Textile value chain Vol-1, Issue 2

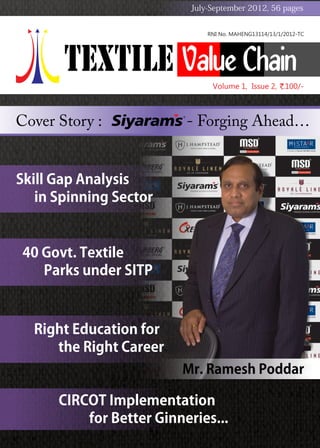

- 1. July-September 2012, 56 pages RNI No. MAHENG13114/13/1/2012-TC Volume 1, Issue 2, .100/- Cover Story : - Forging Ahead… Skill Gap Analysis in Spinning Sector 40 Govt. Textile Parks under SITP Right Education for the Right Career Mr. Ramesh Poddar CIRCOT Implementation for Better Ginneries...

- 2. FIBER GINNER YARN SPINNER FABRIC WEAVER GARMENT RETAIL MANUFACTURER FASHION DESIGNER WHOLESALER WOVEN CHEMICALS FINISHING DYES ORGANIC Reshaping textile industry... TRIMMINGS EXPORT A company having an expert panel for individual tasks. Associate with Textile Value Chain and Boost your Business as well as Indian Economy to New Heights. EMBLISHMENT IMPORT Book your Advertisement space now !!! Subscribe today for interesting information, analysis and much more...

- 3. Editorial Thanks to all who whole-heartedly accepted our 1st issue of Textile Value Editor & Publisher Chain and gave us valuable feedback, suggestions & improvement scope. Jigna Shah After introducing our 1st Textile Quarterly Magazine / Guide in India, we are proceeding ahead with our new issue. This magazine not only provides Chief - in - Editor Rajul Shah knowledge regarding the textile and fashion industry but also provides meaningful information to our readers. Technical Advisory Board In the context of the Indian market, our industry has very few organised Dr. Ela Dedhia, Associate Professor professional players. In this issue, we are sharing a milestone success story of Nirmala Niketan College, Mumbai Siyaram's, a journey from a family-owned business start-up to a professional Mr. B.V. Doctor, organisation in just 3 decades. A journey from a 10 crores company to 1000 HOD Knitting Dept, crores... SASMIRA, Mumbai In this issue, we share with you detailed research papers from CIRCOT in association with NAIP and CICR, on 'Cotton Value Chain', how following Advertisement & Marketing Md. Tanweer few suggestions given by the team, will reap huge benefits for the Ginners...! The Textile Committee shared Star Rating of Ginner's and its importance for Graphic Designer an acceptance in international market and a doctorate shares with us the Vaibhav Gosar functional and technical aspects of apparel. An article from a consultant Manoj Kumar company also talks about technical textiles which have a huge scope in India but it is still in a nascent stage. Authors Dr. R.P. Nachane After giving a brief Skill Gap Analysis of the industry in the last issue, this time Mr. S. Ulganathan we are continuing in detail with the Spinning sector. We also talk about Dr. K.R.K. Iyer fashion and textile education and the different career options and how French Ms. Bhavna Rawat King Louis XIV developed fashion in the 17th century so people would not Mr. N.S. Kazi rebel against him. We also have an Overview on Government policy about Mr. Shivram Krishnan Integrated Textile Parks, 12th Plan for the development of Industry Mr. Kalyan Roy Contributors and 40 parks details in brief. Ms. Sarita Raut Ms. Parinita Devadiga We are reaching out to all the contributors of textiles like Manufacturers, Ms. Sarah Nizam Wholesalers, Educational Institutes, Associated Professionals, Consultants, Government, Industry Associations, and many more to associate with us. Registered Office : Come join us for our Vision: “Reduce the GAP amongst all the Textile Innovative Media & Information Co. Contributors...” 189/5263, Sanmati, Pantnagar, Ghatkopar (East), Mumbai - 400075. 'Textile Value Chain' is your platform where you can share 'The Truth', ' The Maharashtra, INDIA. Real Picture' (not just being politically correct) and we will share your ideas Tel / Fax: +91-22-21029342 and view points and try to make our industry more organized, professional Cell: +91-9769442239 and internationally popular with better professionals!! A Better Industry to Email: info@textilevaluechain.com have more FDI's, a Better Industry for people to look upon us and make them Web: www.textilevaluechain.com join and be part of this industry...!!! Owner, Publisher, Printer and Editor Best Regards, Ms. Jigna Shah printed & processed by Jigna Shah her at, Impression Graphics, Gala Editor & Publisher no.13, Shivai Industrial Estate, behind All rights reserved Worldwide; Reproduction of any of the content from this issue is prohibited McDonald, Andheri Kurla Road, without explicit written permission of the publisher. Every effort has been made to ensure and Sakinaka, Andheri (E), Mumbai-72, present factual and accurate information. The views expressed in the articles published in this Maharashtra, India. magazine are that of the respective authors and not necessarily that of the publisher. Textile Value chain is not responsible for any unlikely errors that might occur or any steps taken based in the information provided herewith. Copyright 2012 by Textile Value Chain.

- 4. ADVT.

- 5. Textile Value Chain In This Issue... Cover Story : Siyaram Silk Mills Limited 04 Fibre : Cotton Value Chain: CIRCOT 08 Star Rating- A Figure of Merit for Ginneries 11 Bamboo- An Eco Fibre 16 Yarn : Ratan Glitters Industries Limited 18 Fabric : Cloth Production in India 20 Life Cycle Analysis of Textiles 23 Garment : Quality Tools in Garment Manufacturing 25 Apparel Aspects 28 Fashion : King Louis XIV's- A Fashion Developer 18 Technical Textiles 35 SME Corner : Wholesalers view 39 Skill Gap Analysis- Spinning Sector 40 Career Opportunities : People in textile and fashion : Ÿ Sarah Nizam 44 Ÿ Rajul Shah 45 International Colleges for Textile & Fashion 47 College focus : VJTI 48 Textiles Trade Shows 50 Government Policy- SITP 52 Corporate Fun 56

- 6. Textile Value Chain Siyaram Silk Mills is a gigantic name in the textile market today. What is the history behind it and how has the journey been so far? Incorporated in 1978, Siyaram Silk Mills Limited is the Flagship Company of the Siyaram Poddar Group. Initially, the company started with trading activities in fabrics and in 1981 started manufacturing activities at Tarapur with 66 indigenous looms. Over a period of time, we have Siyaram’s Showroom modernized and upgraded the machineries gradually Today Siyaram's has more than 1000 direct in stages by inducting modern technology machines. employees and 5000 indirect employees. Please Siyaram's today is the largest producer of blended highlight on the core team who started the entire suiting and shirting in India, producing 40 million Siyaram Silk Mills and brought it to a place this metres annually. Siyaram's has been in the business of far. fashion for almost 3 decades now. In this span of time, Siyaram Silk Mills was started by Shri Siyaram and other brands under the group have Dharaprasadji Poddar and Shri Ram Prasadji Poddar. become house hold names. It may be one of the very In 1980-81 Shri Rameshji Poddar joined Siyaram's few brands in the country which has an urban and when the turnover was less than Rs. 10 crores. He rural brand acceptance and penetration. worked relentlessly & acquired many skills of business under the expert guidance of Shri Could you please highlight the various brands Ramprasadji Poddar. He took full charge of the under the Siyaram umbrella? business in 1982. Since then, there has been no In the fabric space, we have successful brands like looking back for Siyaram's. Over the years, Siyaram's Siyaram's, J.Hampstead and Mistair. In the has scaled new heights and reached a turnover of Rs. readymade space, we once again have established 1000 crores. Starting with merely 4 employees, today brands like Oxemberg, MSD and we have also Siyaram Silk Mills under the astute leadership of Shri recently introduced J.Hampstead in the Premium Rameshji Poddar has not only expanded its presence Ready-to-wear space as well. Siyaram Home in India but also reached out to global markets. Furnishing is a relatively new business that we have introduced some time back. This segment also has a How much is the monthly production at Siyaram huge potential and we definitely see ourselves as a Silk Mills? For the same, please specify the prominent player in the time to come. We are also production quantity, the manufacturing facilities catering to the hospitality & corporate business as well as the machinery. sectors through one of our brands Unicode and the Today, Siyaram’s produces more than 60 million school uniform business which has grown in recent metres of fabric per annum. It has state-of-the-art, times gets handled through our brand, Little world-class fully automated weaving and processing Champs. machines at its factories in Tarapur and Silvassa. ADVT. 4 July - September 2012

- 7. Textile Value Chain Siyaram's also has one of the best facilities in Daman segment. It is largely dominated by unorganized, to produce garments. Besides this we also have a local and imported fabrics. There are barely few strong and dedicated R&D team at our Design organized players operating on a national level in this Studio. space. Siyaram Home Furnishing is modern luxury at affordable prices and with the appeal, equity and the What are the core beliefs and the vision of the penetration that Siyaram brand has in all markets company? across India, we hope to piggy-ride on this and grow Siyaram’s is founded on the principles of mutual the business. respect and appreciation for human capital. The vision of the company is 'To grow forever by What is the driving force behind Siyaram's success consistently achieving customer delight and being the - in both the fabric as well as readymade sectors? most preferred partner to every stakeholder'. It has One of the core factors which have influenced the been our philosophy to provide its customer value- growth of Siyaram's has been the ability and the quick for-money products, world-class quality and the turnaround time to launch innovative and fashion latest in international style and design. We have end products. We have continuously re-invented to stayed contemporary with a vision well-focused on create excitement both for trade and for consumers. the future. Our ability to spot international trends and the infrastructure to develop and launch great designs in Siyaram’s journey started with fabrics but has India and overseas is something that is a huge driving grown extensively in ready-made sector as well. factor for us, always. Your thoughts on the same. Initially, we were engaged in the trading of How is the distribution network for Siyaram's? suitings and shirtings only. Over a period, we Today, Siyaram has more than 65,000 retailers expanded, diversified and integrated our facilities selling Siyaram's and its other brands. Siyaram today substantially and currently we are the market leader of is a national player operating in metros and Tier I /II man-made fibre (MMF) fabric segment. We produce towns. We are happy to be a part of their business and 60 million metres of fabric per annum. Our are constantly striving to make their business more processing units are also one of its kinds in India and profitable with us. they can process diverse fibres such as wool, cotton and polyester blends, all under one roof. In fabric, we In any textile company the fabric used is very have different brands for different segments of the important. Could you throw some light on the market like Siyaram's, Mistair, J Hampstead, etc. fabric you manufacture? Are they natural or Siyaram's is a very popular brand and is present in synthetic or both? around 65,000 odd retail outlets across the country. Fabric is the core product which can be sold as is Keeping this in mind, we thought of leveraging on or used to convert into garments. Hence the feel, fall this and hence we are extending the brand to our and texture of the fabric are extremely important ready-mades known as Oxemberg & MSD. They are characters as they have to be appealing to the end user. basically a brand extension from fabric to garment. The texture of the fabric is the outcome of the yarns used for production as well as the value addition done Siyaram is also seen in home furnishings - what are through processing the fabric into various finishes. your future plans to promote this vertically? Siyaram's is a market leader in blended suitings The home furnishing segment is a fast growing pioneered to cater to the ever-changing trends in the ADVT. July - September 2012 3

- 8. Textile Value Chain fashion world. We use both natural as well as synthetic yarns to manufacture our fabrics. However, now we have ventured into 100% natural fabrics like cottons and linens through our recently launched new brands Zenesis, Moretti and Royale Linen as there is a huge demand for natural fabrics. Do you have in-house yarn production at Siyaram's? What are the types of fibres getting manufactured at your end? We are not into producing yarns, however we are in the business of value-added dyed & fancy yarns with expertise in the manufacturing of wide range of cottons and synthetic yarns catering to the fashion R&D, we are constantly exciting our trade and fabric manufacturers across India. consumers with new products which the consumers have seen or experienced in global markets but have We see a certain trend with hiring A-list celebrities not been able to get it in the Indian markets. We have as brand ambassadors for the textile brands. Any recently launched Royal Linen Collection with specific reason for Siyaram's to have different Manish Malhotra. The collection is 100% pure linen brand endorsers for the various brands? and is one of the finest linen fabrics in the world. The trend was started by Siyaram's. In the late Moretti is another brand that we have launched 90's, Siyaram's was quick to identify the importance which is into premium cotton shirting fabrics. of having the right celebrity for the brand. Soon Today's consumers are all about individual identity thereafter, Siyaram's has been associated with some of and that reflects in their clothing as well. the biggest names in fashion, sports and bollywood. Be it Manish Malhotra, Boris Becker, Leander Paes, Networking in the textile industry is an integral Mahesh Bhupati, Dhoni or Vijender Singh, Lara part of the business. What is your take on building Dutta, Bipasha, Priyanka Chopra, Neil Nitin relations with the traders? Mukesh or Hrithik. We have them all. More Like in every business, the role of a retailer is very important we have not just roped in celebrities, we crucial. A retailer is a bridge between the wholesaler, have used them tactically to the advantage of the the supplier and the mill. He is an important brand in different markets. This has helped the brand marketing intermediary who by his timely to get out of the clutter and carve a space for itself. communication informs the manufacturers/ Today being the trendsetters that we are and also the distributors/ dealers regarding which product is larger portfolio that we have, we have strategically acceptable in the market as they know the pulse of the identified the right celebrity with the brand and have market. Due to this information the wholesaler also used them effectively. confidently distributes his products even in the remotest part of the country. I believe that the real What is the road ahead with regards to the value India lies in the rural parts of our country. We have added products vertically? always strived to develop the best of relations with Going forward, value added products are going to these retailers, by encouraging them and supplying be a large part of our business. Through our focused ADVT. 6 July - September 2012

- 9. Textile Value Chain the most fashionable goods at best rates. We are also their positioning of “Come Home to Siyaram's” proud that with our growth, our channel partners has been able to create a strong space in the minds of have also grown. This has been the underlying global Indian consumers and this has been philosophy of Siyaram's. accelerating the growth pace of brands like Siyaram's and Oxemberg in the global markets. We are catering Did the 2012 Budget put any repercussions on the to markets in Middle east, USA and Europe as well. textile industry? We wholeheartedly compliment the Government Could you explain the garments in detail for continuation of exempted route for clearance of specifying topics like export, domestic etc.? textiles under Notification No.30/2004-CE. The Indian consumers are converting from Although the excise duty on branded ready-made stitched apparel to ready-to-wear clothing range. garments and made-ups has not been abolished, its Accordingly, those companies which are engaged in impact is reduced from 4.5% to 3.6% which is also a business of manufacturing and distribution of quality welcome step. The Hon'ble Finance Minister fabrics to garment industry have a promising future. announced in his Budget Speech that automatic Indian companies are now eyeing the huge shuttle-less looms are exempt from basic customs opportunity in partnering with luxury brands duty of 5% which is great. However, in the present wishing to enter India. Retailers and private equity Budget, duty on cotton stream of production has firms on the other hand are ready to make huge investments in promising growth of apparel brand. been increased to 6% from 5%, but that on man- Meanwhile brands are also buying stakes into retail made stream from 10% to 12%. Thus, the difference companies to grasp a wider market. Textile companies in duty has widened, at a time when the man-made are strengthening front and back-end operations textile industry is facing rough weather. Government through mergers and acquisitions in the textile should therefore fix a uniform rate of 6% for both the industry. streams of production. Manufacturing is a thrust area for the Indian government, as Indian industry and the government Way forward 2012- 2013, future investments and see foreign companies more as partners in building expansions plans, if any? domestic manufacturing capabilities rather than a Siyaram’s aims to become a Rs. 1500 crores threat to Indian business. Following this through, the company in the next 2 years and would be investing central governments as well as various states are close to Rs. 160 crores in expanding the executing various schemes such as integrated textile manufacturing capacities of the business. and apparel parks. Thus, India's garment business is poised to fuel What are your expectations from the overseas the country's textile segment as it provides the highest market? per unit realization and has high value added content. The overseas market is growing tremendously. Thus we can see that the textile industry has an Thanks to the many Indians who are settled abroad. important role to play along with being one of the key There is a great acceptance for Siyaram fabrics and its growth engines of the economy. other brands. Indian consumers abroad are connected to their roots in India. Siyaram through ADVT. July - September 2012 7

- 10. Textile Value Chain FIBRE lack of facilities for quality assessment of individual bales. Although spinning sector is performing better Cotton Value with modern facilities, weaving/knitting sector still Chain needs to improve in quality and product up gradation to meet the international standards. Further, processing such as preparatory chemical treatments of Dr. R. P. Nachane yarns and fabrics, eco-friendliness, energy use Principal Scientist, efficiency, and its treatment are factors that need NAIP Project on immediate attention. In the handloom sector, workers are exposed to harmful chemicals and environment is “Cotton Value Chain (CVC)” also vitiated with chemical effluents in rural areas. CIRCOT, Mumbai In this context, a World Bank funded project 1. INTRODUCTION entitled, “A Value Chain for Cotton Fibre, Seed and The Indian Textile Industry uses about 62% cotton Stalk: An Innovation For Higher Economic Returns as its raw material, unlike the global textile industry to Farmers and Allied Stake Holders” was sanctioned that has a 40:60 mix of cotton and man-made fibres. by National Agricultural Innovation Project (NAIP) There has been a phenomenal increase in cotton under Component 2 in consortium mode with production in India in recent years. Central Institute for Research on Cotton Technology In the conventional value chain there are a few (CIRCOT), Mumbai as lead center and Central missing as well as weak links. Ginning is considered to Institute for Cotton Research (CICR), Nagpur, Super be one of the weakest links characterized by excessive Spinning Mill Ltd., Coimbatore as consortium use of energy, presence of contaminants and trash and partners with the following objectives. Ÿ To grow established cotton genotypes in the adopted villages with integrated production technology practices Ÿ To reduce the level of contaminants in cotton by adopting appropriate on- farm and off-farm management practices and to label cotton bales with fibre attributes after appropriate ginning Ÿ To prepare yarn, fabrics and garments in the modern mill, market and manufacture eco-friendly textiles in handloom sector by employing CIRCOT technology for bio-scouring and natural dyes Ÿ To ensure additional income to farmers and alternate raw material to the industry by establishing cotton stalks supply scheme to board industries/ briquetting Ÿ To demonstrate innovative scientific processing of cotton seed for oil extraction and value addition to its by- products The present work, addresses some of the above mentioned weak/missing links to increase the efficiency and economic competitiveness of cotton cultivation, processing and value addition. Best management practices encompassing INM and IPM modules were adopted to raise crop in three locations, namely, Nagpur, Coimbatore and Sirsa. Harvesting of contaminant free cotton was carried out by utilizing appropriate picking methods for seed cotton, on farm storage and transportation. The seed cotton was ginned and individual bales were tagged for fibre attributes and were spun. Cotton plant stalks were collected, chipped and transported to board industry for making particle boards. Edible oyster mushroom crop was raised on anaerobically pre-treated cotton stalks. 8 July - September 2012

- 11. COTTON VALUE CHAIN Textile Value Chain 2. COTTON PRODUCTION: It is felt that an “Integrated Cultivation” approach by bringing together small holding farmers and ensuring quality inputs at competitive price would not only bring down the cost of cultivation but also result in cotton with low levels of contaminants. Similarly, drip irrigation, multi-tier cropping systems including vegetables and pulses and poly-mulching technology at the small farm level have clearly shown significant economic gains for the farmer in terms of improved seed cotton yield (2 to 3 times the conventional yield) could be achieved. Such technologies need to be demonstrated at the farmers' fields to convince growers for further large scale adoption. CICR with its expertise on production technologies executed this job in the current project and CIRCOT did the post harvest on-farm and off-farm management to produce clean seed cotton. 3. POST HARVEST MANAGEMENT Indian cottons are hand picked and ought to have been the cleanest; actually it is not so, due to improper handling of seed cotton, poor on-farm and off-farm management and contamination during storage and transport. It can improve if practices like proper on-farm storage of seed cotton, avoidance of any other fibre material which can work as contaminant for use during storage can be implemented. Also grading of kapas in terms of moisture and fibre attributes are issues that deserve special attention. In this project, cotton picking was carried out under the supervision of CIRCOT. Farmers were trained in the use of simple practices such as use of head gear (scarf ), use of cotton cloth bags for collecting kapas in the field, emptying these bags only on the thick plastic sheets away from the edges filling kapas in big cotton cloth bags, etc. After CIRCOT worked with farmers in Coimbatore, Nagpur and Sirsa it resulted in reduced contamination by 3.5g in 1200kg lint. 4. GINNING AND QUALITY ASSESSMENT OF BALES Ginning is one of the most crucial links in the value chain that decides the lint quality. CIRCOT with its expertise in ginning and quality characterization had provided this crucial input to the present project. CIRCOT in selected ginning factories at Coimbatore, Nagpur and Sirsa, accompanied pre-cleaning and post-cleaning with ginning. This reduced trash and contamination in the lint (~1%). 5. PRODUCTION FROM RAW MATERIAL TO MARKETING 5.1 Yarn production Bales were segregated according to the fibre parameters like, MIC, 2.5% Span length, Uniformity etc. Different groups of bales were made according to the MIC value. Accordingly 30s & 80s count yarn was spun and converted in to the fabric. The yarn made from the segregated July - September 2012 9

- 12. COTTON VALUE CHAIN Textile Value Chain bales was tested for its physical & mechanical seeds. Thus we are getting more oil and more properties. industrial material and kernel cake can be used for cattle feed or for extracting edible protein. 5.2 Bio-Scouring of Yarn and fabric making The spinning industry in the country is one of 7.2 Enzymatic treatment and Delinting the most modern and vibrant links in the value chain. When batches of cottonseeds were treated with Equally export worthy are the knitted fabrics and microbial consortium and passed through delinting garment produced from the country, albeit their low machine, the results clearly indicated lower lint unit value realization. What is bothering is the “not so content and trash in the treated lot as compared to the strong” finishing link, particularly, with its chemical control (untreated batch). This is due to the softening utilization and discharge of effluents. The preparatory of the cell wall structure making the fibres extracted processes in the chemical chain such as scouring and easily and hence less energy is consumed. bleaching are energy intensive and add to the pollution load. CIRCOT's bio-scouring technology 7.3 Enzymatic pre-treatment of kernels and oil would bring in the much desired benefits in terms of extraction saving in energy and reduction in effluent load. Also It was observed that when kernels were pre-treated application of natural dye in place of eco-unfriendly using 0.1% cellulose and 0.2% papain, it gave a synthetic dyes would also bring in not only slightly higher yield of oil than the control (untreated environmental benefit but also provide the right kind kernel). Trials were undertaken for the extraction of of raw material to the handloom sector (employment oil from enzymatically pre-treated kernel however to personnel below poverty line). they have not been satisfactory. Few more trials are required to come to a conclusion about enhancement 6. UTILIZATION OF COTTON PLANT of oil extraction by using enzymatic treatment to the STALKS cotton seed kernel. After harvesting of kapas, cotton stalks left in the fields of the farmers associated with the project was 7.4 Bio-enrichment of Hulls & cattle feed trial collected and chipped under CIRCOT's supervision. The delinted seeds were processed to separate hull The chipped stalks were transported to the particle and kernel. CIRCOT's microbial consortium was board making factory for board making. This results used to enrich cottonseed hulls for protein with in an additional income for the farmers. increased digestibility by solid state fermentation. The feed efficacy of bio-enriched hulls as cattle feed was 7. UTILIZATION OF COTTON SEED evaluated by undertaking feeding trials on cross-bread Cottonseed is not grown exclusively for oil but is cows at National Dairy Development Board available as a by-product of cotton and was once (NDDB), Anand. There haven't been conclusive considered to be a feed for animals. Earlier, results. cottonseed was being processed to recover oil and the cake, what remained after oil extraction was used as CONCLUSION animal feed. During the last few decades, cottonseed By employing CIRCOT technology industry can is being processed scientifically to get oil, meal, hulls benefit at all levels. If appropriate on-farm and off- and linters. farm management practices are used, trash and contamination at every level can be reduced. This will 7.1 Delinting of seeds & separation to Hull and enhance the quality of the raw material and thus the Kernel and Oil extraction end product. By value addition to by-products there Crushing ginned seeds not only leads to loss of can be less wastage, more employment and money linter which is a good industrial raw material but also and eco-friendly textiles can be prepared. oil extracted is about 10-12% of seed weight. If delinting is done linters of about 3-5% of seed weight For the complete article with in-depth comparison becomes available for industrial application. If hulls and analysis, please visit our website: and kernel are separated from delinted seed then hull www.textilevaluechain.com and click on Cotton can be use as a part of cattle feed and when kernel is Value Chain. crushed to extract oil we get 4-6 % extra oil as compared to that obtained by crushing of ginned 10 July - September 2012

- 13. COTTON GINNING Textile Value Chain The cotton production in the country rose from 23 G-A lakh bales during 1947-48 to 295 lakh bales during STAR RATIN MERIT 2009-10. The cotton production in 2010-11 is FIGURE OF RIES FOR GINNE estimated to be 325 lakh bales. From being an importer of cotton during pre-independence years, India has not only become self-sufficient but has Mr. S.Ulaganathan, Director (EPQA) & turned into an exporter of cotton. India is the second Dr. K.R.K.Iyer, Consultant, largest producer of cotton yarn contributing nearly Textiles Committee, Mumbai 20% to global cotton yarn trade . COTTON SCENARIO IN INDIA PROBLEMS IN COTTON CULTIVATION Amongst all the cotton growing countries of the Though India today is the second largest producer world, India ranks number one in area under cotton of cotton in the world, in productivity it is placed cultivation spreading out to over 10 million hectares. below most of the major cotton growing countries. Although only second in cotton production, India has Excessive reliance on rain, inadequate availability of several distinctions to its credit. India is the only quality seeds, high incidence of bollworm and sucking country in the world that grows on a commercial scale pests, ineffective transfer of technology to farms, all four cultivated species of cotton viz. Gossypium fragmented land holding and illiteracy of farmers have Arboreum, Gossypium Herbacium, Gossypium been the main factors contributing to low Hirsutum and Gossypium Barbedense. productivity. Today, there are hundreds of improved varieties Though the evolution of new and high yielding and hybrids belonging to the above four species being varieties and hybrids through breeding research has grown in different parts of the country. India is also helped in improving productivity, it has led to mixing the first to cultivate hybrid cotton on a commercial of varieties at the farm, market yards and ginneries scale and can take pride in being the only country that impairing the consistency of cotton quality. grows the complete range of staples from short and coarse un-spinnable Assam Comillas to the extra long GINNING SCENARIO IN INDIA superfine cotton 'Suvin', which in fibre quality The purpose of ginning is to separate cotton fibres matches, with Giza 45 of Egypt and spins 120s count. from the seeds. Ginning process is the most important The ginning outturn of cotton also presents a wide mechanical treatment that cotton undergoes before it spectrum of variation from 24% to 42%. is converted into yarns and fabrics. Any damage caused to the quality of fibres during ginning cannot be rectified later in the spinning or subsequent processes. At the same time, any quality improvement at raw material stage goes a long way in the process improvement of the entire supply chain as well as in the overall quality improvement of the final product. Till recently, the ginning industry in India presented a dismal picture. In the years before 2000, Indian ginneries were in a primitive condition where the ginning and bale press machines were manufactured between 1895 and 1920 and were In crop duration, there are varieties in India that running with poor standard of efficiency. Many complete their life cycle in about 145 days while some factories performed only ginning operations and their others take as long as 270 days. The period of growth installed capacity as low as 6-12 double roller gins. of cotton is also widely variable from region to region and is planted and processed in one part of the PROBLEMS IN COTTON GINNING country or another throughout the year. Over the years, comparisons have often been made July - September 2012 11

- 14. COTTON GINNING Textile Value Chain between ginning practices in India and abroad and the differences observed in the quality of ginned lint, particularly in terms of trash content and presence of contaminants. In countries like USA, Australia, Uzbekistan etc, the seed cotton which is machine picked and which arrives at the ginning factories with trash content in excess of 25%, leaves the ginning factories in the form of pressed bales with less than 2% trash. Even in African countries like Uganda, Tanzania, Egypt, etc where the cotton is hand-picked like in India, trash content in bales is comparable with that of US cotton because of good house keeping and the use of pre- and post-cleaning machines in their ginning system. In India, the hand-picked seed cotton, which arrives in ginning factories with substantially less trash than the machine-picked American or Australian cotton, leaves the factory with higher trash than in these countries. Excessive quantities of foreign matter due to improper picking and ginning practices had earned notoriety for the Indian cotton as the most unclean cotton in the world. Ginning factories contribution to contamination is quite significant. Modernization through technology upgrade and infrastructure improvement along with good work practices was the answer to the problems in cotton cultivation and ginning. GOV’T. INITIATIVES – TMC & TUFS CIRCOT had conducted the first ever survey on the status of the ginning industry in India and had published its report as early as in 1958. In later years, CIRCOT carried out surveys of ginning industry in some states in collaboration with ATIRA and SITRA. All such surveys had revealed the deplorable state of the Indian ginning industry and had underscored the urgent need for its modernization. Based on the results of the above surveys and recognizing the importance of cotton crop, Govt. of India launched the Technology Mission on Cotton (TMC) in February 2000. The focus of TMC was on cotton research, transfer of technology to farms and modernization of market yards and ginneries. The TMC had four component Mini Missions as follows: Mini Mission Trust Area Nodal agency Financial outlay(Rs) Cotton research and technology Indian Council for Agricultural Mini Mission I generation Research (ICAR) 700 Crores Dept of Agriculture and Mini Mission II Transfer of technology Co-op, Min. of Agriculture Development of market Mini Mission III Ministry of Textiles infrastructure 498 Crores Modernization / Up gradation of Mini Mission IV Ministry of Textiles ginning and pressing factories The target for modernization of ginneries under machine for fibre quality testing subject to a max of TMC was 1000 and by the time the scheme came to a Rs. 4 lakhs. close in December, 2010 about 850 Ginning and Almost simultaneous with TMC, the Ministry of Pressing (G & P) units were modernized or newly set Textiles launched another initiative called Technology up. Under TMC, modernized or newly set up Upgradation Fund Scheme (TUFS) under which factories conforming to TMC norms were given interest subsidy of 5% is admissible to textile financial support in the form of one-time subsidy as manufacturing units including G and P factories for follows: modernization as well as for the setting up of new 1. 25% of the costs for general items of machinery units. This scheme is continuing even today and a few and civil infrastructure subject to a max of Rs. 20 lakhs hundred ginneries have so far availed of interest in case of a large factory and Rs. 15 lakhs in case of a subsidy benefit. small factory. 2. 25% of the costs for installing new automatic bale MODERNIZATION UNDER TMC press subject to a max of Rs. 7 lakhs. The various components of modernization under 3. 25% of the costs for purchasing HVI/ MVI TMC are broadly grouped under four categories: 12 July - September 2012

- 15. COTTON GINNING Textile Value Chain I) Essential machines a) Ginning machine g) Lint conveyor system b) Pre-cleaner h) Bale press c) Lint cleaner I) Humidifiers/ Moisturizers d) Kapas conveyor j) Fire fighting system e) Seed conveyor k) Underground wiring f) Weigh bridge ii) Essential infrastructure a) Kapas platform d) Bale storage space b) Lint halls (pala halls) e) CC road c) Seed storage space f) Boundary wall/ fencing iii) Essential conditions a) Quality awareness boards f) Variety-wise/ grade-wise heaping b) Headgear/ uniform g) Covering of cotton as it arrives c) Training of gin fitters h) Bale packaging d) Disposal of rubbish I) Gin / press fitters, 2 in each shift e) Gummed boards iv) Desirable machines a) HVI/ MVI e) Moisture meter b) Generator f) Workshop machines c) Laboratory model gin g) Roller grooving machine d) GP balance h) Cotton pod opener R AT I N G O F G I N N I N G & P R E S S I N G WHAT IS RATING? FACTORIES Rating is the process of placing modernized G and As the effects of modernization started becoming P units into classes based on the quality of visible in cotton quality in the early years of TMC, the infrastructure, comprising (i) machinery, (ii) civil user mills were eager to know more about the structural items and (iii) the management practices technical merits of modernized G and P factories and and (iv) the contamination level of ginned cotton. wanted to identify the superior ones among the Since the quality of cotton processed in a ginnery will modernized units. The elite ginning factories greatly depend on the excellence of its infrastructure, expected some kind of recognition for the quality of the rating assigned to a unit will be a performance equipment, civil infrastructure and management indicator that will be of concern and interest to both practices as well as process conditions adopted by the cotton trade and textile mills alike. them to deliver clean cotton bales. Rating of the G and P factories was the only answer to the needs of the OBJECTIVES OF RATING textile industry in general and of G and P factories in Star rating of ginneries intends to achieve particular. Accordingly, a methodology for star rating objectives like (i) accord recognition to the quality of of modernized ginneries was developed by TMC and infrastructure in ginneries, encourage modernization this was bequeathed to the Textiles Committee (TC) of more ginning units (ii) promote quality culture for implementation in February 2009. Under the among ginners through good management practices rating methodology, fine-tuned by TC, star ratings are (iii) improve the quality of baled cotton (iv) create a awarded to ginneries on the basis of quality of brand for clean cotton (v) justify a higher price tag for infrastructure set up in the factory, management quality cotton and (vi) indirectly promote better price practices and the quality of ginned cotton. The star realization by farmers. rating scheme undertaken by TC is of a unique kind in so far as rating ginneries is not practiced anywhere else RATING METHODOLOGY in the world. The star rating scheme specifies various conditions such as (i) minimum eligibility criteria (ii) essential July - September 2012 13

- 16. COTTON GINNING Textile Value Chain parameters, (iii) minimum marks for each rating (iv) VALIDITY AND STATUS OF RATING additional fulfilling requirements for 4 star and 5 star Rating once assigned to a G and P factory is valid ratings and (v) analysis of contamination level in for a period of three years with compulsory annual ginned cotton. G and P factories seeking star rating visits from assessment teams. The response from the G have to fulfill the minimum eligibility requirements. and P factories to the star-rating scheme is As per the rules of rating scheme, an on-site overwhelming. The user industries, spinning mills, assessment will be carried out by a team of experts. have also welcomed the initiatives of the Govt. of During on-site assessment, 21 infrastructural India and are look forward to reaping the benefits of components comprising machinery and civil the rating scheme. So far, 510 applications have been structures are assigned marks ranging from 1 to 5 received for assessment till 22.02.2011. The depending on their technical merits. Weight assessment status of G and P factories is as follows: representing the degree of importance in controlling trash and contamination has also been assigned to Assessment Status each of these 21 components. The mark assigned No. of applications received till 31.12.2011 673 multiplied by the weight factor would give the weight mark for each component. Similar marking scheme is No. of Factories rated 479 also prescribed for the 13 management parameters Rating Status (Assessed during last cotton season) including contamination level in ginned cotton. A “Five-Star” rated factories 5 maximum of 200 marks are assigned for infrastructural parameters and a maximum of 175 “Four-Star” rated factories 22 marks are assigned for management parameters. “Three-Star” rated factories 63 Rating is awarded in five classes, viz. 'TC-Single Star' “Two-Star” rated factories 198 to 'TC-Five Star,' based on Ÿ Percentage of marks scored in infrastructural “Single-Star” rated factories 52 parameters Total no. of units rated 340 Ÿ Percentage of marks scored in management No. of units under Provisional Rated Status 139 parameters Ÿ Fulfillment of criteria for essential parameters TOTAL 479 Ÿ Fulfillment of criteria for additional fulfilling requirements (for 4 Star and 5 Star only). BENEFITS FROM RATING The star rating scheme is set to bring benefit to RATING LOGO & CERTIFICATE different sections of stake holders in cotton TC has developed a logo for rating through NID, production and utilization. Some of the benefits are Ahmedabad. The logo will be registered as a trade discussed below. mark under Trade Marks Act and will be promoted as (I) Benefit to Mills a brand for clean cotton. The information on website about star ratings of G and P factories, on successful completion of Ginning and Pressing units will help mills in selecting assessment, will be awarded a 'Certificate of Rating'. the appropriate ginnery while sourcing their cotton. Information on the rating assigned to G and P The mills which are inclined to undertake their own factories will also be placed on the TC's website for the ginning can choose the factories of desired rating. information of textile mills and cotton trade. The (ii) Benefit to the Ginneries factories that do not qualify for any rating as per the For the ginner who is also a cotton trader, the rating rating criteria will be given 'Provisional Rated Status' will serve as an effective marketing tool. Higher for one year. The provisional rated factories are premium could be demanded for cotton processed in expected to make necessary improvements and seek ginneries with superior star rating. A high star rating reassessment for rating within one year. will indeed boost the credibility of the factory both in domestic and overseas markets. A ginner carrying out job work can demand higher rates depending on the 14 July - September 2012

- 17. COTTON GINNING Textile Value Chain rating secured by the factory. The rating will help the improvement in ginning infrastructure in the country factories to know their present quality status and may be fully realized. examine whether scope exists for further improvement in the infrastructure. The rating will LOOKING FORWARD also help G and P factories in securing working capital The rating scheme discussed above is the first of its and loans from financial institutions. kind ever used for classifying ginneries not only in (iii) Benefit to Cotton Traders India but the world over. The day is not far when Since the quality of baled cotton is bound to depend buyers of cotton bales in India and abroad would start on the star rating of the factory, traders will find it easy specifying the star rating of the ginnery in which they to choose the ginnery for processing cotton to the level would like their cotton to be ginned. Being processed of quality demanded by each mill. in a star rated ginnery will enhance the brand value of (iv) Benefit to Government of India cotton bales and promote their sale in domestic and Modernization of ginneries and the resulting quality overseas markets. The quality upgrade made at the upgrade of Indian cotton have favoured raw material stage adds new dimension to the overall unprecedented rise in cotton exports (more than ten- improvement of the quality at various stages in the fold in a decade). Periodic assessment and rating will entire supply chain of the cotton industry. Textiles generate a spirit of competition amongst the G and P Committee could then take pride in having factories whereby the Govt's objective of sustained refurbished the image of the Indian cotton. Cotton Bales: Manufacturer & Exporter of Raw Cotton Bales, Asha Cotton Industries. Our Cotton Ginning Pressing Factory Located at Mahuva, Gujarat, India. Asha Cotton Industries is TMC (Technical Mission on Cotton, Approved by Textile ministry of India- Govt. of. India) approved Ginning Pressing Company. The Company is founded by our Chairmen Dr.B.T.Valia in 1998; we engaged in manufacturing and export of best quality cotton bales, cotton seeds, cotton cake, Peanuts and Sesame Seeds in all principal word market and to the end users in the major word market. We are professionally managed company having large network and infrastructure in home as well as abroad, company is equipped with state-of-art infrastructure backed by large and fully automatic plant for cotton to cotton bales. Office Address : Asha Cotton Industries,Vasi Talao Gate, Mahuva 364290 Dist. Bhavnagar, Gujarat, INDIA. Factory Address : Asha Cotton Industries, Mahuva-Bhavnagar Road, Vadli-Mahuva 364 290 Dist. Bhavnagar, Gujarat, INDIA. ADVT. Tel : +91-2844-223258, +91-2844-247600, +91-2844-224220 | Fax : +91-2844-223258 E-mail : info@cottonasha.com | Website : www.cottonasha.com, www.cotton-asha.com July - September 2012 15

- 18. ECO FIBRE Textile Value Chain EXTRACTION OF BAMBOO FIBRE BAMBOO Two types of processing are done to obtain A GREEN FIBRE bamboo fibres- Mechanical Processing and Chemical Processing. In both the processes, the raw bamboo has to be split to get bamboo strips. After that, bamboo fibre is extracted either through chemical or mechanical processing. Bhawana Rawat, ŸChemical Processing: It is basically a hydrolysis alkalization process. The crushed bamboo is "cooked" Assistant Professor, with the help of Sodium hydroxide (NaOH) which is NIFT, Mumbai also known as caustic soda or lye into a form of regenerated cellulose fibre. Hydrolysis alkalization is then done through carbon disulfide combined with multi-phase bleaching. Although chemical processing Bamboo fibre is a cellulose fibre which is extracted is not environmental friendly but it is preferred by from naturally grown bamboo and is the fifth-largest many manufacturers as it is a less time consuming natural fibre after cotton, linen, wool and silk. process. Bamboo fibre not only has good air permeability, ŸMechanical Processing: In this method, the water absorption, strong wear-resistance and good crushed bamboo is treated with biological enzymes. dyeing and other features, but also has natural This breaks the bamboo into a mushy mass and antibacterial, antimicrobial, mites, anti-odor and individual fibres are then combed out. Although anti-ultraviolet. Bamboo fibre is a natural, expensive, this process is eco-friendly. environment friendly green fibre. BAMBOO PRODUCTION FLOW CHART HISTORY OF BAMBOO FIBRE ---bamboo tree The use of bamboo goes back a long time. In fact, ---cutting into bamboo sheet bamboo has been considered to be a symbol of good ---(hydrolyzing --- stewing --- bleaching) fortune in Asian cultures for over 4,000 years. ---pulp Historically in Asia, bamboo was used for the hand- ---(saturate) made production of paper. Bamboo has traditionally ---cellulose been used in China to make musical instruments, ---(dissolving---spinning---cutting) drinking cups, buckets, fishing rods, walls and ---after treatment (washing---oil adding---drying) structural posts, wicker furniture, rafts, carpets and ---bamboo fibre even phonograph needles. Many of these bamboo ---packing components are still being used today. Bamboo Production Flow Bamboo Bamboo sheets Refined Bamboo pulp Bamboo Cellulose 16 July - September 2012

- 19. ECO FIBRE Textile Value Chain PROPERTIES OF BAMBOO FIBRE 1. Strong durability, stability & tenacity 2. Round and smooth surface 3. Anti-bacterial 4.Excellent wet permeability, moisture vapour transmission property 5.Softer than cotton 6. Moisture absorbency is twice than that of cotton with extraordinary soil release value 7. Anti-ultraviolet 8. Products of bamboo fibre are eco-friendly and bio-degradable. Bamboo fibre Use of bamboo as plant Use of bamboo as material Ornamental Local industries 3. Medical and Mine protection: Use as absorption horticulture Artisanat fibre, conductive and anti-static radiation function. Furniture More suitable for protective clothing for on-site work Ecology A variety of utensils clothes in medical, mining, oil and gas operations. Stabilize of the soil Houses 4. Military Space: Bamboo viscose fibre is used in Uses on marginal land missile, rocket launchers and other operator Hedges and screens Wood and paper industries protective clothing. Minimal land use Strand boards 5. Transportation and Tourism: Bamboo viscose Agro-forestry Medium density fiberboard fibre is suitable for cars, boats, transport aircraft seat Natural stands Laminated lumber fabrics and interior products, also suitable for hotels, Plantations Paper and rayon halls and other decorative items. Mixed agro-forestry Parquet systemsa FUTURE SCOPE OF BAMBOO FIBRE Nutritional industries Bamboo fabric is not only popular for its softness Young shoots for human and versatility, but also for its environmental friendly consumption quality. Bamboo fibre requires very less chemical and Mixed agro-forestry systems water for production and processing. The pulp is Fodder bleached without using chlorine. This is more environmental friendly than the way other textiles are Chemical industries made. The bamboo pulp is also very easy to dye and it Biochemical products takes less water and harsh chemicals than Pharmaceutical industry conventional dyeing methods. There are also great environmental values to bamboo fabric. From being a Energy completely renewable resource to being easy to Charcoal process, bamboo fabric is an ecologically friendly Pyrolysis choice for the future. Gasification It's cool in summer, warm in winter, is anti- bacterial and is as soft and luxurious as cashmere. And Various uses of bamboo [Gielis 2002] best of all, it's sustainable. END USE OF BAMBOO FIBRE References: Currently the main uses of bamboo products are: Ÿ http://www.bambooindustry.com 1. Bedding series: Mattresses, pillows, bedspreads, Ÿ http://www.bambooandtikis.com/bamboo- sheets, etc. history Ÿ t t p : / / w w w. t e o n l i n e . c o m / k n o w l e d g e - h 2.Fashion series: Knitting, weaving high-grade fabrics, underwear, vest, socks, towels and other centre/bamboo-fibre.html clothing. Its anti-ultraviolet nature is suitable to make Ÿ http://www.abtexintl.net summer clothing more suitable for elderly, infants and Ÿ http://resources.alibaba.com pregnant women. Ÿ http://www.bamboogrove.com July - September 2012 17

- 20. Textile Value Chain YARN and other processing chemicals used for Dyeing, Finishing of linen, Cotton, Pure Silk, Denim and Ratan Glitter Woolen Fabrics. Industries The Pure Silver Metallic Yarn can also be used for different types of Embroidery and special effects. The Limited threads come in different structure, thickness, colors and a combination of materials allowing Designers Ratan Glitter Industries Limited is a 35 year old and Embroidery specialists to create an unique and organization managed by a highly experienced team. outstanding look to the Fabric. The Pure Silver yarn We are the pioneer in the metallic yarn industry in effectively enhances the details and embellishes your India, having been one of the first companies to products giving it added glamour and zing. export metallic yarns. Some of the leading Indian mills and some We have one of the world's latest Metalizing Plant companies' overseas already use our products. that metalizes Pure Silver on Polyester Film. Quality assured since we use the latest Japanese Our Specialized Pure Silver Metalized Yarn can be Technology thus ensuring the best quality, color and used to weave with materials such as Denim Fabric, pin hole free products. The products are capable of Cotton Fabric, Pure Silk Fabric & Woolen Fabrics etc. running on high speed weaving, knitting and It can be washed with Heavy Detergent Caustic Soda embroidery machines. It can also be used in hand embroidery. METALLIC YARN Along with Pure Silver Metallic Yarn, we also produced ST and Zebra Type Yarns in fluorescent, rainbow and several other colours. These are highly used in computerized embroidery machines, circular knitting and weaving machines. SPECIALIZED PURE SILVER METALLIC YARN For the first time in India, 3 different Types of Pure Silver Metallic Yarn has been Developed to be used in weaving with the following materials : Denim Pure Silk Linen and Cotton with Lurex Metallic Yarn with Lurex Metallic Yarn with Lurex Metallic Yarn These yarns can be industrially washed using The Pure Silver coating, effectively enhances the chlorine, bleaching agents, heavy duty detergents details and embellishes the final products giving to containing chlorine or peroxide as used in industrial glamour and zing. All of them are available in various washing. This yarn is suitable for suitable for sewing colours and the finished material can be dyed in any and weaving. color without affecting the metallic yarn. 18 July - September 2012

- 21. Ratan Glitter Industries Limited METALLIC YARN Along with Pure Silver Metallic Yarn, we also produce ST and Zebra Type Yarns in fluorescent, rainbow and several other colours. These are highly used in computerized embroidery machines, circular knitting and weaving machines. PURE SILVER M TYPE YARN Pure Silver M Type Metallic Yarn produced in 12 micron and 24 micron in different cuts of 1/69, 1/85, 1/100. These are capable of running on high speed weaving, knitting and circular knitting machines. Also, it is used for making ST Yarn in Cotton, Polyester and Viscose. PURE SILVER ST YARN Polyester Metallized Pure Silver Yarn are highly used on Schiffli embroidery machines, computerized embroidery machines and in hand embroideries. It is widely used for tapestry and made-ups. PURE SILVER MX YARN Pure Silver MX Type Metallic Yarn produced in 12 micron and 24 micron in different cuts of 1/69, 1/85, 1/100. The core yarn is in Polyester or Nylon. These yarns are capable of running on high speed weaving, knitting and circular knitting machines. PURE SILVER FABRICS Pure Silver fabrics made from Pure Silver Metallic Yarn are highly used in clothes and for decorative purpose in: Gift Articles, Home Furnishings & accessories such as hand bags ADVT. and various other products. Gala Woodwork compound, opp. B.D.D. Chawl No. 114, Worli, Mumbai-400013, India. Tel: (+91-22) 24966002/4/6; Fax: (+91-22) 24962002; email: ratanglitter@gmail.com website: www.ratanglitter.com contact person: Mr. Mahendra Yadav : +91 9004661657

- 22. Textile Value Chain FABRIC to GDP and 17% to export earnings. It provides direct employment to over 35 million people, the on Cloth Producti second largest provider of employment after in India - agriculture. Thus, the growth & all-round sis A Sector Analy development of this industry has a direct bearing on the improvement of the economy of the nation. The Indian textile industry is extremely varied with Prof. N.S. Kazi, the hand spun & hand woven sectors at one end of the MA (Economics), spectrum & the capital intensive sophisticated mill Former Sasmira Co-ordinator of sector at the other. The industry consists of organised Merchandising Programme as well as unorganised sectors like power loom, INTRODUCTION handloom, and hosiery. This provides the industry Textile industry is one of the oldest & largest with the capacity to provide a large variety of products industries in India. Apart from providing one of the suitable to the different segments of the market both basic necessities of life, the industry also plays a pivotal within the country & outside the country. role through its contribution to industrial output, INSTALLED CAPACITY employment generation & export earnings. It The installed capacity in terms of spindles, looms contributes about 14% to industrial production, 4% and fibre and filament production can be seen as below: Items Units 2001-02 2010-11 CAGR % Spindles Million Nos. 38.33 38.33 1.3 Rotors Lakh No. 4.8 7.07 4.4 Looms (organised Sector) Lakh No. 1.41 0.57 -9.57 Power Room Lakh No. 16.66 22.61 3.45 Man-Made Fibre Million kg 1090 1763.1 5.49 Man-Made Filament Million kg 1135 2188.2 7.57 As seen in the table, the number of spindles increased from 38.33 million in 2001-02 to 43.06 million in 2010- 11. The CAGR is 1.3%. The number of rotors increased from 4.8 lakh to 7.09 lakh. The number of looms in the organised sector decreased from 1.41 lakh in 2001-02 to 0.57 lakh in 2010-11. This may be due to the closure of number of composite mills in the country. However, the number of looms in the unorganised sector increased from 16.66 lakh to 22.61 lakh during the same period. The installed capacity for man-made fibre has increased from 1090 million kg in 2001-02 to 1763.1 million kg in 2010-11. The CAGR is 5.49% and the installed capacity for man-made filament has gone up from 1135 million kg to 2188.2 million kg with 7.57% CAGR. NUMBER OF SPINNING & WEAVING MILLS The number of spinning & weaving mills during the last one decade can be seen as below: Description 2001-02 2010-11 CAGR % Spinning Unit (Non Small Scale Industry) 1579 1713 0.64 Composite Units 281 183 -4.66 Exclusive Weaving Units (Non Small Scale Industry) 207 183 -1.36 Spinning Units (Small Scale Industry) 1046 1299 2.44 Power Loom (Lakhs) 16.66 22.61 3.45 Hand Loom (Lakhs) 38.91 23.77 -5.33 It can be seen from the above that the number of spinning units both (non SSI) as well as SSI show increasing trends. Composite mill numbers have declined from 281 in 2001-02 & 183 in 2010-11, a decline by 4.66%. The numbers of powerlooms have gone up from 16.66 lakh & 22.61 lakh with CAGR of 3.45% while in case of handlooms the numbers have declined from 38.91 lakh in 2001-02 & 23.77 lakh in 2010-11, a decline by 5.33%. 20 July - September 2012

- 23. PRODUCTION ANALYSIS Textile Value Chain Thus, the organised mill sector shows a declining trend while the unorganised powerloom sector shows an increasing trend. TRENDS IN FIBRE & YARN PRODUCTION* It can be seen from the below analysis, that there is all-round improvement in the production of man-made fibres as well as yarn. Description 2001-02 2010-11 CAGR % Man-Made Fibres 834 1268 5.38 Man-Made Filament Yarn 962 1522 5.90 Total Spun Yarn 3101 4193 3.84 (a) Cotton 2212 3079 4.22 (b) Blended and Non-cotton 889 1114 2.86 In Million kgs SECTOR-WISE CLOTH PRODUCTION* The sector-wise cloth production over the period can be seen from the following table: Sector 2001-02 2009-10 CAGR % Mill Sector 1546 2016 3.37 Hand Loom 7585 6806 -1.35 Power Loom 25192 36997 4.92 Hosiery 7067 13702 8.63 Khadi & Wool & Silk 714 812 3.22 Total Cloth Production 41390 60333 4.51 It can be seen that the total cloth production In Million Sq. Mtr. registered an increase of 4.51% during 2001-02 to followed by hosiery sector at 22.71% and handloom 2009-10. The highest growth rate is in the hosiery sector at 11.28%. sector (8.63%) followed by powerloom sector COTTON/ BLENDED/ NON-COTTON (4.92%), mill sector (3.37%) & khadi & wool & CLOTH PRODUCTION* silk (3.22%). Handloom sector witnessed a The production can be seen as below: marginal decline in the cloth production from 7,585 million sq. mtr. in 2001 to 6,806 million sq. Fibre 2004-05 2010-11 mtr. in 2010. Cotton 20655 (46.23) 31742 (51.43) SECTORAL COMPOSITION IN CLOTH Blended 6032 (13.49) 8278 (13.41) PRODUCTION Non-cotton 17998 (40.28) 21710 (35.16) The composition can be seen as below: Total 44685 (100) 61730 (100) (*In Million Sq. Mtr. Figures in brackets represent percentage to total) Contribution (%) It can be seen that the total cloth production which was 44,685 million sq mtr. in 2004-05 increased to 61730 million sq mtr. in 2010-11. Cotton cloth production which was 20,655 million increased to 31742 million sq mtr. Its percentage share increased from 46.23 to 51.43%. Blended cloth production increased from 6032 million sq mtr. to 8278 million sq mtr. Its percentage It can be seen that the organised sector (mill share has remained at 13%. Sector) contributes only 3.34% of fabric production In the case of non cotton cloth production, it has & the remaining 96.66% fabric is being produced increased from 17998 million sq. mtr. to 21710 by the unorganised sector. Powerloom sector million sq. mtr. but its percentage share has decreased contributes maximum fabric production at 61.32%, from 40.28 to 35.16. July - September 2012 21

- 24. PRODUCTION ANALYSIS Textile Value Chain However the share of non cotton has declined from CLOTH PRODUCTION BY MILL SECTOR* 58% to 53% & that of cotton has increased from 26% The cloth production by mill sector & the to 31%. composition of cotton, blended & non cotton cloth CLOTH PRODUCTION BY HANDLOOM can be seen as below. SECTOR* Fibre 2004-05 2010-11 The cloth production can be seen as below: Cotton 1072 (70.25) 1604 (72.75) Fibre 2004-05 2010-11 Blended 243 (15.93) 526 (23.85) Cotton 4792 (83.75) 6016 (86.61) Non-cotton 211 (13.82) 75 (3.40) Blended 146 (2.55) 143 (2.05) Total 1526 (100) 2205 (100) Non-cotton 784 (13.70) 790 (11.34) (*In Million Sq. Mtr. Figures in brackets represent percentage to total) Total 5722 (100) 6949 (100) It can be seen that cotton cloth production by mill (*In Million Sq. Mtr. Figures in brackets represent percentage to total) sector has increased from 1,072 to 1,605. Its share has It can be seen from the table that handloom sector increased from 70.25% to 72.75%. In the case of produces cotton cloth 86.61% while the share of non- blended cloth, the production increased from 243 cotton cloth is 11.34% & that of blended cloth only million sq. mtr. to 526 million sq. mtr., its share has 2.05%. gone up from 15.93% to 23.85%. However, non CLOTH PRODUCTION BY HOSIER Y cotton cloth production by mill sector has decreased SECTOR* from 211 to 75 million sq. mtr. and its percentage The cloth production can be seen as below: share has come down from 13.82% to 3.40%. Fibre 2004-05 2010-11 CLOTH PRODUCTION BY POWERLOOM SECTOR* Cotton 7430 (81.54) 12270 (83.78) The cloth production can be seen as below: Blended 1117 (12.26) 1756 (11.99) Fibre 2004-05 2010-11 Non-cotton 565 (6.20) 620 (4.23) Cotton 7361 (25.98) 11852 (31.25) Total 9112 (100) 14646 (100) (*In Million Sq. Mtr. Figures in brackets represent percentage to total) Blended 4526 (15.97) 5853 (15.43) It can be seen from the table that hosiery sector Non-cotton 16438 (58.05) 20224 (53.32) mainly produces cotton cloth accounting for 83.78% Total 28325 (100) 37929 (100) followed blended cloth (11.99%) & NC cloth (*In Million Sq. Mtr. Figures in brackets represent percentage to total) (4.23%). It can be seen from the above that powerloom FIBRE-WISE / SECTOR-WISE COMPARISON sector produces maximum non-cotton cloth A comparison of difference sectors in fibre-wise accounting for 53.32% in production. It is followed cloth production over the period can be seen as below by cotton cloth (31.25%) & Blended cloth (15.43%). in percentage terms. Mill Power Loom Hand Loom Hosiery Fibre 2004-05 2010-11 2004-05 2010-11 2004-05 2010-11 2004-05 2010-11 Cotton 70.25 72.75 25.98 31.25 83.75 86.61 81.54 83.7800 Blended 5.93 23.85 15.97 15.43 2.55 2.05 12.26 11.99 Non-Cotton 13.82 3.40 58.05 53.32 13.70 11.34 6.20 4.23 Total 100 100 100 100 100 100 100 100 It can be seen that mill, handloom and hosiery sectors mainly produce cotton cloth while powerloom sector mainly produces non-cotton cloth. In all the four sectors, there is an increasing trend of cotton cloth production and decreasing trend of non-cotton cloth production. It indicates that the production of cloth by different sectors have greater similarities than differences even though the end product made from the cloth may differ widely. Thus, the cloth production trend of de-centralised sector reflects the production pattern of the organised sector. Reference : Textile Committee 22 July - September 2012