Report

Share

Recommended

Recommended

More Related Content

What's hot

What's hot (20)

Functional Dairy Foods for Combating Metabolic Disorder

Functional Dairy Foods for Combating Metabolic Disorder

HTST Pasteurization- Introduction, Working, Components

HTST Pasteurization- Introduction, Working, Components

Water activity and types of food based on water activity

Water activity and types of food based on water activity

determination of moisture content in a food stuff.

determination of moisture content in a food stuff.

Viewers also liked

Viewers also liked (8)

Similar to Lecture 02: STKM3212

Characterizing The Fate And Transport Of Chemicals Of Emerging Concern (CEC’s...

Characterizing The Fate And Transport Of Chemicals Of Emerging Concern (CEC’s...National Institute of Food and Agriculture

Similar to Lecture 02: STKM3212 (20)

Food engineering kyambogo university faculty of science

Food engineering kyambogo university faculty of science

9783110654806_Solutions to Excercises Ind Sep Proc 2nd Ed.pdf

9783110654806_Solutions to Excercises Ind Sep Proc 2nd Ed.pdf

Aspen Plus - Bootcamp - 12 Case Studies (1 of 2) (Slideshare)

Aspen Plus - Bootcamp - 12 Case Studies (1 of 2) (Slideshare)

Material balance for multiple units without chemical equation

Material balance for multiple units without chemical equation

Stoichiometry Lab – The Chemistry Behind Carbonates reacting with .docx

Stoichiometry Lab – The Chemistry Behind Carbonates reacting with .docx

Characterizing The Fate And Transport Of Chemicals Of Emerging Concern (CEC’s...

Characterizing The Fate And Transport Of Chemicals Of Emerging Concern (CEC’s...

Microbial catalysis of syngas fermentation into biofuels precursors - An expe...

Microbial catalysis of syngas fermentation into biofuels precursors - An expe...

Elizabeth Towle Separation Process for the Reutilization of Acetone and Metha...

Elizabeth Towle Separation Process for the Reutilization of Acetone and Metha...

More from Saiful Irwan Zubairi

Bio-Pesticide Product Costing Template (Pilot Plant Scale Production April 2006)

Bio-Pesticide Product Costing Template (Pilot Plant Scale Production April 2006)Saiful Irwan Zubairi

More from Saiful Irwan Zubairi (20)

Bio-Pesticide Product Costing Template (Pilot Plant Scale Production April 2006)

Bio-Pesticide Product Costing Template (Pilot Plant Scale Production April 2006)

Fever-Coolant Sachet Award Winning Invention (MTE Invention 2006)

Fever-Coolant Sachet Award Winning Invention (MTE Invention 2006)

Empangan Timah Tasoh (FOCUS Magazine January 1997)

Empangan Timah Tasoh (FOCUS Magazine January 1997)

British Invention Show (BIS) Newspaper Article 2004

British Invention Show (BIS) Newspaper Article 2004

BIS Abstract: Environmental-Friendly Bio-Pesticide 2004

BIS Abstract: Environmental-Friendly Bio-Pesticide 2004

HPLC CERTIFICATE OF ANALYSIS (COD) FOR A.I. CONTENT

HPLC CERTIFICATE OF ANALYSIS (COD) FOR A.I. CONTENT

3rd Group Meeting VIVA M.Phil Transfer 2010 2nd Draft

3rd Group Meeting VIVA M.Phil Transfer 2010 2nd Draft

Lecture 02: STKM3212

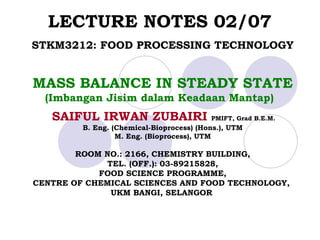

- 1. LECTURE NOTES 02/07 STKM3212: FOOD PROCESSING TECHNOLOGY MASS BALANCE IN STEADY STATE (Imbangan Jisim dalam Keadaan Mantap) SAIFUL IRWAN ZUBAIRI PMIFT, Grad B.E.M. B. Eng. (Chemical-Bioprocess) (Hons.), UTM M. Eng. (Bioprocess), UTM ROOM NO.: 2166, CHEMISTRY BUILDING, TEL. (OFF.): 03-89215828, FOOD SCIENCE PROGRAMME, CENTRE OF CHEMICAL SCIENCES AND FOOD TECHNOLOGY, UKM BANGI, SELANGOR

- 18. CONTINUE: No chemical reactions are given. BASIS (the amount have been given at the OUTPUT STREAM). So, “Input = Out” ---------- STEADY STATE TOTAL MASS BALANCE: P + B = 100 kg ------------- (1) FATS MASS BALANCE: (0.2)(P) + (0.8)(B) = (0.25)(100) 0.2P + 0.8B = 25 ------------- (2) Substitute (1) into (2) (0.2)(100 - B) + 0.8B = 25 20 - 0.2B + 0.8B = 25 B(0.8 - 0.2) = 25 - 20 B = 8.33 kg P = 100 - 8.33 = 91.67 kg

- 21. CONTINUE: No chemical reactions are given. BASIS (the amount have been given at the INPUT STREAM). So, “Input = Out” ---------- STEADY STATE TOTAL MASS BALANCE: 15 + B = M ------------- (1) NaCI MASS BALANCE: (0.2)(15) = (0.10)(M) 3 = 0.1M ------------- (2) M = 30 kg B = 30 kg - 15 kg = 15 kg

- 23. CONTINUE: No chemical reactions are given. NO BASIS are given -------- Put a BASIS of 100 kg/hrs of grape juice So, “Input = Out” ---------- STEADY STATE TOTAL MASS BALANCE: 100 = W + C ------------- (1) H 2 O MASS BALANCE: (0.2)(100) = (0.50)(C) 20 = 0.5C 40 kg/hrs = C ------------- (2) Substitute (2) into (1) 100 = W + 40 W = 60 kg/hrs REDUCTION OF MASS: 100 kg - 40 kg = 60 kg % REDUCTION OF MASS: 60 kg/100 kg × 100% = 60% (w/w)

- 25. CONTINUE: No chemical reactions are given. BASIS (the amount have been given at the H 2 O STREAM). So, “Input = Out” ---------- STEADY STATE TOTAL MASS BALANCE: F = 500 + C ------------- (1) H 2 O MASS BALANCE: (0.88)(F) = 500(1) + (0.55)(C) --------- (2) Substitute (1) into (2): (0.88)(500 + C) = 500 + 0.55C 440 + 0.88C = 500 + 0.55C 0.88C - 0.55C = 500 - 440 0.33C = 60 C = 181.8 kg/hrs F = 500 + 181.8 = 681.8 kg/hrs

- 27. CONTINUE: No chemical reactions are given. BASIS (the amount have been given at the OUTPUT STREAM). So, “Input = Out” ---------- STEADY STATE TOTAL MASS BALANCE: x + y = 100 ------------- (1) SOLIDS MASS BALANCE: (0.65)( x ) + (0.15)( y ) = (0.45)(100) 0.65 x + 0.15 y = 45 ------------- (2) Substitute (1) into (2): 0.65(100 - y ) + 0.15 y = 45 65 - 0.65 y + 0.15 y = 45 y(0.15 - 0.65) = 45 - 65 y = -20/-0.5 y = 40 kg x = 100 kg - 40 kg = 60 kg

- 29. CONTINUE: No chemical reactions are given. BASIS (the amount have been given at the OUTPUT STREAM). So, “Input = Out” ---------- STEADY STATE TOTAL MASS BALANCE: x + y + z = 100 ------------- (1) FATS MASS BALANCE: (0.14)( x ) + (0.89)( y ) = (0.20)(100) 0.14 x + 0.89 y = 20 ------------- (2) H 2 O MASS BALANCE: (0.67) ( x ) + (0.08)( y ) + (1)( z ) = (100)(0.65) 0.67 x + 0.08 + z = 65 --------- (3) Substitute (1) into (3): 0.67 x + 0.08 + 100 - x - y = 65 Substitute (2) into (3): 0.67 x + 0.08 + 100 - x - (20 - 0.14 x /0.89) = 65

Editor's Notes

- ftrr5