Low cost building materials

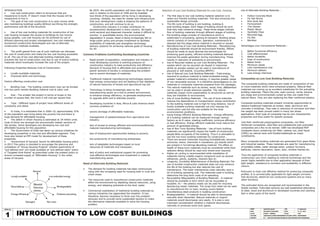

- 1. SHEET NO. INTRODUCTION TO LOW COST BUILDINGS1 cent in relation to the level of 1996 and by thatdate two-thirds of the population will be living in developing countries. Globally, the need for shelter and infrastructure that such development create is shaping the patterns of construction, and will continue to do so. Construction industry is a major contributor to socioeconomic development in every country. Its highly multi-sectoral and dispersed character makes it difficult to monitor, in quantifiable terms, the environmental degradation it causes. Need is being increasingly felt to forge public policy and private investment to facilitate availability of materials and strengthen technology delivery systems for achieving national goals of Housing for All. Common Problems Confronting Developing Countries Rapid growth of population, urbanisation and industry in most developing countries is exerting pressure on construction industry to raise productivity and efficiency. Demand of housing that is affordable and accessible to poorer sections of society is compounding the problem due to severe shortages of materials. Traditional material manufacturing technologies require high energy consumption and are leading to fast depletion of natural resources of forests and agricultural top soil. Technology is being increasingly seen by the manufacturing sector as a tool to protect environment, to enhance energy efficiency; to generate employment; to upgrade skills and to alleviate poverty. Developing countries in Asia, Africa & Latin America share common problems of: - severe shortage of affordable materials; - - management of wastes/residues from agriculture and industry; - lack of access to energy efficient and environmentfriendly material manufacturing technologies; - lack of employment opportunities leading to poverty; - low productivity of manufacturing enterprises; - lack of adaptable technologies based on local resources of materials and manpower; - lack of policy and institutional support for promoting cost-effective technologies and investment in material manufacturing sector. Need of Alternate Building Materials The demand for building materials has been continuously rising with the increasing need for housing both in rural and urban areas. The resources used to manufacture construction materials affect the environment by depleting natural resources, using energy, and releasing pollutants to the land, water. Commercial exploitation of traditional building materials by various industries has aggravated the situation. It has, therefore, become necessary to think over this problem seriously and to provide some sustainable solution to make the alternative materials available to solve the housing problem. SEM SCALE DATE 10 - 03 - 2018 1:500 COLLEGE SUBJECT CLASS R.NO. 613 - LOW COST BUILDING MATERIALS AND CONSTRUCTION TECHNIQUES. SOUMITRA SMARTNAME JAWAHARLAL NEHRU ENGINEERING COLLEGE, CIDCO, AURANGABAD. 20213220171703210006 M-ARCH - GENERAL 2nd SEMESTER List of Alternate Building Materials : Hollow Concrete Block Fly Ash Bricks Rice Husk Ash Ferrocement Tire Veneer Plastic Wood Synthetic Fiber Recycled Agg. Fly Ash Bamboo Advantages over Conventional Materials : 1. Better functional efficiency 2. Cost effectiveness 3. Better durability 4. Ease of construction 5. Better finish 6. Minimum waste 7. Less maintenance cost 8. Minimum defects 9. Less energy intensive Composites as Low Cost Building Materials The composite building materials are made of composition of two or more materials which have enhanced property. Natural fiber materials are coming up as excellent substitutes for the prevailing building materials. Fibers like jute, sisal coconut, ramie, banana are cheap and environmentally suited as they are made from natural fibers. They are also replacing the fiber reinforced plastics. Composite building materials present immense opportunities to replace traditional materials as timber, steel, aluminum and concrete in buildings. They help in reduction of corrosion and their low weight has been proved useful in many low stress applications. Each type of composite has its own characteristic properties and thus useful for specific purpose. Jute fiber reinforced polypropylene composites, coir fiber reinforced composites, sisal fiber and wollastonite jute pultruded composites are a few to be named. CBRI has developed MDF composite doors containing coir fiber, cashew nut, shell liquid (CNSL) as natural resin and Paraformaldehyde as major constituents. Many composite building materials are generated from glass fibres and industrial wastes. These materials are used for manufacturing of portable toilets, water storage tanks, outdoor furniture, bathtubs, interior decoration, basin, door, window frames etc. Thus the application of composite building materials in construction vary from cladding to internal furnishings and the owner highly benefits due to their application because of their light weight, resistance to corrosion and availability in different colours. Pultrusion is most cost effective method for producing composite profiles. It is commercially applicable for light weight corrosion free structures, electrical non conductive systems and so many other functions. The pultruded items are recognized and recommended in the Global markets. Pultruded sections are well established alternative to steel, wood and aluminium in developed countries and catching fast in other parts of the world. INTRODUCTION Low cost construction refers to structures that are inexpensive to build. IT doesn't mean that the houses will be inexpensive to live in. The goal of low-cost construction is to save money while also maintaining buildings quality,Without sacrificing the strength, performance and life of the structure. Use of low cost building materials for construction of low cost housing increases the access to buildings by low income group peoples. Low cost housing can be achieved by use of efficient planning and project management, low cost materials, economical construction technologies and use of alternate construction methods available. The profit gained from use of such methods can decrease the cost of construction and make the low cost housing accessible to all. The use of low cost alternate building materials also prevents the rise of construction cost due to use of scarce building materials which eventually increase the cost of the project. Following Properties Reduces Cost of Construction: Locally available materials . Improved skills and technology. Factors affecting construction cost Building Cost : The building construction cost can be divided into two parts namely:Building material cost & Labor cost . Size : The smaller the project in terms of scope or the number of square feet, the more it will cost per square foot. Type : Different types of project have different levels of complexity and detail. of the population was living below the poverty line and there is huge demand for affordable housing. The deficit in Urban housing is estimated at 18 million units most of which are amongst the economically weaker sections of the society. Some developers are developing low cost and affordable housing for this population. The Government of India has taken up various initiatives for developing properties in low cost and affordable segment. They have also looked at PPP model for development of these properties. 'Government of haryana' launch its affordable housing policy in 2013 This policy is intended to encourage the planning and completion of "Group Housing Projects" wherein apartments of "pre-defined size" are made available at "pre-defined rates" within a "Targeted time-frame" as prescribed under the present policy to ensure increased supply of "Affordable Housing" in the urban areas of haryana. Selection of Low Cost Building Materials for Low Cost Housing The first step to low cost building material selection is to select eco-friendly building materials. This also enhances the sustainable design principle. The life cycle of building is pre-building, building & post-building stages. Each stage of building should be such that they help conserve energy. These three stages indicate flow of building materials through different stages of building. Pre-building stage consists of manufacture which is subdivided in processing, packing & transport. Building phase mainly consists of construction, operation, maintenance & disposal last the stage where material is recycled or reused. Manufacturing of Low Cost Building Materials - Manufacturing of building materials should be environment friendly. Efforts should be made to study &revise the technologies for producing good quality, efficient building materials &should improve the waste generation during manufacturing. These results in reduction of pollutants to environment. Use of Recycled wastes as Low Cost Building Materials - The wastes which can be recycled can &used in masonries whilst as wooden wastes can be used in manufacture of plywood or soft boards. (Courtesy-BMTPC) Use of Natural Low Cost Building Materials - Total energy required to produce material is called embodied energy. The of non-renewable sources. It is therefore advantageous to use materials or composite materials prepared from the wastages. The natural materials such as stones, wood, lime, s&&bamboo can be used in ample wherever possible. The natural materials impact more sustainability to structures as well as they are friendlier to environment. Use of Local Building Materials - The use of local materials reduces the dependence on transportation whose contribution to the building material cost is high for long distance. Use of locally available building materials not only reduces the construction cost but also are suitable for the local environmental conditions. Using Energy Efficient Building Materials - Energy efficiently of a building material can be measured through various factors as its R value, shading coefficient, luminous efficiency or fuel efficiency. Energy efficient materials must reduce the amount of generated energy. Use of Non-Toxic Building Materials - Use of toxic building materials can significantly impact the health of construction people &the occupants of the building. Thus it is advisable to use the non-toxic building materials for construction. There are several chemicals including formaldehyde, benzene, ammonia, resins, chemicals in insulations, ply boards which are present in furnishings &building material. The effect on health of these toxic materials must be considered while their selection &they should be used only where-ever required. Higher air cycling is recommended while installation of materials having volatile organic compound such as several adhesives, paints, sealants, cleaners &so on. Longevity, Durability &Maintenance of Building Materials The use of durable construction materials does not only enhance the life of the building but also reduces the cost of maintenance. The lower maintenance costs naturally save a lot of building operating cost. The materials used in building determine the long term costs of an operating. Recyclability &Reusability of Building Materials - A material should be available in form which can be recyclable or &producing newer materials. The scrap from steel can be used to manufacture the rcc bars, binding covers &other miscellaneous steel products in building construction. Biodegradability - A material should be able to decompose naturally when discarded. Natural materials or organic materials would decompose very easily. It is also a very important consideration whether a material decomposes naturally or produces some toxic gases.

- 2. SEM SCALE DATE SHEET NO. 10 - 03 - 2018 1:500 COLLEGE SUBJECT CLASS R.NO. 613 - LOW COST BUILDING MATERIALS AND CONSTRUCTION TECHNIQUES. SOUMITRA SMARTNAME JAWAHARLAL NEHRU ENGINEERING COLLEGE, CIDCO, AURANGABAD. 20213220171703210006 M-ARCH - GENERAL 2nd SEMESTER RESEARCH AND DEVELOPMENT BY VARIOUS ORGANIZATIONS - BMTPC 4 The Building Materials and Technology Promotion Council (BMTPC) was setup in 1990 as an inter-ministerial apex organisation to bridge the gap between laboratory development and large scale field application of innovative materials and technologies and to facilitate production of materials on commercial scale. Emphasis was laid on environmental protection through use of wastes, energy conservation, development of substitute materials for scarce materials like wood etc, disaster resistant construction technologies, and consequent social advantages of cost reduction, energy conservation and sustainable development strategies. Objectives To promote development, production, standardisation and large-scale application of cost-effective innovative building materials and construction technologies in housing and building sector. To promote manufacturing of new waste-based building materials and components through technical support, facilitating fiscal concessions and encouraging entrepreneurs to set up production units in different urban and rural regions. To develop and promote methodologies and technologies for natural disaster mitigation, vulnerability & risk reduction and retrofitting/ reconstruction of buildings and disaster resistant planning of human settlements. To provide support to professionals, construction agencies and entrepreneurs in selection, evaluation, upscaling, design engineering, skill-upgradation, and marketing for technology transfer from lab to land in the area of building materials and construction. THRUST AREAS Improving the policy environment for sustained growth of costeffective building materials, production and availability. Promotion of production units of building materials / components based on Flyash, Redmud, Phosphogypsum, agricultural residues and other wastes and by-products. Modernization of small scale and village level building materials production units in rural and urban areas. Promoting economy in construction costs. Formulation of standards for local building materials. Strengthening industrial extension services for attracting more investment in building materials sector by working with national and international agencies. Upscaling of technologies, know-how acquisition, absorption and dissemination. Assessing vulnerability and risk in natural disaster prone areas. Promoting disaster resistant construction technologies. Global technology search and encouraging joint ventures in building materials and construction sector. Facilitating fiscal incentives like excise duty and custom duty exemptions for waste-based building materials and components. Machines Developed/Promoted for Production of Prefab Building Components 1. Alternate Station Hydraulic Brick Press (Model : AS-4/2) 2. Bi-Directional Vibro Press (Model : AS-189) 3. Bi-Directional Vibro Press (Model : AS-1818) 4. Bi-Directional Vibro Press (Model : AS-1824) 5. Solid/Hollow Concrete Block Machine (Egg laying Type) (Model : CB-1) 6. Solid/Hollow Concrete Block Machine (Standing Type) (Model : CB-2) 7. Concrete Block Machine (Sakar) (Model : CB-3) 8. Stationary Block Machine (Model : ASH-168) 9. Solid/Hollow Concrete Block Machine (Handheld Type) (Model : SVC-1) 10. C-Brick Machine (Model : SL1) 11. Compressed Earth BlockMachine (Balram) (Model :MB-1) 12. Compressed Earth Block Machine (Mardini) (Model :MB-2) 13. Compressed Earth Block Machine (Hydraform)(Model:M-5) 14. Ferrocement Wall Panel Machine (Model : WP-1) 15. TNG Rural Housing Kit (Model : AS-1) 16. Ferrocement Roofing Channel Machine (Model : FCR-1) 17. Precast RCC Plank Casting Machine (Model : CP-1) 18. RCC Plank Casting Machine (Rotating Type) (Model : CP2) 19. Precast RCC Plank Casting Machine (Egg Laying Type) (Model:CP-3) 20. Precast RCC Joist Casting Machine (Model : CJ-1) 21. RCC Joist Casting Machine (Egg laying Type) (Model : CJ-2) 22. Ferrocement C-Beam Machine (Model : FB-1) 23. Micro Concrete Roofing Tile Machine (Model : MCR-1) 24. Precast L-Panel Machine (Model : LP-1) 25. Terrazo/Chequered Tile Machine (Model : ASH-40) 26. Precast concrete Door/ Window Frame Machine(Model : CC-1) 27. Combination Machine (Model : LP-2) 28. Multipurpose Stone Processing Machine (Model SP-1) 29. Stone/Coal Disintegrator (Model : AS-1714) 30. Bar and Pipe Cutting Machine (Model : AS-12) Support Services Offered The Council with its extensive networking with various R&D Institutions, Ministries/Government Departments, Universities, Financial Institutions, Public Agencies, Business Federations/Organizations and various International organizations such as UNIDO, UNCHS, ADB, World Bank etc., strives to provide multifaceted support services to the various stakeholders in the construction industry. Support for identification and development of technologies and building materials based on agricultural and industrial wastes and promotion of proven technologies for rural and urban housing construction. Advise entrepreneurs in technology selection, prototype development, commercial production and marketing and extend appropriate support for training and development/upgradation of process/technologies and procuring equipment, etc. Assist in arranging technology transfer from other countries and selection and evaluation of foreign technologies. Undertake Techno-Economic Feasibility Studies and formulation of detailed Project Reports on innovative energy-efficient building materials/ products and construction systems. Assist in capacity building and skill development through training of village artisans, craftsmen and help in production of simple building components using local materials, skills and manpower and to coordinate with national, state and local level institutions of periodic training and orientation courses for professionals like engineers, architects, town planners, contractors and construction managers for creating confidence in use of new materials and technologies. Evaluation, validation, certification and standardization of new building materials and construction technologies through Performance Appraisal Certification Scheme. As a clearing house of technology transfer from lab to land, through production and application and as repository of information on all types of building materials including conventional and newly developed, under development in India and abroad. Persuade Central and State Government agencies, housing development and construction agencies and organizations in private and community sectors for application of proven cost effective and energy-efficient building materials and construction technologies. Rendering of design services on adoption and application of innovative building materials and construction technologies in the housing projects and slum development programmes of Government, Public and Private agencies/bodies. Undertake Rapid Damage Assessment Studies of the disaster affected areas and to develop and promote disaster resistant construction technologies. Advise on vulnerability and risk assessment and on formulation of relief, reconstruction and rehabilitation programs for disaster mitigation and assist in capacity building for disaster preparedness. Recommend to Government for fiscal and other concessions to be provided for promoting and scaling up new technologies and building materials. PROJECT PROFILE Name of Scheme : VAMBAY -Ministry of HUPA Location of site : Kalamna, Nagpur No. of Units : 70 (Ground + 1) Built-up of each unit : 181 sq.ft. Unit consist of : One room, kitchen space, bath room and WC Cost per unit : Rs. 50,000 Cost per sqft. : Rs.275/- Nodal State Agency : Nagpur Improvement Trust TECHNOLOGIES / SPECIFICATIONS Foundation - Under Rimmed Piles Walling - Solid / Hollow Blocks using flyash/gypsum RCC Tie and plinth band for earthquake resistance. Roof/Floor - RCC Filler Slab using blocks IPS flooring Doors & Windows Pre-cast RCC door frames Ferrocement Door Shutters for main door Flyash polymer door shutter for toilet Cement jalli in Ventilators Others External cement plaster Whitewash in internal walls Waterproof cement paint on external walls The Scenario in India and the Role of BMTPC - From Lab to Land Research institutions have developed a large number of alternate materials and constructions systems, based on utilisation of agro-industrial wastes which otherwise cause severe environmental problems. To improve the awareness about these innovative building materials, and to facilitate their transfer from lab to land, the Building Materials & Technology Promotion Council (BMTPC) has been set up by the Government of India as an inter-ministerial apex organisation, under the aegis of the Ministry of Urban Affairs and Employment. The Council co-ordinates with various institutions involved in R&D, finance, industrial promotion and housing to promote innovative technologies, scale up proven technologies, materials and products and facilitate establishment of manufacturing/production units. BMTPC's working strategy: Promotion of sound design practices based on local materials and cost effective, innovative technologies. Promotion of building materials, components, products and systems based on indigenous raw materials, agro-industrial wastes and cost and energy efficient processes. Quality improvement and cost reduction through standardisation and adoption of modern information and management systems. Technical, financial, and fiscal policy support to enhance production and marketability. CASE STUDY - BMTPC has been promoting cost-effective and environment-friendly building materials and construction techniques in different regions of the country. During recent past, the Council has been laying emphasis on putting up demonstration structures utilising region-specific technologies. Such efforts for demonstrating innovative technologies have created a much better impact and helped in building up confidence and acceptability in private and public construction agencies, professionals and contractors etc. Demonstration Housing Project at Nagpur, Maharashtra

- 3. SHEET NO. AVD CONSTRUCTION TECHNIQUES5 Arch and Vault, a fundamental construction system in architecture used to span the space between walls, piers, or other supports and to create a roof or a ceiling. Until the 19th century the arch and vault were the only alternative to the far more limited and simpler post-and-lintel system supporting a flat or peaked beamed roof. Brief history - The use of arch, vault and cupola building systems in construction can be traced back to most ancient times. As early as the 3rd millennium BC, they were very widely used in the countries of the Middle East and Egypt. Arches, vaults and cupolas were also fairly widely used by Roman, Sassanid and Byzantine builders before being adopted in many regions of Europe. Very many applications also emerged in North Africa, the Sudan Sahel belt of Africa, as well as in the northern regions of China. Many of these countries still boast a rich heritage of this kind of building, both in urban and in rural areas. In many cases, building them is still a living tradition, well suited to modern popular housing needs. Diversity The numerous types of arches, vaults and cupolas allow a great variety of architectural models. As a result, the technology can adapt to the most varied climatic conditions: zones which are arid or rainy, cold or hot. Although arches, vaults and cupolas are traditionally used to cover limited spaces, they are perfectly well suited to build much larger spaces, up to tens of meters. Thus they can meet the needs of any building programme, public or private, low cost or quality housing, granaries, warehouses, shops, schools, public, religious buildings, etc. Recent projects Forgotten by the formal building sector since the appearance of concrete, arches, vaults and cupolas were rediscovered in the 40's by the Egyptian architect, Hassan Fathy, who found inspiration in the popular Nubian tradition for the design and construction of the village of New Gourna. ARCH An arch, in construction, is a rigid span curving upward between two points of support. It appears in a variety of structures, such as an arcade, formed by a row of arches, supported by load-bearing arches or a roof or a bridge, or as a single, freestanding triumphal or memorial arch. The traditional stone or brick arch, formed of many segments held in place by lateral thrust, was developed to connect a greater distance between two supports than a single horizontal beam, or lintel, could bridge. Since the 19th century, arches have also been made of single, curved spans of iron, steel, or reinforced concrete. The masonry arch has many elements. Its supports may be walls, piers, or columns, and the capstones from which it springs are known as imposts. The upper part of the arch is the crown, the portions near the impost are the haunches, its wedge-shaped segments are voussoirs, and the central or crowning voussoir is the keystone. The inner edge of the arch is the intrados; the outer edge, the extrados; and the undersurface, the soffit. The molded band that often is found around the opening of the arch is the archivolt. The wall spaces on either side of an arch, or between adjacent arches, are spandrels. If the space between the arch and the lintel is filled in, the resulting flat surface is the tympanum. Arches have been built since prehistoric times. Rude prototypes were made by leaning two slabs of rock together or by constructing a stepped, or corbeled, arch in which projecting elements from a wall rise in steps from the supports to meet in the center. The Egyptians, Babylonians, and Greeks used the arch, generally for secular structures, such as storerooms and sewers. The Assyrians built palaces with arched ceilings, and the Etruscans used arches in bridges, passageways, and gates. The Romans, however, were the first to develop the arch on a massive scale. They used the semicircular arch freely in secular structures such as amphitheaters, palaces, and aqueducts, but their temples usually had the post-and-lintel construction of Greek temples. The few vaulted exceptions, however, include the Pantheon in Rome. During the Middle Ages, Byzantine architecture in the East and Romanesque architecture in the West retained the characteristic round Roman arch. Islamic architects developed a rich variety of pointed, scalloped, horseshoe, and ogee (S-curve) arches for mosques and palaces. In Moorish Spain, horseshoe arches were set on delicate columns, giving a characteristic airy effect. Gothic architecture in Western Europe was characterized by the pointed arch, which minimized outward thrust and thus made possible higher, thinner, window-filled walls, creating the lofty, spacious interiors of Gothic cathedrals. In the 20th century, arches of molded reinforced concrete based on the curve of a parabola have been used in all sorts of public structures. A vault, in architecture, is an arch-shaped structure, usually of masonry, used as the ceiling of a room or other enclosed space, as the roof of a building, or as the support for a ceiling or roof. Masonry vaults are usually composed of wedge-shaped pieces called voussoirs, which are held in place, like the stones of an arch, by the pressure of the neighboring pieces. Because of the combined pressure of its components, any arch exerts an outward pressure at its base, and the base, therefore, must be so constructed as to withstand the outward as well as the downward thrust of the arch. This construction can be accomplished by using strong, heavy walls to support the arch or by supporting the walls with exterior structures, or buttresses. A temporary supporting structure must be erected within the vaulted area during construction, because a masonry vault does not become self-supporting until the central voussoirs or keystones are put in place. A number of different types of vaults are used architecturally. The simplest of these is the barrel, or tunnel, vault, the roof of which is shaped like half a cylinder and is supported by straight walls. The annular vault is similar to the barrel vault, except that the passage within it is not straight but curved, giving the entire structure the appearance of a portion of a ring. A groined vault is formed by the intersection of two vaults of the barrel type, usually at right angles to each other. The junctures at which the two vaults meet are elliptical ridges, called groins. In the simplest form of groined vault, the two conjoined vaults are of the same size and the floor of the vault is square; if the vaults are of different sizes, however, the floor of the vault is rectangular and the two areas of the ceiling between the groins are of unequal shape and size. Project of the architect Hassan Fathy, villa at Fayoum, Egypt, 1984 DOMES Domes are obtained by rotating an arch, except for faceted domes which more closely resemble the dominical vault. A dome can be semi-circular, segmental, ogival, conical, etc. domes are circular in plan. They can, however, be used to cover square or rectangular rooms by using pendentives or squinches. Domes on pendentives can be used to cover any kind of polygonal shape in plan. It is possible to combine several domes or to combine domes with vaults. A dome is a spherical vault resting on a circular base wall. Pendentives are portions of spherical vaults, or spherical triangles, placed in the corners of square or other polygonal structures to form a circular base for a dome above. More complicated vaults include ribbed vaults, in which the inner vault surface is subdivided by a number of independent supporting arches, or ribs. A further refinement is the fan vault, most common in English late Gothic structures, in which the ribs are multiplied and grouped in the shape of an open fan. A VAULT ADVANTAGES OF ARCHES, VAULTS AND CUPOLAS The materials used for the construction of arches, vaults and cupolas can be the same as those used for walls and can be found or produced locally. There is no use of wood, which also totally eliminates the risks of fire. The massive nature of these structures provides good heats to rage capacity and delay in heat transmission, meeting comfort requirements, especially in dry climate regions. This mass also gives good sound insulation. SUITABILITY Arches, vaults and cupolas can often provide a good solution for covering all kinds of buildings of all sizes. However, their acceptability and suitability to genuine needs and local climatic conditions cannot always be taken for granted. To ensure that structures are well designed and well built, specialized training must be given at all levels: design, engineering and construction. Preliminary surveys are required. LIMITATIONS OF USE Some local conditions can limit the benefits of building with arches, vaults and cupolas: rejection by the inhabitants for cultural reasons, high cost of labor, high cost of suitable building materials, and use in earthquake areas requires special care, lack of building norms. The technology must be adjusted to a given context and the techniques must be mastered, to warrant the advantages of using arches, vaults and cupolas. SEM SCALE DATE 10 - 03 - 2018 1:500 COLLEGE SUBJECT CLASS R.NO. 613 - LOW COST BUILDING MATERIALS AND CONSTRUCTION TECHNIQUES. SOUMITRA SMARTNAME JAWAHARLAL NEHRU ENGINEERING COLLEGE, CIDCO, AURANGABAD. 20213220171703210006 M-ARCH - GENERAL 2nd SEMESTER

- 4. SHEET NO. AVD construction details with compressed stabilized earth blocks These blocks must have been well cured for 1 month and left for drying for 3 more months. The reason is that earth blocks, even stabilized ones, always shrink because of clay in the soil. This time period is essential to allow the blocks to shrink fully. If this requirement is not followed and the blocks are used too early, they will shrink in the vaulted structures. Thus they will create tension in the masonry and the latter will crack. One should know that arches always tend to crack, even if they are well built. The reason is that the arch has a different behaviour than the masonry above it, and the line of thrust changes when the arch is loaded. Compressed stabilised earth blocks used for building AVD should have a very accurate and regular thickness. The Auram Press 3000 allows accuracy within 0.5 mm for the block thickness, from corner to corner and from block to block It is essential to control regularly their thickness during the production process. SEM SCALE DATE 10 - 03 - 2018 1:500 COLLEGE SUBJECT CLASS R.NO. 613 - LOW COST BUILDING MATERIALS AND CONSTRUCTION TECHNIQUES. SOUMITRA SMARTNAME JAWAHARLAL NEHRU ENGINEERING COLLEGE, CIDCO, AURANGABAD. 20213220171703210006 M-ARCH - GENERAL 2nd SEMESTER NUBIAN TECHNIQUE This technique came from Nubia, in the south of Egypt, hence the name Nubian. It has been used since ages, as is testified the vaults of the granaries of the Ramasseum at Gourna, Egypt, which was built during the XIXth Dynasty, around 1300 BC . The Nubian technique was revived and disseminated by the Egyptian architect Hassan Fathy. The Nubian technique traditionally needs a back wall to stick the blocks onto. The vault was built arch after arch and therefore the courses were laid almost vertically. The binder, about 1-1.5 cm thick, was the silty-clayey soil from the Nile and the blocks used were adobes, the sun dried bricks. The unevenness of the adobes made it necessary to slightly incline the courses, so as to increase the adhesion by force of gravity. The basis of this technique is that the blocks adhere to each other with earth glue. The principle is that the dry block sucks by capillarity the water along with the clay of the glue which will bind the blocks. It is essential that the blocks are very thin, so as to have a high ratio thinner the block is, the better will be the adhesion. The Nubian technique was also used for building circular domes, using a compass, as is shown hereafter. This technique has the advantage of allowing one to build vaults and domes without centring. This technique with vertical courses has a major disadvantage, which is that the earth glue is very liquid and the blocks are very thin. Therefore the shrinkage of the glue is important and it induces cracks, especially in vaults. When compressed stabilised earth blocks are used to build vaults using this technique, the course can be absolutely vertical as it is not needed any more to incline the courses for the adhesion. The even regularity of CSEB produced by the Auram press 3000 allows building with a cement-stabilised earth glue of only 1-2 mm in thickness. The Nubian technique has been developed by the Auroville Earth Institute to build other types of vaults, such as cloister and groined domes, and has evolved towards the Free Spanning technique. Starting the inclined course first course fourth course Building arch after arch Shaping the curve onto the adobe wall FREE SPANNING TECHNIQUE The free spanning technique is a development of the Nubian technique. It allows courses to be laid horizontally. This technique combines also the use of vertical courses, like in the Nubian technique. Depending on the shape of vaults, structures are built either with horizontal courses, vertical ones or a combination of both. The basis of the technique with horizontal courses is not anymore the adhesion of the blocks by the earth glue, but the equilibrium of gravity forces of the various courses, and their transfer onto the next courses and the masonry in general. It is essential to study the location of the centers of gravity so that the weight of the masonry never goes beyond the springers. It is needed also to develop a certain sense of how the forces behave in the masonry. The transfer of loads always takes the shape of catenary curves, and assumes the most direct way. The vault rises with horizontal courses Building a semicircular vault of 6m span The vault, being built with horizontal courses, rises like a corbel which is curved and has courses inclined at the same angle as the radius of the curve. 12. Wedge the keystone with stone chips 9. Pour water on the keystone 10. Apply glue on the 4 laying faces 11. Insert the keystone 7. Wedge the block with stone chips 8. Grind the keystone to adjust its thickness 5. Insert the block. Note the mortar on the sides 6. Adjust the block by sliding it vertically 3. Grind a block to adjust its length 4. Apply 2-3 mm of glue on the block 1. Start the vault on both sides 2. Check the linearity of the last course CONSTRUCTION OF VAULT WITH FREE SPANNING TECHNIQUE AVD CONSTRUCTION TECHNIQUES5.1

- 5. SEM SCALE DATE SHEET NO. 10 - 03 - 2018 1:500 COLLEGE SUBJECT CLASS R.NO. 613 - LOW COST BUILDING MATERIALS AND CONSTRUCTION TECHNIQUES. SOUMITRA SMARTNAME JAWAHARLAL NEHRU ENGINEERING COLLEGE, CIDCO, AURANGABAD. 20213220171703210006 M-ARCH - GENERAL 2nd SEMESTER BAMBOO ARCHITECTURE 6 Bamboo is a perennial grass and not a tree as is commonly perceived. Bamboo, like true wood, is a natural composite material with a high strength-to-weight ratio useful for structures. Bamboo has a higher compressive strength than wood, brick or concrete and good tensile strength and low weight. The strongest part of a bamboo stalk is its node, where branching occurs. They are renewable and extremely versatile resource with multi-purpose usage. It has been one of the most used building material as support for concrete, especially in those locations where it is found in abundance. Bamboo has been in wide usage since ancient times as a low-cost material for houses, bridges etc. Recently started appearing in designer homes as flooring, walling and paneling material Is viewed as a material preferred only by the poor or for temporary constructions Unpopular in conventional construction due to low durability, lack of structural design data, exclusion from building codes etc. 1450 species are found in diverse climates across the world, however, not all of these are suitable for construction. One of the fastest growing plants on Earth. Its growth rate ranges from 30cm to 1 m in 24 hours. Bamboo as a building material is conventionally associated with the region of Southeast Asia and South America where climate is best suitable for its cultivation. Among many uses of bamboo, Housing is one of the major areas applications especially in the wake of residential shortages around the globe. Bamboo for Foundations There is very limited use of bamboo as foundation material because when in contact with moisture laden surface they decay fast. However, this issue can be tackled to quite an extent though proper treatment using appropriate chemicals. The various types of foundations constructed with bamboo are: Bamboo which is in direct contact with ground surface. Bamboo fixed to rock or preformed concrete footings Composite bamboo or concrete columns Bamboo piles Bamboos are used in various shapes and forms to build foundation. Some of the common shapes of bamboos are: Flattened bamboo shape which is acquired by splitting freshly cut bamboo stalks and then rolling and flattening them. Bamboo mats as thin as 5-6mm or 10-15mm in size are woven according to design prerequisite. Phenolic resins are used in structures employing bamboo mats. Bamboo plastic composite is a pioneering technology in which bamboo fiber as raw material is blended with plastic as the core material. These mats are highly resistant to moisture and structurally more stable. Methods of Working on Bamboo For a bamboo to be used as a building material, it must be worked on to create desired shape, bend and length to be used for structural or other purposes. Following are the different works involved with use of bamboo: Bamboo as a Building Material Utilization of Bamboo for construction is achieved by a structural frame technique which is related to same approach applied in usual timber frame design and construction. In the case bamboo, floor, walls and roof are interconnected and often rely on the other for overall stability. Bamboo has played a vital role in the growth of enterprises and the rural transformation. Bamboos are treated in such a way that they assume desired shapes and structures while they grow: Squared cross-section can be obtained by compressing the growing stalk of bamboo within a square section. Arch shapes of bamboo can also be created by compressing the the desired shape. This would cost lesser than it would to get the same form with normal timber. Curved and Flat shapes of bamboo are achieved through traditional techniques like applying heat and pressure. Various Structural Shapes of Bamboo as a Building Material Walls Construction with Bamboo as a Building Material Bamboo is extensively used for construction of walls and partitions. Posts and beams are the main elements normally constructed with bamboo provide structural framework for walls. They positioned in a way to be able to withstand forces of nature. An infill is used between framing elements to add strength and stability to the walls. Roofing with Bamboo as a Building Material Bamboo is one of the best roofing materials and provides ample sturdiness to the structure. It is a proven shield against forces of nature or animals and are considerably light weighted which makes them easy to install. The bamboo roofs encompass purlins, rafters and trusses. Scaffolding with Bamboo as a Building Material Due to advantageous properties of bearing heavy load bamboos are considered as one of the highly-endorsed materials for scaffolding even for tall structures. For the construction of scaffolding, cane extensions are obtained by lashing cane ends using several ropes. The ties are positioned in such a way that forces acting vertically downwards lodge the nodes in the lashing. This technique has immense significance since the joints can be re-aligned in the right degree. Advantages of Bamboo as a Building Material Tensile strength: Bamboo has higher tensile strength than steel because its fibers run axially. Fire Resistance: Capability of bamboo to resist fire is very high and it can withstand temperature up to 4000 C. This is due to the presence of high value of silicate acid and water. Elasticity: Bamboo is widely preferred in earthquake prone regions due to its elastic features. Weight of bamboo: Bamboos due to their low weight are easily displaced or installed making it very easier for transportation and construction. Unlike other building materials like cement and asbestos, bamboo poses no danger to health. They are cost effective and easy to use. They are especially in great demand in earthquake prone areas. Disadvantages of Bamboo They require preservation Shrinkage: Bamboo shrinks much greater than any other type of timber especially when it loses water. Durability: Bamboo should be sufficiently treated against insect or fungus attack before being utilized for building purposes. Jointing: Despite prevalence of various techniques of jointing, structural reliability of bamboo is questionable. Is viewed as a material preferred only by the poor or for temporary constructions Unpopular in conventional construction due to low durability, lack of structural design data, exclusion from building codes etc. Preservation of Bamboo A thorough treatment of Bamboo is required to protect it against insects and rot before it is put into use. Commonly a mixture of Borax and Boric acid are utilized for this purpose. Another procedure generally employed is to boil cut bamboo to remove the starches that draw insects. Splitting of Bamboo The bamboo canes are split into halves or quarter sections using a knife ideal for the job and setting them apart by a wedge. About four or eight segments can be acquired which are used as canes, strips or battens. Canes can be peeled to make strings and ropes up to the age of 18 months. Shaping of Bamboo Even though bamboos are naturally circular in form but if they are grown in a box of square shape they acquire a shape as desired. Bending of Bamboo Bamboos can be bent while they are freshly cut by heating them above the retain this shape even after cooling and drying off.

- 6. SHEET NO. This low-cost housing project is situated in a flood-stricken region that receives extreme temperatures year-round. meeting the basic residential needs of a residential dwelling, the building will be assembled using minimal components and bamboo module units. secured using anchors, ties and solid connections, the structure will be strong enough to float in floods. built with local materials such as bamboo, leaves and recycled oil containers, the concept combines traditional architectural characteristics to distinguish the exterior fabric. costing just under 2000USD per unit, the plan allows for mass-production, and the ability for villagers to build themselves. SEM SCALE DATE 10 - 03 - 2018 1:500 COLLEGE SUBJECT CLASS R.NO. 613 - LOW COST BUILDING MATERIALS AND CONSTRUCTION TECHNIQUES. SOUMITRA SMARTNAME JAWAHARLAL NEHRU ENGINEERING COLLEGE, CIDCO, AURANGABAD. 20213220171703210006 M-ARCH - GENERAL 2nd SEMESTER 6.1 BAMBOO LOW COST HOUSING FOR SIX MEMBER FAMILY BAMBOO ARCHITECTURE

- 7. SEM SCALE DATE SHEET NO. 10 - 03 - 2018 1:500 COLLEGE SUBJECT CLASS R.NO. 613 - LOW COST BUILDING MATERIALS AND CONSTRUCTION TECHNIQUES. SOUMITRA SMARTNAME JAWAHARLAL NEHRU ENGINEERING COLLEGE, CIDCO, AURANGABAD. 20213220171703210006 M-ARCH - GENERAL 2nd SEMESTER EARTH ARCHITECTURE7 Mud, a mixture of earth and water, is economical, practical, functional and attractive. It is easy to work with, and it takes decoration as well. Mud is especially useful in humid and hot climates. Mud is a natural building material that is found in abundance, especially where other building materials such as bricks, stone or wood are scarce due to affordability and or availability. The mud architecture is a great resource that focuses on architecture constructed of mud brick, rammed earth, compressed earth block and other methods of earthen construction. The proliferation of concept to use mud and improved techniques in order to raise the level of living in the population is a very welcome idea. This can go a long way not only in the form of changing the look of population centers, rural as well as urban, but also in solving environmental problems and problems related to energy and other finite resources. Various reasons for using mud as a construction material is described below: Energy Consumption In mud construction, minimum fossil fuel energy is consumed and is naturally abundant throughout the world, where as in brick construction fossil energy is consumed for manufacturing process and transportation. Recycling Recycling of modern materials for building construction is expensive. Recycling of soil does not need fossil fuel and labour requirement is also less. The characteristic of recycled soil for construction remains the same whereas in modern building material it acquires inferior character after recycling. Abundance The abundance availability of soil in large areas helps the economically weaker section of the society to afford the mud construction. It is easily adaptable and the technology can be transferred easily. Housing demand A huge deficit of housing demand in urban and rural areas linked with limited resources on all fronts make it absolutely essential that the housing solution have o be best effective, through optimal and efficient use of all resources of land and building material. MANIFESTATION OF MUD Depending on the characteristics of the mud available, availability of supporting materials and technology used, different manifestations of mud are used. These include Adobe or Sun-dried bricks, Cob, Rammed earth, Pressed brick, Wattle and Daub etc. Cob: technique using hand formed lumps if earth mixed with sand and straw. Cob is easy to learn and inexpensive to build. It dries to hardness similar to lean concrete. This ancient mining, nor depend on manufactured materials or power tools. Cob is non-toxic and completely recyclable. Regular working windows are embedded in the cob along with their lintels while the layers are building up. If fixed window is needed we can use any kind of glass embedded into the cob. Cob houses have been known to last for centuries. Adobe: Adobe is a natural building material made from sand, clay, water and some kind of fibrous or organic material (sticks, straw and or manure),which the builders shapes into bricks using frames and dry in sun. Adobe buildings are similar to cob and mud brick buildings. Adobe structures are extremely durable, and account for some of the oldest existing building in the world. In hot climates, compared with wooden buildings offer significant advantage due to their greater thermal mass, but they are known to be particularly susceptible to earthquake damage. Buildings made up of sun-dried earth are common in the West Asia, Northern Africa, West Africa, South America, Spain, Eastern Europe and East Anglia. Rammed earth: Rammed earth is a technique used in the building of walls using the raw materials of earth, chalk, lime and gravel. It is an ancient building method that has seen a revival in recent years as people seek more sustainable building materials and natural building methods. Rammed earth walls are simple to construct, incombustible to water damage. Traditionally, rammed earth buildings are found in every continent except Antartica, from the temperate and wet regions of Northern Europe to semi-dry deserts, mountain areas and the tropics. Wattle and Daub : Wattle and daub is a building material used for making walls, in which a woven lattice of wooden strips called wattle is daubed with a sticky material usually made of some combination of wet soil, clay, sand,animal dung ang straw. It is an important construction material in many parts of the world. The wattle is made by weaving thin branches or slats between upright stakes . The wattle may be made in place to form the whole of a wall. Daub is generally created from a mixture of certain ingradients from three categories: binders, aggregates and reinforcement. Binders hold the mix together and can include clay, lime, chalk dust and limestone dust. Aggregates give the mix its bulk and dimensional stablity through mateials such as earth,sand, crushed chalk and crushed stone.Reinforcement is provided by staw hair, hay or other fiberous material and helps to hold mix together as well as to control shrinkage and provide flexibility. The daub may be mixed by hand or by treading either by humans or livestock it is then applied to the wattle and allowed to dry and oftenthen whitewashed to increase its resistance to rain. Compressed Earth Blocks: the soil, raw or stabilized , is slightly moistened, poured into a steel press and then compressed either with a manual or motorized press. It is developed from traditional rammed earth. The input of soil stabilization allowed building higher with thinner walls, which have a much better compressive strength & water resistance.