EADS Innovation Works Aerospace Brackets - Direct Metal Laser Sintering with EOS of Germany Technology

•

1 like•1,521 views

EADS Innovation Works Aerospace Brackets - Direct Metal Laser Sintering with EOS of Germany Technology

Report

Share

Report

Share

Download to read offline

Recommended

Peter Zimm - MRO WORKSHOP - SPOTLIGHT: Additive manufacturing (3D printing) is expected to have a profound impact on global supply chains, including in the aviation industry. What does 3D printing mean for the future of manufacturers and MROs?Peter Zimm - MRO WORKSHOP - SPOTLIGHT: Additive manufacturing (3D printing) i...

Peter Zimm - MRO WORKSHOP - SPOTLIGHT: Additive manufacturing (3D printing) i...IBAS International Brazil Air Show

Recommended

Peter Zimm - MRO WORKSHOP - SPOTLIGHT: Additive manufacturing (3D printing) is expected to have a profound impact on global supply chains, including in the aviation industry. What does 3D printing mean for the future of manufacturers and MROs?Peter Zimm - MRO WORKSHOP - SPOTLIGHT: Additive manufacturing (3D printing) i...

Peter Zimm - MRO WORKSHOP - SPOTLIGHT: Additive manufacturing (3D printing) i...IBAS International Brazil Air Show

International Workshop on Technology and Policy Solutions for Energy-Efficient and Low Carbon Light-Duty Vehicles

6/4/2014-6/5/2014

Beijing, ChinaGlobal Lightweight Vehicle Developments and Policy Design Implications - Nic ...

Global Lightweight Vehicle Developments and Policy Design Implications - Nic ...International Council on Clean Transportation

Cranial Implant manufactured with Laser Sintering using EOS Additive Manufacturing in PEEK PlasticCranial Implant manufactured with Laser Sintering using EOS Additive Manufact...

Cranial Implant manufactured with Laser Sintering using EOS Additive Manufact...Machine Tool Systems Inc.

More Related Content

What's hot

International Workshop on Technology and Policy Solutions for Energy-Efficient and Low Carbon Light-Duty Vehicles

6/4/2014-6/5/2014

Beijing, ChinaGlobal Lightweight Vehicle Developments and Policy Design Implications - Nic ...

Global Lightweight Vehicle Developments and Policy Design Implications - Nic ...International Council on Clean Transportation

What's hot (20)

Additive Manufacturing Simulation - Design and Process

Additive Manufacturing Simulation - Design and Process

Global Lightweight Vehicle Developments and Policy Design Implications - Nic ...

Global Lightweight Vehicle Developments and Policy Design Implications - Nic ...

Leverage Modern Technology to Build Fuel Efficient Aircrafts

Leverage Modern Technology to Build Fuel Efficient Aircrafts

IRJET - Experimental Investigation of Carbon Fiber Reinforcement T-Stiffe...

IRJET - Experimental Investigation of Carbon Fiber Reinforcement T-Stiffe...

Metal Additive Manufacturing - Basics Zero to One - June 2018b

Metal Additive Manufacturing - Basics Zero to One - June 2018b

Design of automobile front bumper for collision energy Attenuation

Design of automobile front bumper for collision energy Attenuation

IRJET- Modeling & Analysis of a 100CC I.C. Engine Connecting ROD

IRJET- Modeling & Analysis of a 100CC I.C. Engine Connecting ROD

a review performance study of electrochemical machining on metal

a review performance study of electrochemical machining on metal

7th Annual Advancements in Automotive Light-Weighting Summit

7th Annual Advancements in Automotive Light-Weighting Summit

ASSESSING THE REDUCTION OF CARBON DIOXIDE EMISSIONS THROUGH APPLYING HIGH-STR...

ASSESSING THE REDUCTION OF CARBON DIOXIDE EMISSIONS THROUGH APPLYING HIGH-STR...

Selective Laser Melting versus Electron Beam Melting

Selective Laser Melting versus Electron Beam Melting

Vehicle Light Weighting - A Greener, Composite Solution (for Class A Body Pan...

Vehicle Light Weighting - A Greener, Composite Solution (for Class A Body Pan...

A review on Comparison of Aluminium Alloy LM-25 with Al/Sic

A review on Comparison of Aluminium Alloy LM-25 with Al/Sic

IRJET- Analysis of Dimpled Sheet and its Optimization using Taguchi Method

IRJET- Analysis of Dimpled Sheet and its Optimization using Taguchi Method

Viewers also liked

Cranial Implant manufactured with Laser Sintering using EOS Additive Manufacturing in PEEK PlasticCranial Implant manufactured with Laser Sintering using EOS Additive Manufact...

Cranial Implant manufactured with Laser Sintering using EOS Additive Manufact...Machine Tool Systems Inc.

Bell Helicopter makes production grade flight certified hardware via Selective Laser Sintering with EOS Additive ManufacturingBell Helicopter makes production grade flight certified hardware via Selectiv...

Bell Helicopter makes production grade flight certified hardware via Selectiv...Machine Tool Systems Inc.

Viewers also liked (11)

Cranial Implant manufactured with Laser Sintering using EOS Additive Manufact...

Cranial Implant manufactured with Laser Sintering using EOS Additive Manufact...

CastForm PS Plastic - SLS Systems - Material properties (EN)

CastForm PS Plastic - SLS Systems - Material properties (EN)

Bell Helicopter makes production grade flight certified hardware via Selectiv...

Bell Helicopter makes production grade flight certified hardware via Selectiv...

SLS Design Guide for Quickparts 3D printing services (EN)

SLS Design Guide for Quickparts 3D printing services (EN)

selective laser sintering;a rapid prototyping technology

selective laser sintering;a rapid prototyping technology

Similar to EADS Innovation Works Aerospace Brackets - Direct Metal Laser Sintering with EOS of Germany Technology

EOS Model M400 DMLS: The story is about the antenna bracket for the Sentinel satellite and emphasizes the extensive testing and validation process because in the aerospace sector, this comprises up to 80% of the total scope of a project.

Franck Mouriaux, General Manager Structures at RUAG, is very happy with the results and says: ”Additive manufacturing has shown that it can fulfill the fundamental procedural demands of space travel. The multiple design advantages and the characteristics of the component itself have certainly proven this. I see great potential for this technology going forward.“

EOS Model M400 DMLS Client, Ruag Citim, antenna bracket for the Sentinel sate...

EOS Model M400 DMLS Client, Ruag Citim, antenna bracket for the Sentinel sate...Machine Tool Systems Inc.

Airbus Defence Space uses EOS DMLS Additive Process for 3D Printing of Satellite PartsAirbus Defence Space uses EOS DMLS Additive Process for 3D Printing of Satell...

Airbus Defence Space uses EOS DMLS Additive Process for 3D Printing of Satell...Machine Tool Systems Inc.

EOS - Sustainability approach by Design Optimization for Advanced Layer ManufacturingSustainability approach by design optimization for advanced layer manufacturing

Sustainability approach by design optimization for advanced layer manufacturingAlberto Garcia Romera

Advanced Materials International Forum, Bari 18-19 settembre, conferenza internazionale dedicata ai materiali avanzati e alle loro possibili applicazioni nei settori industriali, con un focus particolare sui trasporti (aerospazio, automotive, navale e cantieristico).AMIF2014 – [Aerospazio] Silvio Pappadà, Componenti per elicottero, in materia...![AMIF2014 – [Aerospazio] Silvio Pappadà, Componenti per elicottero, in materia...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![AMIF2014 – [Aerospazio] Silvio Pappadà, Componenti per elicottero, in materia...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

AMIF2014 – [Aerospazio] Silvio Pappadà, Componenti per elicottero, in materia...ARTI-Apulian Regional Agency for Technology and Innovation

Presentation by David Hartman, Senior Technical Staff, Owens Corning at CAMX on October 15, 2014. Advances in reinforcement materials, specifically glass fiber materials, should not go unnoticed. In this presentation discover new advances in glass fiber technology areas, applications to various markets and the needs of those markets, as well as current advances in fiber reinforcement materials and forms.Advances in Reinforcement Materials (Glass Fiber Materials)

Advances in Reinforcement Materials (Glass Fiber Materials)Owens Corning Composites Solution Business

Composite materials are becoming popular in various industries such as aerospace industry, automotive industry, and wind energy. We have seen global surge in the demand of composites particularly carbon fiber reinforced plastic (CFRP) composites, which has led to huge volume of manufacturing and end-of-life waste material. The most common way for disposing of composite waste is through landfills. However, current, and impending legislations such as Directive on Landfill of Waste, have limited the amount of composite waste permitted for landfilling. Also, for making of pristine carbon fiber requires high amount of energy if we compare it to other materials like steel and aluminium. This generates a need to find out a way to recycle and reuse the waste material or the end-of-life material in different sector applications. This study mainly focuses on the strength comparison of pristine(virgin) CFRP with recycled CFRP and conducting finite element analysis on some parts made from virgin and recycled material. Also, details about mechanical recycling, cost estimation for producing virgin material as well as for recycling the material must be taken into account.MECHANICAL RECYCLING OF CFRP ALONG WITH CASE STUDY OF BICYCLE FRAME

MECHANICAL RECYCLING OF CFRP ALONG WITH CASE STUDY OF BICYCLE FRAMEInternational Research Journal of Modernization in Engineering Technology and Science

Paul Fennell (Imperial College London) - Cost comparison of different technologies for industrial CCS - UKCCSRC Cranfield Biannual 21-22 April 2015Paul Fennell (Imperial College London) - Cost comparison of different technol...

Paul Fennell (Imperial College London) - Cost comparison of different technol...UK Carbon Capture and Storage Research Centre

Similar to EADS Innovation Works Aerospace Brackets - Direct Metal Laser Sintering with EOS of Germany Technology (20)

EOS Model M400 DMLS Client, Ruag Citim, antenna bracket for the Sentinel sate...

EOS Model M400 DMLS Client, Ruag Citim, antenna bracket for the Sentinel sate...

Airbus Defence Space uses EOS DMLS Additive Process for 3D Printing of Satell...

Airbus Defence Space uses EOS DMLS Additive Process for 3D Printing of Satell...

Sustainability approach by design optimization for advanced layer manufacturing

Sustainability approach by design optimization for advanced layer manufacturing

Design and Additive Manufacturing Considerations for Liquid Rocket Engine Dev...

Design and Additive Manufacturing Considerations for Liquid Rocket Engine Dev...

AMIF2014 – [Aerospazio] Silvio Pappadà, Componenti per elicottero, in materia...![AMIF2014 – [Aerospazio] Silvio Pappadà, Componenti per elicottero, in materia...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![AMIF2014 – [Aerospazio] Silvio Pappadà, Componenti per elicottero, in materia...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

AMIF2014 – [Aerospazio] Silvio Pappadà, Componenti per elicottero, in materia...

Design and Additive Manufacturing Considerations for Liquid Rocket Engine Dev...

Design and Additive Manufacturing Considerations for Liquid Rocket Engine Dev...

IRJET- Design and Analysis of Composite Top Frame of Hydraulic Valve Test...

IRJET- Design and Analysis of Composite Top Frame of Hydraulic Valve Test...

A Review on Composite Filaments for Fused Deposition Modeling Process

A Review on Composite Filaments for Fused Deposition Modeling Process

Advances in Reinforcement Materials (Glass Fiber Materials)

Advances in Reinforcement Materials (Glass Fiber Materials)

Rotor Blades: The use of composites in rotor blade design

Rotor Blades: The use of composites in rotor blade design

MECHANICAL RECYCLING OF CFRP ALONG WITH CASE STUDY OF BICYCLE FRAME

MECHANICAL RECYCLING OF CFRP ALONG WITH CASE STUDY OF BICYCLE FRAME

Paul Fennell (Imperial College London) - Cost comparison of different technol...

Paul Fennell (Imperial College London) - Cost comparison of different technol...

IRJET- Design and Analysis of Opto Wing of an Aircraft using Ansys Workbench

IRJET- Design and Analysis of Opto Wing of an Aircraft using Ansys Workbench

More from Machine Tool Systems Inc.

Technology Keeps Patient First.

Healthcare providers operate in an evolving

environment influenced by policy, regulations,

and changing technology. Yet, the number one

priority remains patient care.

In a recent survey1, nearly half (49%) of healthcare

provider executives said revamping the patient

experience is one of their organization’s top three

priorities over the next five years.

This focus is helping fuel the rise of point-ofcare

(POC) manufacturing enabled by additive

manufacturing (AM), commonly known as

3D printing.Point of Care - EOS Additive Manufacturing with Selective Laser Sintering - ...

Point of Care - EOS Additive Manufacturing with Selective Laser Sintering - ...Machine Tool Systems Inc.

Ariane Aerospace - Production of an injection head for rocket engines with as few components as possible and lower unit costs. EOS DMLS client. Ariane Aerospace - Production of an injection head for rocket engines using E...

Ariane Aerospace - Production of an injection head for rocket engines using E...Machine Tool Systems Inc.

Amada Machine Tools America - CNC Surface and Profile Grinder - Open House invite of Precision CNC Grinding Technology with On-Board InspectionAmada Machine Tools America - CNC Surface and Profile Grinder - Open House in...

Amada Machine Tools America - CNC Surface and Profile Grinder - Open House in...Machine Tool Systems Inc.

GF Machining Solutions - Agie Charmilles Drill 300 Series - Hole Drilling EDMGF Machining Solutions - Agie Charmilles Drill 300 Series - Hole Drilling EDM

GF Machining Solutions - Agie Charmilles Drill 300 Series - Hole Drilling EDMMachine Tool Systems Inc.

GF Machining Solutions - Agie Charmilles Drill 20 Series - Hole Drilling EDMGF Machining Solutions - Agie Charmilles Drill 20 Series - Hole Drilling EDM

GF Machining Solutions - Agie Charmilles Drill 20 Series - Hole Drilling EDMMachine Tool Systems Inc.

United Grinding - Walter Grinders - CNC Tool Grinder - Top Loader AutomationUnited Grinding - Walter Grinders - CNC Tool Grinder - Top Loader Automation

United Grinding - Walter Grinders - CNC Tool Grinder - Top Loader AutomationMachine Tool Systems Inc.

Plus Medica OT. Design, CAD engineering and production of orthoses that combine several functions, optimally tailored to the needs of the patientEOS P396 SLS user - Plus Medica OT - CAD engineering and production of orthoses

EOS P396 SLS user - Plus Medica OT - CAD engineering and production of orthosesMachine Tool Systems Inc.

Case Study: Topology Optimization & Additive Manufacturing of Actuator Support Fitting

The following is a case study of an aircraft bracket built on an EOS M280 in Aluminum AlSi10Mg optimized with Altair to improve the original design. The geometries used can only be achieved through Additive Manufacturing (AM).

EOS DMLS - Case Study: Topology Optimization & Additive Manufacturing of Actu...

EOS DMLS - Case Study: Topology Optimization & Additive Manufacturing of Actu...Machine Tool Systems Inc.

GF Machining Solutions - Microlution - Perfect Walls and Edges enable new productsGF Machining Solutions - Microlution - Perfect Walls and Edges enable new pro...

GF Machining Solutions - Microlution - Perfect Walls and Edges enable new pro...Machine Tool Systems Inc.

More from Machine Tool Systems Inc. (20)

The Artistry of the Grinding Universe - Invitation 2018

The Artistry of the Grinding Universe - Invitation 2018

Point of Care - EOS Additive Manufacturing with Selective Laser Sintering - ...

Point of Care - EOS Additive Manufacturing with Selective Laser Sintering - ...

United Grinding Universe Event - April 18th - 19th, 2018 - save the date

United Grinding Universe Event - April 18th - 19th, 2018 - save the date

Ariane Aerospace - Production of an injection head for rocket engines using E...

Ariane Aerospace - Production of an injection head for rocket engines using E...

Amada Machine Tools America - CNC Surface and Profile Grinder - Open House in...

Amada Machine Tools America - CNC Surface and Profile Grinder - Open House in...

GF Machining Solutions - Mikron Form P Series Milling Machines

GF Machining Solutions - Mikron Form P Series Milling Machines

GF Machining Solutions - Agie Charmilles Drill 300 Series - Hole Drilling EDM

GF Machining Solutions - Agie Charmilles Drill 300 Series - Hole Drilling EDM

GF Machining Solutions - Agie Charmilles Drill 20 Series - Hole Drilling EDM

GF Machining Solutions - Agie Charmilles Drill 20 Series - Hole Drilling EDM

GF Machining Solutions - Agie Charmilles CUT P Series - Wire EDM

GF Machining Solutions - Agie Charmilles CUT P Series - Wire EDM

GF Machining Solutions - Agie Charmilles CUT E Series - Wire EDM

GF Machining Solutions - Agie Charmilles CUT E Series - Wire EDM

GF Machining Solutions - Agie Charmilles Form P Series - Die Sinking EDM

GF Machining Solutions - Agie Charmilles Form P Series - Die Sinking EDM

GF Machining Solutions - Agie Charmilles Form E Series - Die Sinking EDM

GF Machining Solutions - Agie Charmilles Form E Series - Die Sinking EDM

United Grinding - Walter Grinders - CNC Tool Grinder - Top Loader Automation

United Grinding - Walter Grinders - CNC Tool Grinder - Top Loader Automation

EOS P396 SLS user - Plus Medica OT - CAD engineering and production of orthoses

EOS P396 SLS user - Plus Medica OT - CAD engineering and production of orthoses

EOS DMLS - Case Study: Topology Optimization & Additive Manufacturing of Actu...

EOS DMLS - Case Study: Topology Optimization & Additive Manufacturing of Actu...

GF Machining Solutions - Microlution - Perfect Walls and Edges enable new pro...

GF Machining Solutions - Microlution - Perfect Walls and Edges enable new pro...

Recently uploaded

Recently uploaded (20)

What Are The Drone Anti-jamming Systems Technology?

What Are The Drone Anti-jamming Systems Technology?

Automating Google Workspace (GWS) & more with Apps Script

Automating Google Workspace (GWS) & more with Apps Script

TrustArc Webinar - Stay Ahead of US State Data Privacy Law Developments

TrustArc Webinar - Stay Ahead of US State Data Privacy Law Developments

Mastering MySQL Database Architecture: Deep Dive into MySQL Shell and MySQL R...

Mastering MySQL Database Architecture: Deep Dive into MySQL Shell and MySQL R...

Handwritten Text Recognition for manuscripts and early printed texts

Handwritten Text Recognition for manuscripts and early printed texts

How to Troubleshoot Apps for the Modern Connected Worker

How to Troubleshoot Apps for the Modern Connected Worker

The Role of Taxonomy and Ontology in Semantic Layers - Heather Hedden.pdf

The Role of Taxonomy and Ontology in Semantic Layers - Heather Hedden.pdf

Advantages of Hiring UIUX Design Service Providers for Your Business

Advantages of Hiring UIUX Design Service Providers for Your Business

Strategies for Unlocking Knowledge Management in Microsoft 365 in the Copilot...

Strategies for Unlocking Knowledge Management in Microsoft 365 in the Copilot...

Understanding Discord NSFW Servers A Guide for Responsible Users.pdf

Understanding Discord NSFW Servers A Guide for Responsible Users.pdf

Powerful Google developer tools for immediate impact! (2023-24 C)

Powerful Google developer tools for immediate impact! (2023-24 C)

The Codex of Business Writing Software for Real-World Solutions 2.pptx

The Codex of Business Writing Software for Real-World Solutions 2.pptx

08448380779 Call Girls In Diplomatic Enclave Women Seeking Men

08448380779 Call Girls In Diplomatic Enclave Women Seeking Men

The 7 Things I Know About Cyber Security After 25 Years | April 2024

The 7 Things I Know About Cyber Security After 25 Years | April 2024

Factors to Consider When Choosing Accounts Payable Services Providers.pptx

Factors to Consider When Choosing Accounts Payable Services Providers.pptx

Breaking the Kubernetes Kill Chain: Host Path Mount

Breaking the Kubernetes Kill Chain: Host Path Mount

EADS Innovation Works Aerospace Brackets - Direct Metal Laser Sintering with EOS of Germany Technology

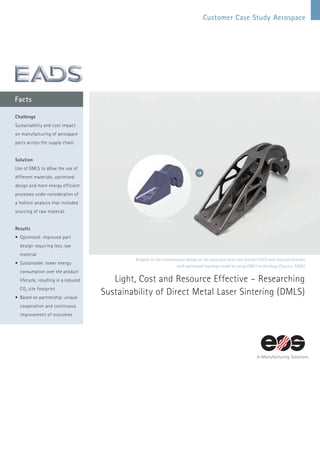

- 1. Customer Case Study Aerospace Facts Challenge Sustainability and cost impact on manufacturing of aerospace parts across the supply chain. Solution Use of DMLS to allow the use of different materials, optimised design and more energy efficient processes under consideration of a holistic analysis that includ d e sourcing of raw material. Results • Optimised: improved part design requiring less raw material • Sustainable: lower energy consumption over the product lifecycle, resulting in a reduced CO 2 site footprint • Based on partnership: unique cooperation and continuous improvement of outcomes Graphic of the conventional design of the assessed steel cast bracket (left) and titanium bracket with optimised topology made by using DMLS technology (Source: EADS) Light, Cost and Resource Effective – Researching Sustainability of Direct Metal Laser Sintering (DMLS)

- 2. Joint EADS Innovation Works (IW) and EOS study demonstrates savings potential for manufacturing in the aerospace industry Over the last 40 years aviation’s challenge has shifted from getting airborne, easily and safely, to Short profile providing a more sustainable and cost-efficient flying experience. Where Daedalus and Icarus used EADS is a global leader in nothing more than feathers and wax to realize the dream of flight, the design and construction aerospace, defence and related of modern aircraft requires highly developed methods and technologies to meet its challenges. services. In 2011, the Group – comprising Airbus, Astrium, EADS IW, EADS’ Research and Technology organisation, is always investigating new ways for Cassidian and Eurocopter – improving manufacturing processes. One of the most recent target areas in this field is the use of generated revenues of € 49.1 Direct Metal Laser Sintering (DMLS), a technology that has been used by EADS IW to research the billion and employed a benefits of optimised design and general production sustainability, by using DMLS to manufacture workforce of over 133,000. demonstrators of aerospace parts, including an Airbus nacelle hinge bracket. Address EADS Innovation Works Challenge created a lifecycle cooperation solutions, EADS IW defined new Building 20A1 Set forth in the EADS vision 2020 in order to gain a better under- Technology Readiness Level (TRL) Golf Course Lane is the group‘s desire to be geared- standing of particular industry criteria focusing on sustainability. Filton, Bristol BS34 7QQ (UK) up for the challenges of the 21st requirements and get an overview Indeed, aerospace Research and century. With the challenge of the of the EOS technology’s perfor- Technology (RT) at EADS must environment being a key driver, mance in the areas of quality, pass nine TRL processes before a sustainability and a reduction in sustainability and environmental technology can be qualified for costs of the group’s manufacturing criteria. use in production. For each TRL review, a technology‘s level of operations and operational phase of its products underlies the As quality, costs and environ maturity is evaluated in terms of group’s research. EADS IW as a mental effects play a major role performance, engineering, manu- customer and EOS as a technology in the decision-making process facturing, operational readiness, supplier for DMLS solutions for design and manufacturing as well as value and risk. For each of these criteria, new components must out-perform existing ones. The results were expected to show reduced CO 2 emissions and higher energy and raw material efficiency as well as optimised recycling. When analysing energy consumption, the company‘s investigation must include not Further example of improved part design: prototype of a topology optimised Airbus A380 bracket made of stainless steel powder produced via DMLS with conventional bracket behind (Source: EADS). only the production phase, but also aspects such as the sourcing and transportation of raw materials, argon consumption for the atomization process of the metal powder material, and the overall

- 3. waste produced during the operational phase) of the the engine cowling hinge allowed Part of the project‘s success was atomization process. brackets was lowered by almost EADS and EOS to demonstrate due to their continued striving 40 % , despite the fact that the potential to reduce weight per towards further improvements, Solution during the manufacturing phase plane by approximately 10 kg – evidenced in the swapping of A Streamline Life Cycle Assess- the EOS technology uses signifi- a noteworthy figure in aviation the EOSINT M 270 for an EOSINT ment (SLCA) performed by EADS cantly more energy. where every kilo counts. CO 2 M 280 using titanium instead emissions of the door hinges were of steel, which led to additional IW highlighted, amongst other things, the potential cost and In the next step, these ‘static reduced by almost 40 % over CO 2 savings. DMLS has the poten- sustainability benefits of DMLS phases’ were evaluated. The the whole lifecycle by optimising tial to help make future aircraft technology during the opera iot manufacturing process of one the design, and consumption lighter, leading to savings in nal phase in the re-design of part was compared for the EADS of raw materials was reduced by resources which help to meet Airbus A320 nacelle hinge brack- application in titanium with 25 % compared to rapid invest- sustainability goals without com- ets. EADS IW’s data was backed- optimised design, built with rapid ment casting. promising on safety.” up by test results from EOS, investment casting and on an and in an additional step, by test EOS platform. The energy con- “DMLS has demonstrated a results from a raw material sump ion for the production of t number of benefits, as it can (powder) supplier – a truly unique the bracket, including raw mate - support the optimisation of “We see several advantages in approach. Together the compa- rial production, manufacturing design and enable subsequent the use of DMLS, mainly con- nies enriched the lifecycle infor- process and end-of-life is slightly manufacture in low volume cerning freedom of design and mation: the new brackets were to smaller when moving from rapid production. In general, the joint ecological aspects. We can opti- be lighter in order to significantly investment casting to the EOS study revealed that DMLS has the mize structures and integrate reduce energy consumption over platform. The advantage of the potential to build light, sustain dedicated functionality and their lifetime. EOS technology: the process able parts with due regard for the DMLS can significantly reduce itself uses only the material that company’s CO 2 footprint,” says sites’ CO 2 footprints as our In the first step, cast steel nacelle is really needed to build the appli- Jon Meyer at EADS IW. “A key study with EOS demonstrated.” hinge brackets were compared cation. Thus the consumption driver of the study was the inte- to an additively manufactured of raw material can be reduced grated and transparent coopera- “Considering ecology and de- by up to 75 % . tion between customer and sign taken together, optimised supplier with an open approach structures can also result in Results that saw an unprecedented level reduced CO 2 emissions due to It is important to note that this of information sharing. This weight reduction. study focused on a one-part transparent collaboration has set I see tremendous potential in comparison between the DMLS the standard for future studies DMLS technology for future and a rapid investment casting involving the introduction and aircraft generations, when it manufacturing process and that adoption of new technologies and comes to both development and manufacturing. (AM) one with optimised titanium design by measuring the energy consumption over the whole lifecycle. The technology turned out to be a good fit for the design optimization of the nacelle hinge brackets as for this application the operational phase is typically the question of scalability is yet processes. Even after the first the static phases (e.g. manufac- to be addressed. However, by positive results were evident, turing of the part). By using the working together with partners neither of the parties settled for Jon Meyer, over the whole lifecycle the the outcome, but continued to ALM Research Team Leader study produced some impressive investigate options for further at EADS Innovation Works upshots: the optimised design of improvement.” 100 times more important than optimised design, energy consumption over the whole lifecycle (including manufacturing and

- 4. EOS GmbH Electro Optical Systems Corporate Headquarters Robert-Stirling-Ring 1 82152 Krailling/Munich Germany Phone +49 89 893 36-0 Fax +49 89 893 36-285 Further EOS Offices EOS France Phone +33 437 49 76 76 EOS India Phone +91 44 28 15 87 94 EOS Italy Phone +39 02 33 40 16 59 EOS Korea Phone +82 32 552 82 31 EOS Nordic Baltic Phone +46 31 760 46 40 EOS of North America Phone +1 248 306 01 43 EOS Singapore Phone +65 6430 05 50 EOS Greater China Phone +86 21 602307 00 EOS UK Phone +44 1926 62 31 07 www.eos.info • info@eos.info Think the impossible. You can get it. Status 7/2013. Technical data subject to change without notice. EOS is certified according to ISO 9001.