Sust 4103 capstone project poster rookstool

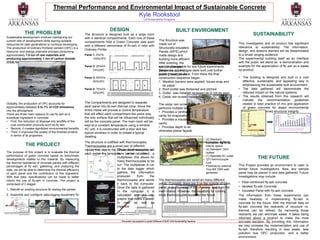

- 1. Thermal Performance and Environmental Impact of Sustainable Concrete Kyle Rookstool UA Sustainability Programs DESIGN BUILT ENVIRONMENT THE PROBLEM The structure is designed built as a large room SUSTAINABILITY Sustainable development involves maintaining our with 4 identical compartments. Each one of these current rate of development while leaving suitable The Structure was compartments hold a Green Concrete slab each This investigation and its product has significant resources for later generations to continue developing. made out of with a different percentage of fly-ash in ratio with relevance to sustainability. The information, The production of ordinary Portland cement (OPC) is a Structurally-Insulated- Ordinary Portland Concrete aggregate. design, and lessons learned will be disseminated resource- and energy-intensive process consuming Panels (SIPS) which approximately 1.5 ton of raw materials and Panel 1: 0%FA- made design and to a broad ranging audience. producing approximately 1 ton of carbon dioxide 100%OPC building more efficient. The experimental building itself as an interface (CO2) for each ton of OPC produced. After erecting, the with the public will stand as a demonstration and Panel 2: 25%FA- are interchangeable for any future experiments. sample concrete example for the appreciation of fly ash as a waste 1 2 3 4 75%OPC Temporary appendages were built until further panels are put into by-product. building couldpanels place. These be done. From there the final Panel 3: 50%FA- construction sequence began. • The building is designed and built in a cost 50%OPC 1. Weather barriers were applied; house-wrap and effective, sustainable, and appealing way in 1 2 3 4 tar paper. emphasizing the sustainable built environment Panel 4: 75%FA- 2. Roof profile was thickened and pitched. • The data gathered will demonstrate the 25%OPC 3. Gutter was installed recessed as to not be seen. reduced impact on the natural systems. Fly-Ash Landfill www.ombwatch.org 4. Cedar rain screen installed. • The results obtained from this research will indicate the recommendation guidelines Globally, the production of OPC accounts for The Compartments are designed to separate related to best practice of mix and application The cedar rain screen approximately between 5 to 7% of CO2 emissions each panel into its own thermal zone. Since the of green concrete for lesser environmental performs multiple tasks. into the atmosphere. entire inside will provide a control temperature • Provides a ventilation impact and preserved structural integrity. There are three main reasons to use fly ash as a that will effect each compartment the same way, cavity for evaporation substitute ingredient in concrete: the only surface that will be influenced individually • Provides a insulation • First, the reduction of disposal into landfills of the will be the concrete panel. The main room will be cavity. coal combustion products such as fly ash. kept at a constant temperature using a window • Second, it creates significant environmental benefits • Provides depth to an AC unit. It is constructed with a door and two • Third, it improves the quality of the finished product otherwise planar façade. typical windows in order to imitate a typical http://cpcbenvis.nic.in in terms of its properties. dwelling. http://ecosmartconcrete.com • (2) Standard The structure is outfitted with thermocouples. The Interior was wired with thermocouples, lighting, fluorescent lights for THE PROJECT Thermocouples are a wired pair of different and power. interior space. metals that, due to the difference of resistance will These thermocouples in • (2) Standard 120V The purpose of this project is to evaluate the thermal outlets each metal, the temperature can be calculated. a be wired into performance of green concrete based on benchmark • (1) Specialty AC outlet developments related to this material. By measuring multiplexer, this allows for • (27) thermocouple THE FUTURE many thermocouples to be runs the thermal resistance of concrete panels with different percentages of fly ash, gathering, and analyzing the run. The multiplexer is run • Powered by external This Project provides an environment to cater to data, we will be able to determine the thermal efficiency to the data logger which Troy-Bilt 7000 watt similar future investigations. Now, any sample of each panel and the contribution of this ingredient. gathers the information generator. panel may be placed in and data gathered. Future With that data, specifications can be made to better produced from the investigations may include: inform the use of fly-ash in concrete. The project is thermocouples and sends The thermocouples are wired an many different points. Currently, there are 3 on the outside of each • Fiber-reinforced fly-ash concrete comprised of 3 stages: it back to the computer. Once the data is gathered panel, 3 on the inside of the chamber, and 3 on the • Aerated fly-ash Concrete 1. Retrofit an existing structure for testing the panels. • Insulated Panel with fly-ash concrete in the computer it is main interior. However, the capability for running 2. Assemble and configure data-logging equipment for calculated and put into more thermocouples exists for the future. The information from these experiments can structure. graphs that make it easier make headway in implementing fly-ash in 3. Develop the structure into a pleasing design, to read as well as concrete for the future. With the thermal data on suitable for the public eye. organize. fly-ash concrete the restraints of structure vs. Type T: Thermocouple thermal can be refined. By narrowing those http://www.fhwa.dot.gov/ Courtesy UC/CITRIS (copper–constantan) restraints we can eliminate waste. It takes being informed about a product to make the most This poster was prepared in partial fulfillment of SUST 4103 Sustainability Capstone accurate decision. By providing this information we may increase the implementation and use of fly-ash therefore resulting in less waste, less pollution due OPC production, and a better environment.