILLAR MINING - A Case Study. INTRODUCTION: One of the hazards of pillar mining is the possibility of collapse of pillars in course of time. The mode of pillar failure might be either gradual or sudden. Gradual failure occurs in the form of pillar spalling and slabbing and such failure can be controlled. Sudden failure is not necessarily by deterioration of the pillars. Once the process has started, it cannot be controlled. Gradual failures do not generally cause deaths or injuries, but sudden collapses have been resulted in disasters. In 1960, in South African Coal brook North colliery, an area of over 2.5 sq.km, standing on pillars had suddenly collapsed killing 437 persons. Sudden collapses of pillars have invariably been associated with severe air- blasts. Lists of the disasters due to pillar collapses in Indian mines are given below Sl.No. Name of Mine Date of occurance No. of persons killed. 1. Chanda Colliery(Jharia coal field) 31-08-1915 10 2. Bhowrah Colliery(Jharia coal field) 05-02-1916 24 3. Rawanwara colliery(M.P.) 14-04-1923 15 4. West Chirmiri Colliery(M.P.) 11-04-1968 14 5. GDK.NO.-8A Incline(SCCL) 2003 16 6. VK-7(SCCL) 2006 4 Hence, natural support has a very important role in controlling overlying strata, while extracting coal from underground mines. Artificial supports erected after creation of voids to ensure stability during the formation and extraction of pillars, and during the period between such formation and extraction are merely for immediate roof. Because artificial supports are designed for resisting strata loads upto a certain height of roof rock. Artificial supports by props, cogs etc.cannot prevent premature collapse; they can prevent falls of immediate roof

- 2. only. Therefore, the premature collapses can be controlled by natural supports only. Natural supports mean supports or resistances offered by natural sources, like strength of pillar, strength of overlying strata, strength of underlying floor etc. Hence, scientific base is necessary for proper design of natural supports to ensure stability of workings and also for minimizing loss of valuable property inside the collapsed strata. In this paper author is sharing his experience for proper design of pillars to ensure stability of workings during the formation and extraction of pillars. The author is working in underground coal mines since last eight years and has observed from very close about the conditions and behavior of standing pillars while extraction. STATUTORY BACK-UP: CMR-1957 has made some guidelines for design of pillars in underground working to ensure safety of men, machinery and coal (a national property). Following are the directives regarding the above subjects made by the statutes Reg. -99 Development Work; The dimensions of pillars and galleries, and the shape of pillars, formed in any seam or section shall be such as to ensure stability during the formation and extraction of pillars, and during the period between such formation and extraction. No gallery in a seam or section shall exceed 3m in height or 4.8m in width at any place without prior permission of RIM. The pillars formed in any seam or section shall normally be rectangular in shape. The distance between the centres of any two adjacent pillars left in seam or section shall not be less than that specified in the appended table as corresponding to the depth of the seam or section from the surface at that point and the width of the galleries in the workings The distance between centres of adjacent pillars shall not be less than Depth of seam from Where the Where the Where the Where the surface width Width of width of width of of the galleries the galleries the galleries the galleries does not does not does not does not exceed exceed 3.0m exceed 3.6m exceed 4.2m 4.8m (1) (2) (3) (4) (5)

- 3. Meter Meter Meter Meter Not exceeding 60m 12.0 15.0 18.0 19.5 Exceeding 60m but 13.5 16.5 19.5 21.0 not exceeding 90m 16.5 19.5 22.5 25.5 Exceeding 90m but not 22.5 25.5 30.5 34.5 exceeding 150m Exceeding 150m but 28.5 34.5 39.5 45.0 not exceeding 240m 39.0 42.0 45.0 48.0 Exceeding 240m but not exceeding 360m Exceeding 360m 6. In the case of all workings, where in the opinion of the RIM, the dimensions of the pillars or galleries are such as to render it likely that crushing of pillars or the premature collapse of any part of the workings will occur either before or during the extraction of pillars, he may by an order in writing, require such modification of the dimensions aforesaid in respect of any further working as he may specify. LIMITATIONS OF THE ABOVE MENTIONED STATUTORY BACK-UP REGARDING PILLAR DESIGN: Dimensions of pillar given above as per the Reg.-99 are based on the experience and past working conditions only. It has some limitations and drawbacks. It has no scientific base and it can be used upto a depth of 360m only. Mine workings are going deeper and deeper, and in future there will be no alternative except deep mining. Hence, for deep mining design of natural supports is very essential for the safety point of view and for this there is need of scientific approach towards rock load estimation and strength of the load bearing pillars. ROCK LOAD CALCULATION FOR DESIGNING PILLARS: For pillar design, rock load is calculated by ` Tributary –Area Method ` which is shown in figure given below;

- 4. Fig.1 Plan view of Bord and Pillar System Where in the Fig. 1, W= is the length of square pillar corner to corner ; b = the width of the gallery (bord). Here rock load (P) on the pillars calculated by the tributary – area method is as follows, P = µH( W + b/W )2 t/m2 , where `µ` is the density of overlying rock in `t/m3` and H is the depth of working in meters .The rock load calculated above in `t/m2` can be converted into `Mpa` (mega Pascal) in the following ways; P = µH{(W+b)/W}2 *103 Kg/m2 [ 1 tonne = 1000 Kgs ] Or, P = µH{(W+b)/W}2 * 103* 10 N/m2 [ 1 Kgf. = 10 N ] Or, P = µH{(W+b)/W}2 *104 Pa [ 1 N/m2 = 1 Pascal & 1 Mpa = 106 Pascal ] Or, P = µH{(W+b)/W}2 * 10-2 Mpa . Taking µ = 2.5 t/m3 (approximately), Hence, P = 0.025 H{(W+b)/W}2 Mpa …………………………(1)

- 5. Author’s observation : From the Fig.1 and equation (1), it is clear that the pillar is designed as natural support based on strata load coming on the pillars during development stage only. There is no consideration of dynamic loads( shock bumping etc.) transferring on pillars during final extraction of pillars , which should be the main criteria for pillars design in bord and pillar mining . Because in Reg-99(1), it is clearly mentioned that`` the dimensions of pillars and galleries, and the shape of pillars, formed in any seam or section shall be such as to ensure stability during the formation and extraction of pillars, and during the period between such formation and extraction`` . Hence, for load calculation to design pillars, the effect of dynamic loading during extraction of pillars should also be considered for more stability of underground workings. The dynamic loads transferring on pillars at the time of final extraction are different in magnitude for different method of extraction . In case of sand stowing it is negligible, but in case of caving it is disastrous ,which leads overriding of pillars and premature collapse of workings. History of disasters due to premature collapse is very dreadful. In recent past, the author has seen two major disasters due to premature collapse in SCCL, in which about 20 persons were killed. The author has done some case study and suggested a modified formula for load calculation in pillars design. Author’s suggestion: As the author has explained in detail that the dynamic loading is a major contributing factor for premature collapse of pillars and workings, so there must be a dynamic load factor in calculation of rock load while, designing pillars for final extraction. Also, before designing pillars, there must be a pre-plan of method of working i.e. whether the pillars shall be extracted by sand stowing method or by caving method .Because the dynamic load factor shall be different for both the method of workings. For the sand stowing it will be around unity(1),because there will be less effect of settled goaf stowed with sand on the unextracted pillars, but in the caving method dynamic loading is very-very disastrous . Sometimes it is more than the static load calculated by the Tributary-area method, which may create the condition of premature collapse of workings. Although, in caving method of workings there is provision of `Breaker line supports`, but practically it is very difficult to limit the effect of

- 6. dynamic loading on surrounding pillars by using breaker line supports, particularly in strong and massive strata . The static and dynamic loading of pillars has been shown in Fig.2 given below. The arrow shows the static load due to overburden and the curve line shows the dynamic load due to hanging goaf. In Fig.2 , W = width of the pillar , b = width of the gallery and h = height of the gallery(or pillar height ) Dynamic load curves Static Load Hanging Goaf

- 7. Modification of formula suggested by the author for load calculation on pillar: From the equation (1) and Fig.2 , the formula for load calculation can be written in the following way; P = 0.025KH(W+b/W)2 Mpa ……………………………..(2) Where , P = load on pillar( in Mpa) , K = a dynamic load factor, H = depth of cover (in meter), W = size of square pillar (in meter), and b = width of gallery (in meter). Here , K = 1 for sand stowing method and for the caving method it will be more than unity(1). The value of K can be taken in range of 1.3- 1.6 . For easily cavable strata K = 1.3 and for strong and massive strata K = 1.6 . The assumed values of dynamic load factor (K) are not actual. The author has assumed these values for the convenience and simplicity. STRENGTH OF PILLAR FOR DESIGNING NATURAL SUPPORT IN UNDERGROUND COAL MINES;. Estimation of strength of pillars is a critical part of the pillar design . There is no straight forward formula for calculating strength of the pillars. Based on experience and the conditions of geological formation, some empirical formulae have been developed by scientists, which are explained below in detail about their merits and demerits. Salomon & Munroe formula: They have developed formula for calculating strength of pillar based on size of the pillar and height of extraction , which is given below ; S = 1320*(W)0.46/(h)0.66 Psi …………………………….(3) Where , S = strength of pillar (in Psi), W = equivalent width of pillar (in ft.), = 4A/P = 4(W1*W2)/2(W1+W2) = 2W1*W2/W1+W2; where W1 & W2 are length and width of rectangular Pillar (in ft.) h = height of extraction (in ft.)

- 8. The strength of the pillar can be changed from Psi to Mpa , by taking width of pillar and height of extraction in meters in the following ways; S = 1320(3.28W)0.46/(3.28h)0.66 *145 Mpa [1Mpa = 145 Psi ] [ 1 meter = 3.28 ft.] Or , S = 1320(W)0.46/(3.28)0.66*145(3.28)0.20 Mpa Or ,S = 7.18 (W)0.46/h0.66 Mpa …………………………….(4) Where , W and `h` are in meters. Author’s observations; From the equation (4) , the strength of pillar can be calculated by knowing width of pillar and height of extraction only. There is no consideration of depth of working and geological intrusions into the pillars i.e. the pillars having same width and height of extraction shall have same strength irrespective of depth of workings. Also in Salomon & Munroe formula, less weightage has been given to the width of the pillar, which estimates less than the actual strength of the pillar. The author thinks that it is not suitable for Indian conditions. Because Indian statute has strictly restricted the height of extraction to 3m, but there is no any restriction for higher limit of the width of pillar. Therefore, in author’s view , width of pillar(W) should be given more weightage for calculating actual strength of pillars. CMRI formula developed by Dr. P. R. Sheorey for calculating strength of pillar: In Dr. Sheorey,s formula, major factor for calculating strength of the pillar is depth of working(H). There is far difference in strength values calculated by Salomon - Munroe and Dr. Sheorey. In Salomon - Munroe’s formula, there is no depth factor , but in Dr. , Sheorey s formula strength of pillar varies as the depth of cover(H) increases .The author has made comparative studies in detail, and also given some suggestion for modification in strength formula, which will be discussed later. Dr. Sheorey,s formula for strength calculation is given below; S=0.27pc* h-0.36 +(H/250 +1)(W/h -1) Mpa………………………………….(5) Where, S = strength of pillar (in Mpa) pc = compressive strength of sample of 25mm cube (23.8 Mpa); h= height of extraction (in meter); H = depth of cover(in meter) , and W= equivalent width of pillar (in meter)

- 9. = 4A/P = 2W1*W2/W1+W2 (for rectangular pillar ) The author’s observations and suggestion: In Dr. Sheorey,s formula of strength calculation, there are two parts. First part is function of compressive strength of the sample piece and height of extraction and second part is function of depth of cover and size of the pillar. In this formula, if we assume size of pillar (W) and height of extraction (h) as constants for any depth, the strength of pillar of particular dimensions will be directly proportional to the depth of cover (H) as shown in Fig.4, i.e. more the depth of cover, more will be strength of pillar. In author’s view, there is contradiction between the assumptions of two scientists mentioned ` above. The author has critically diagnosed about the above mentioned systems of pillar design, which are as follows; Assuming, width of pillar (W) and height of extraction (h) as constants for any depth and expanding this formula, we get; S = (0.27pc*h-0.36 + W/h -1) + H(W/h – 1)/250 As per assumption W, h, pc are all constants, therefore (0.27pc*h-0.36 + W/h- 1) = a constant ( C1 ), and also (W/h- 1)/250 =an another constant (C2) Hence, putting these constants in equation (5) we get S = C1 +C2*H …………………………………(6) From the equation (6), we can infer that it is an equation of straight line in S and H i.e. the strength of pillar is directly proportional to the depth of cover for a particular size of pillar and height of extraction. In other words, it can also be inferred that the strength of a coal seam will vary proportionally to the depth of cover, which is not possible. Because, the strength of any material is its internal property and, it will not change in great extent by changing only external conditions (like pressure and temperature due to increase in depth). In author’s view, the strength of coal seam will change with the depth of cover, but in small extent due to metamorphism of coal under heat and pressure. Strength of coal generally varies with the age of formation and compactness. Moreover, compactness depends upon internal granular structure (i.e. cohesiveness) of rock mass. Hence, strength of coal decreases in order from highest rank of coal to lowest rank i.e. anthracite to lignite. In author’s view, both the scientists (Salomon- Munroe & Dr. Sheorey) have assumed only external conditions for calculating strength of pillar. They have not considered about internal conditions (weaknesses). Internal weakness means any geological disturbance like clay band,

- 10. joints, slip, fault, fold etc. embedded into the seam. The author has observed that in same mine (GDK.NO.-10 Incline) and in same seam (NO.3 Seam); a coal pillar developed at 150m depth is stronger than the pillar developed at 350m depth. The above-mentioned seam is not having any internal weakness at 150m depth, but the same seam after 230m depth is intruded with 1.0m clay& shale band at 4.0 m height from the floor. Therefore, in the mine pillars have been developed after leaving 1.5m coal in floor due to strata control problem, which has positioned the clay & shale band just below the roof. Due to this band inter granular cohesive bond of the coal seam got weakened. Hence, when strata weighting occurs, the coal pillars start spalling from its sides. Due to sides spalling effective area of the pillar decreases, and load on the pillar (P/A) increases, which may cause premature collapse of the workings. All these can be understood by the pictorial representation shown in Fig.3. Strata Load Strata Load Clay & Shale Floor Floor reaction Coal pillar having no internal weakness Coal pillar having internal weakness (Clay & Shale band) Clay & Shale band Shape of pillar after sides spalling

- 11. Fig. 3 From the Fig.3, it is clear that, in case of coal pillar having discontinuities like clay & shale band shown in the figure as example, the total strata load is not transferring to the floor. Only a fraction of it is transferred to the floor of the seam and greater portion of the load is diverted towards sides of the pillar due to discontinuity of rock mass as shown in the Fig.3, which causes sides spalling and weakening the pillars. On the other hand, in case of the pillar developed in uniform and undisturbed seam maximum strata load is transferred to the floor of the seam, which indicates strongness of the pillar. Length of arrow in the figure shows the magnitude of the load. Comparative studies between Salomon – Munroe and Dr. Sheorey,s hypothesis for pillar design: Assumptions : Width of the pillar : 40m, Height of extraction : 2.8m From equation (6),Dr, Sheorey,s strength formula is S = C1 + C2*H ,where C1 and C2 are constants for a particular width of pillar (W) and height of extraction (h). Here S = strength of the pillar, C1 = (0.27pc*h-0.36 + W/h -1), C2 = (W/h– 1)/250. Assuming width of pillar (W) and height of extraction (h) constants for any depth of cover (H) for calculating strength of pillar and factor of safety(FOS) for a particular width of pillar and height of extraction. Hence, W = 40m, h = 2.8m, pc = 23.8(assumed by Dr. Sheorey ). Therefore, C1 = 0.27pc*h-0.36 +W/h -1 = 0.27*23.8*(2.8)-0.36 +40/2.8 -1 = 17.72. and C2 = (W/h – 1)/250 = (40/2.8 -1)/250 = 0.053 Thus, Dr. Sheorey,s formula for strength of the pillar can be expressed in the following way; S = 17.72 + 0.053H Mpa ……………………………..(7) and Salomon – Munroe formula for strength of pillar is;

- 12. S = 7.18W0.46/h0.66 Mpa And factor of safety (FOS) = strength /load = S/P Where, P(load) = 0.025H(W+b/W)2 Mpa Quantitative comparison of strength of pillar and factor of safety of pillar design, taking width of pillar(W) and height of extraction (h) as constants for any depth of working is tabulated below; Dept Widt Height Width Load on Strength Strength Factor Factor of h of h of of of pillar(P) of of of safety cover pillar extractio gallery in Mpa. pillar(S1 pillar(S2) safety (FOS2) (H) (W) n (h) (b) in ) in Mpa, by (FOS1) By in in mtr. in Mpa , -Salomon- by Salomon mtr. mtr. by Munroe Dr.She - Dr.Sheor orey Munroe ey 100 40 2.8 4 3.02 23.02 19.86 7.61 6.56 200 40 2.8 4 6.05 28.32 19.86 4.68 3.28 300 40 2.8 4 9.07 33.62 19.86 3.70 2.19 400 40 2.8 4 12.10 38.92 19.86 3.22 1.64 500 40 2.8 4 15.12 44.22 19.86 2.92 1.31 600 40 2.8 4 18.15 49.52 19.86 2.73 1.09 700 40 2.8 4 21.17 54.82 19.86 2.59 0.94 800 40 2.8 4 24.20 60.12 19.86 2.48 0.82 900 40 2.8 4 27.22 65.42 19.86 2.40 0.73 1000 40 2.8 4 30.25 70.72 19.86 2.34 0.66 1100 40 2.8 4 33.27 76.02 19.86 2.28 0.60 1200 40 2.8 4 36.30 81.32 19.86 2.24 0.55 1300 40 2.8 4 39.32 86.62 19.86 2.20 0.50 1400 40 2.8 4 42.35 91.92 19.86 2.17 0.47

- 13. Surface 100m 200m 300m Depth 1200m 1300m 1400m Coal Seam Square Coal Pillars (40m width) Graphical representation of strengths of pillar by using Dr. Sheorey and Salomon – Munroe formulae has been sown in Fig.4 given below, in which width of the pillar and height of extraction have been fixed for the depth of the cover from 100m- 1200m.

- 14. Graphical comparision of Dr. Sheorey and Salomon- Munroe 80 Strength of pillar(S) in Mpa 60 S1(Strength of pillar by Dr. Sheorey) 40 S2(Strength of pillar by Salomon- 20 Munrou) 0 100 300 500 700 900 1100 Depth of cover (H) in meter Fig.4 From the above table and Fig.4, according to Dr. Sheorey, strength of a 40m square pillar is increasing with the depth of cover and it is about 81 Mpa at the depth of 1200m, which is impossible. On the other hand, according to Salomon – Munroe, strength of a pillar (keeping size of pillar constant) is not changing with the depth of cover. Also in Fig.5, a graph has been drawn between factor of safety and depth of cover(H), in which as per Dr. Sheorey,s assumption factor of safety of a 40m square pillar is 2.24 at depth of 1200m. It means a 40m square pillar is sufficient for the stability point of view at 1200m depth. Contrarily, according to Salomon- Munroe, there is no meaning of a 40m square pillar at depth of 1200m. These are the main aspects, the author wants to summarize in this article.

- 15. Comparision of factorof safety of pillar by using formula of Dr. Sheorey and Salomon- Munroe 8 7 6 Factor of safety(FOS) 5 Factor of safety(FOS1) by Dr.Sheorey 4 Factor of safety (FOS2) by Salomon- Munroe 3 2 1 0 100 300 500 700 900 1100 1300 1500 Depth of cover(H) in mtr. Fig.5 Modification of strength formula suggested by the author: The author has designed the formula for calculation of strength of the pillar based on Salomon- Munroe and Dr. Sheorey,s assumptions. Some inherent factors have been considered for representing all types of coal at various depths.

- 16. Assumptions : W : width of pillar (in mtr.) , h : height of extraction( in mtr.), S : strength of pillar (in Mpa ). As we have discussed earlier that more the width of pillar, more will be the strength, but more the height of extraction, lesser will be its strength. So, the strength of pillar will be designed on the basis of these assumptions and then factors for internal weakness and ranking of coal will be considered. The author has assumed that the relationship among strength, width of pillar and height of extraction will be same for sample piece and standing pillars for determining values of some unknown factors. For this purpose sample pieces from strong portion of the coal seam shall be collected, as shown in Fig.6 and their uniaxial compressive strengths will be determined in the laboratory. h2 h1 W1 W1 W1 W1 h2 W2 W2 Fig. 6 Now Strength of sample piece(s) α (w)m , and also

- 17. Strength of sample piece(s) α 1/(h)n Where `m` and `n` are exponent to width of sample piece (w) and height of sample piece (h) respectively. Hence, combining the above two equations, we get; s α (w)m/(h)n ; or , s = K1 *wm/hn Mpa ……………………………….(8) And strength of whole pillar can be formulated from equation (8) by assuming same factors (m), (n) and a factor (K) the constant of proportionality for the standing pillars. Here another factors K2 (factor for internal weaknesses) and K3 (factor for ranking or grade of coal ) shall be considered for representing all types of coal deposits. It has been observed that the constant of proportionality (k) for the sample piece and standing pillar varies inversely to the shape factor (w/h ratio). Thus, for the sample piece, K1 α 1/(w/h); And , for the standing pillar K α 1/(W/h). Thus comparing above two equations we get, K/K1 = (w/h)sample piece/(W/h)standing pillar Or, K = K1 * (w/h) sample piece/ (W/h) standing pillar Or, K = K1 *(w/h)/(W/h). Thus, the strength of pillar (S) = KK2K3*Wm/hn Mpa ……………………………(9) Where, K = proportionality constant. As per Salomon- Munroe’s assumption K= 1320(or, 7.18 in SI system) and, m= 0.46, n= 0.66.; K2 = a factor for internal weaknesses (i.e. any geological disturbance or discontinuity embedded in working section of coal Seam); K3 = a factor for ranking (grade) of coal which depends upon the age of coal formation . and depth of working; W = width of pillar in meter, and h = height of extraction in meter. Determination of values of constants K1, K2, K3, m, and `n` : From equation (6), the strength of a sample piece is; S = K1* (w)m/ (h)n Mpa. a

- 18. Taking two sample pieces from Fig.6, having same width but different height (or length), whose compressive strengths are S1 and S2 respectively. Therefore, S1 = K1* (w1)m/(h1)n Mpa , and ………………………… (10) S2 = K1*(w1)m/(h2)n Mpa . ………………………….(11) Dividing the above two equations we get; S1/S2 = (h2)n/(h1)n = (h2/h1)n Taking logarithm both sides, we get; Loge(S1/S2) = Loge(h2/h1)n , Or , Loge(S1/S2) = n* Loge(h2/h1) , Or, n = Loge(S1/S2)/ Loge(h2/h1) ………………………………………..(12) Here , h1 and h2 are known and S1 , S2 can be known by the compressive strength test of sample pieces . Hence, value of `n` can be determined by putting values of h 1, h2 , S1 and S2 in equation (12). Again taking two samples from Fig.6, having different widths (w1 and w2) but same height (or length), whose compressive strengths are S2 and S3 respectively; Thus, S2 = K1* (w1)m/(h2)n , ……………………………….(13) and S3 = K1* (w2)/(h2)n. …………………………………….(14) Dividing the above two equations we get; S2 /S3 = (w1)m/(w2)m , Or, S2/S3 = (w1/w2)m . Again , taking logarithm both sides ; Loge(S2/S3) = Loge(w1/w2)m Or, Loge(S2/S3) = m* Loge(w1/w2),

- 19. Or, m = Loge(S2/S3)/Loge(w1/w2). ……………………………..(15) We know the values of w1, w2 from sample pieces and corresponding values of S2 , S3 can be known by compressive strength test of sample pieces. Hence, value of `m` can be determined by putting the values of w1, w2 , S2 and S3 in equation (15). Now, the value of `K1` can be determined from equation (10); S1 = K1* (w1)m/(h1)n Mpa. ; Or, K1 = S1*(h1)n/(w1)m ……………………………………(16) Here, values of S1, w1 , h1, m, and `n` are known. Values of K2 and K3 can be assumed by observation of seam section in bore hole samples or in cross- measure drift covering whole seam thickness and assessment for ranking (or grade) of coal seam. Here K2 = a factor for internal weakness ( any disturbance or discontinuity like fault, fold, clay & shale band, joints etc.embedded into the working section of coal seam), and K3 = a factor for ranking (grade) of coal. Values of K2 can be assumed less than one(1) for the seam having internal weaknesses and one(1) for the seam having no intrusion. Also for K3 , it is one(1) for lower rank of coal and 1.2 - 1.5 for higher rank of coal. Thus, K2 = 0.7-0.8 for the coal seam having internal intrusions, and = 1.0 for the coal seam having no internal intrusion. K3 = 1.0 for the lower rank of coal , and = 1.2- 1.5 for higher rank of coal . The above values of K2 and K3 are not actual. It has been assumed by the author for simplicity. Conclusion;

- 20. The author’s approach can be verified in the field for determining satisfactory values of the factors, which have been used by the author in this paper. The author’s approach is based on the practical experience and study of disasters due to pillar failure. Therefore, if it is applied in the field, it will certainly be a handy tool for mining engineers to control strata and make the underground workings safe and technically viable. Declaration: All the statements and comments made by the author are personal and not necessarily to the organisation. References: Kejriwal, B.K., Professor,ISM-Dhanbad, Safety in Mines Coal Mines Regulation, 1957 Signature of the author Date (Tikrshwar Mahto) 27-06-07