INTEGRATING LEAN CONSTRUCTION IN PROMOTING HEALTH AND SAFETY ON SITES

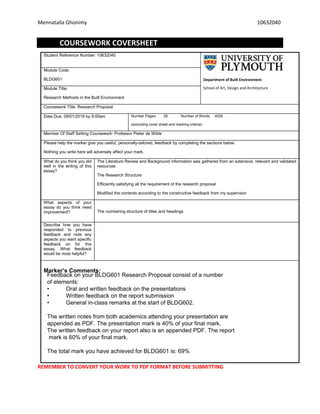

- 1. Mennatalla Ghonimy 10632040 COURSEWORK COVERSHEET Student Reference Number: 10632040 Department of Built Environment School of Art, Design and Architecture Module Code: BLDG601 Module Title: Research Methods in the Built Environment Coursework Title: Research Proposal Date Due: 09/01/2019 by 9:00am Number Pages: 26 Number of Words: 4020 (excluding cover sheet and marking criteria) Member Of Staff Setting Coursework: Professor Pieter de Wilde Please help the marker give you useful, personally-tailored, feedback by completing the sections below. Nothing you write here will adversely affect your mark. What do you think you did well in the writing of this essay? The Literature Review and Background information was gathered from an extensive, relevant and validated resources The Research Structure Efficiently satisfying all the requirement of the research proposal Modified the contents according to the constructive feedback from my supervisor What aspects of your essay do you think need improvement? The numbering structure of titles and headings Describe how you have responded to previous feedback and note any aspects you want specific feedback on for this essay. What feedback would be most helpful? Marker’s Comments: REMEMBER TO CONVERT YOUR WORK TO PDF FORMAT BEFORE SUBMITTING Feedback on your BLDG601 Research Proposal consist of a number of elements: • Oral and written feedback on the presentations • Written feedback on the report submission • General in-class remarks at the start of BLDG602. The written notes from both academics attending your presentation are appended as PDF. The presentation mark is 40% of your final mark. The written feedback on your report also is an appended PDF. The report mark is 60% of your final mark. The total mark you have achieved for BLDG601 is: 69%

- 2. Mennatalla Ghonimy 10632040 PRESENTATION (40%) (REPORT (60%) Mark allocation CRITERION 1 Present a research proposal using appropriate written and verbal presentation techniques. CRITERION 2 Professional interaction with relevant staff, answering questions and keeping to time CRITERION 3 Undertake a focused literature review and synthesise information to identify the possibility of new concepts within the built environment knowledge framework CRITERION 5 Identify and develop aims and objectives for a self-directed research project. CRITERION 5 Identify and select appropriate methodologies to carry out research in a specific subject area. 86-100% Outstanding presentation. Professional communication of research plan, highly engaging with the audience. Outstanding self- management. Highly independent and ensuring project progress; proactive. Outstanding literature review, based on a wide range of sources. Full Harvard referencing. Compares and contrasts findings from different sources. Clear identification of a knowledge gap. Outstanding aims and objectives. High level of understanding of subject matter and analysis, informed choice of challenging research direction. Outstanding methodology, very clear and innovative research design. No errors or omissions. 70-85% Excellent presentation. Professional communication of research plan, for expected audience. Excellent self- management. Independent and well in control of progress. Good contact with staff. Excellent literature review, based on wide range of sources. Full Harvard referencing. Good overview of existant knowledge. Clear synthesis and identification of key concepts. Excellent aims and objectives, providing the basis for a challenging and well-directed research project. Excellent methodology that clearly will allow the student to meet all aims and objectives. No errors or omissions. 60-69% Good presentation. Clear communication of what research is planned. Good self- management, on time and making fair progress.. Regular contact with staff. Good literature review, based on solid number of sources. Harvard referencing but with some errors. Good overview of existant knowledge. Some synthesis. Good aims and objectives, providing the basis for a well-directed research project. Good methodology, clearly describing what research is to be carried out. Some minor errors and omissions. 50-59% Adequate presentation. Satisfactory clarity but with some errors and omissions. Adequate self- management, on time. Some reliance on staff to ensure project progress. Adequate literature review, based on basic reading. Harvard referencing but with some errors. Fair report of existant knowledge but not leading to new insights. Adequate aims and objectives. Will allow a fair research project but with some errors or omissions. Adequate methodology, providing a relevant research design. However, includes some errors and omissions. 40-49% Poor presentation. Some structure but lack of clarity. Some grammar and spelling errors. Poor self- management, behind schedule. However aware of this issue and trying to address the issues. Poor literature review, based on few sources only. No use of Harvard referencing. Repetitive use of single sources. No identification of state-of- the-art and how that relates to the dissertation project. Poor aims and objectives. Weak definition of research direction, but some relevant ideas. Weak knowledge of the subject matter. Poor methodology, weak in terms of research design. Some relevant ideas but incomplete and with omissions. < 40% Very poor presentation. Lack of structure, grammar and spelling errors. Time overrun of presentation Very poor self- management, behind on schedule. Requiring significant chasing Very poor literature review, with little reference to sources. No use of Harvard referencing. No identification of state-of- the-art and how that relates to the dissertation Very poor aims and objectives. Weak definition showing lack of knowledge of the subject Very poor methodology, weak in terms of research design. Unclear how data will be collected FINAL MARK (%) (To be completed by marker) Date by which work, feedback and marks have been returned (should be no more than 20 working days after the submission date)

- 3. Mennatalla Ghonimy 10632040 INTEGRATING LEAN CONSTRUCTION IN PROMOTING HEALTH AND SAFETY ON CONSTRUCTION SITES _____________________ The Proposal Presented to The Department of Architecture and Built Environment University of Plymouth _____________________ In Partial Fulfilment Of the Requirements for the Degree of Bachelor of Architectural Engineering _____________________ Mennatalla Ghonimy January 2019

- 4. Mennatalla Ghonimy 10632040 Table of Contents Abstract ................................................................................................................................ 3 List of Abbreviations ................................................................................................................ 4 List of Figures............................................................................................................................ 4 Introduction .......................................................................................................................... 5 UK Construction industry current situation ............................................................................... 5 Health and Safety within Sustainable construction ................................................................... 5 Lean Construction for sustaining Health and Safety..……………………………………………………………. 6 Research problem ……………………………………………………………………………………………………………..….7 Research Aim and Objectives …..……………………………………………………………………………………………8 Research Aim………..………………………………………………………………………………………………………………..8 Research objectives……………………………………………………………………………………………………………..…8 Background …………………………………………………………………………………………………………………………..….9 Lean Construction Principles ……………………………………………………………………………………………..…..9 Lean Construction tools and their relevance to Health and Safety …………………………………….……9 Last Planner System ………………………………………………………………………………………………………….……9 The 5S (house-Keeping) ……………………………………………………………………………………………………..…10 First Run Studies ………………………………………………………………………………………………………………..…11 Error-Proofing ………………………………………………………………………………………………………………………11 Increased Visualization ……………………………………………………………………………………………………...…12 Daily Huddle Meetings DHM ……………………………………………………………………………..…………………12 Literature Review ……………………………………………………………………………………………………………..……13 Methodology ……..…………………………………………………………………………………………………………………..16 Expected Findings ……………………………………………………………………………………………………………………17 Future Work Plan …………………………………………………………………………………………………………………….17 Structural Map of the paper ……………………………………………………………………………………………………21 References ………………………………………………………………………………………………………………………………24

- 5. Mennatalla Ghonimy 10632040 List of Figures Figure 1 link between the keywords of this research paper source: by the author to be published (2018) Figure 2 applied system of estimating the cost of accidents and ill health at work a review of methodologies [European Agency for Health and Safety at Work- EU-OSHA 2014] ..Error! Bookmark not defined. Figure 3 Non-fatal injuries reported under RIDDOR 2014/15-2016/17 .....................................................11 Figure 4 fatal injuries reported under RIDDOR 2012/13-2016/17 .............................................................11 Figure 5 diagram indicating the flow of LPS planning schedule based on Should-Can-Will Analysis Source Figure illustrated by the author of this paper (2018) with reference to Briso (2011)................................14 Figure 6 comic illustrating the roles of each method of 5S system Source: Lan Thinkin and 5S by Cireddu (2015)..........................................................................................................................................................15 Figure 7 -3D Model for on-site practices of Increased Visualization, Lean Construction tool ...................17 Figure 8 Gantt chart scheduling the planned future work for this research..............................................23 Figure 9 demonstration of the structure of Literature Chapter .................................................................24 Figure 10 illustrating the Research Methodology Map ..............................................................................25 Figure 11 Graph of the content included in each chapter..........................................................................26

- 6. Mennatalla Ghonimy 10632040 List of Abbreviations LC – Lean Construction HSE – Health and Safety Executive EASW – European Agency for Safety and Work SCSH – The Sustainable Construction Safety and Healt IVMSA – The Integrated Value Model for Sustainability Assessment COSHH – Control of Substances Hazardous to Health RIDDOR – Reporting of Injuries, Diseases and Dangerous Occurrences Regulations HSAW – Health and Safety Act at Work CDM15 – Construction (Design and Management) Regulations 2015

- 7. Mennatalla Ghonimy 10632040 Abstract Within the UK construction industry, Health and safety problems have always been a paramount concern. In account of the poor health and safety records conducted from the numerous reported cases of work-related injuries and fatalities, the construction industry has been categorized as one of the most hazardous industries. The main problem this paper is addressing, is the poor health and safety practices on construction sites that lead to numerous injuries and fatalities. One approach to address the problem is Lean Construction (LC). LC has been suggested as an effective method to promote health and safety on construction sites. Existing literature have further confirmed that Lean Construction strategies eliminate, and reduce occupational accidents –a major health and safety problem on-site. However, the synergies between Lean Construction tools and health and safety problems have always been controversial. Thus, the purpose of this paper is to develop a framework for integrating Lean Construction tools to promote health and safety on construction sites. In order to achieve this aim, the methodology followed is collecting data from secondary resources as extensive relevant literature review, and primary data from a qualitative source in form of interviews with top sixty-(60) Lean-certified contractor and consultant organizations. The findings of this study will help identify the effectiveness of Lean Construction practices in promoting Health and safety on construction sites. Figure (1) shows the link between the keywords of this paper. Keywords: Lean Construction; Health and Safety; Construction industry; Accidents; waste. Figure 1 link between the keywords of this research paper source: by the author to be published (2018)

- 8. Mennatalla Ghonimy 10632040 1.0 Introduction UK Construction industry current situation For several decades, the construction industry in the UK has been categorized as one of the most hazardous industries (HSE, 2017), and has consistently been criticized for poor safety records (Anvari et al. 2011; Moaveni et al., 2018). Construction industry statistics show an annual average of 80,000 work related injuries and 30 fatalities (LFS, 2017), posing great demotivation for people working in the industry and constituting a considerable threat to sustainability and the economy (EASW, 2013). Furthermore, the dynamic and complex nature of the construction industry increases the risk probability of occupational accidents (Bajjou et al., 2017; Ghosh et al., 2009, Howell et al., 2009) In an attempt to address the situation, the government has priorities Health and Safety sustainability into construction policies (Bashir et al, 2011), consequently moving the construction industry towards sustainability at a significant pace (Cray, 2013). Health and Safety within Sustainable construction However, the primary concern of the sustainable development has been managing the consumption of water, energy, materials and the indoor environmental quality, rather than health and safety (Bezalel and Issa, 2016). This indicates that little has been done to integrate H&S considerations within the sustainable construction development (RICS 2016; Greg 2012; Howard 2011). In an effort to promote H&S considerations, several research studies have suggested various practices and methods aside from the mere compliance with rules and regulations. For instance, the Corporate Manslaughter Act which was enforced in 2007 (HSE, 2018), the health and safety rating systems SCSH and IVMSA (RICS, 2016; Rajendran, 2006; Reyes, 2014), “Rethinking Construction- Egan Report” (Murray and Langford, 2003), “Revitalizing Health and Safety” by Oloke et al. 2008, “One Death is Too Many” (Donaghy, 2009) and several other reports (McKay, 2010; Gambatese et al., 2008; FISCA, 2006; Haslam et al., 2005; Suraji et al., 2001; Baxendale and Jones, 2000). Besides the government efforts in developing policies and regulations as CDM15, HSAW Act 1974, COSHH, RIDDOR, and Working at heights Regulations 2005. These

- 9. Mennatalla Ghonimy 10632040 methods and approaches have improved the statistics of the industry (HSE, 2017); however, accidents still exist (Bashir, Suresh, Proverbs and Gameson, 2011). The reasons why on-site accidents still occur; because governmental and traditional approaches adopted in construction projects tended to separate health and safety planning from the construction planning (Sarhan and Fox, 2012). Consequently, this urges the need of integrating health and safety considerations in the execution plans in order to efficiently improve health and safety on construction sites Lean Construction for sustaining Health and Safety Lean Construction (LC) is a management strategy pioneered in 1992 by Koskela. LC is aimed at eliminating waste and increasing value while taking into account safety considerations (Bashir et al., 2011). Lean principles primarily consider safety as a way to maximize value and productivity, as well as minimize cost and waste. On-site accidents result in wasting productive days and adding extra costs for compensations. To demonstrate, Figure (2) represents an applied system of monetary expenses and loss outcomes from work-related accidents. As a consequence, Lean Construction consider accidents as waste that must be eliminated. Accordingly, LC strategy focuses on eliminating safety hazards and addressing construction problems in order to prevent work-related injuries and fatalities (Al-Aomar, 2011; OGC, 2007). Accordingly, to apply lean strategy, a diverse of tools have been developed such as, Last Planner System, 5S, Error-Proofing, Increased Visualization, Daily Huddle meeting and First Run Studies (Marhani, 2013; Edwards, 2015). Several research studies concluded that lean tools are efficient in eliminating main causes of on-site construction accidents (Bashir et al., 2011; Larios et al., 2012; Ghosh et al, 2009; Anvari et al, 2011). Nevertheless, the existing literature does not provide a holistic view of the mechanism of applying Lean Construction tools and principles to promote sustainable health and safety within the construction industry. This emphasizes the value of this paper, which aimed at investigating the applicability and potential effectiveness of Lean Construction techniques in promoting sustainable health and safety on construction sites.

- 10. Mennatalla Ghonimy 10632040 Figure 2 applied system of estimating the cost of accidents and ill health at work a review of methodologies [European Agency for Health and Safety at Work- EU-OSHA 2014] 1.1 Research Problem The primary problem this paper is addressing is the poor health and safety records of the construction industry, and how Lean Construction principles and tools could be applied on construction sites to address the problem. Poor health and safety practices do not only impact human health but also reduce project productivity, delay the building delivery and over- runs budgets through wasted working days on recovery and compensations. Furthermore, safety envelops every process, material, machinery, any individual involved in the project as well as the public who are in the vicinity of the working area. Thus, effectively managing it is a matter of great importance. Lean techniques appear to be an efficient method to address the key causes of injuries and fatalities on construction sites (Passale and Bagi, 2013). Some of the main causalities of the non-fatal injuries are illustrated in Figure (3), and the fatalities causes are shown in Figure (4) below:

- 11. Mennatalla Ghonimy 10632040 Figure (3) and (4) above indicate that most of the common causes of accidents usually occur on construction sites. Therefore, the research will particularly be focusing on promoting health and safety on construction sites. Figure 3 Non-fatal injuries reported under RIDDOR 2014/15-2016/17 Figure 4 fatal injuries reported under RIDDOR 2012/13-2016/17

- 12. Mennatalla Ghonimy 10632040 1.2 Research Aim and Objectives 1.2.1 Research Aim The principal aim of this paper is to develop a framework of integrating Lean Construction tools to promote health and safety on UK construction sites. 1.2.2 Research Objectives In order to sustain the aforementioned aim, the following objective were set: Critically review the existing literature related to health and safety within construction industry, and determine the common causes of accidents and explore how they can be addressed by lean Critically review the current literature related to Lean Construction principles, tools and techniques and how they are relevant to health and safety considerations on construction sites Determine which Lean Construction Tools and Techniques are most related and best applicable to health and safety within construction industry Develop a conceptual framework of how Lean Construction methods can be implemented in order to promote sustainable health and safety on construction sites Gather data from companies and organizations to test the components of the conceptual framework Develop and validate the integration of the conceptual framework Draw a conclusion on the applicability of Lean Construction in promoting sustainable health and safety within UK construction industry, and provide recommendations to practitioners for future studies.

- 13. Mennatalla Ghonimy 10632040 2.0 Background 2.1 Lean Construction Principles: Lean Construction is a management strategy aimed at eliminating any waste of materials, time, and effort by eliminating accidents and avoiding hazardous risks, as a mean to achieve the maximum possible value of the project (Abdel-Hamid and Salem 2005). The strategy was also identified by Zimmer and Salem (2005) as a continuous process of safety and risk management, by focusing on preventing accidents of loss, or injuries to maintain sustainable construction. Lean Construction principles perceive any interruption to the value-adding flow, or any accident that impacts workers; as waste that must be eliminated (Bashir, 2013). Consequently, LC consists of five main principles determined by Womack and Jones (1996-2003) as; identifying value from the client’s perspective, value stream, and flow of value, attaining clients pull at the right time, as well as endeavoring perfection by a continual improvement. moreover, Koskela 1992 has further identified Lean Construction principles as; minimizing variability, lifecycle and number of process required, maximizing transparency of processes, balancing the conversions and the flow improvement, and finally focalizing the management on the entire process. In an attempt of achieving the principles, Lean Construction tools have been developed as following; Last Planner System, 5s, First Run Studies, Error-proofing, Increased Visualization, and Daily Huddle Meetings, (Mossman, 2013). Consequently, several studies have concluded that most of the Lean tools have a great synergies with health and safety standards (Edwards, 2015; Forman, 2010) 2.2 Lean Construction tools and their relevance to Health and safety 2.2.1 Last Planner System (LPS): One of the most effective ways to improve health and safety conditions on construction sites is to avoid risks and eliminate hazards; which can be attained through adequate project planning, managing and scheduling (Larios et al, 2012). Last Planner System was proposed by Glen Ballard in 2000, who asserted that effective planning is achieved by addressing the construction problems, and determining the specific tasks as possibly close to the execution date. Further, several researchers have indicated that LPS techniques include a collaborative planning between construction and health and safety requirements (Tsao, 2014; Alves, 2010).

- 14. Mennatalla Ghonimy 10632040 Based on existing literature, LPS relies on last planners in form of foremen, supervisors, engineers as well as health and safety coordinators; whose responsibility is to schedule and fit tasks according to workers' expertise and capabilities (Tokede et al, 2016; Briso, 2011). This could assist avoiding hazardous risks and accidents resulting from poor planning and control (Nahmens and Ikuma, 2009). Moreover, LPS incorporates safety in the “Should, Can, Will” analysis as shown in Figure (5); in which “Should” represents all the tasks that should be executed, “Can” determines the tasks that can be carried out while considering site constrains, risks and hazards, and finally “Will” indicates the tasks to be executed besides empowering workers to commit themselves to the construction activities that fit their skills (Salem et al, 2005). Thus, this will greatly promote health and safety on construction sites by eliminating occupational accidents correlated to physical and mental inabilities and lack of skills (Bashir, 2011; Saurin et al., 2006; Mitropoulos et al., 2007). In addition, the common occupational accidents caused by time pressure, excessive stress and organizational pressure can as well be eliminated by the LPS adequate planning (HSE, 2016; Suraji et al., 2001; Loughborough and UMIST 2003; Haslam et al., 2005; FISCA 2006) 2.2.2 The 5S (House-keeping): One of the common causes of incidents on sites is poor organization (CDM15, 2015; HSE, 2016; Larios et al; 2012; Abdulhamid et al., 2005 and FISCA 2006). Thus, the 5S (House- Figure 5 diagram indicating the flow of LPS planning schedule based on Should-Can-Will Analysis Source Figure illustrated by the author of this paper (2018) with reference to Briso (2011)

- 15. Mennatalla Ghonimy 10632040 keeping) tool based on 5 principles includes (Seiso, Seiton, Seiri, Seiketsu and Shitsuke). The 5S system was developed by the Japanese Toyoda in 1988 in an effort to address this problem (Osada and Takashi, 1995). Further, the 5S is a strategic method based on high standard principles of a clean, organized work environment. As in Figure (6), a simple comic visually presenting the aim of each method. To illustrate, Seiso (Shine) implies cleaning the construction site from any machinery, equipment or material that are not currently in-use to avoid site congestions and obstruction which are major drivers of accidents (HSE, 2017; Abdelhamid et al, 2005; Howell et al., 2002; Bicheno, 2000). Further, Seiton (Set-in-order) involves placing all materials and machines in their optimal location in order to sustain their function, smooth the workflow, and to elminate the chance of tripping or slipping which is another common cause of site incidents (Pasale et al., 2013; Edwards, 2015). In the same manner, Seiri (Sort) differentiate and categorize items according to their schedule of operation and place them in suitable locations to maintain a safer circulation as well as to avoid exposing workers to hazards risks of falls and trips (Singh et al, 2014; Nahmens and Ikuma 2009). Likewise, Seiketsu (Standardize) asserts maintaining the machines at good maintenance to ensure best performance and prevent the accidents resulted from machinery problems (Pasale et al., 2013, Bashir, 2013). This is emphasized by Shitsuke (Sustain), which includes the consistent improvement of safety culture within the workers (Abdelhamid et al, 2005; Edwards, 2015). Interestingly, some researchers have added ‘Safety’ as the sixth principle to the methodology changing it to a 6S system. (Gapp, Fisher, and Kobayashi 2008). Therefore, it can be seen that this methodology has a great potential of eliminating on-site occupational accidents and thereby promote health and safety on construction sites. Figure 6 comic illustrating the roles of each method of 5S system Source: Lean Thinking and 5S by Cireddu (2015)

- 16. Mennatalla Ghonimy 10632040 2.2.3 First Run Studies (FRS) According to the complex and dynamic nature of the construction industry, some activities require specific skills and complicated work techniques (Bertelsen, 2003; Wood, 2008). FRS is a Lean Construction tool utilized for developing alternative methodologies to execute a critical construction activity (Mossman, 2013). The execution of planning a critical activity includes studying the procedures and reviewing alternatives to select the most applicable method with least hazard risk which is compatible with workers skills and convenience (Salem et al, 2006; Forman, 2010). Thus, First Run Studies could prevent injuries and health related issues resulted from poor work methods. 2.2.3 Error-Proofing Statistics shows that human-error is a one of the major causes of occupational accidents on construction sites (UMIST, 2003; Katsakiori et al., 2009). Consequently, Error-proofing tool includes all the possible techniques and methods that can avoid human failings and thus contribute to eliminating occupational accidents (X). To illustrate, Error proofing may include risk analysis, continual monitoring, visual inspection, as well as devices and gadgets that alarms in case of detecting error and automatically shut down the operating machinery, or in case of crossing an unsafe boundary (Bajjou, 2017; Saurin et al. 2005). Thus, human-failings resulted from rushing, stress, lack of concentration, or negligence can be minimized using error proofing techniques. 2.2.4 Increased Visualization Existing literature demonstrates that visual management is a principal element of promoting health and safety on construction sites (Salem et al., 2007; Saurin et al., 2005; Fewings, 2013). Visual management by signs and annotations, can provide the essential communication for workforce particularly the ones with low level of literacy, and indicate any work hazards as tripping or slipping risks that are common causes of site accidents (HSE, 2016; Salem et al., 2007; Tyler and Lamont 2008; Fewings 2013). As illustrated in Figure (7), visual annotations, signalization tools and billboards are placed as instructions to avoid hazards and risk.

- 17. Mennatalla Ghonimy 10632040 Figure 7 -3D Model for on-site practices of Increased Visualization, Lean Construction tool 2.2.5 Daily Huddle Meetings (DHM) This is another effective LC tool based on conducting a daily start-up meetings to collect and revise reports on the current phase of the work (Salem et al., 2007). The reports includes issues related to the work progress, construction problems, risk and hazards to the health and safety. DHM is an efficient tool which rapidly address the problems on daily basis rather than delaying the work to further notice (Bajjou, 2017; Saurin et al. 2005). Furthermore, the meetings are held between the leader and the team to engage them directly in the problem solving which increase their job satisfaction and thereby the productivity (Salem et al., 2005).

- 18. Mennatalla Ghonimy 10632040 3.0 Literature Review Cooney (2016) demonstrated that UK construction industry has an international reputation for the buildings sustainability and quality, however, occupational accidents and fatalities still exist in a high percentage. Pursuant to this, Gilding et al 2002 asserted that no building that neglects avoidable occupational accidents of injuries and fatalities or work-related illness can pretense to be sustainable. Traditionally, during a project execution, the management plan is often implemented without any linkage to the health and safety plan, causing a communicational gap between the coordinator of health and safety and the director of the project execution (Brioso et al, 2018). On this premise, studies have established that poor communication within the organization is one of the major drivers of occupational accidents (Cooney, 2016). Further, Vitharana et al. (2015) deduced that many of the construction workers are self-employed with low skills and lack the sufficient knowledge about the practices of health and safety standards on construction sites, and thereby poor health and safety practices are implemented throughout the project execution which increase the number of occupational accidents. Likewise, The Egan report Rethinking Construction (Murray, 2003) found that construction accidents resulted from poor health and safety practices account an average of 6% of the total project expenditures. This indicates the significant impinge occupational accidents have upon the UK economy and social sustainability, giving rise to the importance of promoting health and safety on construction sites. Several researchers have asserted that health and safety is a cardinal/substantial consideration in regards to the country, clients, contractors, workforce, or any person who is in the vicinity of the construction execution (Griffith et al, 2014; Nahmens et al 2009). Existing literature shows that UK government has contributed a noted advance of health and safety integration within the construction industry through establishing several regulations (Vitharana et al., 2015); for instance, the HSWA in 1974 (Bashir et al, 2013), and CDM Regulations in 1994 (HSE, 2017). However, the construction industry still suffer from poor health and safety records according to the wide number of work-related injuries and fatalities reported annually (HSE, 2017). Lean

- 19. Mennatalla Ghonimy 10632040 Construction was identified by (X) in (20xx) as an efficient method to prevent on-site accidents, which is one of the paramount drivers of health and safety problems within the construction industry. Contrarily, Garrahan et al. (1992) and Green (2001) argue that Lean Construction has exploited workers and exposed them to excessive pressure and stress. In the same manner, Fucini et al. (1990) and kamata (1982) claimed that Lean Construction strategies deprive workers' freedom. On the other hand, Lean Construction advocates indicate that applying LC tools rather empower workers to commit themselves to tasks that match their skills, abilities, and convenience in an attempt to minimize accidents resulted from physical or mental disability (Brioso et al, 2018). Furthermore, Nahamens and Ikuma (2009) dictates that LPS, a LC tool, assist controlling, planning and managing the project execution on monthly and weekly basis, which aid predicting and avoiding construction problems as hazards risks and occupational accidents. Lean Construction has been widely criticized by Graham Winch, a leading thinker in the field of construction management, in the 1st and 2nd ed. of Managing Construction Projects (Winch, 2002; Winch, 2010). Winch (2010) contends that Lean Construction is not applicable for neither complex, dynamic, large projects nor refurbishments projects. Furthermore, he alleges that Lean construction have limited capabilities in regards to modern construction techniques and thus it cannot be implemented in novel construction projects. Lean Construction advocates countered Winch's argument and clarified LC flexibility and adaptability based on the diverse tools and techniques that correspond to any project requirements (Ballard and Koskela, 2011). More critics on Lean Construction includes associating LC with traffic congestion which expose workers to on-site accidents of injuries and fatalities (Green, 1999; Rehdar, 1994; Fucini et al. 1990). This assumption was however dismissed by Abulhamid et al (2005), Bashir et al. (2011), Nahmens et al (2009) and Saurin et al. (2006), by underlining the application impacts of LC tools, as 5S system and LPS, which rather addressed construction problems including site congestion, risk probabilities and thus improved the health and safety on construction sites.

- 20. Mennatalla Ghonimy 10632040 Furthermore, Bae and Kim (2007) asserted that Lean Construction tools conduce smooth execution of the project's construction and eliminate accidents resulted from site congestion by planning, controlling and maintaining everything in its optimal place. On the same grounds, Huges et al, (2008), Abdulhamid et al (2005) and Bashir (2013) affirmed that 5S strategy as a LC tool engage the use of devices, gadgets and alarms that aid preventing an accident from happening. A growing body of evidence prove that projects which implemented Lean Construction principles are safer than those implemented traditional practices (Howell et al., 2017; Nahmens and Ikuma 2009; Leino 2010; Thomassen 2002). Based on that, Othman and his associates (2014) asserted that traditional practices tend to plan execution processes before studying or elaborating health and safety concerns. Consequently, Dinesh et al. (2017) and Koskela (2013) demonstrated that Lean Construction is a management concept which integrates H&S in the construction process by categorizing accidents as waste ought to be eliminated. The researchers of the 6th national conference on innovative practices in construction (2017) concluded that LC has a great potential for improving health and safety measures on construction sites. Therefore, eliminating accidents and addressing construction problems seem to be the major elements for promoting health and safety on site.

- 21. Mennatalla Ghonimy 10632040 4.0 Methodology The paper will adopt different research methods in order to provide a comprehensive investigation on the potential effectiveness of Lean construction tools in promoting Health and safety. First, a critical review through an extensive relevant literature will be conducted to determine the impacts of Lean Construction practices on Health and Safety on construction sites and how LC tools are relevant to H&S issues. In addition, analyzing the root causes of accidents on construction site and how LC tools and techniques could overcome them. Data gathered from text books, academic journals, conference papers and published PhD/Master thesis. Furthermore, a qualitative analysis will be attained from structured interviews with the top (60) sixty Lean-certified contractor and consultant construction organizations, in order to identify which Lean Construction tools are most applicable to address construction problems related to health and safety. Besides, determining whether the companies actually use Lean Construction techniques for the purpose of improving Health and safety on sites and are they aware of its significance, or is it just a consequence impact of LC practices on H&S. The use of different methodologies allows the author to avoid over-dependence on statistical information. Where using qualitative sources beside the existing literature provide in-depth data and eloquent interpretations based on real-life experiences ( Jogulu and Pansiri, 2011). in addition, using different research methods provides strengths which recompense the weaknesses of each method, as well as provides a complete image of the topic for better study and research (Creswell, 2003). Further by studying different case-studies, the researcher will be able to develop a framework for effectively integrating Lean Construction in a structured methods and recommendations in order to promote Health and Safety on construction sites and achieve best results. Interviews will be based on main questions as following: What are the health and safety benefits of LC? How LC was utilized to address causes of accidents?

- 22. Mennatalla Ghonimy 10632040 How LC was integrated through the construction phase of the projects? What are the barriers and limitations facing Lean implementation? What are LC drawbacks (if there’s any) on H&S? To what extent workers are compatible with the use of LC tools and techniques? Recommendation to improve LC practices? Are the companies aware of the health and safety significance? Whether they apply LC with Health and Safety as a primary concern or is it just a consequence of the practices followed? Through analyzing the results and findings of the aforementioned methodologies, the researcher will be able to determine the potential effectiveness of LC on improving Health and Safety, and identify the best applicable tools and techniques used in addressing the construction problems. In addition, the findings will provide a holistic overview of how companies perceive Health and Safety concerns and to what extent H&S is considered throughout the project execution. Further, determine the relevance of LC tools in promoting H&S on sites, as well as identify the barriers and limitations affecting the implementation of Lean Construction. and the possible recommendation of the possible improvements for ensuring smooth integration of LC practices in promoting health and safety.

- 23. Mennatalla Ghonimy 10632040 5.0 Expected Findings At the end of the study, it is expected that Lean Construction has a great potential of positively impacting the Health and Safety on Construction sites, LC tools have synergies with H&S standards and considerations, and that projects implementing LC practices are safer than those using traditional practices. However, it is expected to find limitations and barriers of LC implementation resulted from different reasons such as, inadequate supervisions to ensure work is done in the assigned way or the workforce are not compatible with the innovative techniques. In addition, it is also predicted that companies are not completely aware of the significance of Health and safety issues, and thereby they intend to use lean for the purpose of increasing productivity and reducing expenses rather than Health and Safety. Consequently, this paper will contribute to promoting health and safety and emphasizing its significance on the social and economic sustainability, by integrating Lean construction practices through the construction phases of the projects. 6.0 Future Work Plan The future work on the research is planned in the following Gantt chart, in an attempt to effectively achieve the aim of the study in a scheduled time for better organized results. Figure 8 Gantt chart scheduling the planned future work for this research

- 24. Mennatalla Ghonimy 10632040 7.0 Structure of the Research Chapters 7.1 Literature Chapter Map Figure 9 demonstration of the structure of Literature Chapter

- 25. Mennatalla Ghonimy 10632040 7.2 Methodology Chapter Map Figure 10 illustrating the Research Methodology Map

- 26. Mennatalla Ghonimy 10632040 7.2 Research Chapters Structure Figure 11 Graph of the content included in each chapter

- 27. Mennatalla Ghonimy 10632040 8.0 References 1. Anvari, Zulkifli and Yusuff (2011). Evaluation of Approaches to Safety in Lean and Safety Management Systems and Clarification of the Relationship Between Them. World Applied Sciences Journal, 15 (1):(19-26, 2011). 2. AL-Aomar (2011). A framework for assessing the cost effectiveness of lean tools. 3. Bajjou, Mohamed Saad & Chafi, Anas & En-Nadi, Abdelali. (2017). The Potential Effectiveness of Lean Construction Tools in Promoting Safety on Construction Sites. International Journal of Engineering Research in Africa. 33. 4. Allan, N. (2000). Managing Health & Safety in Building & Construction. Structural Safety, 22(3), pp.291-292. 5. Brioso, Xavier & Humero, Antonio & Calderon-Hernandez, Claudia. (2018). Teaching how to integrate Last Planner System and the Safety and Health Management System. 2. 12. 10.20868/abe.2018.1.3691. 6. Bashir, A M, Suresh, S, Proverbs, D and Gameson, R (2011) A critical, theoretical, review of the impacts of lean construction tools in reducing accidents on construction sites In: Egbu, C. and Lou, E.C.W. (Eds.) Procs 27th Annual ARCOM Conference, 5-7 September 2011, Bristol, UK, Association of Researchers in Construction Management, 249-258 7. Baxendale T. and Jones O. (2000) Construction Design and Management Safety Regulations in Practice - Progress on Implementation. International Journal of Project Management 18 pp. 33-40 8. Bezalel, O. and Issa, M. (2016). A literature review of sustainable health and safety in the construction industry. Department of Civil Engineering, University of Manitoba. 9. Bertelsen, Sven & , Sven. (2003). Construction as a Complex System. Proceedings for the 11th Annual Conference of the International Group for Lean Construction. 10. Cary, U. 2013. Achieving Sustainability in Construction Safety Programs.Occupational health and safety 11. Cooney, J. (2016). Health and Safety in the Construction Industry: A Review of Procurement, Monitoring, Cost Effectiveness and Strategy. Master Degree. University of Salford.

- 28. Mennatalla Ghonimy 10632040 12. COSHH (2017). Control of Substances Hazardous to Health (COSHH) - COSHH. [online] Hse.gov.uk. Available at: http://www.hse.gov.uk/coshh/ [Accessed 15 Dec. 2018]. 13. S. Dinesh, R. Sethuraman & Shruthi Sivaprakasam, “The Review on Lean Construction an Effective Approach in Construction Industry”, Special Issue, April, Page Number 119-123, 2017 14. Donaghy (2009). One Death is too many. Inquiry into the Underlying Causes of Construction Fatal Accidents. [Accessed 1 Dec. 2018]. 15. European Agency for safety and work –EASW (2013) Occupational Safety and Health Issues Associated With sustainable Buildings 16. Edwards, S. (2015). A guide to the 5S Lean production method for occupational health and safety. 67. 27-29. 17. FISCA (2006) An Analysis of the Significant Causes of Fatal and Major Injuries in Construction in Scotland; factors Influencing Scottish Construction Accidents (FISCA), Health and Safety Executive Research Report 443 18. Forman, Marianne. (2010). Lean construction and health and safety on site: Analysed in a planning and empowerment perspective. Association of Researchers in Construction Management, ARCOM 2010 - Proceedings of the 26th Annual Conference. 19. Guo, B. H., Yiu, T. W. & Gonzalez, V. A. 2015. Identifying behaviour patterns of construction safety using system archetypes. Accident Analysis & Prevention, 80, 125-141 20. Gambatese J. A., Behm M., Rajendran S. (2008) Design’s Role in Construction Accident Causality and Prevention: Perspectives From an Expert Panel. Safety Science, 46, pp. 675– 691. 21. Ghosh and Young-Corbett (2009). Intersection between Lean Construction and Safety Research: A Review of the Literature. Myers Lawson School of Construction. Virginia Polytechnic Institute and State University. 22. Greg, B. 2012. Safety Goes Green Occupational Health and Safety [Accessed 15 Oct. 2018]. 23. Haslam R. A., Hide, S.A., Gibb, A.G.F., Gyi, D.E., Pavitt T., Atkinson S., Duff, A.R. (2005) Contributing Factors in Construction Accidents. Applied Ergonomics, 36, pp. 401– 415

- 29. Mennatalla Ghonimy 10632040 24. HSE (2017). Health and Safety Executive, construction industry health and safety statistics [online] Available at: http://www.hse.gov.uk/statistics/ [Accessed 23 Dec. 2018]. 25. HSE (2015). Construction (Design and Management) Regulations 2015. [online] Hse.gov.uk. Available at: http://www.hse.gov.uk/pubns/books/l153.htm [Accessed 8 Dec. 2018]. 26. HSE (2015). Health and Safety Executive, construction industry health and safety statistics [online] Available at: http://www.hse.gov.uk/statistics/ [Accessed 10 Nov. 2018]. 27. Howard, J. 2011. Summary of the Making Green Jobs Safe Workshop. National Institute for Occupational Safety and Health. 28. Hanapi N.M., Kamal M.M.M., Ismail M.I. Identifying Root Causes and Mitigation Measures of Construction Fall Accidents. Grading Bus. Manag. J. 2013;17:65–79 29. Howell, Gregory & Ballard, Glenn & Demirkesen Çakır, Sevilay. (2017). Why Lean Projects Are Safer. 10.24928/2017/0116. 30. Katsakiori P., Sakellaropoulos G. and Manatakis E. (2009) Towards An Evaluation of Accident Investigation Methods in Terms of their Alignment With Accident Causation Models. Safety Science 47, pp.1007–1015 31. "Labour Force Survey". Office for National Statistics. UK construction industry statistics, fatal and non-fatal injuries. 32. Larios, Sanz, Pellicer and Catalá (2012). Construction Health and Safety from Lean Approach. Universitat Politècnica de València. 33. Marhani, Jaapara, Baria and Zawawib (2013). Sustainability through Lean Construction Approach: A literature review. In: AMER International Conference on Quality of Life. Procedia - Social and Behavioral Sciences 101 ( 2013 ) 90 – 99. 34. McKay, J. (2010). The effect of construction on occupational health and safety. A Doctoral Thesis. Loughborough University Institutional Repository. 35. Murray, M. (2003) Rethinking Construction: The Egan report (1998), in Mike Murray and David Langford (eds) Construction Reports 1944-98, Blackwell, Oxford, 178-194 36. Mossman, Alan. (2013). Last Planner- 5 + 1 crucial & collaborative conversations for predictable design & construction delivery (Apr 2013). 37. Oloke, D., Yu, H. and Heesom, D. (2007), “Developing Practitioner Skills in Construction Health and Safety Management: An Integrated Teaching and Learning Approach”, Journal for Education in Built Environment, Vol. 2 No 1, pp. 3-30.

- 30. Mennatalla Ghonimy 10632040 38. OGC (2007). Risk and value management, Achieving Excellent in Construction Procurement Guide. 39. A Pasale, R & J S Bagi, Prof. (2013). 5S Strategy: A workplace improvement lean tool. Paripex - Indian Journal of research ISSN 2250 - 1991. 2. 151-153. 40. Rajendran, S. (2006). Sustainable Construction Safety and Health Rating System. Civil and Environmental Engineering. Corvallis, OR, Oregon State University. Doctorate 41. RIDDOR (2017). Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 2013 - RIDDOR - HSE. [online] Hse.gov.uk. Available at: http://www.hse.gov.uk/riddor/ [Accessed 8 Jan. 2019]. 42. Reyes, J. P., San-José, J. T., Cuadrado, J. & Sancibrian, R. 2014. Health & Safety criteria for determining the sustainable value of construction projects. Safety science, 62, 221-232 43. Suraji, A., Duff, R. and Peckitt S. J. (2001) Development of Causal Model of Construction Accident Causation. Journal of Construction Engineering and Management, 127(4), pp. 337-344 44. Sarhan and Fox (2012). Trend and Challenges to the Development of a Lean Culture among UK construction Organizations. [Accessed: 25 Dec. 2018] 45. Singh, Jagtar & Vikas, Rastogi & Sharma, Richa. (2014). Implementation of 5S practices: A review. Uncertain Supply Chain Management. 2. 155-162. 10.5267/j.uscm.2014.5.002. 46. Salem, Ossama & Asce, M & Solomon, J & Genaidy, Ash & Minkarah, I. (2006). Lean Construction: From Theory to Implementation. Journal of Management in Engineering - J MANAGE ENG. 22. 10.1061/(ASCE)0742-597X(2006)22:4(168). 47. Saurin, T.A., Formoso, C.T. and Guimaraes, L.B.M. (2004) Safety and Production: An Integrated Planning and Control Model. Construction Management and Economics, 22(2), pp.159-169 48. Tyler M. and Lamont D. (2008) Construction Health and Safety. Institution of Civil Engineers 49. Wood, Hannah & Gidado, Kassim. (2008). Project Complexity in Construction. COBRA 2008 - Construction and Building Research Conference of the Royal Institution of Chartered Surveyors.

- 31. Mennatalla Ghonimy 10632040 50. UMIST, Loughborough University (2003). Causal factors in construction accidents Prepared by Loughborough University and UMIST for the Health and Safety Executive 2003