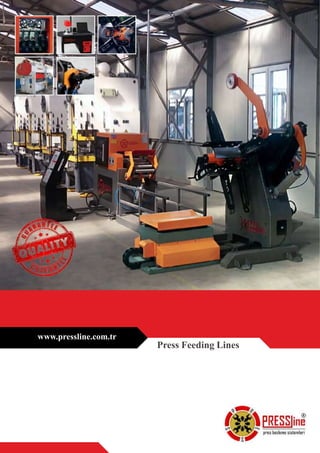

Press Feeding Lines Manufacturer

- 2. About Us Ozay Kalip and Machine Tools Co. Ltd. Was Established and began to manufacture in Istanbul, 2012. The Company produces under the Brand name of Pressline. Pressline in a short time has been become the leader national firm in its field through respecting the Customer Satisfaction, using quality labor and materials without compromising ethics commercial understanding. Pressline works for 100% customer satisfaction with its experienced engineering and technical team and RE&DE Department in respect of quality. Pressline has been exporting their machines that manufactured with CE certificate all over the World. Pressline is aware of its responsibilities arising from being a leader national firm and it promise its valuable customers that it shall continue to serve in same understanding. Vision Our Competitor is ourselves This is our principal and main Value that have already been phased out by using up for sale, after-sales support delivery to continuously improving ourselves in every product and service. Mission Giving the Highest standards quality of the products and Services During the time that keeping the Customers, Employees and distributors Satisfaction at the optimum levels without risking honesty, reliability, and good prices. Making difference and add value to the industry, environment and the National Economy by increasing continuously our export rate and Range. Following technological developments in hydraulic press manufacturing in the world, to upgrade product range and perpetuate performance of productivity improvement by speeding up research development work; being able to respond our Customers special demands in a shorter time, and presenting new technologies and Knowhow to our sector.

- 3. Our Services Pressline feeding systems are especially designed to drive plate metal sheets sensitively and quickly by servo control, using our machines will enable our customers to : Minimize the working hours. Maximize both the productivity and profitability. Minimize the labor cost. Minimize the error rate. Our machines can be used in all the Metal related industries and showed great success especially in many sectors with Using our manufactured Moulds. Sectors Our range of moulds, Decoilers, Feeders, Straighteners and Compact systems offers superior support for the storing and Decoration Sector industry, the Household Appliances industry, In The Construction Field and similar Industries. Providing an array of equipment solutions and tailored packages, Pressline can assist your business in machine selection, comprehensive finance offerings, service support and parts requirements. It doesn’t matter if you’re a one-man-show, or a larger business, you will get the same great service from the staff at Pressline.. Storing and Decoration Sector Wrounght iron (Fer Forge) Storage shelves Metal Furniture Metal acccesori es for furnitue Exhibitings stands Household Appliances Sector Hinges and accessories Any kinds of metal spare parts Metal slides for household appliances The Construction Field Steel scaffoldings. Shoring facades Base beams Form work parts Metallic cable trays.

- 4. PRODUCT INDEX Mechanical Decoiler Conical Mandrel Decoiler Hydraulic Decoiler Servo Feeder Plate Servo Feeder Mini Straightener Servo Feeder Intelligent Straightener Servo Feeder Advanced Straightener Servo Feeder Compact Lines Wire Flattening and Winding Lines Cut to Lenght Lines Coil Slitting Lines Special Mould Systems Eccentric Presses Lazer Cutting and Marking Machines Press Brake & Shears Tube Punching Machines Automation Systems and Brands 4-5 6-7 8-9 10-11 12-13 14 15 16-17 18 19 20-21 22 23 24-25 26-27 28-29 30 31

- 6. 4 www.pressline.com.tr Schneider PLC and HMI (7” veya 10”) Schneider inverter. High Quality AC Motor IE2/IE3 PMD Series 500 kg - 4.000 kg Coil Capacity 30 mm - 600 mm Coil Width Speed Control Bi-Directional Design Upper - Lower Press Support Arm Spesification Max 4.000 kg Coil Capacity Dynamic main body Different work type models (motor, brake) Pneumatic upper / lower support arm Mechanical Decoiler * P LC & HMI are used with feeder systems. For High Speed models please contact to Pressline.

- 7. 5www.pressline.com.tr Mechanical Decoiler Working System Pressline produces different Mechanic Decoiler Models with capacities ranging from 500 kg up to 4.000 kg. After loading the metal coils, you can easily adjust tightening of coil by external arm with special mandrel tightening system. Upper press support arm and both side support arms provide decoiling without losing central angle. Standart decoilers use loop sensor for movement. You can fix decoiler to land with four legs. If you need speed and time we advise low cost coil cars. Coil cars move forward-backward, up and down with hydraulic system. Mechanical Decoiler

- 8. 6 www.pressline.com.tr Schneider PLC and HMI (7” veya 10”) Schneider inverter High quality AC motor IE2/IE3 PCD Series 4.000 kg Coil Capacity 80 mm - 1000 mm Coil Width capacity Speed Control Bi-directional Design Upper/Lower Press Support Arm Specification 4.000 kg coil capacity Bi-directional design Dynamic main body Differ work type models (motor, brake) Conical Mandrel Decoilers * PLC & HMI are using with feeder systems. For High Speed models please contact to Pressline.

- 9. 7www.pressline.com.tr Conical Mandrel Decoiler Working Systems Pressline produces different Conical Decoiler Models with capacities ranging from 500 kg up to 4.000 kg. After loading the metal coils, you can easily adjust tightening of coil by external arm with special mandrel tightening system. Upper press support arm and both side support arms provide decoiling without losing central angle. Standart decoilers use loop sensor for movement.You can fix decoiler to land with four legs. If you need speed and time we advise low cost coil cars. Coil cars move forward-backward, up and down with hydraulic system. Conical Mandrel Decoiler

- 10. 8 www.pressline.com.tr Schneider PLC and HMI (7” veya 10”) Schneider inverter High quality AC motor IE2/IE3 PHD Series 6.000 kg - 30.000 kg Coil Loading Capacity 80 mm - 2000 mm Metal Sheet Width Speed Control Bi-Directional Design Upper / Lower Press Support Arm Specification 6.000 kg - 30.000 kg coil loading capacity Automatic coil tightening system High quality hydraulic unit Hydraulic Decoiler * PLC & HMI are using with feeder systems. For High Speed models please contact to Pressline.

- 11. 9www.pressline.com.tr Hydraulic Decoiler Working System Hydraulic decoilers have some differ specification when you compare with mechanical decoilers. Hydraulic Decoilers tightening system is working automatically. Also its coil capacity is highest than mechanical decoilers. Hydraulic Decoiler’s upper press support arm is standart. Hydraulic Decoiler

- 12. 10 www.pressline.com.tr Mini Servo Feeders Schneider PLC and HMI (7” or 10”) Schneider high speed servo motor High quality servo reducer. Specification Direct connection to presses 10 mm - 600 mm strip width 0.2 mm - 2 mm strip thickness * Note : If you have differ size strip please contact to Pressline for identifying special design. PFM Series 10 mm - 600 mm Strip Feeding Capacity 0,2 mm - 2 mm Strip Width High Speed Servo Motor We produce different models of roll metal strip servo driver without case, operation iron strip having width Ranging from 10 mm up to 600 mm, and the thickness of the iron strip is between 0.2 and 2 mm. The device is produced to drive metal strip opened from coil sensitively and quickly by servo control.

- 13. 11www.pressline.com.tr Advance Servo Feeder We produce feeders with case operate at metal sheet width between 35 mm and 1600 mm and iron sheet thickness between 0.4 mm up to 3 mm The device is produced to drive metal sheet opened from coil sensitively and quickly by high speed servo control. Schneider PLC & HMI (7” , 10”) High speed servo motor High quality servo reducer Specifications Up to 2000 mm sheet widht. 0.4 mm - 4 mm sheet thickness. * Note : If you have differ size strip please contact to Pressline for identifying special design. PFA Series Up to 2000 mm Sheet Width 0,4 mm - 4 mm Sheet Tickness High Quality Rollers

- 14. 12 www.pressline.com.tr Plate Sheet Feeders Schneider PLC & HMI (7” or 10”) Schneider servo motor High quality servo reducer Specifications 300 mm & 1600 mm sheet widht. 0,4 mm - 3 mm sheet thickness. * Note : if you have different strip size please contact Pressline for determine right roller and new design. PPF Series 300 mm - 1600 mm Plate Sheet Width 0,4 mm - 3 mm Plate Sheet Thickness High Speed Servo Motor

- 15. 13www.pressline.com.tr Plate Strip Feeders Plate strips feeder’s system has 2 part. Feeder & Puller. Two machines and press sync with each other. Mini plate strip servo feeders are eaisly mounted on the presses and save space. Plate strip feeders also have two differ series. One of them is mini another is advanced.Mini series can be fixed on the press both sides easily and it is used with thin and narrow strips. Advanced series is used with wide and thick strips. PPF Mini Series 10 mm - 600 mm Strip Feeding Capacity 0,2 mm - 2 mm Strip Width High Speed Servo Motor Schneider PLC & HMI (7” or 10”) Schneider servo motor High quality servo reducer Specifications 10 mm & 600 mm sheet widht. 0,2 mm - 2 mm sheet thickness. * Note : if you have different strip size please contact Pressline for determine right roller and new design.

- 16. 14 www.pressline.com.tr Mini Straightener Feeder Our simple straightener without case operates at metal strip width varying between 10 mm - 300 mm and thickness between 0,2 mm - 2 mm. Schneider PLC & HMI Recipe & Memory High speed servo motor Specifications High quality rollers Easy installation Long life mechanical equipments * Note : if you have different strip size please contact Pressline for determine right roller and new design. PSM Series 10 mm - 600 mm Strip Width 0,2 mm - 2 mm Strip Thickness High Speed

- 17. 15www.pressline.com.tr Intelligent Straightener Servo Feeder What is intelligent straightening servo feeder and how it works? PSI intelligent straightening servo feeder is a system that is fully innovated by Pressline, it works using PIT technology and it facilitates using different metal thicknesses, the straightening option can be adjusted independently from the main operator. This operation can be full automatic or half automatic. The advantages of intelligent straightening servo feeder; 1- Saving the straightening operational time. 2- No need to connected to a special operator. 3- All the straightening options will be saved on the system’s options so this will save labor, time and energy. 4- The production capacity and quality will be enhanced, as the straightening options can be adjusted to the best level. 5- It maximizes the production life of the machine. PSI Series Up to 2000 mm Sheet Width Up to 6 mm Sheet Thickness High Speed Mold Height Adjustment

- 18. 16 www.pressline.com.tr Advance Straightener Servo Feeder Schneider PLC and HMI (7” or 10”) Recipe and memory system High speed servo motor Specifications High quality rollers Long life mechanical system * Note : if you have different sheet size please contact Pressline for determine right roller and new design. PSA Serisi Up to 2000 mm Sheet Width Up to 6 mm Sheet Thickness Speed Control Mold Height Adjustment

- 19. 17www.pressline.com.tr Straightener Servo Feeders Working Type Straightener Servo Feeders have wide range models. Selection of model design starts after sheet or strip thickness and width selection we prepare infrastructure of sytem after selected material thickness and width range. After this we choose servo motor and another electronic design belongs to press’s rpm, feeding size and line speed. Advance Straightener Servo Feeder

- 20. 18 www.pressline.com.tr Compact Systems PCL Series Up to 1600 mm Sheet Width Up to 6 mm Sheet Thickness Speed Control Compact products are designed to be a solution for area problem in workshops and plants. In case of working in narrow areas, also when the production space has high cost Compact products are preferred. Another important advantages of compact systems is it that they shorten the set period. Our compact lines consists of three main groups; 1) Opening - straightening line, 2) Straightening - feeding lines, 3) Opening - straightening and feeding lines, These three groups to be designed according to the width, thickness and weight of the coils. Specifications Schneider PLC and HMI (7” or 10”) Adjustable structure Electronic Handwheel. * If you have differ size sheets please contact Pressline for determine right roller and new design.

- 21. 19www.pressline.com.tr Wire Flattening and Winding Lines PFW Series Wire flatting machines are used for espagnolette lama and special lama which used at ovens cooker parts. Wire winding machines used to recoiling of lamas. * If you have differ size sheets please contact Pressline for determine right roller and new design.

- 22. 20 www.pressline.com.tr Cut to Length Lines PCT Series Up to 2000 mm Sheet Width Up to 12 mm Sheet Thickness High Speed Specifications High speed servo systems Motion controlled shear systems Friendly HMI interface High accuracy ratio Long life shears * If you have different sheet size please contact Pressline for determine right roller and new design.

- 23. 21www.pressline.com.tr Cut to Length Lines The Cut to length lines to be designed according to the customers requirements and the requested material characteristics (Width, Thickness, Speed), in addition to the options of having stacking system or conveyor, Also according to the same characteristics the shear to be chosen (Standard – Flying shear – Rotating shear). Cut the length lines and special sheet process in lines are specially designed lines for each company according to their demands.They show variety of width thickness and material quality values of metal sheets to be used. Please contact to our company for more detailed information relate to these lines that many optional features can be attached according to customer expectations.

- 24. 22 www.pressline.com.tr Coil Slitting Lines Recoiler machine Recoiler unloading car Turnstile group Strip tipping unit Hydraulic systems Pneumatic systems Control system Slitting Lines Parts Coil loading cars Decoiler Tomatic edge control unit Spade and pulling group Edge cutting shear and guiding group Knife group Scrap peeling machine Loop group Streching and scrap pressing machine * If you have different sheet size please contact Pressline for determine right roller and new design. PSL Series Up to 2000 mm Sheet Witdh Up to 10 mm Sheet Thickness High Quailty Rollers Coil Slitting Lines ; Uncoil the coils , slit the coils into strips by circular slitter knives positioned at certain intervals and recoil these strips.Slitting lines are designed to provide the best slit width tolerance and finest cutting for cold and hot rolled carbon steel , galvanize , stainless , aliminum , brass ,copper and different special alloy steel coils of different width and weight between 0,3 mm to 10 mm thickness

- 25. 23www.pressline.com.tr Mold Systems PSM Series Pressline has practised about cutting and stamping mold is confident of experience in metal forming and renders service to the industry of the country. Moulds Progressive cutting moulds Plastic injection’s moulds Metalic injection’s moulds Plastering moulds * If you have different sheet size please contact Pressline for determine right roller and new design.

- 26. 24 www.pressline.com.tr Eccentric Presses PPC Series C Frame Safety system as per CE norms Sliding ram system on 6 points Gear system with liquid lubrication Balancing pistons of ram 40.000 kg - 250.000 kg Capacity

- 27. 25www.pressline.com.tr Eccentric Presses PPH Series H Frame Safety system as per CE norms Sliding ram system on 8 points Gear system of liquid oil chamber Gear or automatic stroke adjustment system 100.000 kg - 800.000 kg Capacity

- 28. 26 www.pressline.com.tr Laser Cutting Systems PLC Series 300w - 6kw raycus laser source as standart IPG and SPI optional laser source Table size standart 1500 x 3000 mm Table sizes can be configured. Chiller system 9 bar. Maximum free speed (80 m / min) Motor and driver Yasakawa. User and CNC program: CypCut. Movement Systems Kramayer gear. Cutting Head: LaserMech /Precitec (opt.) Cutting Limit 1: 12 mm carbon steel. Cutting Limit 2: 8 mm stainless steel. Assist Gas: Oxygen, nitrogen, compressed air. Documentation format: DWG, DXF, JPG, BMP, Tİ, EZM, PLT, AL, DST, DSB, GIF, PNG, ICO, CUR Z Axis response time: 0.01 ms Wireless control system

- 29. 25www.pressline.com.tr Laser Marking Systems PLM Series Laser Source Output Power Wave Lenght Lens Focus Marking Area Marking Speed Cooler System Control System Computer Operation Systm Software Document Format Fiber 20 W 1070nm +/-10nm 180mm 100mm / 100mm 1000 chracter/ sec Air Cooler Pressline Mark LapTop Windows Pressline Mark dwg, dxf, Jpg, bmp, ti, ezm, plt, al, dst, dsb, gif, png ico, cur,

- 30. 28 www.pressline.com.tr Press Brakes PBH Series CNC Hydraulic Press Brakes Configured from 3 Axes (Y1, Y2, X) to 8 Axes (Y1, Y2, X1, X2, R1, R2, Z1, Z2) Optional 3D controller Parallelism of top beam is achieved by proportional valve system Hydraulic, CNC motorized and manual crowning system options High quality linear scales Front sliding support system with flip stop Cylinder oil flow control Automatic tonnage adjustment depending on thickness of material and V die Automatic, semi-automatic and manual working modes, Adjustable working speed Automatic axis referencing Programmable bending and backgauge speeds Honed and chrome plated cylinders Adjustable backgauge finger blocks Automatic stroke adjustment according to bending angles Hoerbgier hydraulic system Siemens electric system Real Innovation, High Quality, High Performance and Good Price, User Friendly Control Unit, Monoblock, Steel Welded Construction, High Precious Bendings PBH Series Heavy Duty Press Brakes Configured from 3 Axes (Y1, Y2, X) to 8 Axes (Y1, Y2, X1, X2, R1, R2, Z1, Z2) Optional 3D controller Hydraulic, CNC motorized and manual crowning system options High quality linear scales Front sliding support system with flip stop Cylinder oil flow control Automatic, semi-automatic and manual working modes, Adjustable working speed Automatic axis referencing Programmable bending and backgauge speeds Honed and chrome plated cylinders Adjustable backgauge finger blocks Automatic stroke adjustment according to bending angles Hoerbgier hydraulic system Siemens electric system Real Innovation, High Quality, High Performance and Good Price, User Friendly Control Unit, Monoblock, Steel Welded Construction, High Precious Bendings,

- 31. 29www.pressline.com.tr Guillotine Shears PGS Series CNC Hydraulic Guillotine Shears PRESSLINE variable rake angle hydraulic guillotine shear has strong structure and easy usage. Automatic blade gap, rake angle and backgauge position adjustment are done by CNC controller according to thickness of material and any type of sheet material can be cut with best quality. Machines can be easily controlled by Cybelec Cybtouch-6 touch screen controller. Real Innovation, High Quality, High Performance and Good Price, User Friendly Control Unit, Monoblock, Steel Welded Construction, High Precious Cuttings. PGS Series Heavy Duty Guillotine Shears PRESSLINE variable rake angle hydraulic guillotine shear has strong structure and easy usage. Automatic blade gap, rake angle and backgauge position adjustment are done by CNC controller according to thickness of material and any type of sheet material can be cut with best quality. Machines can be easily controlled by Cybelec Cybtouch-6 touch screen controller. PGS Series Electromechanical Guillotine Shears PGS Series electromechanical shear has been designed for cutting of sheet metal, plastic materials. Pressline meets thin and accurate cuttings. It provides effective and economical solutions to users.

- 32. 30 www.pressline.com.tr Tube Punching Machines PTP Series Main body steel construction Hydroulic press Both side punching specification Servo motors with linear movent High quality HMI Easy changable moulds Automatic burr cleaning system Automatic working with footswitch Specifitions Speed : 45 punch per minute Press Capacity : 25 ton Total Power : 12,5 kW

- 33. 31www.pressline.com.tr Automation Systems and Brands Pressline Automation and 3D CAM programs are totally made by Pressline engineering team. For The automation parts of our machines Pressline chooses the highest quality American and Europian Automation Brands. For PLC , HMI , servo motors and inverter solutions Pressline uses Schneider Electric products, for faults and error fast control Pressline uses remote control technology. Instead of the Pulse System Pressline prefers using Canopen system (Which is more secure and sensitive) at the PLC-servo motor technology. For Pressline choses Telemecanique, Banner Engineering and Sick brands for its sensors. The electric parts inside Pressline electric panels are Schneider, Allen Bradley and Omron Brands. Pneoumatic systems solutions brands Festo.

- 36. www.pressline.com.tr OZAY MOULD and MACHINE SET. CO. Esensehir Mah. Muradiye Sk. No: 38 Umraniye / ISTANBUL - TURKEY Phone : +90(216) 540 6706 (pbx) Fax : +90(216) 540 6707 E-mail : info@pressline.com.tr