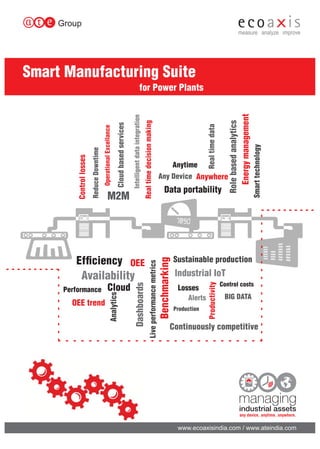

Smart Manufacturing Suite for Power Industry

- 1. Smart Manufacturing Suite for Power Plants

- 2. Introduction In the competitive power generation industry, increased consumer demand for high-quality and consistent power supply necessitates high reliability of various mechanical and electrical equipment, improved plant operations, fuel management, and maintenance processes. Trouble-free operation, avoidance of unforeseen failures, improved performance coupled with cost savings and avoidance of penalties are becoming business drivers. Rapid handling of performance deviations that otherwise contribute to increased heat rate, lost capacity and increased fuel consumption are vital in the power generation units of today. EcoAxis’ solution provides a decision support system for online operations & maintenance that integrates plant operations, fuel and water chemistry management and maintenance processes to help generate information for operating decisions that creates savings in fuel, personnel costs and maintenance costs – hence extending the life of your power plant. How we can help you – EcoAxis' solution EcoAxis' Internet of Things (IoT) based monitoring solutions tracks critical parameters of power plant operations (such as boiler temperature profile, turbine vibration parameters, equipment operations, run-hours, stoppages, water chemistry), performance and maintenance on a minute-by-minute – or even faster – basis, followed by managing the operation of the plant through advanced supervision and diagnostic tools to reduce power plant operating and maintenance costs. Trouble-free operation, avoidance of unforeseen failures, improved performance coupled with cost savings and avoidance of penalties are today’s business drivers.Ability to access and respond to data/information in a quick manner, can make all the difference. Power generation companies generally use DCS-SCADA systems to operate the plant within prescribed operating ranges. While the information presented by these systems is in real-time, it is available mainly in control rooms within a power plant. There is a pressing need to make relevant data of critical parameters available beyond the confines of the control room or even the plant to experts who can remotely guide and resolve issues quickly. In multi-site generation plants, you may not have the luxury of site-wise deployment of highly qualified personnel. What is needed is access to relevant information for key resources. Unavailability of relevant information at the right time and place Optimum utilisation of key resources Slow response time to information flow Do you face these challanges?

- 3. • Take informed decisions allowing greater flexibility in power plant operations and maintenance • Schedule power generation as per grid demand along with load-based performance monitoring (instead of capacity- based), thereby giving a better indication of power plant performance • Increase plant availability by controlling and effectively managing unscheduled stoppages • Achieve improved plant reliability through individual tracking of run hours, vibration and temperature profile of various critical rotating parts like motor and roller bearings • Reduce maintenance cost by shifting from break down maintenance to condition based predictive maintenance by detecting defects early and carry out maintenance during schedule shutdown rather than having unplanned shutdown • Attain peak operational efficiency through real-time integration of fuel management accounting systems • Improve de-aeration effectiveness and minimize boiler corrosion risk • Avoid breakdowns & save operative costs • Have better control on O&M operations by linking it to KPI-based performance Solution architecture KPIs & Advanced Analytics Customer Scope Utility Equipment Process Plant Central Supervision OPC Server OPC Client Axislog Data Logger Define user roles Create users Functionality EcoAxis Solution Trending Tabular Data Export to Excel Export to PDF a isx EYE a sxi EYE a sxi GURU a isx NOTIFY Alerts & Notifications Application Server Database Server Configuration Organisation Users Sites Equipments • End User • O & M • OEM • Operator • Maintenance Team • Management (KPIs) Plant Data ManagementData Acquisition What can you achieve with IoT based continuous monitoring system? Personalized login with role-based & asset-based functionality approach Configuration of alerts, email notification & escalation MIS reports with meaningful analytics Personalized dashboards published as web pages Operations control screens made available to experts for viewing real- time data remotely

- 4. A.T.E. ENTERPRISES PRIVATE LIMITED T-126, T Block, MIDC, Bhosari, Pune 411 026 T | +91 20 3088 1100 E | contact@ecoaxisindia.com W | www.ecoaxisindia.com / www.ateindia.com (Business Unit: )EcoAxis Waste water effluent disposal monitoring Continuous Measurement & Verification (CMV) Analytics for renewable energy Discrete equipment monitoring Facility monitoring Utilities monitoring Plant process monitoring Understand your most critical challenges Setup systems to collate the most pertinent data Data acquisition & historization Build advanced analytics Generate insights for better decisions Cloud based platform EcoAxis Solution Manual Entry Trending Tabular Data Export to Excel Export to Pdf ax si EYE - Historian EcoAxis Hardware OPC Client Process 1 Process 2 Process 3 Process n Basic Functionality Additional Information Any device, Anytime, Anywhere Alerts & NotificationsAnalytics GURUax si NOTIFYax si Your Scope Our Solution Process 4 Data Acquisition Data Management Advanced Analytics