CEIT Biomedical Engineering - Cranial Implants with EOS Additive Manufacturing using PEEK / PEAK Plastics

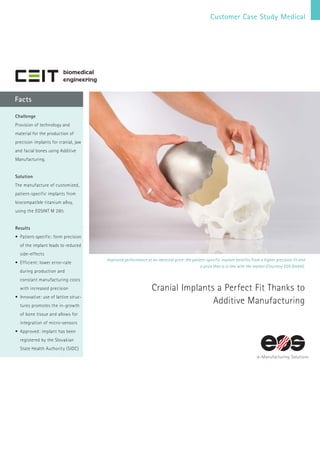

- 1. Customer Case Study Medical Facts Improved performance at an identical price: the patient-specific implant benefits from a higher precision fit and a price that is in line with the market (Courtesy EOS GmbH). Cranial Implants a Perfect Fit Thanks to Additive Manufacturing Challenge Provision of technology and material for the production of precision implants for cranial, jaw and facial bones using Additive Manufacturing. Solution The manufacture of customized, patient-specific implants from biocompatible titanium alloy, using the EOSINT M 280. Results • Patient-specific: form precision of the implant leads to reduced side-effects • Efficient: lower error-rate during production and constant manufacturing costs with increased precision • Innovative: use of lattice struc- tures promotes the in-growth of bone tissue and allows for integration of micro-sensors • Approved: implant has been registered by the Slovakian State Health Authority (SIDC)

- 2. Slovakian Healthcare Pioneer CEIT Biomedical Engineering, s.r.o. Relies on EOS Technology for Cranial Implants Short Profile CEIT Biomedical Engineering, s.r.o. is a spin-off company of the Technical University of Košice (TUKE). The company focuses on biomedical engineering services. Address CEIT Biomedical Engineering, s.r.o. Tolsteho 3 040 01 Kosice Slovakia www.ceit-ke.sk info@ceit-ke.sk Cranial implants are generally only necessary when patients have suffered accidents or serious illness. The attending doctors face a major task with each procedure: there is no room for error while working on an open skullcap, and doctors must also ensure that, following the procedure, the patient is able to live a life free of discomfort. This makes it all the more important that suitable implants are used. To put it simply: an exact fit of the implant is a prerequisite to ensure the procedure will be successful in the long term. Slovakian company CEIT Biomedical Engineering, s.r.o. relies on EOS technology in providing doctors with bone replacement material for their patients as quickly as possible. Challenge The basics of medical implant manufacture were, until now, control technology, the relevant machine-tools, and often manual work carried out during the oper- ation itself. Yet as in other areas these technologies led to certain problems. Despite the relatively fine control offered by CNC machines, their design limitations mean that it was simply impossi- ble to manufacture certain shapes. In addition, the process is relatively drawn out and expen- sive, particularly in the manu facture of custom-made parts. Because of this, it is not ideally suited to the production of parts designed to reside within the human body. The team at the Slovakian company CEIT Biomedical Engineering, s.r.o. was well aware of these issues. CEIT is a spin-off company of the Technical University of Košice (TUKE), and was created for the purpose of promoting Additive Manufacturing in the medical sector. “As a company with close links to the university we were familiar with the technology. We wanted to explore its potential for implantology and at the same time develop solutions for patients which were both helpful and economical,” explains Assoc. Prof. PhD Radovan Hudak, Managing Director of CEIT. The aim and the challenge were thereby clearly defined: how can Additive Manufacturing contrib- ute towards the manufacture of a custom-made, perfectly fitting cranial implant for surgery? It was necessary to explore the limits of the technology and its potential applications as well as discovering the optimum process and finding a suitable material. Precision, reproducibility and surface-quality were all high up the list of specifications, along with a production process that was as free as possible from production errors. The main aim was then to acquire state certifi- cation for cranial, jaw and facial bone implants. This additively manufactured skull implant is made from a biocompatible titanium alloy and was approved by the Slovakian State Institute for Medicinal Control (Courtesy EOS GmbH).

- 3. Solution Following intensive research, Hudak‘s CEIT team decided on EOS as its technology provider, while opting for a titanium alloy as the starting material: “We took a year to explore the market and analyze what was available,” confirms Hudak, describing his detailed search for the right solu- tion. “EOS and its EOSINT M 280 convinced us by meeting the core criteria, such as experience, market success and penetration as well as offering the complete package. In addition, a number of clients confirmed their satis faction with the system itself.” The decision paved the way for meeting the required technologi- cal criteria – hence the flaws in the CNC area: on the one hand, it enabled manufacture of extreme- ly thin walls with the necessary uneven surface geometries. In addition, the CEIT team was now able to introduce cavities to the implants – such as shapes comprising complex hollows or canals. Lattice structures became a key element in the scope of possibilities. For the actual manufacturing process of the first implants, all that was needed was a suitable patient and their medical records. In this specific case, the task was to produce a piece of the cranium approximately 15 cm in size from the titanium alloy Ti-6Al-4V – a biocompatible standard alloy in medical technology with excellent mechanical characteristics. To achieve this, the team used the results of the computed tomog- raphy examination, where all the necessary contouring information is recorded in detail. The data transformation to a CAD program and the design and manufacture of the implant all took place at CEIT. Results The first success was at the tech- nological level: CEIT was able to successfully implement the production process for both the series production of standard implants and the production of one-off, custom implants. The team was also able to produce the desired lattice structures by means of Additive Manufacturing. The first patient-specific manu- factured implant weighed just 63 g, with a thickness of only 1.5 mm. A feature of the implant was that the team successfully created the previously mentioned hollow structure, enabling the integration of micro-sensors for the recording of medical data inside the implant. “Thanks to Additive Manufac- turing we are in a position to be able to offer a product with improved performance at an identical price. Due to the higher precision fitting of our implants, we are helping to reduce healthcare costs while providing patients with an optimum recovery process. I‘m very happy to have such possibilities at our disposal.” Assoc. Prof. PhD Radovan Hudak, CEO at CEIT Biomedical Engineering, s.r.o. Even greater success for the company followed with the regis- tration of the implant for cranial, facial and jaw applications with the Slovakian State Institute for Medicinal Control (SIDC). This resulted in official EU-wide approval. Negotiations with the largest national insurers over cost coverage also proved successful. One reason for this is the fact that the sales price is in line with the market. The implant benefits from higher precision contouring and a lower error rate in produc- tion. So the company director Assoc. Prof. PhD Radovan Hudak is able to draw a positive conclusion: “We were able to meet all of our challenges and achieve our goals. The great thing about it is that we can give people a higher qual- ity of life thanks to the precision fit of the implants. The accurate contouring has a positive effect on recovery, long-term compati- bility and the final visual result. When the wound has healed the exact insertion of the implant makes evidence of the procedure far less noticeable. This aids the psyche of the individual signifi- cantly.” Additive Manufacturing as support for both body and soul – a truly innovative techno- logical masterpiece. EOS systems are able to manufacture medical devices. However, EOS cannot offer any guarantee that these devices meet all requirements.

- 4. Status 8/2014. Technical data subject to change without notice. EOS is certified according to ISO 9001. EOS GmbH Electro Optical Systems Corporate Headquarters Robert-Stirling-Ring 1 82152 Krailling/Munich Germany Phone +49 89 893 36-0 Fax +49 89 893 36-285 Further EOS Offices EOS France Phone +33 437 49 76 76 EOS India Phone +91 44 28 15 87 94 EOS Italy Phone +39 02 33 40 16 59 EOS Korea Phone +82 32 552 82 31 EOS Nordic Baltic Phone +46 31 760 46 40 EOS of North America Phone +1 248 306 01 43 EOS Singapore Phone +65 6430 05 50 EOS Greater China Phone + 86 21 602307 00 EOS UK Phone +44 1926 62 31 07 www.eos.info • info@eos.info Think the impossible. You can get it.