Kenr6200 01

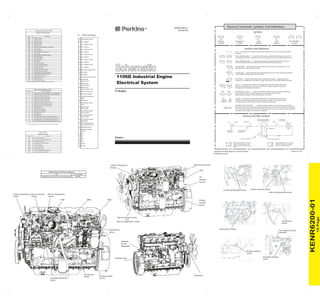

- 1. @Perkins Component Identifiers (CID1) ® Electrical Schematic Symbols And Definitions KENR 6200-01 January 08 Symbols Engine Control Module C ID J2 C o m po n e n t 0001 Cylinder #1 Injector 0002 Cylinder #2 Injector 0003 Cylinder #3 Injector 0004 Cylinder #4 Injector 0005 Cylinder #5 Injector 0006 Cylinder #6 Injector 0041 ECM (Engine Control Module) 8 Volt DC Supply 0091 Throttle Position 0100 Engine Oil Pressure 6 ECM connector No 6 injector return T Pressure Symbol 62 No 6 injector 7 No 5 injector return Temperature Symbol 63 No 5 injector Fuse - A component in an electrical circuit that will open the circuit if too much current flows through it. 64 No 4 injector Engine Coolant Temperature Sensor 0168 System Voltage 0172 Intake Manifold Air Temperature Sensor 0190 Engine speed Signal 0247 SAE J.1939 Data Link 0253 Personality Module 0261 Engine Timing 0262 5 Volt Sensor DC Supply 33 No 3 injector return Switch (Normally Open): A switch that will close at a specified point (temp, press, etc.). The circle indicates that the component has screw terminals and a wire can be disconnected from it. 59 No 3 injector 34 No 2 injector return Switch (Normally Closed): A switch that will open at a specified point (temp, press, etc.). No circle indicates that the wire cannot be disconnected from the component. 58 No 2 injector 0268 35 No 1 injector return Programmable Parameters Fault 0342 Secondary Engine Speed Sensor Ground (Wired): This indicates that the component is connected to a grounded wire. The grounded wire is fastened to the machine. 57 No 1 injector 0526 Turbo Wastegate Drive 0774 Secondary Throttle Position Sensor 1639 Machine Security System Module 1743 Engine Operation Mode Selection Switch 38 IMP return 1797 Fuel Rail #1Pressure Valve Solenoid 1785 Intake Manifold Pressure Sensor 55 IMP signal 46 IMP Power supply (+5V) 1797 Fuel Rail Pressure Sensor Ignition Key Switch 2246 Glow Plug Start Aid Relay 39 Oil pressure sensor return 1 The CID is a diagnostic code that indicates which circuit is faulty. 56 Oil pressure sensor signal 48 FMP sensor power supply (+5V) Failure Mode Identifiers (FMI)1 Data valid but above normal operational range (most severe). 1 Data valid but below normal operational range (most severe). 2 Data erratic, intermittent, or incorrect. 3 Voltage above normal or shorted high. 4 Voltage below normal or shorted low. 5 Current below normal or open circuit. 6 Current above normal or grounded circuit. 7 Mechanical system not responding properly. 8 Abnormal frequency, pulse width, or period. 9 Abnormal update. 10 Abnormal rate of change. 11 Failure mode not identifiable. 12 Bad device or component. 13 Out of calibration. 14 Special Instruction. 15 Data valid but above normal operating range (least severe). 16 Data valid but above normal operating range (moderate severe). 17 Data valid but below normal operating range (least severe). 18 Data valid but below normal operating range (moderate severe). Reed Switch: A switch whose contacts are controlled by a magnet. A magnet closes the contacts of a normally open reed switch; it opens the contacts of a normally closed reed switch. Sender: A component that is used with a temperature or pressure gauge. The sender measures the temperature or pressure. Its resistance changes to give an indication to the gauge of the temperature or pressure. T PJ (Engine) 40 FMP sensor ground Failure Description 0 Ground (Case): This indicates that the component does not have a wire connected to ground. It is grounded by being fastened to the machine. 1106D Industrial Engine Electrical System 47 Oil pressure Power (+5V) 1834 FMI No. Relay (Magnetic Switch): A relay is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close the switch part of the relay. 51 FMP sensor signal 43 Coolant temperature signal Solenoid: A solenoid is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close a valve or move a piece of metal that can do work. 42 IMT Signal 37 Temperature sensor return MAGNETIC LATCH SOLENOID - A magnetic latch solenoid is an electrical component that is activated by electricity and held latched by a permanent magnet. It has two coils (latch and unlatch) that make electromagnet when current flows through them. It also has an internal switch that places the latch coil circuit open at the time the coil latches. 10 Speed sensor power (+8V) 52 Crankshaft position sensor signal 53 Secondary position sensor signal Harness And Wire Symbols 25 Fuel injection pump PWM signal Pin 26 Fuel injection pump solenoid PWM return 1 The FMI is a diagnostic code that indicates what tpye of failure has occurred. Socket P High Air Filter Restriction E232 High Fuel / Water Separator Water Level E360 Low Engine Oil Pressure Plug High Engine Coolant Temperature 23 J1939 - E362 Engine Overspeed E396 High Fuel Rail Pressure 24 J1939 + E398 Volume 1 2 200-BK 20 CDL - E361 105-9344 Circuit Number Identification 18 Bat + E172 J Receptacle Single Wire Connector 45 Bat - C o n d i ti o n Component Part Number Fuse 1 325-PK 17 Wastegate PWM signal Event Codes Machine Control Wire, Cable, or Harness Assembly Identification Wire Color 44 Wastegate return E v ent C o de Circuit Breaker Symbol Flow Symbol Symbols And Definitions 8 No 4 injector return 0110 Level Symbol Low Fuel Rail Pressure E539 Ground Connection 1 2 High Intake Manifold Air Temperature E2143 21 CDL + Low Engine Coolant Temperature Pin or Socket Number Typical representation of a Deutsch connector. The plug contains all sockets and the receptacle contains all pins. 1 2 Typical representation of a Sure-Seal connector. The plug and receptacle contain both pins and sockets. Printed in U.K. Copyright © Perkins Engines Company Limited All Rights Reserved Coolant Temperature Fuel pressure sensor Sensor ECM Related Electrical Service Manuals Title Form Number SENR9982 Oil pressure sensor Coolant temperature Inlet air pressure sensor sensor Inlet air pressure sensor Inlet air temperature sensor P 681 P 682 P683 Inlet air temperature sensor Primary position sensor Inlet air pressure sensor and Inlet air temperature sensor Oil pressure sensor Fuel pressure sensor Fuel Pressure Sensor Fuel injection pump solenold Solenoid for the Wastegate Primary posisition sensor Secondary position sensor Starting motor Secondary position sensor Oil pressure sensor Primary position sensor Alternator This document has been printed from SPI². Not for Resale 12 Page Coolant temperature sensor KENR6200-01 Troubleshooting: 1104D and 1106D Industrial Engines

- 2. Internal connection to the electronic fuel injector External connection to the electronic fuel injector T306 T305 Connector side Harness Harness side Connector side side J693 T962-BK T956-BK T961-BK T955-BK INJECTOR CYLINDER 6 INJECTOR CYLINDER 5 T303 INJECTOR CYLINDER 4 INJECTOR CYLINDER 3 J691 T958-BK T952-BK T957-BK T951-BK T302 1 J692 T960-BK T954-BK T959-BK T953-BK T304 T301 P2 P693 1 2 3 4 X931-YL X925-PK X930-GY X924-BR P691 1 2 3 4 P691 6 62 7 63 X929-BU X923-OR X928-GN X922-WH P692 1 2 3 4 System Overview J2 ECM Connector 8 64 33 59 X927-YL X921-PK X926-GY X920-BR P692 J691 P693 J692 P511 T301 T302 T303 T305 T304 4 3 4 P r e s s u r e c o n n e c to r 3 2 1 No.1 34 58 35 57 No.2 No.3 No.4 No.5 P200 INJECTOR CYLINDER 1 2 3 P201 1 2 3 1 Fuel Rail Pressure Sensor 1 Signal 2 Ground 2 Signal 2 3 Ground 3 Temperature sensor P228 Temperature sensor T997-OR T993-BR X731-BU P402 47 39 56 R997-0R Y948-BR Y946-BU P200 P228 J23 P201 P103 P100 P100 1 Coolant Temperature Sensor Harness side ECM side 1 43 42 37 25 32 32 8 33 995-BU C967-BU L731-BR 25 8 2 57 57 33 40 64 64 40 1 1 2 Inlet Manifold Temperature Sensor P401 Crankshaft Position Sensor 1 P401 48 40 51 P103 1 2 3 P532 46 38 55 L730-OR Y947-BR 994-GY 1 Inlet Manifold Pressure Sensor T e m p e r a tu r e c o n n e c to r Pressure sensor Voltage 1 No.6 J1 Oil Pressure Sensor Pressure sensor T306 J511 INJECTOR CYLINDER 2 2 J693 1 2 996-GN E965-BU P920-BR 2 10 52 53 P402 Secondary Postion Sensor 1 2 P532 1 Fuel Injection Pump Solenoid Pin 40 2 Y950-YL Y951-PU C211-BK M795-WH P511 1 Wastegate Solenoid Inlet air pressure connector Fuel injection pump solenoid connector A 9 Pin diagnostic connector J23 D E B D C E F A Pin 33 Pin 32 Pin 8 Pin 1 18 45 944-OR 945-BR Y793-YL Y792-PK 21 20 23 24 Pin 25 Pin 8 Pin 32 Pin 33 J2 Pin 57 Pin 40 Pin 64 H J G H Connection for No.1 and 2 electronic injector J J1 Pin Location Industrial Engine (+) BATTERY Pin Number Description (+) BATTERY SWITCHED Function Pin Number Description Function Battery (-) Battery –ve 33 VS_RET Sensor 0V Return Battery (-) Battery –ve Battery –ve 34 35 VS_RET SWG_ RET Sensor 0V Return Battery (-) 4 N/A N/A 36 SWB 2 Maintenance Reset 5 N/A 37 SWB 1 6 N/A N/A N/A 38 SWG 11 N/A Air Filter Restriction Switch 7 Battery (+) 40 SWG 10 SWK_0 Mode Switch 1 Battery (+) Battery +ve Battery +ve 39 8 9 Battery (-) 41 VS_5_200mA 10 Battery (-) Battery -ve Battery -ve 42 VS_5_200mA Sensor 5V Supply Sensor 5V Supply 11 DF_PWM 2 Shield N/A 43 12 N/A N/A 44 VS_8_100mA SWG 9 13 DF_PWM 2DF_PWM 2+ 45 SWG 8 Throttle 1 IVS 14 N/A N/A 46 SWG 7 Mode Switch 2 15 Battery (+) SWG 6 Throttle Selection Switch or Coolant Level Switch Battery (+) Battery +ve Battery +ve 47 16 48 SWG 5 Remote Shutdown Switch (NO) 17 N/A N/A N/A 49 SWG 4 PTO Mode Disengage (NC) N/A N/A 50 PTO Mode Raise/Resume 51 SWG 3 SWG 2 J1939 CAN DL + 52 SWG 1 PTO Mode ON/OFF 53 STARTING CIRCUIT 1 (-) BATTERY / SENSOR RETURN 12 Page, Color 2 KENR6200-01 G F 101-RD 229-BK C B Secondary position connector J1 Pin 57 Pin 1 J23 Diagnostic Connector J 23 Pin 64 Pin 25 2 Coolant temperature connector Inlet air temperature connector 25 26 44 17 2 3 SENSOR / ACTUATOR SUPPLY Oil pressure connector SIGNAL PLUS TO ECM SIGNAL MINUS TO ECM CONTROL PLUS FROM ECM CONTROL MINUS FROM ECM DATA LINK (J1939) CAN DATA LINK Battery Connection for No.3 and 4 electronic injector Starting and charging - + J23 Diagnostic connector Relay Fuse 18 19 Switch Return Ignition Switch Input PWM Throttle Sensor 8V Supply Throttle 2 IVS PTO Mode Set/Lower 20 21 CAN (-) J1939 CAN DL - 22 CAN A Shield CAN Shield 54 AIN_ACT/PWM_I 1 PWM Throttle Input Throttle 1 Analogue Input AIN_ACT 7 23 CDL (+) CDL (+) 55 AIN_ACT 5 Throttle 2 Analogue Input 24 CDL (-) CDL (-) 56 AIN_ACT 4 25 DOUT PWM RET PWM Return 57 DOUT_1A 1 26 P2 connector N/A CAN (+) 58 Resistors optional 300 ohms (24V) PWM Return DOUT_0.3A 10 27 DOUT PWM RET N/A N/A Start Aid Control Maintenance Due Lamp 59 DOUT_0.3A 9 28 N/A N/A 60 DOUT_0.3A 8 29 N/A 61 62 DOUT_0.3A 4 DOUT_0.3A 3 PTO Mode Lamp 30 N/A N/A N/A N/A 100 ohms (12V) 31 PWM_2A Return 1 N/A 63 DOUT_0.3A 2 Cold Start Lamp 32 PWM_2A Driver 1 N/A 64 DOUT_0.3A 1 N/A 30 50 Fuel pressuure connector Crankshaft position sensor connector G Starting motor Waste gate connector Connection for No.5 and 6 Electronic injector Alternator B+ D+ W Warning Lamp Shutdown Lamp Low Oil Pressure Lamp Key switch Ignition warning light THIS DIAGRAM IS FOR THE 1100 SERIES INDUSTRIAL ENGINE MODEL PJ. This document has been printed from SPI². Not for Resale