Ged 2505

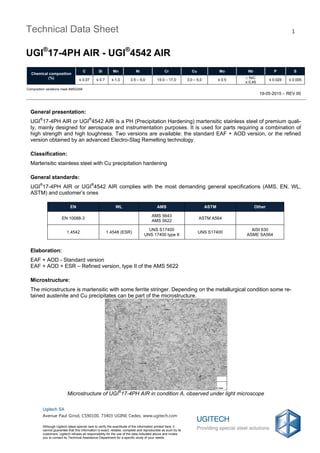

- 1. Composition variations meat AMS2248 19-05-2015 – REV 00 Technical Data Sheet UGI® 17-4PH AIR - UGI® 4542 AIR 1 Chemical composition (%) C Si Mn Ni Cr Cu Mo Nb P S ≤ 0.07 ≤ 0.7 ≤ 1,0 3.5 – 5,0 15.0 – 17,0 3,0 – 5,0 ≤ 0.5 5xC ≤ 0.45 ≤ 0.025 ≤ 0.005 Ugitech SA Avenue Paul Girod, CS90100, 73403 UGINE Cedex, www.ugitech.com Although Ugitech takes special care to verify the exactitude of the information printed here, it cannot guarantee that this information is exact, reliable, complete and reproducible as such by its customers. Ugitech refuses all responsibility for the use of the data indicated above and invites you to contact its Technical Assistance Department for a specific study of your needs. General presentation: UGI® 17-4PH AIR or UGI® 4542 AIR is a PH (Precipitation Hardening) martensitic stainless steel of premium quali- ty, mainly designed for aerospace and instrumentation purposes. It is used for parts requiring a combination of high strength and high toughness. Two versions are available: the standard EAF + AOD version, or the refined version obtained by an advanced Electro-Slag Remelting technology. Classification: Martensitic stainless steel with Cu precipitation hardening General standards: UGI® 17-4PH AIR or UGI® 4542 AIR complies with the most demanding general specifications (AMS, EN, WL, ASTM) and customer’s ones EN WL AMS ASTM Other EN 10088-3 AMS 5643 AMS 5622 ASTM A564 1.4542 1.4548 (ESR) UNS S17400 UNS 17400 type II UNS S17400 AISI 630 ASME SA564 Elaboration: EAF + AOD - Standard version EAF + AOD + ESR – Refined version, type II of the AMS 5622 Microstructure: The microstructure is martensitic with some ferrite stringer. Depending on the metallurgical condition some re- tained austenite and Cu precipitates can be part of the microstructure. Microstructure of UGI® 17-4PH AIR in condition A, observed under light microscope

- 2. Composition variations meat AMS2248 19-05-2015 – REV 00 Technical Data Sheet UGI® 17-4PH AIR - UGI® 4542 AIR 2 Chemical composition (%) C Si Mn Ni Cr Cu Mo Nb P S ≤ 0.07 ≤ 0.7 ≤ 1,0 3.5 – 5,0 15.0 – 17,0 3,0 – 5,0 ≤ 0.5 5xC ≤ 0.45 ≤ 0.025 ≤ 0.005 Ugitech SA Avenue Paul Girod, CS90100, 73403 UGINE Cedex, www.ugitech.com Although Ugitech takes special care to verify the exactitude of the information printed here, it cannot guarantee that this information is exact, reliable, complete and reproducible as such by its customers. Ugitech refuses all responsibility for the use of the data indicated above and invites you to contact its Technical Assistance Department for a specific study of your needs. Physical properties: These properties are dependent on the metallurgical condition which is ordered. For information purposes, the ta- ble below gives the values of some physical quantities of UGI® 17-4PH AIR in condition A (after solution anneal- ing) and after age hardening H1150. Condition A Condition H1150 Density 7750 kg/m3 7860 kg/m3 Weight of round bars (kg/m) 0.0062 x D² (D: diameter in mm) 0.0062 x D² (D: diameter in mm) Weight of hexagonal bars (kg/m) 0.0068 x D² (D: diameter in mm) 0.0068 x D² (D: diameter in mm) Elasticity modulus 197000 Mpa 197000 MPa Thermal conductivity 17 W/m°C 17 W/m°C Expansion ratio 10.8 x 10 -6 /°C 10.9 x 10 -6 /°C Heat treatments and guaranteed levels of mechanical properties According to ASTM A564/A564M and EN10088-3 After solution annealing treatment, performed between 1030°C and 1050°C, UGI® 17-4PH AIR or UGI® 4542 AIR presents a soft martensitic structure with a hardness of around 35 HRC. If the metal is to be used in this condition (called condition A), we recommend a stress-relieving heat treatment at 300°C. The latter will have no significant effect on mechanical properties. From the condition A, aging treatments can be carried out to obtain additional hardness (precipitation harden- ing). The maximum hardness, of around 42 HRC (impact strength of 3 daJ/cm²) is obtained by aging at 480°C for one hour (condition H900). Increasing the aging temperature gives a higher impact toughness but a lower tensile strength or hardness. The choice of aging temperature is a matter of compromise between strength and tough- ness, see table below.

- 3. Composition variations meat AMS2248 19-05-2015 – REV 00 Technical Data Sheet UGI® 17-4PH AIR - UGI® 4542 AIR 3 Chemical composition (%) C Si Mn Ni Cr Cu Mo Nb P S ≤ 0.07 ≤ 0.7 ≤ 1,0 3.5 – 5,0 15.0 – 17,0 3,0 – 5,0 ≤ 0.5 5xC ≤ 0.45 ≤ 0.025 ≤ 0.005 Ugitech SA Avenue Paul Girod, CS90100, 73403 UGINE Cedex, www.ugitech.com Although Ugitech takes special care to verify the exactitude of the information printed here, it cannot guarantee that this information is exact, reliable, complete and reproducible as such by its customers. Ugitech refuses all responsibility for the use of the data indicated above and invites you to contact its Technical Assistance Department for a specific study of your needs. Metallurgical condition Coding Heat treatment applied Guaranteed mechanical characteristics Standards Conditions Rm MPa (KSI) Rp 0.2 MPa (KSI) A % Z % KV (J) HRC HB Condition A EN 10088-3 +AT 1030 / 1050°C annealing 1200 - - - - - 360 ASTM A564 AMS 5622 AMS 5643 Cond A - - - - - 38 363 Hardened ASTM A564 AMS 5622 AMS 5643 H900 1030 / 1050°C annealing Air or oil cooling + hardening 1 h at 480°C / Air cooling 1310 (≥ 190) 1170 (≥ 170) 10 40 - 40 388 H925 1030 / 1050°C annealing Air or oil cooling + hardening 4 h at 495°C / Air cooling 1170 (≥ 170) 1070 (≥ 155) 10 44 8 38 375 Over aged EN 10088-3 +P1070 Annealing 1030 / 1050°C Air or oil cooling + Tempering 4 h at 550°C, Air cooling 1070/1270 1000 10 - - - - ASTM A564 AMS 5622 AMS 5643 H1025 1070 (≥ 155) 1 000 (≥ 145) 12 45 50 35 331 ASTM A564 AMS 5622 AMS 5643 H1075 Annealing 1030 / 1050°C Air or oil cooling + Tempering 4 h at 580°C, Air cooling 1 000 (≥ 145) 860 (≥ 125) 13 45 50 32 311 EN 10088-3 +P960 Annealing 1030 / 1050°C Air or oil cooling + Tempering 4 h at 590°C, Air cooling 960 / 1160 (≥ 140) 790 (≥ 115) 12 - - - - ASTM A564 AMS 5622 AMS 5643 H1100 965 (≥ 140) 795 (≥ 115) 14 45 60 31 302 EN 10088-3 +P930 Annealing 1030 / 1050°C Air or oil cooling + Tempering 4 h at 620°C, Air cooling 930 / 1100 720 16 - 60 - - ASTM A564 AMS 5622 AMS 5643 H1150 930 (≥ 135) 725 (≥ 105) 16 50 80 28 277 EN 10088-3 +P800 Annealing 1030 / 1050°C Air or oil cooling + Tempering 2 h at 760°C, Air cooling + Tempering 4 h at 620°C, Air cooling 800 / 950 520 18 - 80 - - ASTM A564 NACE MR0175 H1150M 795 (≥ 115) 520 (≥ 75) 18 55 80 24 255

- 4. Composition variations meat AMS2248 19-05-2015 – REV 00 Technical Data Sheet UGI® 17-4PH AIR - UGI® 4542 AIR 4 Chemical composition (%) C Si Mn Ni Cr Cu Mo Nb P S ≤ 0.07 ≤ 0.7 ≤ 1,0 3.5 – 5,0 15.0 – 17,0 3,0 – 5,0 ≤ 0.5 5xC ≤ 0.45 ≤ 0.025 ≤ 0.005 Ugitech SA Avenue Paul Girod, CS90100, 73403 UGINE Cedex, www.ugitech.com Although Ugitech takes special care to verify the exactitude of the information printed here, it cannot guarantee that this information is exact, reliable, complete and reproducible as such by its customers. Ugitech refuses all responsibility for the use of the data indicated above and invites you to contact its Technical Assistance Department for a specific study of your needs. Metallurgical condition Coding Heat treatment applied Guaranteed mechanical characteristics Standards Conditions Rm MPa (KSI) Rp 0.2 MPa (KSI) A % Z % KV (J) HRC HB ASTM A564 NACE MR0175 H1150D Annealing 1030 / 1050°C Air or oil cooling + Tempering 4 h at 620°C, Air cooling +Tempering 4h at 620°C Air cooling 860 (≥ 125) 725 (≥ 105) 16 50 80 24 / 33 255 / 311 Microcleanliness: When UGI® 17-4PH AIR or UGI® 4542 AIR is produced via a double melting process with an ESR remelting , the remaining inclusions are very small and are evenly distributed in the section. The following micro-cleanliness, ac- cording to ASTM E45/A is guaranteed: Type A B C D rating Thin Heavy Thin Heavy Thin Heavy Thin Heavy 2 < 2 2 < 2 2 < 2 2 < 2 UGI® 17-4PH AIR is also available in an electro-slag-remelted (ESR) version that offers a higher level of micro- cleanliness. Magnetic particle inspection and macro-graph UGI® 17-4 PH AIR complies with AMS 2300: Frequency/Severity rating 0/0 Macrostructure of UGI®17-4PH AIR is conforming to AMS 5622: classes 1 to 4 are generally quoted severity A according to ASTM A604. Corrosion resistance: UGI® 17-4PH AIR or UGI® 4542 AIR offers good corrosion resistance, sometimes similar to that of type 18 Cr-8Ni austenitic steels in some cases. The structure of this grade makes it insensitive to intergranular corrosion and resistant to fatigue-corrosion as well as to stress corrosion in some conditions (for example, see NACE standard for hydrogen sulfide environment). Furthermore, good resistance to corrosion-erosion should be noted due to the association of high level mechani- cal properties and corrosion resistance. UGI® 17-4 PH AIR or UGI® 4542 AIR is pickled in the same way as 630 type grade steel. If necessary, the follow- ing decontamination treatment process is recommended to move iron particles for example: 1/4 volume of 52% nitric acid (36° Baumé), 3/4 volume water Ambient temperature Duration must be defined Wash carefully when the process is completed.

- 5. Composition variations meat AMS2248 19-05-2015 – REV 00 Technical Data Sheet UGI® 17-4PH AIR - UGI® 4542 AIR 5 Chemical composition (%) C Si Mn Ni Cr Cu Mo Nb P S ≤ 0.07 ≤ 0.7 ≤ 1,0 3.5 – 5,0 15.0 – 17,0 3,0 – 5,0 ≤ 0.5 5xC ≤ 0.45 ≤ 0.025 ≤ 0.005 Ugitech SA Avenue Paul Girod, CS90100, 73403 UGINE Cedex, www.ugitech.com Although Ugitech takes special care to verify the exactitude of the information printed here, it cannot guarantee that this information is exact, reliable, complete and reproducible as such by its customers. Ugitech refuses all responsibility for the use of the data indicated above and invites you to contact its Technical Assistance Department for a specific study of your needs. Remark : the corrosion resistance of a stainless steel depends on many factors related to the composition of the corrosive atmosphere (chloride concentration, presence or absence of oxidizing agents, temperature, pH, agita- tion or no agitation, and so on), as well as to the preparation of the material (surfaces free from metal particles, surface finish, such as hardening, polishing, and so on). Precautionary measures should be taken for certain tests such as the sodium chloride fog test (standard ISO 9227): for example marking labels (that might cause corrosion run-outs and reduce the test resistance time) should not be used on the sample. The table below illustrates a performance scale in different environments: Environment Behavior Nitric acid Good Phosphoric acid Restricted use Sulphuric acid Restricted use Acetic acid Average Sodium carbonate Average NaCl (Saline mist) Good Humidity Excellent Sea water Restricted use Oil/gas Restricted use Forging: UGI® 17-4PH AIR or UGI® 4542 AIR is suitable for forging. Reheating takes place between 1150 and 1200°C, forging between 1200°C and 950°C. Cooling in air, water or oil. The parts obtained in this way can be used: » Annealed (with an expansion treatment lasting 1 to 2 hours at 250°/300°C), or » Hardened (with optional annealing + tempering for one hour at 480°C), or » Softened (with optional annealing + tempering defined by the standards according to the desired level of mechanical properties). Welding: UGI® 17-4 PH AIR can be welded without preheating, using most welding techniques: GMAW or GTAW (with or without filler wire), LASER, resistance or electron beam welding, etc. If the mechanical characteristics of the weld area have to be at the same level as that of the base metal, no filler metal or homogeneous filler metal (such as AWS E/ER 630) have to be used and a post weld heat treatment of precipitation hardening (see the different PH heat treatment on page 4) has to be performed on the weld. If the mechanical characteristics of the weld area does not have to be at the same level as that of the base metal, a filler metal such as ER308LSi (19 9 L Si) can be used. If no precipitation hardening heat treatment is done after welding, a stress relief heat treatment at 250/300°C could be useful to increase the toughness of the HAZ and avoid any risk of cold cracking due to their as-welded martensitic microstructures. Furthermore, it should be restated that the welding design should make allowance for the care required with all high steels with high proof stress: avoiding cut outs and sudden changes in cross sec- tion.

- 6. Composition variations meat AMS2248 19-05-2015 – REV 00 Technical Data Sheet UGI® 17-4PH AIR - UGI® 4542 AIR 6 Chemical composition (%) C Si Mn Ni Cr Cu Mo Nb P S ≤ 0.07 ≤ 0.7 ≤ 1,0 3.5 – 5,0 15.0 – 17,0 3,0 – 5,0 ≤ 0.5 5xC ≤ 0.45 ≤ 0.025 ≤ 0.005 Ugitech SA Avenue Paul Girod, CS90100, 73403 UGINE Cedex, www.ugitech.com Although Ugitech takes special care to verify the exactitude of the information printed here, it cannot guarantee that this information is exact, reliable, complete and reproducible as such by its customers. Ugitech refuses all responsibility for the use of the data indicated above and invites you to contact its Technical Assistance Department for a specific study of your needs. For GMAW, we recommend the use of a protective gas made up of Ar+1%CO2 or 1-2%O2; for GMAW as well as for GTAW, gasses containing H2 and N2 must be avoided. Products available: Product Profile Surface Finishing Tolerance Size (mm) Bar Round Hot rolled & descaled K13 – K12 22 -115 Turned h11 - h10 22-115 Smooth Turned – Peeled Polished h11 - h10 h9 22-115 22-55 Centerless Ground h9 - h8 - h7 5-115 Cold Drawn h9 5-21 Other profiles contact us Applications: UGI® 17-4 PH AIR or UGI® 4542 AIR is suitable for: » Aerospace as premium Aircraft Quality » Sensor manufacturing (weight, force, pressure…sensors) » Medical Ancillary » Mould steel