The Design Process

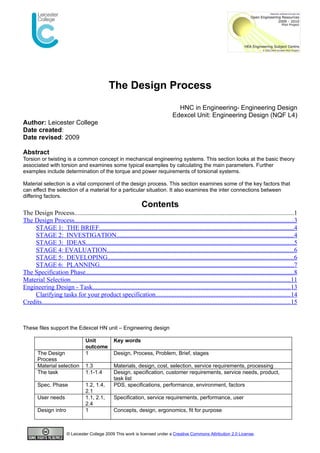

- 1. The Design Process HNC in Engineering- Engineering Design Edexcel Unit: Engineering Design (NQF L4) Author: Leicester College Date created: Date revised: 2009 Abstract Torsion or twisting is a common concept in mechanical engineering systems. This section looks at the basic theory associated with torsion and examines some typical examples by calculating the main parameters. Further examples include determination of the torque and power requirements of torsional systems. Material selection is a vital component of the design process. This section examines some of the key factors that can effect the selection of a material for a particular situation. It also examines the inter connections between differing factors. Contents The Design Process........................................................................................................................................1 The Design Process........................................................................................................................................3 STAGE 1: THE BRIEF........................................................................................................................4 STAGE 2: INVESTIGATION..............................................................................................................4 STAGE 3: IDEAS.................................................................................................................................5 STAGE 4: EVALUATION...................................................................................................................6 STAGE 5: DEVELOPING...................................................................................................................6 STAGE 6: PLANNING........................................................................................................................7 The Specification Phase.................................................................................................................................8 Material Selection........................................................................................................................................11 Engineering Design - Task..........................................................................................................................13 Clarifying tasks for your product specification...................................................................................14 Credits..........................................................................................................................................................15 These files support the Edexcel HN unit – Engineering design Unit Key words outcome The Design 1 Design, Process, Problem, Brief, stages Process Material selection 1.3 Materials, design, cost, selection, service requirements, processing The task 1.1-1.4 Design, specification, customer requirements, service needs, product, task list Spec. Phase 1.2, 1.4, PDS, specifications, performance, environment, factors 2.1 User needs 1.1, 2.1, Specification, service requirements, performance, user 2.4 Design intro 1 Concepts, design, ergonomics, fit for purpose © Leicester College 2009 This work is licensed under a Creative Commons Attribution 2.0 License.

- 2. The Design Process (Engineering Design NQF L4) For further information regarding unit outcomes go to Edexcel.org.uk/ HN/ Engineering / Specifications Page 2 of 15

- 3. The Design Process (Engineering Design NQF L4) The Design Process BRIEF • Recognition of problem • Identification of needs • Recognition of situation INVESTIGATION • Research in topic • Collation of relevant information • Analysis of topic • Specification of requirements IDEAS • Generation of realistic ideas to satisfy design brief EVALUATION • Evaluation of ideas against the specification • Identification of proposed solution DEVELOPING • Sketching, modelling refining proposed solutions PLANNING • Drawings from which the product can be realised • Parts list, planning sheets for realisation Page 3 of 15

- 4. The Design Process (Engineering Design NQF L4) STAGE 1: THE BRIEF Where do you begin when you write a design brief? In some cases you might begin by recognising the problem, for example to automate the assembly of a P.C.B. Another starting point might be seeing the need to improve something, like the instructions for fitting a burglar alarm. A third starting point might be recognising an area where something is not working well, for example a factory layout. In this case you might have to do some research to find the real need. From these differing standpoints you will need to write a design brief. STAGE 2: INVESTIGATION Investigation leads to a clearer understanding of the limits of the design problem. First of all you should read and understand the key words of the design brief. For example take an simple domestic example: ‘Design a storage unit for kitchen roll cling film and aluminium foil, which will take up a visible position and will dispense the material easily’ The key points are storage, the three rolls, dispensing ability and appearance. These give a useful starting point for your design. Having analysed the brief you then need to research into the problems. For example there may be products available that with modification would be a possible solution, or a least a starting point. Through this process you will be able to decide on exact limits and constraints, this is called a SPECIFICATION A simple way of seeing if you have created a good specification is to check whether key factors are covered. These may not all be appropriate to any one problem, but having checked them at least you will know the point has been considered, for example: SIZE FUNCTION APPEARANCE STORAGE COST SAFETY ENVIRONMENT MATERIALS SHAPE ERGONOMICS RELIABILITY FINISH MAINTENANCE Other factors ? The order and priority will change according to the design problem. For example, the design of a ‘pop- up’ book would place a low priority to safety, where as a piece of electrical equipment or industrial machine tool would give a high priority to safety. The design factors will often result in a series of conflicting points being raised. However, balancing these point is the essence of good design and it is now that you move on to the third stage of creating ideas. Page 4 of 15

- 5. The Design Process (Engineering Design NQF L4) STAGE 3: IDEAS Generating ideas, which solve the problem, is the most creative area of the whole designing activity. Ideas can be generated through thinking and sketching. At this stage you might want to draw complete artefacts of components very precisely. This is a mistake, as it tends to create rigid, isolated ideas. It is far better to make quick sketches of outlines and rough form that can easily be modified. Different problems lead to differing approaches. For example, if you are designing a car jack, the functional operation will be a key part of the design. However, if you a designing a piece of jewellery, the starting point may be shapes and forms. The sketches should be a means of thinking on paper. With complex problems, ideas may be created for parts of the problem. There are several ways of working at generating of ideas and different methods can be used, depending on the problem. The following may be helpful: Observation and adaptation: Look at existing solution to similar problems, and from these you can usually develop ideas, consider how this can be adapted. Remember that design is about solving problems in the best form, rather than always creating original ideas. Ideas from drawings: The creation of ideas from drawings is particularly useful for work in creating the shape and forms of a product. These visual investigations are a very effective way of creating ideas. Brainstorming: This is usually a group activity where everyone thinks of ideas to solve the problem. The ideas are shared, which often stimulates further ideas. Checklist: The use of a checklist can provide more starting points to stimulate ideas. A work or a phrase in a checklist can help you think about the problem from another viewpoint. The checklist may be as shown in ‘Stage 2: Investigation’ or in the form of questions: What is the purpose of what I am trying to design? Who may use it? Where is it going to be used? Can it be modified? What is the important part of the design? Page 5 of 15

- 6. The Design Process (Engineering Design NQF L4) STAGE 4: EVALUATION The evaluation of ideas is a critical phase because it is at this stage that the proposed solution is first identified. It is wise to look carefully at all the ideas, but you need to be clear of what you are looking for when you are choosing an idea to develop. These points my be helpful: 1. Does the idea meet the brief you started with? 2. If not does it satisfy the need better? 3. Does it meet the specification? 4. Is it possible for the proposed solution to be made with the resources of time, materials and equipment available? 5. Is it financially viable? In your design work it is wise to write down your reasons for making choices. At the end of a project or assignment you can explain why you chose a particular design. STAGE 5: DEVELOPING Developing and refining the proposed solution is the stage when you convert the idea into reality. Some times at this stage models or C.A.D. are used to help develop and refining a proposal. At this stage, a number of factors are likely to arise and you will be required to make a decision. Materials Materials provide a major constraint. First, you must know how you wish the various parts of your solution to behave. You can then begin to identify an appropriate material for each part. Properties of materials, which you might consider, are: WEIGHT STRENGTH TOUGHNESS HARDNESS FLEXIBILITY FEEL CONDUCTIVITY COLOUR Other factors RESISTANCE TO HEAT/CORROSION Having identified the properties of the material, you should then consider its availability. This will depend on both the material (e.g. acrylic, lo carbon steel), and also its form (e.g. sheet tube or bar etc.). When you specify the form you should give accurate sizes. In choosing materials you should also consider cost. For example the cost of precious metals or specialist electronics components might lead you to reconsider. Size and shape These key points will greatly influence your final design. You may need to consider how your proposed solution will come into contact with people. This will affect sizes, ranging from printed letters that can be easily read, to the height of a table or the shape and position of a lever. Page 6 of 15

- 7. The Design Process (Engineering Design NQF L4) The study of how objects, systems, and the environment can be designed to fit in with people is called ERGONOMICS. This is important when deciding such things as the height of a computer screen, or the smallest size for control knob or button. In order to design solutions that fit in with people, you will need to know human measurements. This is called ANTHROPOMETRIC data. It is also important to consider how your proposed solution will look in its environment. When designing your solution you will therefore need to consider its overall size in relation to other objects. Appearance A highly functional product, which looks awful, is unlikely to sell, as is an attractive product, which does not function. The visual qualities, which contribute to the overall ‘look’ of a product, are called aesthetics. Aesthetics values vary with different cultures, and fashion and styles change. Safety When developing any product, it is important that safety is considered throughout. Will the operating environment present any safety problems? Could your product be mis-used? Is there any British standards or international standards, which are relevant? Appropriate safety standards must be applied to the design. STAGE 6: PLANNING Once the developing and refining of the proposed solution is completed, it is necessary to communicate your design. This is done in two parts. The first is concerned with the creation of technical or production drawings. These drawings are normally of a formal nature, often in orthographic projection. They should show each part and its dimensions, and an assembly drawing can show how all the parts fit together. As well as drawings there may also be a need to provide a parts list. This lists all the materials/electronic components used and their details (e.g. sizes type etc.) You will also need to plan manufacture and the processes selected should reflect the quantity required and the chosen materials. Page 7 of 15

- 8. The Design Process (Engineering Design NQF L4) The Specification Phase Product Design Specification (PDS) It is a dynamic, evolutionary and comprehensively written document that can be subject to change. It specifies what you want but not how to do it. It must be comprehensive and unambiguous. Poor PDS’s lead to poor designs. Good PDS’s do not guarantee the best designs but make the goal more achievable. The elements of a PDS are applicable to all products irrespective of technology. It sets the design in context, representing a comprehensive set of constraints. Performance: Must be fully defined, establishing objectives that can be achieved. How fast, how slow, how often, work rate, etc. Environment: Temperature range (humidity), pressure, shock loading, dirty/dusty, corrosive, noise levels, insects, vibration, etc. Changes may occur to the environment during the manufacturing stages, for example: During manufacture – exposure to fluids, solvents, fluxes, etc. During assembly – assembly forces, contamination from human contact, etc. Also during storage, packaging, transportation, display, etc. Life in service: Is the service life to be long or short? These (Performance) criteria should be specified as part of the PDS. How is product life assessed? (one day, one week, one year, etc). Maintenance Regular maintenance desirable/available. Specify the ease of access to parts that are likely to require maintenance. Target product Established from the outset, checked against cost: existing or ‘like’ products. Competition: Requires a thorough analysis of the competition, such as literature searches, patents, product literature, etc. Shipping: How is the product to be delivered (land, air, sea - at home or abroad). What type of truck or pallet container? The effects of assembly breakdown of the product. Page 8 of 15

- 9. The Design Process (Engineering Design NQF L4) Packing: Necessary for transport, storage, etc. Should the packaging protect against the environmental effects of shipping, such as salt water, corrosion, shock loading, etc. Quantity: Likely numbers, this will affect all aspects of the products design. For example, a ‘one-off’ requires relatively little tooling in comparison to larger quantities. Manufacturing Designing to utilise an existing plant. facility: Is the plant/machinery involved a constraint to the design? Make in or buy out policy? Size: Are there any restrictions on the size of the product such as shipping and maintenance, etc. Weight: Weight = cost (shipping?) Should the design be modular? Aesthetics: Colour, shape, form and texture considered from Appearance: the outset (marketing options). Finish: Materials: Considered choice which will also include legal restraints (e.g. with the use of lead). Product life Is the life span a marketable entity? span: It affects tooling policy and manufacturing facilities. Product life spans are reducing rapidly. Standards: Must be designed to comply with current and Specifications: relevant International/British standards. Should these be specified? Ergonomics: The nature of interaction between man and product, for example height, shape, force, etc. Operational torques must be acceptable to the user. Customer: Knowledge of the customer likes, dislikes, prejudices, misconceptions are all essential to the success of the product. Quality and Reference should be made to the quality standard/ reliability: mark that the product is made to (e.g. ISO9001). Shelf life: Combating decay, for example: rusty gearboxes, Storage: perished rubber components, seized bearings, general corrosion and contamination, etc. Processes: If special processes are required during the Page 9 of 15

- 10. The Design Process (Engineering Design NQF L4) manufacture of the product, they must be defined. Time scales: Time scale for the project as a whole (leader times) must be adequate to ensure that product is designed effectively. Testing: Whether it is decided to test is 1 in 10, 1 in 100 or what ever is considered suitable, the initial test specification must be written at an early stage. Safety: All safety aspects are considered. This includes complying with current legislation and standards. Labelling of the product. Definitive operating instructions. Company Current company practice and manufacturing constraints: facility constraints. This also includes financial and investment constraints, adequate in house facilities for research. Design development testing, quality of personnel. Market Market feedback, are certain components constraints: acceptable in different countries (e.g. the middle East will not use Ford engines). Patents, All areas of useful information should be literature and investigated. product data: Any possibility of patent clashing should be known. Political and What is the likely effect of the product on the social social and political structure of the market or country for implication: which it is designed. Consider the stability of the market. Legal: Consider the legal aspects of the design, for example: EEC product liability legislation, etc. Documentation Instruction for use, maintenance, servicing, etc, : must be completed and comprehensive. Installation: Does the product interface with other products or is it to be assembled onto a larger product (e.g. a building), with considerations being given to fixing holes, lugs, access, system compatibility, power compatibility, etc. Disposal: The effects of disposal on the environment (biodegradable plastics, hazardous/toxic parts, batteries, mercury, lead, etc. Page 10 of 15

- 11. The Design Process (Engineering Design NQF L4) Material Selection When selecting a material for an engineered product or component a range of factors should be taken into account. Broadly speaking these factors can be divided into three factors which are; • Cost • Processing / manufacturing requirements • Service conditions These factors are broken down into categories below but it should be born in mind that each factor cannot be taken in isolation as there are influences and knock on effects for each. The designer is now blessed with an ever-increasing array of materials from which to choose, this however increases the difficulty in deciding which offers the greatest number of advantages for a particular component. The factors listed below is an attempt to provide a concise list of properties which need to be considered when making a choice of suitable materials. The following points need to reviewed: COST ECONOMIC Material costs can be equated against mass volume or strength. Process costs ie. casting, extrusion etc. Working costs ie. forging, pressing etc. Machining costs. Jointing costs. Finishing costs. Availability Quantity required Selling price target SERVICE REQUIREMENTS MECHANICAL Properties such as: Density. Modulus and Damping. Yield strength. Tensile strength. Fatigue strength. Fracture toughness. Hardness. Thermal fatigue resistance. Creep resistance. NON-MECHANICAL Thermal properties. Electrical properties. Magnetic properties. Optical properties SURFACE Properties which affect: Oxidation & Corrosion. Page 11 of 15

- 12. The Design Process (Engineering Design NQF L4) Friction. Abrasion. Wear. PROCESSING PRODUCTION Considerations which will effect the fabrication of the Component: Ductility. Malleability. Castibilty. Machinability. Ease of joining. Heat treatment response. OTHER FACTORS AESTHETICS Qualities: Appearance. Stability. Texture. etc ERGONOMICS Operation Anthropometrics Human / machine interface TIME Factors: Availability. Time taken to fabricate. COST PROCS SERVICE REQS It is important to bear in mind that none of these factors can be taken in isolation. They effect each other and are affected by each other. The final result is nearly always a compromise of conflicting factors. In some cases one particular feature may, however, be predominant – for example safety in certain components for the aircraft or nuclear industries. Page 12 of 15

- 13. The Design Process (Engineering Design NQF L4) Engineering Design - Task © smaedli 2009. Sourced from http://www.flickr.com/photos/smaedli/3790624515/sizes/s/ available for download under a Creative Commons license. Produce a product specification Your company intends to produce a steam iron which is able to use normal tap water to fill the reservoir without incurring fouling, scaling or discolouration. The power rating of the iron should not exceed 1.8kW and the iron should be light and capable of easy handling by both right and left handed users. You are required to; • Research the product and list 10 most important design features of a steam iron. • Produce a design specification which includes at least 6 categories with 6 elements in each. These must not be constraining. • Justify your selection for each of the elements. • Produce at least two preliminary design solutions in the form of a concept sketch with accompanying explanatory notes for each possible solution. Page 13 of 15

- 14. The Design Process (Engineering Design NQF L4) Clarifying tasks for your product specification In order to develop your design brief and specification you need to identify what the end user’s needs are; • What is the need or problem I can Solve? • Who are the potential user(s) /my target market group? • How can I solve the need/problem? • What might the intended product be? • Where will the product be used? • How will it be used? • What benefits will it bring to users? • Does it have to conform to a standard size? • What about aesthetics? • Does it need to fit any regulations such as for safety or quality? • How should the product perform? • What kinds of materials and processes can I use? • What is the potential price range? • Is it something that I can design and make? What sources will you use in order to find this information out ? Internet / Surveys / Questionnaires / Catalogues ????? Page 14 of 15

- 15. The Design Process (Engineering Design NQF L4) Credits This resource was created Leicester College and released as an open educational resource through the Open Engineering Resources project of the Higher Education Academy Engineering Subject Centre. The Open Engineering Resources project was funded by HEFCE and part of the JISC/HE Academy UKOER programme. © 2009 Leicester College This work is licensed under a Creative Commons Attribution 2.0 License. The JISC logo is licensed under the terms of the Creative Commons Attribution-Non-Commercial-No Derivative Works 2.0 UK: England & Wales Licence. All reproductions must comply with the terms of that licence. The HEA logo is owned by the Higher Education Academy Limited may be freely distributed and copied for educational purposes only, provided that appropriate acknowledgement is given to the Higher Education Academy as the copyright holder and original publisher. The Leicester College name and logo is owned by the College and should not be produced without the express permission of the College. Page 15 of 15