Ali Khidr CV

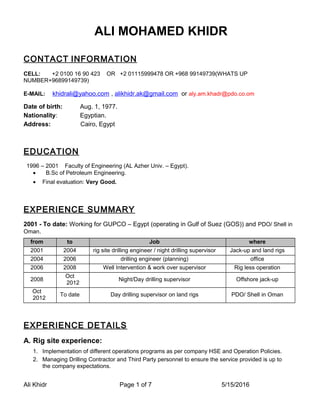

- 1. ALI MOHAMED KHIDR CONTACT INFORMATION CELL: +2 0100 16 90 423 OR +2 01115999478 OR +968 99149739(WHATS UP NUMBER+96899149739) E-MAIL: khidrali@yahoo.com , alikhidr.ak@gmail.com or aly.am.khadr@pdo.co.om Date of birth: Aug. 1, 1977. Nationality: Egyptian. Address: Cairo, Egypt EDUCATION 1996 – 2001 Faculty of Engineering (AL Azher Univ. – Egypt). • B.Sc of Petroleum Engineering. • Final evaluation: Very Good. EXPERIENCE SUMMARY 2001 - To date: Working for GUPCO – Egypt (operating in Gulf of Suez (GOS)) and PDO/ Shell in Oman. from to Job where 2001 2004 rig site drilling engineer / night drilling supervisor Jack-up and land rigs 2004 2006 drilling engineer (planning) office 2006 2008 Well Intervention & work over supervisor Rig less operation 2008 Oct 2012 Night/Day drilling supervisor Offshore jack-up Oct 2012 To date Day drilling supervisor on land rigs PDO/ Shell in Oman EXPERIENCE DETAILS A. Rig site experience: 1. Implementation of different operations programs as per company HSE and Operation Policies. 2. Managing Drilling Contractor and Third Party personnel to ensure the service provided is up to the company expectations. Ali Khidr Page 1 of 7 5/15/2016

- 2. 3. Auditing rig Well Control readiness in the following areas: well control equipment, BOP tests, well control related drills and personnel well control competency. 4. Arrangement of equipment, material and personnel as per operations schedules and weather conditions. 5. Holding Wash-up meetings, capturing and reporting Lessons Learned and Improvement Opportunities. 6. Safety leadership on the rig: participation in STOP system, visiting and auditing different work locations, ensuring controlled work by auditing and approving PTW’s as Area Authority, leading emergency drills (H2S, fire, abandonment), leading pre-tour and pre-job safety meetings, holding periodical HSE audits such as Hazard & Drop Object Hunt surveys, Continuous Auditing process and Lifting Audits, special safety precautions of Simultaneous Operations (SimOps) between rig/production/service barges, Incident Reporting And Investigation, coordination between rig OIM and Emergency Response Team "ERT" and giving technical and logistical support in emergency situations. 7. Drilling operations: directional drilling with PDM’s, RSS & LWD, running & cementing different sizes of casing and liners with single and 2 stages cement job, cement plug gobs, cement squeeze jobs, logging, cut & thread operations, Whipstock operations and cutting casing windows, tripping/reaming in bad hole conditions, drill pipe stuck and jarring operations, blind/string shoot back-off, cutting with severing tool. 8. Completion operations: running gas lift and ESP completions, perforating with TCP, installing and testing wellheads and X/T's both (conventional, compact wellheads and conductor sharing systems) 9. Work over operations: K & P, milling and fishing packers, C/O jobs, acid jobs, different fishing operations for both strings and W/L, W/L operations and setting bridge plugs. 10. Working with High Risk wells: Killing, Intervention and P&A operations on wells classified as “High Risk Wells” due to integrity problems. 11. Well Intervention Operations: W/L and Coiled Tubing Operations on live wells. 12. Jack-up rig move operations. B. Office experience: 1. Worked as a drilling engineer in planning drilling wells. Planned Vertical, Low angle, High Angle, Horizontal, Extended Reach, Grassroots and re-entry Wells. This included: o Preparing Cost estimates and “AFE” using both deterministic and probabilistic (using Crystal Ball software) approaches. o Well design and casing point selection both conventional and using Expandables Technology. o Drilling fluid selection and optimization o Designing and optimizing direction plans using LandMark's COMPASS software. o Drive mechanism and BHA design for vertical and directional wells including high angle and horizontal wells. o Optimizing jar position using “jar placement studies”. o Bit selection. o Optimizing logging programs based on risk/cost studies. o Drilling mechanics analysis using LandMarks's Well Plan software. o Studying offsets drilling problems and preparing proper mitigations in terms of casing point selection and mud type/weight/inhibition with cooperation with mud Co. Ali Khidr Page 2 of 7 5/15/2016

- 3. o Preparing casing and cementing programs for different sizes of casing and liners, single and two stages and for cement plugs. o Planning Whipstock cased hole sidetracks. o Setting different options of different well planning aspects – such as well design, directional plans, drive mechanism selection and W/L logging vs. LWD comparisons – and ranking them based on cost analysis and Pros & Cones to support. management decision making. o Planning horizontal wells incorporating LWD imaging and RNS. o Planning Slot Recovery operations. o Preparing drilling operations programs as per company's HSE and operation policies. 2. Worked in the daily follow-up activities of drilling operations. This included: o Directional performance follow-up. o Cost tracking on DIMS software. o Daily follow-up and analysis of rig non-productive time (NPT). o Drilling mechanics monitoring (T&D, Hydraulics, hole cleaning – actual vs. software prediction). o Updating data bases (mud/drilling problems summary, one page summary (OPS), bit data bases, drive mechanism data bases, key learning data base, cement data bases). 3. Worked in review activities of drilling wells. This included: o End of well reports (EWR). o Post well review (PWR) presentations. o Performance analysis using Key Performance Indicators (KPI's). o Creating stuck incident reports. 4. Worked as a Technical Limit Coach in office drilling team. This included: o Preparing Work Breakdown Structures (WBS) for drilling operations o Organizing/Holding Technical Limit Workshops. o Capturing possible opportunities to improve performance o Capturing lessons learned, highlights and lowlights o Holding Technical Limit Wash-up meetings on rig site. 5. Rig less operation (two years experience) Killing high risk wells. W/L ops, Perforation & coiled tubing ops. Work on snubbing unit (Boots & Coots) changing completions of water wells. Work on barge for killing high risk wells & Plug and abandonment ops. 6. Rig operation in Oman PDO/ Shell (four years experience) Recently Worked 2.0 years in oil horizontal wells and 2.0 years Exploration, developments deep, shallow gas wells • Implementation of different operations programs as per company HSE and Operation Policies. Ali Khidr Page 3 of 7 5/15/2016

- 4. • Managing Drilling Contractor and Third Party personnel to ensure the service provided is up to the company expectations. • Manage the well construction process carried out by drilling contractors and service companies, in accordance with agreed programs, with special attention to well control process. • Drive the full implementation of the DTL (Delivering the Limit) process during drilling program execution, thus optimising the operational and technical performance of the rig and contractors under his custody. • Promote a DTL working culture among the well site team to continuously improve performance year on year. • Ensure that all well site activities conform with company HSE, Security Policies and in Quality management principles. Report in a clear, concise and accurate manner to office based well engineer, using the available communications and computer systems. • Co-ordinate the planning, programming and execution of all well site related activities, from mobilization to a new location (including rig move and transport of materials) to demobilization (including site clearing), in close liaison with company and contractor resources; be on-site controller for all emergencies on the rig (or at the camp) • Represent the company on site well locations and supervise the well site team. • Verify all BOP test and other equipment testing confirms to company standards. • Monitor the operational and technical performance of well site contractor resources against agreed indicators, for surface and sub-surface activities; verify that the quality and cost effectiveness of the drilling and well completion products delivered by his well site organization is meeting agreed customer specifications. • Enhance the execution quality of drilling and well completion activities by optimizing proven techniques and practices, and implementing new technology and innovative operating methods; evaluate and report results; contribute to the development, upgrading and maintenance of drilling and completion standards. • Become aware of all the company policies, procedures, guidelines, training • Reviewing programs in light of work progress and proposing. Discuss proposed Program changes with team leader to improve drilling operations and implement changes in case of emergency or safety hazardous. • Supervise and control the activities of all staff /operations service company personnel involved in the provision of technical services on the assigned rig to ensure safe & timely covering W/L logs, fishing, running and pulling completions, acidizing, cementing, directional drilling, production testing, sampling and coring. • Participate in all safety meetings and drills and elaborates as many required meetings for training the rig crew in the most effective manner to minimize losses. • Worked in different fields in Algeria on various land rigs. • Experienced new technologies like: horizontal drilling with MWD. • Experienced Latest generation of drilling bits (PDC, Tricone bits, core heads ...). • Ensure operational performance and resolve operational problems. • Ensure that the contractor meet all requirements of the contract. • Improve HSE, ensure adherence to safe working practices with safety meetings and safety exercises for all personnel on the rig. • • Monitor the HSE operational, technical performance of the rig and contractors under his control, measure the quality of the products and services and formulate routes for improvement. Ali Khidr Page 4 of 7 5/15/2016

- 5. TRAINING 1. Safety Leadership training for well site leaders. 2. BP Area Authority / Performing Authority (AA/PA) safety training. 3. Incident Investigation training. 4. Landmark's training course on EDM software package (COMPASS – Well Plan – Stress Check) 5. BP Project Management training course in Well Delivery process (Certificate from George Washington Univ.) 6. IWCF (for drilling) 2006,2008,2010 and 2012, 2014 ( in Oman) and 2016 ( in Oman valid till June 2018) 7. IWCF (for well intervention) 2010 8. Helicopter Underwater Escape Training (HUET) 2011 9. Well Cap well control school 2006 (Randy Smith training solutions – Cairo) 10. Training on Slick Line Equipment and Operations (GUPCO – 2010). 11. Boots & Coots "Stuck Pipe Causes, Solutions and Prevention". (OGS – Cairo) 12. Boots & Coots Stuck Pipe Prevention course (OGS – Cairo). 13. BP-Amoco training for unscheduled events "TRUE" 2008 (Randy Smith training solutions – Cairo) 14. 4 days mud school (M-I mud Co.) 15. 2 days directional drilling & MWD school (Pathfinder Co.) 16. Rock bits, PDC's & Impregnated bits school (Smith Co.). 17. Presentation Skills course (OGS – Cairo) 18. Safety awareness (ASA, PTW, JSA, lock out and tag out) 2003. 19. Computer (Windows 2000 and XP, Microsoft office).2003. 20. Safety leader ship course 2010 &2012. 21. Drops object, H2S , Fire, SLS HSE courses in PDO /Shell In Oman 2014/2015/2016. 22. Recently 3 days Root causes analyses course with PDO/Shell in Oman.2015. 23. On scene commander training, 2014. 24. Certified for Occupational health & safety management system auditing team leader (OH&S MS) (Moody): 25. Pilot team program ( 2004 – 2005 )which include: 26. 7 habits for highly effective people (ELTC). 27. 4 rules of leadership (ELTC). 28. Developing the leader in you (Dale Carnegie). 29. Business awareness (GUPCO – Cairo), 2003. 30. HSE courses with PDO. 31. Stuck pipe courses with PDO. Ali Khidr Page 5 of 7 5/15/2016

- 6. SPECIALTY SOFTWARE KNOWLEDGE 1. Landmark’s OpenWells. 2. Landmark’s Drilling Information Management System "DIMS". 3. Landmark’s EDM package (COMPASS – Well Plan – Stress Check) 4. Crystal Ball probabilistic cost estimation software. ACHIEVEMENTS 1. An award in SPE students paper contest (2005 – Cairo) for a presentation about ''Recent Advances in Sand Control''. 2. Participation in SPE paper 128520 named “Real-Time Well Tool Face Information Reduces Directional Uncertainty and Risks in Difficult Sidetracks in Gulf of Suez” about a fist-time- use of Baker Hughes Inteq CoPilot tool measurements to guide directional drilling and steering in a very directionally challenging sidetrack well in GOS. SKILLS 1. Mother language: Arabic. 2. Second language: English – excellent writing & speaking skills. 3. Excellent MS office package skills (Excel – Word – PowerPoint). 4. Car driving (have valid driving license). 5. Ability to relocate and adapt with new environments. 6. Ability to work under pressure. 7. Good negotiation, communication, analytical and problem solving skills. 8. Ability to lead and motivate people. 9. Self motivated, keen to learn & gain experience. 10. Ability to work well with others in a multi-functional team environments. 11. Dynamic and proactive. 12. Creative and produce innovative solutions. 13. Ready to take decisions and accept responsibility. 14. Well developed communication and men management skills with a good leadership awareness. INTERESTS 1. Following latest technologies in E & P especially in well construction. Ali Khidr Page 6 of 7 5/15/2016

- 7. 2. Following world news. 3. Gymnasium, running & football. Dear Sir, I have 15 years field experience. 15 years field experience with gulf of Suez petroleum company (GUPCO) BP- Egypt Business Unit in offshore drilling and work over of oil wells & Well Intervention Team (rig less ops). And I work as a company man with Khalda, Agiba onshore company I work as a company man with Pico & Petro SA offshore company and outside Egypt. Recently I work with PDO/ Shell in Oman As DSV (Drilling supervisor) on land rigs since four years ago. I will be ready to work after completion of formalities. I will be glade to answer all inquires. Sincerely, Ali khidr Ali Khidr Page 7 of 7 5/15/2016