TECHNICAL DATA

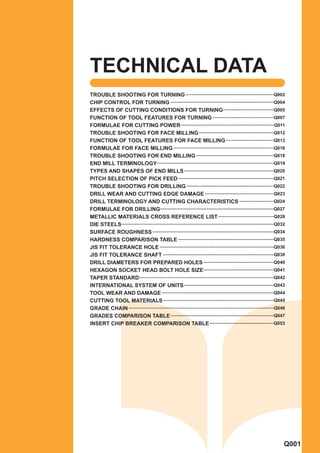

- 1. TECHNICAL DATA TROUBLE SHOOTING FOR TURNING ...........................................................Q002 CHIP CONTROL FOR TURNING .....................................................................Q004 EFFECTS OF CUTTING CONDITIONS FOR TURNING..................................Q005 FUNCTION OF TOOL FEATURES FOR TURNING .........................................Q007 FORMULAE FOR CUTTING POWER .............................................................. Q011 TROUBLE SHOOTING FOR FACE MILLING ..................................................Q012 FUNCTION OF TOOL FEATURES FOR FACE MILLING ................................Q013 FORMULAE FOR FACE MILLING ...................................................................Q016 TROUBLE SHOOTING FOR END MILLING ....................................................Q018 END MILL TERMINOLOGY ..............................................................................Q019 TYPES AND SHAPES OF END MILLS ............................................................Q020 PITCH SELECTION OF PICK FEED ................................................................Q021 TROUBLE SHOOTING FOR DRILLING ..........................................................Q022 DRILL WEAR AND CUTTING EDGE DAMAGE ..............................................Q023 DRILL TERMINOLOGY AND CUTTING CHARACTERISTICS .......................Q024 FORMULAE FOR DRILLING............................................................................Q027 METALLIC MATERIALS CROSS REFERENCE LIST .....................................Q028 DIE STEELS......................................................................................................Q032 SURFACE ROUGHNESS .................................................................................Q034 HARDNESS COMPARISON TABLE ................................................................Q035 JIS FIT TOLERANCE HOLE ............................................................................Q036 JIS FIT TOLERANCE SHAFT ..........................................................................Q038 DRILL DIAMETERS FOR PREPARED HOLES ...............................................Q040 HEXAGON SOCKET HEAD BOLT HOLE SIZE...............................................Q041 TAPER STANDARD ..........................................................................................Q042 INTERNATIONAL SYSTEM OF UNITS ............................................................Q043 TOOL WEAR AND DAMAGE ...........................................................................Q044 CUTTING TOOL MATERIALS ..........................................................................Q045 GRADE CHAIN .................................................................................................Q046 GRADES COMPARISON TABLE .....................................................................Q047 INSERT CHIP BREAKER COMPARISON TABLE ...........................................Q053 Q001

- 2. TECHNICAL DATA TROUBLE SHOOTING FOR TURNING Insert Grade Cutting Style and Design Machine, Selection Conditions of the Tool Installation of Tool Solution Honing strengthens Decrease power and machine Increase clamping rigidity of Improve tool holder rigidity the cutting edge Coolant Cutting speed Decrease holder overhang Corner radius Select a grade with better Select a grade with better thermal shock resistance Depth of cut Lead angle the tool and workpiece Select a tougher grade Select a harder grade adhesion resistance soluble cutting fluid Select chip breaker Do not use water- Rake Feed Determine dry or Class of insert wet cutting Up Up backlash Trouble Factors Down Down Improper a tool grade Insert wear quickly Improper cutting a a a a a generated edge geometry Improper a a a cutting speed Deterioration of Tool Life Wet Improper a tool grade Improper a a cutting conditions Lack of cutting a a a Chipping or edge strength. fracturing of cutting edge Thermal crack a a a a a a occurs Dry Build-up edge a a a a a occurs Wet Lack of rigidity a a a a Poor insert a Dimensions accuracy Out of Tolerance are not constant Large cutting resistance a a a a a a a a a and cutting edge flank Improper Necessary to a tool grade adjust often because of over-size Improper a a cutting conditions TECHNICAL DATA Deterioration of Welding occurs a a a Surface Finish Wet Poor finished Improper cutting a a surface edge geometry Chattering a a a a a a a Improper Generation Workpiece over a a a cutting conditions of Heat heating can cause poor accuracy and Improper cutting short life of insert a a a edge geometry Q002

- 3. Insert Grade Cutting Style and Design Machine, Selection Conditions of the Tool Installation of Tool Solution Honing strengthens Decrease power and machine Increase clamping rigidity of Improve tool holder rigidity the cutting edge Coolant Cutting speed Decrease holder overhang Corner radius Select a grade with better Select a grade with better thermal shock resistance Depth of cut Lead angle the tool and workpiece Select a tougher grade Select a harder grade adhesion resistance soluble cutting fluid Select chip breaker Do not use water- Rake Feed Determine dry or Class of insert wet cutting Up Up backlash Trouble Factors Down Down Notch wear a Burrs improper a a a (steel, aluminium) cutting conditions Wet Improper cutting a a a a a edge geometry improper Burrs, Chipping etc. a a cutting conditions Workpiece chipping Improper cutting a a a a a (cast iron) edge geometry Vibration occurs a a a a Improper a tool grade Improper a a a cutting conditions Wet Burrs (mild steel) Improper cutting a a a edge geometry Vibration occurs a a a a improper a a a a cutting conditions Wet Large chip long chips a control range Poor Chip Dispersal Improper cutting a a edge geometry improper TECHNICAL DATA a a a cutting conditions Dry Chips are short Small chip a and scattered control range Improper cutting a a edge geometry Q003

- 4. TECHNICAL DATA CHIP CONTROL FOR TURNING y CHIP BREAKING CONDITIONS IN STEEL TURNING Type A Type B Type C Type D Type E Type Small Depth of Cut d<7mm Small Depth of Cut d=7 ─ 15mm l < 50mm Less Than 1 Curl Length l Curless l > 50mm 1 ─ 5 Curl i 1 Curl Curl Half a Curl aIrregular con- aRegular con- aChip scattering tinuous shape tinuous shape aChattering Note aTangles around aLong chips Good Good aPoor finished tool and work- surface piece aMaximum a Cutting speed and chip control range of chip breaker In general, when cutting speed increases, the chip control range tends to become narrower. 0.6 0.6 0.6 vc=50m/min vc=100m/min vc=150m/min 0.5 E 0.5 E 0.5 E Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) 0.4 0.4 0.4 B B D B D 0.3 D 0.3 0.3 C 0.2 0.2 C 0.2 C 0.1 0.1 0.1 A A A 1 2 3 4 5 6 1 2 3 4 5 6 1 2 3 4 5 6 Depth of Cut (mm) Depth of Cut (mm) Depth of Cut (mm) Workpiece : S45C(180HB) Tool : MTJNR2525M16N Insert : TNMG160408 Dry Cutting Grade : P10Cemented Carbide a Effects of coolant on the chip control range of a chip breaker If the cutting speed is the same, the range of chip control differs according to whether coolant is used or not. 0.6 Coolant : Dry 0.6 Coolant : Wet (Emulsion) 0.5 E 0.5 E Feed (mm/rev) Feed (mm/rev) 0.4 0.4 TECHNICAL DATA B D B 0.3 0.3 D C C 0.2 0.2 A 0.1 0.1 A 1 2 3 4 5 6 1 2 3 4 5 6 Depth of Cut (mm) Depth of Cut (mm) Workpiece : S45C Cutting Conditions : vc=100m/min Q004

- 5. EFFECTS OF CUTTING CONDITIONS FOR TURNING y EFFECTS OF CUTTING CONDITIONS Ideal conditions for cutting are short cutting time, long tool life, and high cutting accuracy. In order to obtain these conditions, selection of efficient cutting conditions and tool, based on work material, hardness, shape and machine capability is necessary. y CUTTING SPEED Cutting speed effects tool life greatly. Increasing cutting speed increases cutting temperature and results in shortening tool life. Cutting speed varies depending on the type and hardness of the work material. Selecting a tool grade suitable for the cutting speed is necessary. 500 Workpiece : JIS S45C 180HB 400 UE6110 Tool Life Standard : VB = 0.3mm UE6105 Depth of Cut : 1.5mm AP25N Feed : 0.3mm/rev Cutting Speed (m/min) 300 UE6020 Holder : PCLNR2525M12 NX2525 Insert : CNMG120408 200 UE6035 Dry Cutting 150 NX3035 US735 UTi20T 100 80 60 10 20 30 40 60 100 Tool Life (min) P Class Grade Tool Life 500 Workpiece : JIS SUS304 200HB 400 Tool Life Standard : VB = 0.3mm Depth of Cut : 1.5mm Feed : 0.3mm/rev Cutting Speed (m/min) 300 Holder : PCLNR2525M12 US7020 Insert : CNMG120408-MA 200 Dry Cutting 150 US735 100 UTi20T 80 60 10 20 30 40 60 100 Tool Life (min) M Class Grade Tool Life UC5105 Workpiece : JIS FC300 180HB Tool Life Standard : VB = 0.3mm 400 Depth of Cut : 1.5mm UC5115 Feed : 0.3mm/rev Cutting Speed (m/min) 300 Holder : PCLNR2525M12 UE6110 Insert : CNMG120408 AP25N Dry Cutting 200 NX2525 HTi10 150 TECHNICAL DATA 100 UTi20T 80 60 10 20 30 40 60 100 Tool Life (min) K Class Grade Tool Life a Effects of Cutting Conditions 1. Increasing cutting speed by 20% decreases tool life by 1/2. Increasing cutting speed by 50% decreases tool life by 1/5. 2. Cutting at low cutting speed (20─ 40 m/min) tends to cause chattering. Thus, tool life is shortened. Q005

- 6. TECHNICAL DATA EFFECTS OF CUTTING CONDITIONS FOR TURNING y FEED When cutting with a general type holder, feed is the distance a holder moves per workpiece revolution. When milling, feed is the distance a machine table moves per cutter revolution divided by the number of inserts. Thus, it is indicated as feed per tooth. Feed rate relates to finished surface roughness. a Effects of Feed 0.4 1. Decreasing feed rate results in flank wear and shortens tool Flank Wear (mm) 0.3 life. 2. Increasing feed rate increases cutting temperature and 0.2 flank wear. However, effects on the tool life is minimal compared to cutting speed. 0.1 3. Increasing feed rate improves machining efficiency. 0 0.03 0.06 0.08 0.1 0.2 0.3 0.6 Feed (mm/rev) Cutting Conditions Workpiece : JIS SNCM431 Grade : STi10T Tool Shape : 0-0-5-5-35-35-0.3mm Depth of Cut ap=1.0mm Cutting Speed vc=200m/min Cutting Time Tc=10min Feed and Flank Wear Relationship in Steel Turning y DEPTH OF CUT Depth of cut is determined according to the required stock removal, shape of workpiece, power and rigidity of the machine and tool rigidity. a Effects of Depth of Cut 0.4 Flank Wear (mm) 1. Changing depth of cut doesn't effect tool life greatly. 0.3 2. Small depths of cut result in friction when cutting the 0.2 hardened layer of a workpiece. Thus tool life is shortened. 0.1 3. When cutting uncut surfaces or cast iron surfaces, the depth of cut needs to be increased as much as the machine 0 0.03 0.05 0.1 0.2 0.5 1.0 2.0 3.0 power allows in order to avoid cutting impure hard layers Depth of Cut (mm) with the tip of cutting edge to prevent chipping and Cutting Conditions Workpiece : JIS SNCM431 Grade : STi10T Tool Shape : 0-0-5-5-35-35-0.3mm abnormal wear. Feed f=0.20mm/rev Cutting Speed vc=200m/min Cutting Time Tc=10min Depth of Cut and Flank Wear Relationship in Steel Turning Depth of Cut Uncut Surface TECHNICAL DATA Roughing of the Surface Layer that Includes Uncut Surface Q006

- 7. FUNCTION OF TOOL FEATURES FOR TURNING y RAKE ANGLE Rake angle is a cutting edge angle that has a large effect on cutting resistance, chip disposal, cutting temperature and tool life. 200 Tool Life Standard Tool Life Standard : VB=0.4mm Cutting Speed VB=0.4mm Depth of Cut : 1mm Feed= 0.32mm/rev 140 (m/min) Positive Rake 100 120 Rak Angle 80 e An 100 Rak (+) e An gle 1 Cutting Resistance Tool Life (min) 1400 Vertical Force Positive Insert 50 Vertical Force gle 6 Rak 5° 1200 Depth of Cut : 2mm (N) e An Feed : 0.2mm/rev ° 30 Cutting Speed : 100m/min 1000 gle - 20 Rake Face Mean 10° 600 Temperature Depth of Cut : 2mm Temperature 500 Feed : 0.2mm/rev Cutting Cutting Speed : 100m/min (°C) 10 -15 -10 -5 0 5 10 15 20 25 Negative Rake Rake Angle (°) Angle 6 50 100 200 Cutting Conditions (─) Cutting Speed (m/min) Workpiece : JIS SK5 Grade : STi10T Negative Tool Shape : 0-Var-5-5-20-20-0.5mm Insert Cutting Conditions Dry Cutting Grade : STi10 Depth of Cut : 1mm Feed : 0.32mm/rev Effects of Rake Angle on Workpiece : JIS SK5 Cutting Speed, Vertical Force, Chip Disposal and Rake Angle Rake Angle and Tool Life and Cutting Temperature a Effects of Rake Angle When to Increase Rake Angle When to Increase Rake Angle 1. Increasing rake angle in the positive (+) direction in the Negative ( ─ ) Direction in the Positive (+) Direction improves sharpness. uHard workpieces. uSoft workpieces. 2. Increasing rake angle by 1° in the positive (+) uWhen the cutting edge strength is uWorkpiece is easily machined. direction decreases cutting power by about 1%. required such as for uncut uWhen the workpiece or the 3. Increasing rake angle in the positive (+) direction surfaces and interrupted cutting. machine have poor rigidity. lowers cutting edge strength and in the negative (─ ) direction increases cutting resistance. y FLANK ANGLE Flank angle prevents friction between flank face and workpiece resulting in smooth feed. Rake Angle 6° 0.3 vc e 0.2 =2 tur Flank Wear (mm) 00 ac Wear Depth Wear Depth Fr $ vc=1 00 Flank Angle $ 0.1 Large Flank Wear Small Flank Wear vc= 50 0.05 3° 6° 8° 10° 12° 15° 20° TECHNICAL DATA (Same) (Same) Flank Angle ($) D.O.C D.O.C %° %° Cutting Conditions Small Flank Angle Large Flank Angle Workpiece : JIS SNCM431 (200HB) Grade : STi20 Tool Shape : 0 • 6 • $ • $ • 20 • 20 • 0.5 Flank angle creates a space between tool and workpiece. Depth of Cut : 1mm Feed : 0.32mm/rev Cutting Time : 20min Flank angle relates to flank wear. Flank Angle and Flank Wear Relationship a Effects of Rake Angle When to Decrease Flank Angle When to Increase Flank Angle 1.Increasing flank angle decreases flank wear uHard workpieces. uSoft workpieces. occurrence. uWhen cutting edge strength is uWorkpieces suffer from work 2.Increasing flank angle lowers cutting edge required. hardening easily. strength. Q007

- 8. TECHNICAL DATA FUNCTION OF TOOL FEATURES FOR TURNING y SIDE CUTTING EDGE ANGLE (LEAD ANGLE) The side cutting edge angle reduces impact load and affects the amount of feed force, back force and chip thickness. Workpiece : JIS SCM440 80 Grade : STi120 f= Same f= Same f= Same Depth of Cut : 3mm 60 5B Feed : 0.2mm/rev B 1.1 1.04 Dry Cutting 40 B 0.97 0.8 30 h h 7h B : Chip Width Tool Life (min) f : Feed 20 kr =0° kr=15° kr=30° h : Chip Thickness kr : Side Cutting Side Side Edge Angle Side Cutting Edge Angle and Chip Thickness Cutt Cuttin 10 ing E 8 g Ed a Effects of Side Cutting Edge Angle (Lead Angle) dge ge A 6 Ang 1. At the same feed rate, increasing the side cutting edge angle increases the chip contact 5 ngle le 15 length and decreases chip thickness. As a result, the cutting force is dispersed on a longer 4 0° cutting edge and tool life is prolonged. (Refer to the chart.) ° 3 2. Increasing the side cutting edge angle increases force a'. Thus, thin, long workpieces 100 150 200 300 suffer from bending in some cases. Cutting Speed (m/min) 3. Increasing the side cutting edge angle decreases chip control. 4. Increasing the side cutting edge angle decreases the chip thickness and increases chip Side Cutting Edge and Tool Life width. Thus, breaking chips is difficult. When to Decrease Lead Angle When to Increase Lead Angle A a' A uFinishing with small depth of cut. uHard workpieces which produce a uThin, long workpieces. high cutting temperature. uWhen the machine has poor uWhen roughing a workpiece with rigidity. large diameter. uWhen the machine has high Force A is divided Receive force A. rigidity. into a and a'. y END CUTTING EDGE ANGLE The end cutting edge angle avoids interference between the machined surface and the tool (end cutting edge). Usually 5° ─15°. a Effects of End Cutting Edge Angle End Cutting Edge Angle 1. Decreasing the end cutting edge angle increases cutting edge strength, but it also increases cutting edge temperature. 2. Decreasing the end cutting edge angle increases the back force and can result in chattering and vibration while machining. 3. Small end cutting edge angle for roughing and large angle for finishing are Back Relief Angle Side Flank Angle recommended. y CUTTING EDGE INCLINATION TECHNICAL DATA Cutting edge inclination indicates inclination of the rake face. During heavy cutting, the cutting edge receives an extremely large shock at the beginning of each cut. True Rake Angle Cutting edge inclination keeps the cutting edge from receiving this shock and (─) Cutting Edge prevents fracturing. 3° ─ 5° in turning and 10° ─ 15° in milling are recommended. End Cutting Edge Inclination Angle Main Cutting Edge a Effects of Cutting Edge Inclination Corner Radius Side Cutting 1. Negative ( ─ ) cutting edge inclination disposes chips in the workpiece Edge Angle direction, and positive (+) disposes chips in the opposite direction. 2. Negative ( ─ ) cutting edge inclination increases cutting edge strength, but it also increases the back force of cutting resistance. Thus, chattering can easily occur. Q008

- 9. y HONING AND LAND Honing Width Honing Width Land Width Honing Angle Honing and land are cutting edge shapes that maintain cutting edge strength. R Honing can be round or chamfer type. The optimal honing width is approximately 1/2 of the feed. Land is the narrow flat area on the rake or flank face. Round Honing Chamfer Honing Flat Land Principal Force (N) 5000 100 1700 VB KT Tool Life (Number of Impacts) R Honing R Honing 1600 C Honing C Honing 50 1500 Tool Life (min) 1000 1400 500 1400 20 Feed Force (N) 900 10 800 100 0 0.02 0.05 0.1 0.2 0.5 700 5 Honing Size (mm) 0 0.02 0.05 0.1 0.2 0.5 600 Workpiece : JIS SNCM439 (280HB) Honing Size (mm) 800 Grade : P10 Workpiece : JIS SNCM439 (220HB) R Honing Back Force (N) Cutting Conditions : vc=200m/min ap=1.5mm Grade : P10 700 C Honing f =0.335mm/rev Cutting Conditions : vc=160m/min ap=1.5mm f=0.45mm/rev 600 Honing Size and Tool Life Honing Size and Tool Life 500 Due to Fracturing Due to Wear 400 0 0.02 0.05 0.1 0.2 0.5 Honing Size (mm) Workpiece : JIS SNCM439 (220HB) Grade : P10 Cutting Conditions : vc=100m/min ap=1.5mm f=0.425mm/rev Honing Size and Cutting Resistance a Effects of Honing 1. Enlarging the honing increases cutting edge strength, tool life and reduces fracturing. 2. Enlarging the honing increases flank wear occurrence and shortens tool life. Honing size doesn't affect rake wear. 3. Enlarging the honing increases cutting resistance and chattering. TECHNICAL DATA When to Decrease Honing Size When to Increase Honing Size uWhen finishing with small depth uHard workpieces. of cut and small feed. uWhen the cutting edge strength is uSoft workpieces. required such as for uncut uWhen the workpiece or the surfaces and interrupted cutting. machine have poor rigidity. uWhen the machine has high rigidity. * Cemented carbide, coated diamond, and indexable cermet inserts have round honing as standard. Q009