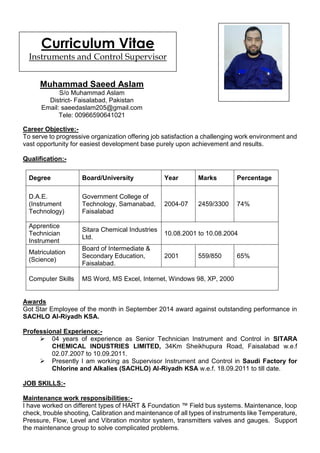

Saeed Aslam

- 1. Career Objective:- To serve to progressive organization offering job satisfaction a challenging work environment and vast opportunity for easiest development base purely upon achievement and results. Qualification:- Degree Board/University Year Marks Percentage D.A.E. (Instrument Technology) Government College of Technology, Samanabad, Faisalabad 2004-07 2459/3300 74% Apprentice Technician Instrument Sitara Chemical Industries Ltd. 10.08.2001 to 10.08.2004 Matriculation (Science) Board of Intermediate & Secondary Education, Faisalabad. 2001 559/850 65% Computer Skills MS Word, MS Excel, Internet, Windows 98, XP, 2000 Awards Got Star Employee of the month in September 2014 award against outstanding performance in SACHLO Al-Riyadh KSA. Professional Experience:- 04 years of experience as Senior Technician Instrument and Control in SITARA CHEMICAL INDUSTRIES LIMITED, 34Km Sheikhupura Road, Faisalabad w.e.f 02.07.2007 to 10.09.2011. Presently I am working as Supervisor Instrument and Control in Saudi Factory for Chlorine and Alkalies (SACHLO) Al-Riyadh KSA w.e.f. 18.09.2011 to till date. JOB SKILLS:- Maintenance work responsibilities:- I have worked on different types of HART & Foundation ™ Field bus systems. Maintenance, loop check, trouble shooting, Calibration and maintenance of all types of instruments like Temperature, Pressure, Flow, Level and Vibration monitor system, transmitters valves and gauges. Support the maintenance group to solve complicated problems. Muhammad Saeed Aslam S/o Muhammad Aslam District- Faisalabad, Pakistan Email: saeedaslam205@gmail.com Tele: 00966590641021 Curriculum Vitae Instruments and Control Supervisor

- 2. Transmitters. Yokogawa, Magnatrol, Yamtake, Rosemount, ABB, Honeywell, Fuji, etc. ON/OFF & Shut-off Valves, Xomox, Arca, Honeywell Leden, Mestonel Limitorque, Rotork and maxseal, Masonelian, Fisher, Emerson Control Valves. Fisher, Masonelian, Serveglcon, Arca, Honeywell, Xomox, Flow Serve, Rotork, Foxboro. Positioners Fisher, Goldey, Arca, Siemens, Honeywell, Masonelian, Krohne, ABB, Matso, Samson etc. Magnetic flow meters: Yokogawa, Yamatake, Fisher, Rosemount &ABB etc. PH, ORP, Conductivity Transmitters: ABB Yokogawa, Rosemount, Hanna, fore bass Marshal etc. Vortex Flow meters, Ultrasonic flow meters, Turbine flow meters, Coriolis mass flow meters, Thermal mass flow meters. Level measurement with different methods like as: Contact and non-contact level sensors, Dp type level transmitters, Displacer type level transmitters, Ultrasonic level transmitters, Sound level transmitters, Radar type level transmitters, Capacitance type level transmitters CO2, SO2, H2S, CS, TOC, Dissolved oxygen, Oxygen analyzer and gas Analyzer. Indicators, Pressure Gauges, Pressure Switches, Level Switches, Vibrations Switches, Temperature switches, Temperature Gauges, Temperature transmitters, Sensors, SOV’s, RTD’s (Resistance Temperature Detector) PT 100/PT 1000, Thermocouples, Thermistor, Radiation pyrometer, Transducers R/I, V/I, I/P, etc. Density measurement with vibrating tube Densito meter. Vibration measurement with Velocity sensors, Electromagnetic linear velocity transducers, Electromagnetic Tachometers generators and Acceleration sensors like Capacitance accelerometer, piezoelectric accelerometer, Potentiometric accelerometers, Servo gauge accelerometer. Installation proximity’s Probe. Radial, Axial, Key phasor, SE probe, Termination gap setting Trouble shooting simulation with TK–3(2E, 2G) field to DCS. Carrying out planned maintenance in accordance with the requirements of the planned maintenance system. Responsible all type of maintenance in field. Calibration, Servicing, Testing and Maintenance of Electronic Pneumatic and Hydraulic Instruments at Workshop Test Bench and In Field online Systems. Shut Down work responsibilities:- Testing, Calibration, commissioning and servicing of all types field instruments. To make the shutdown jobs list and accomplishment of said jobs list. We remove Process equipments instrument for Mechanical work after finish connect back and Troubleshoot during start up. Loop/Function Test and commissioning work responsibilities:- Exposures in Work permit system & safety. Exposure to On Line analyzers and sample handling systems. Testing, Calibration, commissioning and servicing of all types field instruments and Cascading temperature loop, ratio control loop. Parameterization of instrument with (SFC. Hart and FF 375) communicator sequence test and logic test. Closed loop test to confirm the continuity of cables. During loop/Function test, simulated the process variable with hand held communicator or from DCS in manual mode for FF & HART. To monitor the function of instruments and Confirmation availability of inputs alarms & switches on DCS coming from field against Alarm & Trip Set-point List and P&ID. Check Local/ manually the operation & travel of control valves and shut off valves. Also during start up trouble shooting. Excellent communication and interpersonal skills and Work well in a team-environment or as an individual. Erection work responsibilities:-

- 3. Instrument Termination and cable glands according to instrument loop diagram (ILD) and instrument segment diagram (ISD) and As-Built the diagrams. Installation of different kinds of instruments according to P&ID, instrument location plant, piping plan IPL/ILP, isometric and 3D drawings. Good experiences as a loop check coordinator & Installation of Control Panels, conduits or ladders, laying & Termination of instruments & System cables. I can read and worked on P&ID, ILD, and Instrument Location, piping plan, Fire & gas detection Layout, Instrument impulse line/Electro pneumatic hook ups, wiring diaphragm tec. Worked with Standard Test/Master equipments:- Pneumatic Calibrator (Eurotron Model Micro Cal. P.) Electronic Calibrator (CA 100 by Yokogawa) Multifunction Calibrator (Fluke 725) Hand Held Communicators such as Smart (Honeywell, Yamatake) & Hart ABB, Rosemount 275 Yokogawa BT 100, BT200, FF Foundation 375 Communicators. Temp. Calibrator – Haven/Tempcal 650, Jofra calibrator Model 650 SE. Memo Cal 81 for different source e.g. R, ⁰C, mV, mA etc. Analog & Digital Multi meters. Process Calibrator, Simul/Meas, Source mA, mV, RTD, TC, HZ, (Altek Techcheck/ TM- 820 Druck, Fluck, etc.) SMART MANOMETER, Meriam Instrument / 350 Series. Dead Weight Tester – M2000-3, M2800/2, Ruska Instrument Corporation, Budenberg. Wabolator for vibration and speed TK–3(2E, 2G) Control System, PLC & DCS Experience:- PLC by Siemens Semitic S7-300/400. PLC by Triconex for ESD System. FACP (Fire Alarm Control Panel) Proline Protect Limit. HSSD (High Sensitivity Smoke Detector) Siemens. Vibration Monitoring System Bently Nevada 7200, 3300 and 3300XL. DCS of Yokogawa CS 3000. On Off, Proportional, Integral, Derivative Controllers. Boiler Drum Control system, Two Element, Three Element loop Control System. Cascade and Ratio control System, Feed forward, Feedback control system. QA/QC Inspection activities:- Quality assurance/Quality control the purpose of this (QA/QC) is to establish the sequence of requirement for the quality of material quality of works its inspection and records. QA/QC’s ITP’s and QCPprocedure informs about the kinds of quality check (surveillance inspection witness or hold points) means quality of works is being done in proper sequences. ITP procedure addresses the activities and requirement in details. NCR Noncompliance Report, QA/QC personal has reserve the right issue a warning of the contractor doesn’t comply or violate with the standard procedure. General work procedure (WP) activities will be as follows; Receiving Drawing and documents. Reproduction of Drawing Issuing of Drawing to site New issuing new revision Shredding of Drawings Redlining Drawings Transmittal of redlines to client (As built). International standard organization are as below; ISO;9001, ISO;9002, ISO, 9003 etc. Standard height to install the instruments is 1.4 meter but it can very less or more as per locations convenience.

- 4. Required documents for an inspection; RFI (Request for inspection) P&ID for line verification PP for location (pipe plan) Wiring diagram for wiring details Data sheet for calibration and pressure testHookupetc. for remote tubing/air line QR for maintaining record WP, work procedure, to check each and every steps as per spec. QCO for issuing in case of little violation NCR, for issuing in case of major violation etc. Following are the required documents for a remote loop folder: Loop package check list ILD (instrument loop diagrams) Instrument loop acceptance records (TR/test record) P&ID (piping & instrument Diagram) ISS/IDS (instrument specification sheet/instrument data sheet)Alarm List Calibration record (TR) Cable megger report (primary prior to pulling) Cable megger report (secondary after pulling) Pressure test record (TR) MC check record (remote loop)(green color) MC punch list Loop check punch list. Following are the required documents for a local loop folder: Loop package check list ILD (if not mechanical loop) Cable megger report (primary prior to pulling) if not mechanical loop Cable megger report (secondary after pulling) if not mechanical loop Alarm list (if not mechanical loop) P&ID ISS/ISD (instrument specification sheet/instrument data sheet) Calibration record (TR) Pressure test record (TR) if required MC check record (local loop)(green color) MC punch list Visual check punch list/loop check punch list. ITPs inspection and test plan, details of work scope Required types of Inspections Hold point (H) is the level of inspection that client inspection must require through RFI and cannot be proceeded until inspection is done by client. Witness point (W) that inspection activity can be proceeded without client inspection or if client is not available as per RFI timing. Request for inspection (RFI), RFI raise only when the status of the preliminary inspection is satisfactory, and the works (items) are hold or witness point. A project specification specifies the minimum requirements according to the design and relevant international codes and standards. ITP Document that defines the activities requiring inspection or test (witness hold points etc.) the controlling specifications the acceptance criteria the persons responsible and the record to be produced. INSPECTION & TEST PLAN QCP procedures that complements the ITP, by providing information that cannot practically be included in the ITP, but is necessary in order to perform control inspection and test. Project Procedure is a procedure that presents the systematic controls to be implemented and identifies the responsibilities and authorities in loop check to ensure that the system wiring from field to control console functioning fine. Inspection points for a cable tray installation.

- 5. Material check as per approved spec, size and type, trays hook-up, proper distance structure, tray to tray i.e. Power/control/and signal/low voltage and high voltage , support fixed strongly not shaking. Inspection point for field instruments with impulse tubing Is that check materials inspection as per approved spec material, type and size installation as per hook-up, check line route to avoid any obstruction check tube support, compression fitting of ferrules, and then pressure test (hydrostatic test) shall be done Inspection points for cable laying is that to check material inspection as per approved materials, type and size, meggering, cable routing drawing, completion of cable route (Tray conduit or trench etc.) And cable numbering tags, cable bending, use of proper tools and equipment for cable pulling. Inspection points for junction box and Marshalling cabinets. Material inspection, type, size as per approved specification, installation hook-up for frame, bracket or stands, fixed properly means shaking free, name plate and tag no. Determine the correct installation of flow orifice, orifice data (tag) be punched in the upstream of orifice, the data (tag) side shall be in the upstream of flow direction. To ensure shield of signal cable is earthed on both sides to avoid the current noise (resonance). RFI raised when QA/QC department of contractor is satisfied that the work detailed in the construction RFI is completed, then request shall be submitted for inspection to the client QA/QC department. Personal Details Father’s Name : Muhammad Aslam Date of Birth : 15-04-1985 Religion : Islam Marital Status : Unmarried Passport No : BX 1801831 Nationality : Pakistani Covering Letter:- 9 years of experience working for shutdowns, maintenance in Oil & Gas Sector, Refineries, Power Plants, Fertilizers, Petrochemicals, Utility plants and other process industries in Pakistan and abroad. Have experiences installation, Erection, cabling, Logic/Function Testing, loop checking, pre-commissioning, Commissioning & Maintenance of process control instruments. Fault Diagnosis, Trouble shooting of control Panels, Electronic & Pneumatic instruments such as Transmitters, Controllers, Indicators, Converters, Recorders, Switches and Control Valves etc. I have performed my job responsibilities with good career as Instrument & Control Specialist are followings:- 1) Carry out the Preventive Maintenance, Breakdown Maintenance, 2) Online Troubleshooting and Fault Finding of Field Instruments and Control Systems. 3) Upgradation and Modification in Drawings, DCS & SACADA Systems. 4) Solve the all Process and Instrumentation Related Problems, 5) Calibration, Servicing, Testing and Maintenance of Electronic Instruments At Workshop Test Bench and In Field online from DCS Systems. (Instruments Such As Transmitters, Gauges, Controllers, Control Valves, Positioners, Switches, Converters) 6) Control Systems Logic Test, 7) Backups & Installation of Control System, 8) Replacement of I/O’s Cards and Communication Cards, 9) Starting & Resetting of Systems. 10) Minor Changings in Software or Graphics I would be proud to join your team, so please let me know if you need any additional information. I hope to hear from you in the near future. Thank you for your time and consideration.