PRO Creo

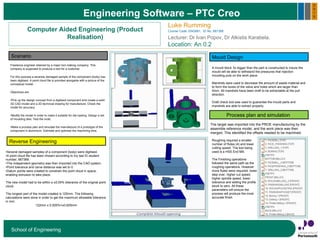

- 1. Engineering Software – PTC Creo School of Engineering Computer Aided Engineering (Product Realisation) 2 0 1 5 Luke Rumming Course Code: ENG661, ID No. 667368 Lecturer: Dr Ivan Popov, Dr Alkistis Karabela. Location: An 0.2 The target was imported into the PROE manufacturing by the assemble reference model, and the work piece was then merged. This identified the offsets needed to be machined. Freelance engineer retained by a major tool making company. This company is supposed to produce a tool for a customer. For this purpose a severely damaged sample of the component (body) has been digitised. A point cloud file is provided alongside with a picture of the conceptual model. Objectives are: •Pick up the design concept from a digitised component and create a solid 3D CAD model and a 2D technical drawing for manufacture. Check the model for accuracy. •Modify the model in order to make it suitable for die-casting. Design a set of moulding dies. Test the mold. •Make a process plan and simulate the manufacture of a prototype of the component in aluminium. Estimate and optimise the machining time. Scenario Reverse Engineering Process plan and simulation Mould Design •Several damaged samples of a component (body) were digitised. •A point cloud file has been chosen according to my last ID student number; 667368. •The independent geometry was then imported into the CAD system. •Point tolerance and carve distance was set to 0. •Datum points were created to constrain the point cloud in space, enabling extrusion to take place. The new model had to be within a ±0.05% tolerance of the original point cloud. The longest part of the model created is 125mm. The following calculations were done in order to get the maximum allowable tolerance in mm: 122mm x 0.005%=±0.625mm A mould block 3x bigger than the part is constructed to insure the mould will be able to withstand the pressures that injection moulding puts on the work piece. Mandrels were used to decrease the amount of waste material and to form the bores of the valve and holes which are larger than 5mm. All mandrels have been draft to be extractable at the pull direction. Draft check tool was used to guarantee the mould parts and mandrels are able to extract properly. Roughing required a smaller number of flutes (4) and lower cutting speed. The tool being used is a HSS End Mill. The Finishing operations followed the same path as the roughing operations. However more flutes were required, lower step over, higher cut speed, higher spindle speed, lower tolerance and setting the profile stock to zero. All these parameters will ensure the process will produce the most accurate finish.