Qsusa Field Results 27th June 2012

•

0 recomendaciones•318 vistas

Denunciar

Compartir

Denunciar

Compartir

Descargar para leer sin conexión

Recomendados

Más contenido relacionado

Destacado

Destacado (15)

Similar a Qsusa Field Results 27th June 2012

Similar a Qsusa Field Results 27th June 2012 (20)

Cyclic steam injection in the quiriquire field of venezuela

Cyclic steam injection in the quiriquire field of venezuela

Hazard operability study - in Industires and plant

Hazard operability study - in Industires and plant

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Volvo BM L70C Wheel Loader Service Repair Manual Instant Download.pdf

Hydraulic Ram Made from Standard Plumbing Parts - University of Georgia

Hydraulic Ram Made from Standard Plumbing Parts - University of Georgia

Más de QuickSilverUSA/// -

Más de QuickSilverUSA/// - (6)

Qsusa Field Results 27th June 2012

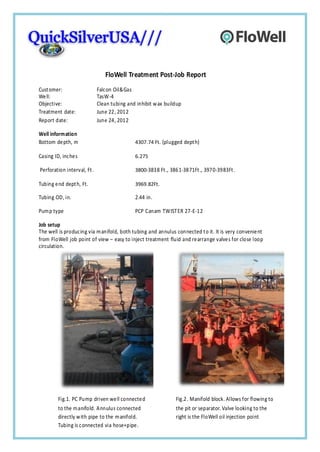

- 1. FloWell Treatment Post-Job Report Cust omer: Falcon Oil&Gas Well: TasW-4 Objective: Clean tubing and inhibit w ax buildup Treatment date: June 22, 2012 Report date: June 24, 2012 Well information Bottom depth, m 4307.74 Ft. (plugged dept h) Casing ID, inches 6.275 Perforation interval, Ft . 3800-3838 Ft ., 3861-3871Ft ., 3970-3983Ft . Tubing end dept h, Ft. 3969.82Ft. Tubing OD, in. 2.44 in. Pump type PCP Canam TWIST ER 27-E-12 Job setup The well is producing via manifold, both tubing and annulus connected t o it. It is very convenient from FloWell job point of view – easy to inject treatment fluid and rearrange valves for close loop circulation. Fig.1. PC Pump driven well connected Fig.2. Manifold block. Allows for flowing to to the manifold. Annulus connected the pit or separator. Valve looking to the directly w ith pipe to the manifold. right is the FloWell oil injection point Tubing is connected via hose+pipe.

- 2. Job sequence of events 1. Stop PC pump. 2. Check annulus fluid level – 2315.99 Ft. 3. Pre-job meeting clarifying job objectives and procedures, safety aspects and concerns. 4. Line up tank trailer and pumptruck at the oil tank to transfer 2641 gals of crude oil into the tank trailer, as in Fig.3 below. 5. Fig.3. Transferring crude oil into the tank trailer. 6. Line up tank trailer and pumptruck at the manifold and mix 55gal FloWell in 2641 gals of crude oil for 20 minutes. 7. Connect pumptruck to the manifold injection point and pump 2641 gals of crude mixed with 55 gals of FloWell oil into the annulus 8. Rearrange manifold valves to make a connected close loop “Tubing-Annulus” 9. Turn on the PC pump 10. Run close loop for 24 hours to achieve 2 complete cycles. 11. Pressure at the manifold gradually rose from zero to 19bar after 24hrs close loop circulation. Update – (this will be added to over the coming days / weeks) “Hi Dauren, Thank you for that ! It’s appreciated “. Are there any early results to report as yet? Did anything exciting happen? Production increases or anything ?” Dauren Tukenov –Chief Application Engineer – “Hi, There is some production Increase from 15 to 25 barrels per day” That is a 40% Increase !! More to come soon ..... but a great start....watch this space !!! w ww.q uicksilverusa.org