Flooring Installation Assessment

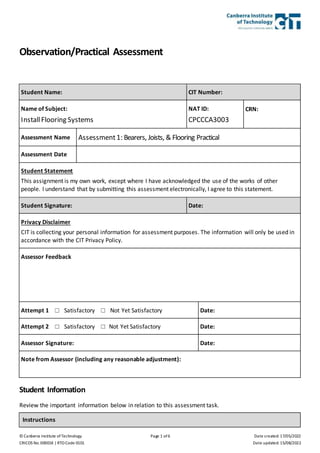

- 1. © Canberra Institute of Technology Page 1 of 6 Date created: 17/05/2022 CRICOS No. 00001K | RTO Code 0101 Date updated: 15/08/2022 Observation/Practical Assessment Student Name: CIT Number: Name of Subject: InstallFlooring Systems NAT ID: CPCCCA3003 CRN: Assessment Name Assessment1: Bearers, Joists, & Flooring Practical Assessment Date Student Statement This assignment is my own work, except where I have acknowledged the use of the works of other people. I understand that by submitting this assessment electronically, I agree to this statement. Student Signature: Date: Privacy Disclaimer CIT is collecting your personal information for assessment purposes. The information will only be used in accordance with the CIT Privacy Policy. Assessor Feedback Attempt 1 ☐ Satisfactory ☐ Not Yet Satisfactory Date: Attempt 2 ☐ Satisfactory ☐ Not Yet Satisfactory Date: Assessor Signature: Date: Note from Assessor (including any reasonable adjustment): Student Information Review the important information below in relation to this assessment task. Instructions

- 2. © Canberra Institute of Technology Page 2 of 6 Date created: 17/05/2022 CRICOS No. 00001K | RTO Code 0101 Date updated: 15/08/2022 You are required to complete a JSA, Safety sign quiz, & Toolbox talk. In groups of 3 students, you will use the following instructions and accompanying plans to set out and construct a sub-floor frame. You will be using the concrete piers in P Block as a base. You will then install sheet platform flooring, tongue and groove flooring and an approved wet-area floor systemto your subfloor frame. Your trainer will allocate teams and ‘flooring sites’, depicted on site plan for your practical assessment. PART 1: 1. Use the diagram/ plan to find your “flooring site”. 2. Pack the piers to a common height. (The highest pier) 3. Install DPC and Termite protection as required. 4. Correctly set out the bearers with max spacings of 1800mm centres. NOTE: On site, bearers would be fixed to piers using specified fixings. To extend the lifespan of the materials used we will not be using these fixings. 5. Using levelling equipment and packing, double check all the bearers are level and in plane. 6. Set out and mark the floor joist position on the bearers @450c max (allow for sheet flooring laps). Checked deep joists will be used for the step down in the wet area. These joists will butt against standard joists. 7. Lay joists on bearers next to set out marks and check for square using Pythagoras. Your diagonal measurement should be: __________ mm 8. Fix joists level and square to bearers using triple grips and 8G 25mm screws. 9. Run string lines with packing blocks or use a straight edge to check joists are in line and adjust joists by packing or planing as required. 10. Measure, cut, and install, solid blocking under external loadbearing walls. Fix with angle brackets and screws. A trimming joist should be used for the external edge of the wet area. NOTE: Solid blocking is required when a 35mm bottom plate is used for a load bearing wall.

- 3. © Canberra Institute of Technology Page 3 of 6 Date created: 17/05/2022 CRICOS No. 00001K | RTO Code 0101 Date updated: 15/08/2022 Part 2: Set out and install particle sheet flooring, fibre cement sheet flooring, and tongue and groove strip flooring, to Australian standards and manufacturers specifications on the subfloor frame from part 1. 1. Set out where each flooring type will be required. 2. Flick a chalk line 100mm back from the first row of sheets to measure back to. It is suggested on larger jobs to check your sheets are straight every 2-3 rows to avoid saw toothing. 3. Tack the PB (particle board) sheets in position at the corners with screws to minimize damage to materials when dismantling. 4. Install FC (Fibre cement) sheet flooring in the stepped down wet area. Secure with screws on each corner to minimise damage when they are removed. 5. Double check your flooring systemfor level and square and then ask you assessor to inspect it. 6. Remove the FC sheets and store appropriately and install T&G (tongue and groove) flooring in the stepped down area. 7. Fix the T&G flooring using floor clamps and correct fixing methods. 8. Check T&G flooring complies to standards and tolerances. 9. After your assessor has checked your flooring systemagain, dismantle and store materials appropriately, using OH&S practices. Pay special attention to de-nailing of timbers and correct storage. Time Allowed 4 hours Assessment Conditions Assessment will be conducted in a simulated work environment at CIT Bruce under teacher supervision. If at any stage the assessor deems the assessment to be unsafe it will be stopped. Access to all resources, manual and standards is permitted. This will be complete during your normal class time, if it is poor weather your assessment maybe moved to another day

- 4. © Canberra Institute of Technology Page 4 of 6 Date created: 17/05/2022 CRICOS No. 00001K | RTO Code 0101 Date updated: 15/08/2022 Materials Provided by CIT All site plans, materials, tools, and equipment required to complete the task will be provided. Materials You Need Personal protective equipment PPE and nail bag and BYOD. Attempts You may have at least two (2) attempts for this assessment. If your first attempt is not successful, your teacher will discuss your results with you and will arrange a second attempt. If your second attempt is not successful, you may be required to re-enrol in this unit. Please refer to the CIT Assessment Policy if you have any questions.

- 5. © Canberra Institute of Technology Page 5 of 6 Date created: 17/05/2022 CRICOS No. 00001K | RTO Code 0101 Date updated: 15/08/2022 MarkingRubric Attempt 1 Attempt 2 S NYS S NYS The student successfully completed the following: 1. Read and interpreted work instructions and planed sequenceof work. ☐ ☐ ☐ ☐ 2. Contributed to the development of a JSA and its control rating,with consideration to environmental requirements. ☐ ☐ ☐ ☐ 3. Actively participated and agreed to the Toolbox talk ☐ ☐ ☐ ☐ 4. Selected and used PPE for given tasks. ☐ ☐ ☐ ☐ 5. Selected tools and equipment and checked for serviceability. ☐ ☐ ☐ ☐ 6. Selected materials required for the task and accurately calculated quantities. ☐ ☐ ☐ ☐ 7. Carried out task in accordancewith the JSA and organisational policies and procedures. The student safely carried outthe task followingwhat was agreed to in the JSA. ☐ ☐ ☐ ☐ The student successfully completed the following: 8. Checked piers for level and packed to suithighestpier. ☐ ☐ ☐ ☐ 9. Marked and cut bearer material to length. ☐ ☐ ☐ ☐ 10. Checked out deep joists for stepped down area. ☐ ☐ ☐ ☐ 11. Planned for damp proof courseand termite protection. ☐ ☐ ☐ ☐ 12. Located and fixed bearers after adjustingfor square,line,and level. ☐ ☐ ☐ ☐ The student successfully completed the following: ☐ ☐ ☐ ☐ 13. Set out joistlocations in accordancewith plans and specifications. ☐ ☐ ☐ ☐ 14. Fixed joists to bearers straight,square,level,and in-line. ☐ ☐ ☐ ☐ 15. Checked joists for straightand level and adjusted as needed. ☐ ☐ ☐ ☐ 16. Cut, fit, and fixed supportingblocks and trimmers for framingmembers and door openings. ☐ ☐ ☐ ☐ 17. Cut, fit, and fixed trimmers to support sheet flooringjoints thatdo not land on joists. ☐ ☐ ☐ ☐

- 6. © Canberra Institute of Technology Page 6 of 6 Date created: 17/05/2022 CRICOS No. 00001K | RTO Code 0101 Date updated: 15/08/2022 The student successfully completed the following: 18. Set out and checked for flooringmaterial suitability. ☐ ☐ ☐ ☐ 19. Confirmed dimensions from plans and cutflooringmaterials for installation with minimum of waste. ☐ ☐ ☐ ☐ 20. Installed and secured fibrecement flooringto manufacturers specifications. ☐ ☐ ☐ ☐ 21. Installed and secured particleboard flooringto manufacturers specifications. ☐ ☐ ☐ ☐ 22. Installed and secured tongue and groove strip flooringto manufacturers specifications. Flooringcomplies with all standards and tolerances priorto askingthe assessorto check ☐ ☐ ☐ ☐ The student successfully completed the following: 23. Dismantled task safely,ensuringminimal waste. ☐ ☐ ☐ ☐ 24. Disposed of unusablematerial safely. ☐ ☐ ☐ ☐ 25. Checked, maintained,and stored tools,equipment, and materials in accordancewith workplacerequirements. ☐ ☐ ☐ ☐