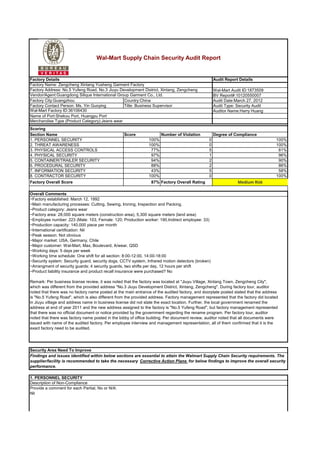

Yusheng Wal-Mart Audit Report

- 1. Security Area Need To Improve Findings and issues identified within below sections are essential to attain the Walmart Supply Chain Security requirements. The supplier/facility is recommended to take the necessary Corrective Action Plans for below findings to improve the overall security performance. 8. CONTRACTOR SECURITY Overall Comments ~Factory established: March 12, 1992 ~Main manufacturing processes: Cutting, Sewing, Ironing, Inspection and Packing. ~Product category: Jeans wear ~Factory area: 28,000 square meters (construction area), 5,300 square meters (land area) ~Employee number: 223 (Male: 103, Female: 120; Production worker: 190,Indirect employee: 33) ~Production capacity: 140,000 piece per month ~International certification: Nil ~Peak season: Not obvious ~Major market: USA, Germany, Chile ~Major customer: Wal-Mart, Max, Boulevard, A/wear, QSD ~Working days: 5 days per week ~Working time schedule: One shift for all section: 8:00-12:00, 14:00-18:00 ~Security system: Security guard, security dogs, CCTV system, Infrared motion detectors (broken) ~Arrangment of security guards: 4 security guards, two shifts per day, 12 hours per shift ~Product liability insurance and product recall insurance were purchased? No Remark: Per business license review, it was noted that the factory was located at "Jiuyu Village, Xintang Town, Zengcheng City", which was different from the provided address "No.3 Jiuyu Development District, Xintang, Zengcheng". During factory tour, auditor noted that there was no factory name posted at the main entrance of the audited factory, and doorplate posted stated that the address is "No.5 Yufeng Road", which is also different from the provided address. Factory management represented that the factory did located in Jiuyu village and address name in business license did not state the exact location. Further, the local government renamed the address at end of year 2011 and the new address assigned to the factory is "No.5 Yufeng Road", but factory management represented that there was no official document or notice provided by the government regarding the rename program. Per factory tour, auditor noted that there was factory name posted in the lobby of office building. Per document review, auditor noted that all documents were issued with name of the audited factory. Per employee interview and management representation, all of them confirmed that it is the exact factory need to be audited. 100% 86% 58%7. INFORMATION SECURITY 2. THREAT AWARENESS 3. PHYSICAL ACCESS CONTROLS 4. PHYSICAL SECURITY 5. CONTAINER/TRAILER SECURITY 6. PROCEDURAL SECURITY 77% 97% Degree of Compliance 100% 100% 81% 96% 5 1 2 2 Score Number of Violation 100% 100% 0 0 Description of Non-Compliance Provide a comment for each Partial, No or N/A: Nil 94% 88% 43% 5 100% 0 90% Merchandise Type (Product Category):Jeans wear Wal-Mart Audit ID:1873509 BV Report#:10120550007 Audit Date:March 27, 2012 Name of Port:Shekou Port, Huangpu Port Factory City:Guangzhou Country:China Scoring Auditor Name:Harry Huang Factory Overall Score 87% Factory Overall Rating Medium Risk Section Name 1. PERSONNEL SECURITY 1. PERSONNEL SECURITY Factory Address: No.5 Yufeng Road, No.3 Jiuyu Development District, Xintang, Zengcheng Vendor/Agent:Guangdong Silique International Group Garment Co., Ltd. Audit Report Details Audit Type: Security AuditFactory Contact Person: Ms. Yin Guoying Title: Business Supervisor Wal-Mart Supply Chain Security Audit Report Wal-Mart Factory ID:36106430 Factory Details Factory Name: Zengcheng Xintang Yusheng Garment Factory

- 2. Provide a comment for each Partial, No or N/A: 1. Finding Details: It was noted that 2 out of 2 vehicles in visitor parking area were not issued with visual identification tag. Requirement: Security guards should assign a visual identification tag to vehicles in visitor parking - such as a temporary color-coded parking decal. 5. CONTAINER/TRAILER SECURITY Description of Non-Compliance Provide a comment for each Partial, No or N/A: 1. Finding Details: It was noted that no written evidence was maintained to prove that the factory require advance notice by a pick-up or delivery transport company. Requirement: The facility should require advance notice by a pick-up or delivery transport company (driver name, company, date and time of arrival, purpose of trip). 2. Finding Details: It was noted that although CCTV system was installed in the loading dock, the security tape can keep record for one day only. Requirement: The entire container/trailer loading process, visual of inside of the container/trailer, should be captured on CCTV and the recording is kept for 45 days. 2. THREAT AWARENESS Provide a comment for each Partial, No or N/A: Nil Description of Non-Compliance Description of Non-Compliance Description of Non-Compliance Provide a comment for each Partial, No or N/A: 1. Finding Details: It was noted that infrared motion detectors were installed along the fence and CCTV system was installed at factory gate; however, it was noted that all these motion detectors were out of function as per on site testing. Factory management stated that the motion detector system was broken and they will fix it as soon as possible. Requirement: Security personnel should use closed circuit television (CCTV) or other surveillance methods to perform 24/7 monitoring of the fence/wall and all facility entrance gates. 2. Finding Details: It was noted that there was no CCTV or another survellinece method used by security to monitor activity in payroll office and system room. Requirement: CCTV or another survellinece method is used by security to monitor activity at sensitive areas within the facility (i.e., receiving, shipping, final packing, payrolll office, lobby, systems room). 3. Finding Details: It was noted that only the business department require advance notice of a vendor visit. Further, the time of arrival was not stated in the notice form. Requirement: The facility should require advance notice of a vendor visit: visitor name, company representing, date and time of arrival, purpose of visit. 4. Finding Details: It was noted that the security guard did not request for positive identification of visitors' including the auditor on the audit day. Requirement: Security guards should require positive identification of any visitor to the facility (photo ID, passport, etc.) 5. Finding Details: It was noted that pick-up and delivery drivers were not required to show photo identification on the audit day. Requirement: Pick-up and delivery drivers should be required to show photo identification. 4. PHYSICAL SECURITY 3. PHYSICAL ACCESS CONTROLS

- 3. Provide a comment for each Partial, No or N/A: Nil Description of Non-Compliance Provide a comment for each Partial, No or N/A: 1. Finding Details: During on site testing, it was noted that 2 out of 3 computers can be accessed without password. Requirement: The facility information systems should be accessed only by using a password. 2. Finding Details: During on site testing, it was noted that the system user passwords were not suspended after three failed access attempts. Requirement: System user passwords should be suspended after three failed access attempts. 3. Finding Details: It was noted that there was no daily report of invalid password attempts and file access maintained by the factory. Requirement: The system administrator should receive and review a daily report of invalid password attempts and file access. 4. Finding Details: It was noted that there was no reported incident maintained and no investigation conducted as a result. Requirement: The system administrator should investigate any reported incident of attempted unauthorized system access. 5. Finding Details: It was noted that there was no network-wide intrusion warning system available in the factory. Requirement: The system administrator should implemente a network-wide intrusion warning system. 8. CONTRACTOR SECURITY Description of Non-Compliance 7. INFORMATION SECURITY recording is kept for 45 days. 6. PROCEDURAL SECURITY Description of Non-Compliance Provide a comment for each Partial, No or N/A: 1. Finding Details: It was noted that the factory could not provide written evidence to prove that the transport company have participated in supply chain security program. Requirement: The transport company should participate in supply chain security program when available - such as C-TPAT, AEO, PIP. 2. Finding Details: It was noted that the factory have never conduct unannounced security check to ensure that the transport company is in compliance with the contract. Requirement: The facility should conduct a periodic unannounced security check to ensure that the transport company is in compliance with the contract. Remark for N/A: No domestic cargo being produced in the factory.

- 4. Page 1 of 2 Digital Photo Form Client: Wal-Mart Date of Audit: March 27, 2012 No. of Pages: 2 Agent: Guangdong Silique International Group Garment Co., Ltd. Report No: 10120550007 No. of photos: 20 Factory Name: Zengcheng Xintang Yusheng Garment Factory Location of Audit Site: No.5 Yufeng Road, No.3 Jiuyu Development District, Xintang, Zengcheng, Guangzhou, Guangdong, China. Factory gate Factory name Factory fence Security guard and security post Badge for visitor Badge for vehicle (prepared but not issued) Resigned name list posted in security room Monitor, telephone and visitor log in security room CCTV system

- 5. Page 2 of 2 Infrared motion detector (broken) Loading dock Parking area for external vehicle Authorized person for power control Authorized name list for sensitive area Photo badge Packing section Material warehouse Finished goods warehouse End Security posters Factory address