Humboldt Sate University Presentation (2014)

•

1 recomendación•4,002 vistas

Humboldt State University Presentation at the 2014 Hydrogen Student Design Contest

Denunciar

Compartir

Denunciar

Compartir

Descargar para leer sin conexión

Recomendados

Efficient barge unloading technology for grain handling on inland waterways

Efficient barge unloading technology for grain handling on inland waterwaysMilling and Grain magazine

Más contenido relacionado

La actualidad más candente

Efficient barge unloading technology for grain handling on inland waterways

Efficient barge unloading technology for grain handling on inland waterwaysMilling and Grain magazine

La actualidad más candente (15)

Application of intelligent well completion in optimizing production

Application of intelligent well completion in optimizing production

Modeling Tribological Contacts in Wind Turbine Gearboxes

Modeling Tribological Contacts in Wind Turbine Gearboxes

New Jersey Transit Bus Garage Groundwater Treatment System Case Study

New Jersey Transit Bus Garage Groundwater Treatment System Case Study

Efficient barge unloading technology for grain handling on inland waterways

Efficient barge unloading technology for grain handling on inland waterways

Hds one sheet 110 product overview hydrogen injection system 160220e

Hds one sheet 110 product overview hydrogen injection system 160220e

Experimental Investigation of the Effect of Injection of OxyHydrogen Gas on t...

Experimental Investigation of the Effect of Injection of OxyHydrogen Gas on t...

Similar a Humboldt Sate University Presentation (2014)

Energy savings using IntelliCOOL cassette smart integrated variable speed coo...

Energy savings using IntelliCOOL cassette smart integrated variable speed coo...ATMOsphere Conferences & Events

Similar a Humboldt Sate University Presentation (2014) (20)

STEP5 S5 Forcourt Dispersers H2 Secure Supplies.pdf

STEP5 S5 Forcourt Dispersers H2 Secure Supplies.pdf

Altra: Miscellaneous Market Applications & Innovations

Altra: Miscellaneous Market Applications & Innovations

Investigation of Solid State Hydrides For Autonomous Fuel Cell Vehicles

Investigation of Solid State Hydrides For Autonomous Fuel Cell Vehicles

Barangaroo South District Cooling Plant (DCP) Fact Sheet

Barangaroo South District Cooling Plant (DCP) Fact Sheet

Mining & Aggregate Conveyors Applications & Innovations

Mining & Aggregate Conveyors Applications & Innovations

Global Perspective on the Future of Subsea Technology

Global Perspective on the Future of Subsea Technology

RV Thuwal - Refit project overview by Maritime Survey Australia

RV Thuwal - Refit project overview by Maritime Survey Australia

New Wave Energy Services Ltd. Presentation 2016 US

New Wave Energy Services Ltd. Presentation 2016 US

Energy savings using IntelliCOOL cassette smart integrated variable speed coo...

Energy savings using IntelliCOOL cassette smart integrated variable speed coo...

Más de HEFContest

Más de HEFContest (8)

Último

Último (20)

Night 7k Call Girls Noida Sector 128 Call Me: 8448380779

Night 7k Call Girls Noida Sector 128 Call Me: 8448380779

BDSM⚡Call Girls in Sector 97 Noida Escorts >༒8448380779 Escort Service

BDSM⚡Call Girls in Sector 97 Noida Escorts >༒8448380779 Escort Service

No Advance 8868886958 Chandigarh Call Girls , Indian Call Girls For Full Nigh...

No Advance 8868886958 Chandigarh Call Girls , Indian Call Girls For Full Nigh...

Andrés Ramírez Gossler, Facundo Schinnea - eCommerce Day Chile 2024

Andrés Ramírez Gossler, Facundo Schinnea - eCommerce Day Chile 2024

Introduction to Prompt Engineering (Focusing on ChatGPT)

Introduction to Prompt Engineering (Focusing on ChatGPT)

Mohammad_Alnahdi_Oral_Presentation_Assignment.pptx

Mohammad_Alnahdi_Oral_Presentation_Assignment.pptx

If this Giant Must Walk: A Manifesto for a New Nigeria

If this Giant Must Walk: A Manifesto for a New Nigeria

Call Girl Number in Khar Mumbai📲 9892124323 💞 Full Night Enjoy

Call Girl Number in Khar Mumbai📲 9892124323 💞 Full Night Enjoy

The workplace ecosystem of the future 24.4.2024 Fabritius_share ii.pdf

The workplace ecosystem of the future 24.4.2024 Fabritius_share ii.pdf

BDSM⚡Call Girls in Sector 93 Noida Escorts >༒8448380779 Escort Service

BDSM⚡Call Girls in Sector 93 Noida Escorts >༒8448380779 Escort Service

VVIP Call Girls Nalasopara : 9892124323, Call Girls in Nalasopara Services

VVIP Call Girls Nalasopara : 9892124323, Call Girls in Nalasopara Services

Governance and Nation-Building in Nigeria: Some Reflections on Options for Po...

Governance and Nation-Building in Nigeria: Some Reflections on Options for Po...

SaaStr Workshop Wednesday w/ Lucas Price, Yardstick

SaaStr Workshop Wednesday w/ Lucas Price, Yardstick

Re-membering the Bard: Revisiting The Compleat Wrks of Wllm Shkspr (Abridged)...

Re-membering the Bard: Revisiting The Compleat Wrks of Wllm Shkspr (Abridged)...

Humboldt Sate University Presentation (2014)

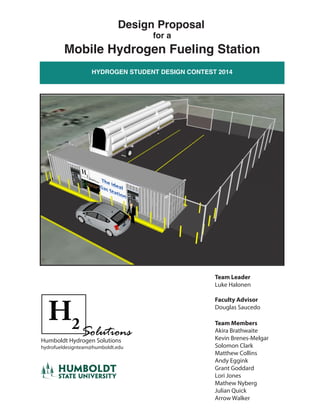

- 1. HYDROGEN STUDENT DESIGN CONTEST 2014 Design Proposal for a Mobile Hydrogen Fueling Station Team Leader Luke Halonen Faculty Advisor Douglas Saucedo Team Members Akira Brathwaite Kevin Brenes-Melgar Solomon Clark Matthew Collins Andy Eggink Grant Goddard Lori Jones Mathew Nyberg Julian Quick Arrow Walker Humboldt Hydrogen Solutions hydrofueldesignteam@humboldt.edu

- 2. The Ideal Gas Station utilizes existing off-the-shelf components, making the station buildable today. The key features of the design include: • Hydrogen obtained from existing suppliers • 200 bar tube trailer delivery • Dynamic cascade storage system minimizes compression • On-demand cascade pre-cooling system • Fast fill SAE TIR J2601 compliant dispensers • 700 bar dispensing pressure doubles vehicle range • Integrated pressure and leak-detection management • Automated hydrogen ordering • Remote maintenance and data collection Tube Trailer (200 bar) Low Pressure Compressor (Min = 20 bar) Cascade Storage System in Isolated Cooling Box (450 bar, 650 bar, & 900 bar) Buffer Tank (103 bar) If tube trailer pressure is greater than 103 bar High Pressure Compressor (Min = 103 bar) Tube Trailer (200 bar) Initial Compression Cascade Storage System in Isolated Cooling Box (450 bar, 650 bar, & 900 bar) Stage 1 Cooling Evaporator -10 °C Booster Compression Stage 2 Cooling Heat Exchanger -40 °C Buffer Tank (103 bar) Hydrogen Fuelled Vehicle (700 bar) Dispenser Process Flow Diagram The key components of the design are illustrated in the Process Flow Diagram: Humboldt State University Ideal Gas Station Hydrogen Education Foundation 2014 Student Design Contest