Textile Training Report on Dalas Fashion Ltd

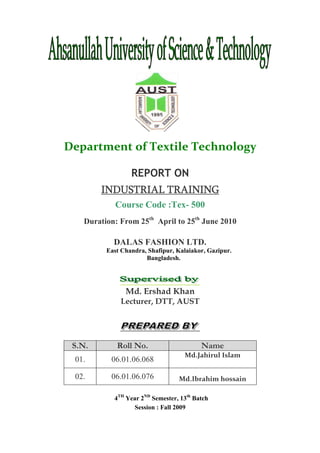

- 1. Department of Textile Technology REPORT ON INDUSTRIAL TRAININGINDUSTRIAL TRAININGINDUSTRIAL TRAININGINDUSTRIAL TRAINING Course Code :Tex- 500 Duration: From 25th April to 25th June 2010 DALAS FASHION LTD. East Chandra, Shafipur, Kalaiakor, Gazipur. Bangladesh. Md. Ershad Khan Lecturer, DTT, AUST S.N. Roll No. Name 01. 06.01.06.068 Md.Jahirul Islam 02. 06.01.06.076 Md.Ibrahim hossain 4TH Year 2ND Semester, 13th Batch Session : Fall 2009

- 2. 2 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t ACKNOWLEDGEMENT At first, we would like to remember the almighty Allah to give our the capacity to continue and complete the Internship program. We convey our deepest thanks to Prof. Dr. Mustafizur Rahman,Prof. Dr. Mustafizur Rahman,Prof. Dr. Mustafizur Rahman,Prof. Dr. Mustafizur Rahman, Head, DTT for his strong guidance. We express our heartiest thanks to. A.S.M AtiquzzamanA.S.M AtiquzzamanA.S.M AtiquzzamanA.S.M Atiquzzaman, Asst. Professor, DTT whose valuable suggestions, constructive criticisms and comments helps to prepare myself for the long run. We are very grateful and deeply indebted to our respected supervising teacher Md. Ershad Khan,Md. Ershad Khan,Md. Ershad Khan,Md. Ershad Khan, lecturer, DTT for his continuous support, encouragement, suggestion, guidance and a special thanks to our project supervisor and honorable teacher Mohammad Mahbubul AlamMohammad Mahbubul AlamMohammad Mahbubul AlamMohammad Mahbubul Alam, Assistant Professor, DTT for his logical guidelines, constant inspirations, necessary instructions and proper supervision. We express our heartfelt gratitude to all our honorable teachers for giving their support and encouragement. We would like to thank to the management of DALAS FASHION LTDDALAS FASHION LTDDALAS FASHION LTDDALAS FASHION LTD.... for giving us the opportunity to undergo Industrial Training there. We would like to express mymymymy sincere gratitude and cordial thanks to the Mr. Zulfikar Ali Sikder –Managing Director , Mr. Tarek Imam, General Manager (Marketing), Mr. Saem Ahmed, Knitting Manager & Mr. Mansur Rahman Rashed, General Manager (Fabric) of the DALAS FASHION LTD.DALAS FASHION LTD.DALAS FASHION LTD.DALAS FASHION LTD. for their kind permission and co-operation that help me to complete my industrial internship and as well as this report.

- 3. 3 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t INTRODUCTION Textile and garments sector is the largest and rapid growing sector in Bangladesh. This sector plays an important role in the economy of our country. World wide it creates a large market of RMG product. At the same time it earns foreign currency and increases life living standard of our people by creating job opportunity. In this sector, the demand of knit garments is increasing day by day. The opportunity of smaller investment, availability of raw material, shipment facility & higher profit than woven garments inspires the investors to empower here. That’s why export of knit garments is increasing steadily for last few years and up to now. Industrial attachment is the basic needs for the education of Textile. This attachment makes a student habituated to factory environment & gives a clear conception about factory work. Students may also find out the implementation of theories in practical. As a student of AUST have completed Eight (08) weeks long industrial training at DALAS FASHION LTD. which is a 100% export-oriented composite Knit Dyeing Industry. It has well planned and equipped fabric knitting, dyeing, and finishing units in order to facilitate knitting and knitwear manufacturing.

- 4. 4 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t CONTENTS Chapter Topics Page No 01 General Information 5-10 02 Manpower Management 11-15 03 Machines 16-21 04 Raw material 22-25 05 Production planning and Sequence of operation 26-55 06 Quality Assurance System 56-66 07 Final Inspection 67-69 08 Production planning & control 70-71 09 Maintenance 72-74 10 Utility 75-84 11 Costing 85-89 12 Conclusion 90-91

- 5. 5 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t

- 6. 6 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Company Profile Dalas Fashion Ltd. Is a composite (Knitting, Dyeing, Finishing, Garments and Embroidery) Factory. It is established at 2005. It is located at Eaast Chandra, Kaliakoir, Gazipur district, about 35 km North of Dhaka North -Bengal Highway. The Industry is equipped with modern state of art machinery and at the same time it complies with: 1. All government, International laws & regulations. 2. The 100% child free labor requirement. 3. Health care facility. 4. Free prevention & fire safety requirements. General Information Address: Corporate and head Office : 20 lake Drive Road, Sector # 07, Uttara Dhaka -1230 Phone : # 88-02-8933435, 8933436 Fax : # 88-02-893340 Factory : Dalas Fashion Ltd. East Chandra, Shafipur, Kalaiakor, Gazipur. Banggladesh. Email : info@dalasfashions.com Bank Details : ISLAMI BANK BANGLADESH LTD. Foreign Exchange Branch Address : 41, Dilkusha Commercial Area Dhaka-1000, Bangladesh Telephone : 88-02-9552444, 9565756, 956412-3 Fax : 88-02-9552444 Email : fex@islamibankltd.com. Telex : 632238, IBF EB BJ SWIFT : IBBL BD.Dha.109 Member of : The Dhaka Chamber of Commerce & Industries, Bangladesh Knitwear Manufactures & Exporters Association.

- 7. 7 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Daily rejection% : 1.50% Shift Hour : 08 Hour No. of Shift : 03 Lunch : 01 Hour Peak Season : October to March. No. of Exit : Every Section has 2 Exit. Product :Knit Dyeing Fabric Yearly working days : 302 Export Type : 100% Export Quality Shift Change: There are three shifts in the industry. So the shifts are changed at every 8 hours. Shift Change/ for worker of Security: A Shift – 06:00 – 14:00 B Shift – 14:00 – 22:00 C Shift – 22:00 – 06:00 Contact person: Mr.Zulfikar Ali Sikder –Managing Director - (01713-031501) Mr.Tarek Imam-General Manager (Marketing) - (01713-066274) Mr.Mansur Rahman Rashed- General Manager (Fabric) - (01713-049611)

- 8. 8 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Different Sections of Dalas Fashion Ltd. a) knitting Section: Knitting Inspection b) Dyeing section: Batch section Dye house Dyeing lab. Quality control Finishing c) Garments section: Merchandising Sample Cutting Section Sewing Section Finishing Section d) Maintenance section: Electrical Mechanical e) Store Section f) Administration Section g) Security Section h) Marketing Section i) Production Planning & Control j) Human Resource & Development Section

- 9. 9 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Production Capacity Sl No. Section Capacity 01 Knitting Fabric -5,000 kg/day, Collar -4,000 pcs/day 02 Dyeing & Finishing 12,000 kg/day 03 Garments 30,000 pcs/day (based on items) 04 Embroidery 20,000 pcs/day (based on items) Working floor Area Total Man Power List S/L No. Section Male Female 01 Office (with Manager) 83 01 02 Knitting 57 - 03 Dyeing 155 - 04 Cutting 52 - 05 Sewing 364 470 06 Quality 105 60 07 Finishing 95 71 08 M & U 20 - 09 Sub-Stuff 45 18 10 Sample 19 01 11 Embroidery 28 24 Total 1023 645 Quality Standard The quality assurance process in DALAS FASHION LTD Is as on going process which begins from the moment yarn arrives at the Factory until the time of Shipment of Ready Made Garments. This Factory works under AQL 1.5 and some of their product are inspected by ITS/SGS Sl No. Division Section Area 01 Textile Knitting 10,000 Sft Dyeing 28,000 Sft Embroidery 2,500 Sft 02 Garments Sewing 3,6000 Sft Cutting 12,500 Sft Finishing 17,500 Sft Sample room 1,500 Sft Office 3,000 Sft Garments Store 2,000 Sft

- 10. 10 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Layout Plan Overall view of the industry: ↓ W ← ← ← ↓ S N E ↓ ↓ ↓ ← ↓ ← ↓ ↓ → Main Gate Security Office Maintenance Department Water Treatment Plant Effluent Treatment Plant. HR & Admin Office Dining Knitting Floor Lab . Office. Dyeing Floor Finishing Floor Batching Area. Grey Store Inspection Dyes & Chemical Store

- 11. 11 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t

- 12. 12 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Organogram of DALAS FASHIONS LTD. Managing Director Director GM(Production) DGM ( HR & Admin) Additional GM (Operation & Planning) Manager (Dyeing) Manager (Finishing) Manager (Knitting) Manager (Accounts) Manager (Admin) Manager (Procurement) Security ITCivil & Construction Manager (Planning) Manager (Marketing) Asst.Manager (Inspection) Manager (Maintenance) Manager (Lab) Manager (Store) Manager (Lab)

- 13. 13 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Laboratory Organogram Knitting Organogram Lab Technician Lab Asst. Lab Technician Lab Asst. Lab In-charge Asst.Manager Store Manager Knitting Master Shift In-Charge Asst.Q.C Operator Helper Fitter man Asst.Fitter Man Knitting Manager Deputy manager Supervisor Q.C In-charge

- 14. 14 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Dyeing Organogram Manager Floor Incharge Shift Incharge -01 Shift Incharge -02 Senior Operator -01 Supervisor 02 Supervisor 01 Senior Operator -02 Helper Helper GM Operator Operator

- 15. 15 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Organogram of Finishing Department Finishing In-Charge General Shift A Shift Q.C in-charge B Shift C Shift Supervisor Operator/ Asst Operator Helper Loader

- 16. 16 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t

- 17. 17 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Knitting Machine Name of Machine Brand Dia (inch) Gauge No. of Set Single Jersey With Spandex Attatchment FUKUHAMA TAIWAN 16 24 01 17 24 01 18 24 01 19 24 01 20 24 01 21 24 01 22 24 01 23 24 01 24 24 01 25 24 01 26 24 01 28 24 01 30 24 01 32 24 01 34 24 01 36 24 01 Fleece FUKUHAMA TAIWAN 30 20 01 32 20 01 34 20 01 36 20 01 Rib with Spandex Attatchment FUKUHAMA TAIWAN 30 18 01 32 18 01 34 18 01 36 18 01 Rib – Interlock with spandex Attatchment FUKUHAMA TAIWAN 30 24 01 32 24 01 34 24 01 36 24 01 Flat Knit (computerized) Young Gin, Chaina 54 14 10

- 18. 18 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Dyeing Laboratory Washing M/C Siemens 01 set Tumble Dryer Siemens 01 set Woven Dryer A & D 01 set Lab Dyeing M/C : Shaking Water Bath A & D 01 set Lab Dyeing M/C : Rapid A & D 01 set Electronic Balance A & D 01 set Color Assessment Cabinet - 01 set Crock Meter Taiwan 01 set Dyeing Machine: Dyeing Finishing Squeezer Man Mool Korea 01 set De twisting & Slitting - - 01 set Dryer Hankuk - 01 set Stenter Ehwa Korea 01 set Open width Compector Pk. Poong Kwang korea 01 set Tubular compactor Tube-Tex USA 01 set Auto Folding & Sticthing - - 01 set Name of Machine Brand Country No.of Set High Pressurized (Winch) Yang Jia Korea 25 kg -03set 50 kg -02 set 150 kg- 01 set 250kg – 01 set 500kg- 02 set 750kg- 02 set 1000Kg- 02 set 1250kg- 01 set

- 19. 19 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Garments Finishing Machine Cutting Machine: S/L No. M/C Name M/C Type Brand Model Quantity Total 01 Needle Detector M/C Auto Hsima HN-750G 01 Set 01 Set 02 Thread Sucker M/C Manual - N/A 02 Set 04 Set 03 Thread Sucker M/C Manual Oshima OP-747S 02 Set 02 Set 04 Spot Cleaner M/C Auto PMM Pmm- MiniSpotty 02 Set 02 Set 05 Iron Table - Oshima OPB-777A 30 Set 54 Set 06 Iron Table - Taiwan - 24 Set M/C Name M/C Type Brand of M/C Model Quantity Cutting M/C Manual K.M KS-AU-V10 09 Set Lay cutting M/C Manual K.M KC-2 02 Set Cutting Table Manual - - 04 Set Srappping M/C Manual Taiwan NT-88 01 Set

- 20. 20 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Sewing Machine: S/L No. M/C Name M/C Type Brand Model Quantity Total 1. Plain M/C Manual Siruba L818F-M1 69 Set 264 Set 2. Plain M/C Manual Yamata FY5550 13 Set 3. Plain M/C Manual Brother SL7340-3 60 Set 4. Plain M/C Auto Brother SL2110-403 4 Set 5. Plain M/C Manual Brother SL1110-3 118 Set 6. Over Lock M/C 4 thread Siruba 747514m2-24 64 Set 193 Set 7. Over Lock M/C 4 thread Kansai UK-1014H-40M-2x4 89 Set 8. Over Lock M/C 4 thread Kansai Uk-1014H-01M- 2x4/ETC 10 Set 9. Over Lock M/C 6 thread Kansai UK-1143H-90M-5x2x4 30 Set 10. Flad Lock M/C Cylinder Bed Siruba W122-356-CH 12 Set 82 Set 11. Flad Lock M/C Cylinder Bed Siruba W222-356-FQ 4 Set 12. Flad Lock M/C Flat Bed Siruba U712-264-FSP 15 Set 13. Flad Lock M/C Flat Bed Siruba Rx9803ALK 03 Set 14. Flad Lock M/C Flat Bed Back Tap Siruba RX-9803CC 09 Set 15. Flad Lock M/C Bottom Hem Kansai MM-1103 20 Set 16. Flad Lock M/C Cylinder Bed Kansai WX-880A-F 04 Set 17. Flad Lock M/C Small Cylinder Bed Kansai H-800A-3 6 Set 18. Flad Lock M/C Flat Bed Kansai FY781 09 Set 19. Button Hole M/C Auto Brother BE-438D 08 Set 09 Set 20. Button Hole M/C Manual Yamata Ke430d-01 01 Set 21. Button Stitch M/C Auto Brother FY1850 07 Set 07 Set 22. Bartack M/C Auto Brother N/A 03 Set 04 Set 23. Bartack M/C Manual Yamata HR808 01 Set 24. Rib Cutting M/C Manual IDEA NH-SB47 04 Set 04 Set 25. Snap Button M/C Manual Honrey HP-450CS 02 Set 04 Set 26. Snap Button M/C Auto Nisho Da-9270-3-264L 02 Set 27. Fusing M/C Auto Hasima PX-302-4W 01 Set 01 Set 28. Feet of the Arm Manual Brother V.C008 02 Set 02 Set 29. P.Q Manual Kansai DFB1411P-XP 02 Set 02 Set 30. PMD Manual Siruba HW-40C 02 Set 03 Set 31. PMD Manual Kansai 01 Set 32. Re- winding M/C Auto Hasima 02 Set 02 Set

- 21. 21 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Embroidery Machine: Sl. No. Name of Machine Brand No.of Set 01 Embroidery Tajma 20 Head (computerized) 6 set 02 Software Wilcom ES 7.1 - Power Section : S/L No. Description of Equipment Model Qty. Company Origin 01 Effluent Treatment Installation work is running 02 Water Treatment Plant ION 01 INDIA 03 325 KVA Gas Generator - 01 Shengly Power CHINA 04 750 KVA Gas Generator - 02 Shengly Power CHINA 05 Boiler (capacity =6000 kg/hr - 02 DAELIM ROYAL Korea 06 Water softening Plant (Boiler REB-50 01 REVOTHERM INDIA 07 Weighing Scale 20 HP, 15 HP 15 PUMA Taiwan

- 22. 22 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t

- 23. 23 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t TYPES OF RAW MATERIAL The basic raw materials are: 1. Yarn 2. Grey Fabric 3. Dyestuffs 4. Chemicals & Auxiliaries 1. Yarn 2. Fabric Singe Jersey: 1. Normal Single Jersey (G.S.M-80-200) 2. Heavy single Jersey(G.S.M-200-270) 3. Single Lacost (P.K) 4. Double Lacost (single P.K) 5. Double Pique (polo P.K) 6. Lycra Single Lacost 7. Lycra double Lacost 8. Half Feeder Lycra 9. Full Feeder Lycra 10. Stripe single Jersey 11. Normal Terry 12. Lycra Terry 13. Design Terry 14. France terry 15. Fleece 16. Terry Fleece 17. Diagonal Fleece Generally used yarn and their count: Cotton 24S , 26S , 28S , 30S , 32S , 34S , 40S Polyester 75D, 100D Spandex yarn 20D,40D, 70D Grey Mélange (C_ 24S , 26S Ecru Mélange (C-85% V-15%) 24S , 26S , 28S Anthra Mélange (C-65% V-35%) 24S , 26S , 28S PC (65%Polyester & 35% cotton) 24S , 26S , 28S , 30S CVC 24S , 26S , 28S , 30S

- 24. 24 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Rib Fabric: 1. 1*1 Rib 2. 2*1 Rib 3. 2*2 Rib 4. Derby Rib 5. English Rib 6. Half Feeder Lycra Rib 7. Full Feeder Lycra Rib Interlock Fabric: : 1. Plain Interlock 2. Mesh Interlock 3. Dyestuff I. Remazol Briliant Yellow-3GL II. Remazol Yellow - RR III. Remazol Blue - RR IV. Remazol Briliant Blue – RSPL V. Remazol Turq Blue – G VI. Moderzol G Yellow – EC VII. Moderzol Blue – EC VIII. Moderzol Navy Blue – EC IX. Moderzol Black – ECN X. Kemifix fixed – 3BS XI. UNIFIX Black – EDH XII. Unifix Yellow – 4GL XIII. Unifix Red XIV. Unifix Black – B XV. Unifix Yellow – DRL XVI. Unifix Red – D2B XVII. Unifix Blue – DGG XVIII. Unifix Orange – 2RXF XIX. Rema Orange – RR XX. Rema Yellow – RGB XXI. Rema Navy – RGB XXII. Rema Red – F3B XXIII. Rema Deep Black – GWF XXIV. Leva Amber – CA XXV. Leva Fast Red – CA XXVI. Leva Blue – CA XXVII. Nova Yellow – S3R XXVIII. Nova Deep Cheray – SB XXIX. Nova Super Black – G

- 25. 25 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t 4. Chemicals & Auxiliaries: Chemical Acid i) Acetic Acid ii) Hydrochloric acid Detergent i) Felosan NOF Washing Agent i) Cibapon R Leveling Agent i) Cibacel DBC Salt i) Gluber Salt Whitening Agent i) Uvitex BAM ii) Uvitex BHV iii) Hostalux ETBN (for polyester fabric) iv) Bluton BBV Softener i) Alkamine CWS ii) Sapamine FPG iii) Sapamine 544 iv) Megasoft TET v) Megasoft FMG (For white fabric) Fixing agent i) Sandofix EC Reducing Agent i) Hydrose Bleaching Agent i) H2O2 Enzyme i) Bio ACE ii) Tinozyme 44L Stabilizer i) Tinoclarite CBB Anticreasing Agent i) Cibafuid C pH Controller i) Acid ii) Neutracid RBT iii) Soda ash iv) Caustic Per-oxide killer i) Invatex PC

- 26. 26 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t

- 27. 27 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t ORDER PROCESSING SYSTEM Marketing G.M deal with Buyer (including all the cost). ↓ Marketing G.M informs to the Merchandiser Manager. ↓ Merchandiser Manager discuss with Merchandiser. They meet with Buying House & manage all the process including buying everything to the Shipment. ↓ Buyer gives color Swatch to Merchandiser & he gives to Dyeing Manager. ↓ Then the Dyeing Manager gives the color swatch to Lab. ↓ Lab collects the same quality fabric from knitting ↓ Lab develops the swatch with three different shades namely: A, B, C. ↓ Lab also checks all the qualities of the fabric according to the Buyer Requirements. ↓ Merchandiser meets the buying house with lab dip swatch & discuss about the Quality requirements. ↓ If the Buyer approves any one from the three options then the lab dip is ok. ↓ Merchandiser discuss with Buyer for P P sample making (a little amount, say 5 kg for submission a fabric sample & a whole garments to Buyer). ↓ Merchandiser gives sample booking to Knitting Manager, then he starts knitting for P.P sample as well as the dyeing is also being completed. ↓ Then the Buyer checks the P P Sample (fabric & the garments with all of their requirements).

- 28. 28 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t ↓ Merchandiser makes for Bulk production booking & gives to Knitting Manager, Dyeing Manager, and Garments section as well as to the Honorable & Responsible persons. ↓ If the Buyer approves P P Sample then the Bulk Production is started. ↓ When the knitting is completed then Dyeing is started ↓ The Bulk production must be same as the lap approval swatch. ↓ The dyed sample is approved by the Dyeing Manager. ↓ Finishing process (Dyeing). ↓ Fabric inspection process. ↓ Garments processing (Fabric delivery to cutting, then sewing). ↓ Final inspection process. ↓ Then the garments are packed. ↓ Buyer inspects the final garments after packing by the Q.C from Buying house or the inspector from any of the Int. Testing Company. Sometimes they directly give to them to test all of their requirements. ↓ If Inspection is ok, then the order is ready for the shipment.

- 29. 29 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t LAB Laboratory: Laboratory is the heart of dyeing Industry. An efficient laboratory can increase the efficiency of dyeing. So, laboratory in-charge is sometimes called pilot. Before bulk production a sample is sent to buyer for approval. Laboratory supplies the recipe to the floor. Purpose of Laboratory: o Get color approval from buyer. o Recipe supply to the floor. o Shade correction. o Minimize the deviation between bulk and laboratory. Laboratory line: Standard sample: At first recipe % of standard sample is measured by CCM (computer color matching) system. Laboratory Trial: Then by taking those recipe laboratory officers produce laboratory trial and match with standard according to buyer requirement. Approved Sample: Then sample swatch, which is matched with the standard, is send to buyer for approval.

- 30. 30 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Lab Working Procedure Sample in (Fabrics) Check & note the Lot no, Style no, Item no& Collar Sample Preparation Run the test Physical test Wet lab Color Fastness to wash Bursting strength Pilling Color Fastness to washing Crocking Evaluate the sample Pre-production Sample Final sample Report Making Test Test Prepared the report prepared the report Pass Fail Deliver Refinish Pass Fail Pass Fail Need to test again Go for the final Refinish Need to test again Dimensional stability. Prepare the sample Wash the sample according to buyer method. Tumble dry Keep the sample flat in the conditioned temperature at least four hours before, after measurement. Measure the sample Prepared the report Pass Fail Ready to delivery Refinish Need to test again

- 31. 31 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Lab. Dip Dyeing Sample: - Type - 100 % cotton fabric - Weight – 5 gm Procedure: - At first the recipe for the sample is calculated according to the sample weight. - The fabric is kept in the dyeing chamber. - Then the dyes, chemicals, salt & required amount of water is taken in that dyeing chamber by digital pipeting on the basis of stock solution. - Then the beaker is set into the lab. dip. dyeing machine for dyeing. - The program for dyeing is started for 20 min at 400 C. - After 20 min soda is added by pipeting. - Then the dyeing program is set for 60 min at 600 C. - When the dyeing time is finished the sample is taken out from the machine at 400 C. - Then the sample is washed off. At first cold wash & then hot wash is done. After it soaping is done. - Then the sample is dried and compared with standard. Recipe Curve: 600 C×60 min 400 C×20 min Wash off Dyes+Salt+Material Soda +Water

- 32. 32 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Salt & Soda: Salt and soda is taken on the basis of the shade%. The salt and soda is used according to the following table: Shade % Salt g/l Soda g/l 0.001-0.100 20 6 0.101-0.500 24 8 0.501-1.000 30 10 1.001-2.000 40 12 2.001-3.000 50 14 3.001-4.000 60 16 Above 4.000 80 20 Type of order: • Swatch: It is a common type of order. Swatch is the sample supplied by the buyer. • TPX : It means textile on paper. • TCX : It means textile on cotton. . Lab dyeing calculation: • Calculation of reagent: (Salt, soda and others) Concentration in g/L X Liquor volume Stock solution % • Amount of dye solution: Material weight X Shade percentage Stock solution% • Total amount of liquor: Material weight X liquor ratio. • Required amount of water: • Total amount of liquor - Amount of dye solution.

- 33. 33 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t BULK PRODUCTION Batching: Batching means the preparation of the fabric for dyeing according to the capacity of the dyeing machine. It has done under instruction of planning department and time schedule of the dyeing department. Function or Purpose of Batch Section: - To receive the grey fabric roll from knitting section or other source. - Turn the grey fabric if require. - To prepare the batch of fabric for dyeing according to the following criteria – • Order sheet (Received from buyer) • Dyeing shade (color or white, light or dark) • M/C capacity • M/C available • Type of fabrics(100% cotton, PC, CVC) • Emergency - To send the grey fabric to the dyeing floor with batch card. - To keep records for every previous dyeing. Preparation of batch Make the priority as per dyeing plan ↓ Check the availability of fabric ↓ Take required quantity of body fabric from the store ↓ Take collar/cuff as per size ↓ Distribution of collar/cuff or rib in each rope equally to ensure equal length ↓ Stitch the fabric to make equal weight ↓ Prepare batch card ↓ Send fabric to the dyeing floor.

- 34. 34 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Batching of a product depends on some factors like: • Fabric type • Yarn count • Fabric width & GSM • Machine load capacity etc. • Ratio of collar cuff with body fabric. Calculation of collar: Calculation of collar in a batch depends on the quantity of body fabric as follows- No. of collar = Total collar quantity (pcs) * Required quantity of body fabric. Total fabric quantity (kg) = Amount of collar. Note: During batching 11% wastage for body fabric and 5% for collar is considered for further processing. There are some face knitted fabrics like Pique, S/j, Lacoste etc that needs to be tuned by turner to avoid any type of dyeing fault in the face side. Turning of the fabric has done here with the help of a turner. Remarks: The preparation of batch card indicates the dyeing schedule of the dyeing floor. It will ensure the proper quantity of dyeing as per machine capacity.

- 35. 35 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t DYEING

- 36. 36 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Process Flow Chart for Pretreatment Scouring, Bleaching & Enzyme Treatment: Level in NOF + Stabilizer (600 C by injection) Fabric Load Caustic Dosing (600 C X10 min) H2O2 Dosing (700 C X10 min) Temperature raise at 1050 C Run time 30 min Drain H2O2 Killer hot wash (800 C X10 min) Drain Acetic Acid (600 C X10 min) MIR Rinse (10 min) Acetic Acid (550 C injection) Check PH -4.5 Enzyme Dosing (550 C X 5 min) Run time 30 min Drain CS hot wash (900 C X10 min) MIR Rinse (20 min)

- 37. 37 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Dyeing Production Flow Chart: Production flow chart for 100% cotton fabric Fabric Load ↓ Water Level – As Required ↓ Raise temp to 600 C ↓ Add Felosan NOF & Tinoclarite CBB at 600 C ↓ Add Caustic at 700 C – Dosing time 10 min ↓ Add H2O2 – Temp. ≤ 800 C Raise temp. to 1050 C and run 30 min (PH – 10.5-11) ↓ Drain ↓ Water Level – As required ↓ Add Feloson NOF at 980 C & run 5 min ↓ Drain ↓ Rinse (Cold Water) ↓ Add Acetic Acid & Invatex PC at 600 C and run 10 min ↓ Drain ↓ Water Level – As required ↓ Add Acetic Acid at 550 C ↓ Add Bioace at 550 C and run 30 min (PH – 4-5) ↓ Drain ↓ Add Invatex CS at 900 C and run 10 min ↓ Cold Wash for 10 min ↓ Drain ↓ Water Level – As required ↓ Add Leveling agent (Cibacel DBC), Anticreasing Agent (Cibafluid C) & Acetic Acid at 600 C (PH – 5-6) ↓

- 38. 38 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Add Color at 600 C – Dosing time 20 min ↓ Machine Run time – 15 min ↓ Add Salt at 600 C & run time 15 – 20 min ↓ Add Soda at 600 C – Dosing time 35 min ↓ Machine Run ↓ After 20 min Sample Cutting & Shade Matching ↓ Raise the temp & run the machine as required to match the shade ↓ If shade match ↓ Drain (Bath Drop) ↓ Rinse for 5 min ↓ Add R and run for 10 min ↓ Drain ↓ Add Acetic Acid at 550 C ↓ Add Bioace at 550 C and run for 30 min ↓ Drain ↓ Hot Wash ↓ Add Sandofix EC (Fixing agent) at 450 C and run for 15 min ↓ Drain ↓ Add Water ↓ Add Acetic Acid & Softener at 450 C and run for 15 min ↓ Drain ↓ Cold Wash ↓ Unload Fabric

- 39. 39 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Production Flow Chart for White Color Fabric Load ↓ Water Level – As Required ↓ Raise temp to 600 C ↓ Add Feloson NOF & Tinoclarite CBB at 600 C ↓ Add Caustic at 700 C – Dosing time 10 min ↓ Add H2O2 – Temp. ≤ 800 C ↓ Add Uvitex BAM (OBA) ↓ Raise temp. to 1050 C and run 30 min (PH – 10.5-11) ↓ Drain ↓ Water Level – As required ↓ Hot Wash ↓ Add Acetic Acid at 550 C ↓ Add Bioace at 550 C and run 30 min (PH – 4-5) ↓ Drain ↓ Add Invatex CS at 900 C and run 10 min ↓ Cold Wash for 10 min ↓ Add Acetic Acid ↓ Add Megasoft FMG (Softner) ↓ Drain ↓ Cold Wash ↓ Fabric Unload

- 40. 40 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Production Flow Chart For 100% Polyester Fabric Load ↓ Water Level – As Required ↓ Raise temp to 600 C ↓ Add Feloson NOF ↓ Raise temp.to 900 C & run time 10 min ↓ Drain ↓ Water Level – As Required ↓ Raise temp. to 450 C ↓ Add Neutracid RBT (Non volatile Acid) & runtime 10 min ↓ Drain ↓ Water Level – As Required ↓ Raise temp. to 450 C ↓ Dye dosing for 10 min ↓ Raise temp. to 1300 C & run for 45 min ↓ Drain ↓ Water ↓ Cooling at 700 C & sample cheek if shade ok then bath drop ↓ Hydrose+ Caustic at 800 C for 20 min ↓ Hot wash ↓ Acetic wash at cold temp. for 10 min ↓ Acetic Acid + Softener is added at 450 C & run for 10 min ↓ Cold Wash ↓ Fabric Unload

- 41. 41 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Common dyeing faults with their remedies 1. Uneven dyeing: Causes: - Uneven pretreatment (uneven scouring & bleaching). - Improper color dosing. - Using dyes of high fixation property. - Uneven heat-setting in case of synthetic fibers. - Lack of control on dyeing m/c Remedies: - By ensuring even pretreatment. - By ensuring even heat-setting in case of synthetic fibers. - Proper dosing of dyes and chemicals. - Proper controlling of dyeing m/c 2. Batch to Batch Shade variation: Causes: - Fluctuation of Temperature. - Improper dosing time of dyes & chemicals. - Batch to batch weight variation of dyes and chemicals. - Dyes lot variation. - Improper reel speed, pump speed, liquor ratio. - Improper pretreatment. Remedies: - Use standard dyes and chemicals. - Maintain the same liquor ratio. - Follow the standard pretreatment procedure. - Maintain the same dyeing cycle. - Identical dyeing procedure should be followed for the same depth of the Shade. - Make sure that the operators add the right bulk chemicals at the same time and temperature in the process. - The pH, hardness and sodium carbonate content of supply water should check daily.

- 42. 42 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t 3. Patchy dyeing effect: Causes: - Entanglement of fabric. - Faulty injection of alkali. - Improper addition of color. - Due to hardness of water. - Due to improper salt addition. - Dye migration during intermediate dyeing. - Uneven heat in the machine, etc Remedies: - By ensuring proper pretreatment. - Proper dosing of dyes and chemicals. - Heat should be same throughout the dye liquor. - Proper salt addition. 4. Roll to roll variation or Meter to Meter variation: Causes: - Poor migration property of dyes. - Improper dyes solubility. - Hardness of water. - Faulty m/c speed, etc Remedies: - Use standard dyes and chemicals. - Proper m/c speed. - Use of soft water 5. Crease mark: Causes: - Poor opening of the fabric rope - Shock cooling of synthetic material - If pump pressure & reel speed is not equal - Due to high speed m/c running Remedies: - maintaining proper reel sped & pump speed. - Lower rate rising and cooling the temperature - Reducing the m/c load - Higher liquor ratio

- 43. 43 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t 6. Dye spot: Causes: - Improper Dissolving of dye particle in bath. - Improper Dissolving of caustic soda particle in bath. Remedies: - By proper dissolving of dyes & chemicals - By passing the dissolved dyestuff through a fine stainless steel mesh strainer, so that the large un-dissolved particles are removed 7. Wrinkle mark: Causes: - Poor opening of the fabric rope - Shock cooling of synthetic material - High temperature entanglement of the fabric Remedies: - Maintaining proper reel sped & pump speed. - Lower rate rising and cooling the temperature - Higher liquor ratio 8. Softener Mark: Causes: - Improper mixing of the Softener. - Improper running time of the fabric during application of softener. - Entanglement of the fabric during application of softener Remedies: - Maintaining proper reel sped & pump speed. - Proper Mixing of the softener before addition. - Prevent the entanglement of the fabric during application of softener

- 44. 44 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t FINISHING Finishing: Textile finishing , in a restricted sense , is the term used for a series of processes to which all bleached , dyed , printed and certain grey fabrics are subjected before they are put on the market . In fact , finishing includes the final treatment of every kind of fabric made from every kind of fiber . Objective of finishing: • Improving the appearance – Lustre, whiteness, etc. • Improving the feel , which depends on the handle of the material and its softness , suppleness , fullness , etc . • Wearing qualities , non – soiling , anticrease , antishrink , comfort , etc . • Special properties required for particular uses – water – proofing , flame – proofing , etc. . • Covering of the faults in the original cloth. • Increasing the weight of the cloth. Types of finishing: 1. Chemical finishing: - Chemical reaction of auxiliaries with fibers. - Application of the handle modifying products / additives. 2. Mechanical finishing: Finishing effects: • Easy – care • Crease recovery. • Dimensional stability. • Good abrasion resistance. • Improved tear strength. • Good sewability • Soft or stiff handle. • Shine or luster

- 45. 45 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Flow chart of finishing Section Raising/Sueding Stenter /Dryer Finishing section Open fabric Tube fabric Slitting machine Stentering/Dryer Compacting machine Final inspection Dewatering machine Drying machine Tube Compacting machine Final inspection Turning machine Calendaring machine

- 46. 46 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Dewatering Machine Function: Apply over feed to give some compaction. Open the fabric from the rope form. Width wise stretch the fabric. Reduce water content. Apply chemicals Plait the fabric. Working principle of Dewatering: After completing the dyeing process from the dyeing m/c then the fabrics are ready for de-watering. In de-watering m/c tubular fabrics are mainly processed. There is a magnetic sensor which scene the twist of the fabric and its direction and turn the fabric in opposite direction to remove twist automatically. De-watering is the process to remove the water from the fabric completely by squeezing and it is done by the padder. A suitable expander is used before the fabric is passed through the nip of the padders, which expands the fabric flat wise and adjust the width. The expander width is adjusted as S/J- 20%, PK-25%, Int.-35%, Lacoste-40% wider than the required width. There is a pair of rubber coated padder, where water is removed from fabric when passed through the nip of it. Normally squeezer contain single or double padders where, • One for removing water and • Other for applying finishing chemicals such as softener. But this finishing is done only for the tubular fabric. Open width knitted fabrics is applied finishing treatment later in stenter. Here present the compressor which given compress air to form ballooning before passing through the padder. This balloon remove crease mark but not form the maximum balloon otherwise shrinkage increase

- 47. 47 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Hydro-extractor Function: Remove water from fabric by centrifugal force. Working Procedure: The moving basket is round and made by steel. There are lots of hole in the metal body of the basket. The wet fabric is rotated at a high speed into the metal case. This rotation develops a centrifuge force which forces the wet fabric to the wall of the cage. Water is then forced out through the perforations of the cage and drained away. 60-70% of water can be removed from fabric by this way. Dryer Machine After de-watering then the fabric through the dryer. Function: • To dry the fabric. • To control the overfeed system. • To control the vibration which increase the G.S.M. Working principle of dryer: This machine contains two chambers. Two mesh endless conveyors are placed lengthwise to the chamber named conveyor net and filter net, each chamber contain a burner, which supply hot air .This hot air is guided through the ducting line by suction fan .There are nozzles placed in between filter net and conveyor net .When the fabric pass on the conveyor net, hot air is supplied to the wet fabric to dry it. There are exhaust fan which such the wet air and deliver to the atmosphere through the ducting line. The speed of the dryer depends on the temperature of the m/c & the G.S.M of the fabric. If the m/c temp. is high then m/c speed also high and the m/c temp. is low then m/c speed also low . The vibration speed of the m/c for heavy fabric is 730 m/min and normal fabric is 480 m/min.

- 48. 48 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Chamber-1 Chamber-2 Chamber-3 Chamber-4 Wet fabric in Dry fabric out Fig: Flow path of dryer

- 49. 49 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Slitting machine Slitting is a process that is applied for cutting the tubular fabric through the intended break Wales line on lengthwise direction prior to stenter processing. Machine parts: 1. Rotary blade: To cut the fabric through break Wales line. 2. Ring: To help cutting. 3. Guide Roller: To guide the fabric to plaiting. 4. Plaiting: To plait the fabric. 5. Sensor: Sense for cutting through break Wales line. Working principle: The slitting m/c has 4 units – (1) initial squeezer, (2) de-twisting, (3) sitter and (4) padder. After dyeing completed and falling of water from fabric the fabric is fed in slitting m/c. So it is necessary to remove some water initially for the case of further processing in this m/c. The initial squeezer does this work. The de-twisting unit removes twists that may present in tubular rope form fabric. This unit has 3 de- twisting rollers, one rotation drum and 2 feeler rollers with sensors. By these rollers it detects twist in fabric and removes by rotating rope fabric in opposite direction. Before slitting there is a blower which blows air to open the tubular fabric & makes it easy to pass over cigger. The cigger can be extended in circumference and opens the tubular fabric in full circumference. Slitting is done by using open mark detecting golden eye by around knife. Then the fabric passes through the padder where washing or chemical treatment is done. Squeezer is used to remove 60-70% of water. After removing water width is controlled by stretcher and fabric is delivered by folding device. Operational parameter: • Set the padder pressure as required (3-7bar) • Set the speed as much as possible (30-80m/min).

- 50. 50 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Function of the Machine: • Used to remove excess water after pretreatment and dyeing • To slit the tube fabric by the knife for opening of the fabric and ready for stentering • Delivered fabric is crease free state • Before squeezing balloon is formed with the help of compressed air passing by a nozzle or air sprayer • It can control the diameter of fabric and GSM and shrinkage by over feeding mechanism • To impart soft finish to the fabric by using required softener. Picture of slitting machine Detwister Rotary Knife Cutter Slitting m/c

- 51. 51 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Open Compactor Machine specification: Model no : EHWHA Company : KOREA No of motor : 12 Over feed : m/min Machine speed : m/min Speed range : 13-22m/min Temperature range : 100-1400 C Maximum width : 86″ Minimum width : 36″ Applied for : Open fabric Left over feed : -20% → +20% Right over feed : -20% → +60% High production : -20% → +60% Front over- feeding cylinder : -20% → +60% Middle belt : -20% → +60% Heating system : Steam Function of the Machine: 1. To compact the fabric 2. To control the shrinkage 3. To maintain proper width and G.S.M Main parts of the machine: 2. Heating chamber 3. Blower (2, one at the entry chain zone for uncurling and another at the entry of compacting zone) 4. Synthetic blanket as a conveyor, 5. Folder 6. Exhaust fan 7. Unpinning cylinder (-40% → +40%) 8. Belt cylinder (-40% → +40%) 9. Uncurling device at entry of compacting zone. 10. sensor 11. brush roller

- 52. 52 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Additional attachment: i) Selvedge cutting ii) Selvedge safety iii) Pinning safety iv) Selvedge unrolling v) Selvedge drying vi) Steam zone heating vii) Steam Controlling points: • Water pressure 2.5 lb • Air pressure 4 lb • Steam pressure 6 lb PICTURE: OPEN COMPACTOR MACHNE

- 53. 53 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Stenter machine Machine specification: Model no : Ehwa Country : Korea Year : 2005 Other specification: Speed range : 15-30 m/min (for knit) 15-80m/min (woven) No of motor in drying unit : 29 Total no of motor : 49 Temperature range : 20-2500 C Maximum width : 102″ Minimum width : 30″ Steam pressure : 2 bar Air pressure : 10 bar Applied for : Open width fabric Extra attachment: i) Mahlo attachment for bowing control. ii) Selvedge gumming device iii) Selvedge cutting device Function of the Machine: i) Drying ii) GSM control iii) Width control iv) Shrinkage control v) Decrease sprirality vi) Decrease Bowing effect vii) Softener application viii) Surface coating for Teflon finish ix) Soil release chemical finish x) Heat set for cotton lycra fabric

- 54. 54 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Main parts of the machine: i) Feed zone • Centering device ii) Chemical padding zone • Squeezing roller • Chemical tray iii) Bowing control zone • Bowing roller (rubber roller, no of roller -2) • Sensor (no of sensor -6) • Uncurling roller iv) Chain entry zone • Uncurling device (both side of the chain entry) • Sensor (both side of the chain entry) • Brush roller (for attaching the fabric with the pin of the chain, no of brush roller -4) • Selvedge gumming device with gum box under the chain entry v) Drying zone • Gas rotamatic burner (10) vi) Cooling zone vii) Delivery zone Chemical used: Silicon softener (It is used to soft and slippery of the fabric) Manpower Required: Worker: 6 Production: Capacity : 5 tones/shift Actual production : 3.5-4.5 tones/shift. Temperature: Maximum : 2500 C Sample :1100 C Average : 130-1700 C

- 55. 55 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Standard Operating Parameter for Different Fabric in Stenter: Fabric Type GSM Dia Temperat ure Over Feed Padder Pressure Speed (rpm) Blower rpm Single jersey 115-150 2”+ 110-140 40-45% 2 bar 30-35 1100-1300 Single jersey 160-220 2”+ 120-170 40-45% 2.5 bar 25-30 1200-1400 Lycra Single jersey 160-200 4”+ 130-160 50% 2 bar 25-30 1200-1400 Lycra Single jersey 200-250 4”+ 140-160 50% 2 bar 24-28 1200-1400 Pique 160-200 3”+ 130-160 40-45% 1.5-2bar 25-30 1200-1400 Lycra Pique 190-220 4”+ 130-160 50% 2 bar 20-25 1200-1400 Fleece/Terry 260-300 4”+ 140-170 40-45% 2 bar 20-25 1300-1400 1x1 Rib 160-220 2”+ 130-160 45% 2 bar 24-28 1300-1400 2x2 Rib 190-220 2”+ 140-160 45% 2 bar 20-25 1200-1400 Interlock 190-220 3”+ 130-160 50% 2 bar 20-25 1200-1400 *S/J fabric feed at 3-5 degree angle. *Others fabric feed, straight. Figure: Of Stenter Machine

- 56. 56 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t o

- 57. 57 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Scope of Quality Control, Quality Assurance and Testing The scope of quality control, quality assurance and testing are good. It has very well: o Testing Laboratory. o Machine auditing system. o A good training system. o Excellent analytical backup. o Technical expertise. Responsibility of Quality Assurance Manager: • Responsible for all quality matter of fabric. • Yarn selection. • Monitoring product development. • Organize Laboratory. • Control grey and finished fabric inspection under 4- point system. • Documentation after shade check of every lot. Responsibility of In-charge of Quality Control: • Making report. • Supervise the grey Q.C. • Check machine is running according to program or not • Check program can meet the requirement. Which is mentioned in the order sheet or not. • Check yarn is approved by Q.C. or not.

- 58. 58 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Quality management system in Dalas Fashion Ltd. Online Quality control: There are two types of online quality control. These are as follows: - • Raw material control: Raw material control means control the quality of raw materials (e.g.- Quality of Grey fabric, Dyes, Chemicals and Auxiliary) • Process control: Process control means the selection of right process and controlling of some parameters. Such as PH , Water hardness, water volume, Temperature, Reel Speed, Pump pressure, etc. Responsibility of ON-Line Quality Control: To check the following things: • M/C Dia/Gauge • Buyer • Design • Grey fabric GSN & Stitch Length • Yarn count & Lot no • Yarn whether approved or not by Q.C. Department • Finished dia & grey dia. Fabric quality checking under 4-point system QA On-Line Off-Line

- 59. 59 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Online Tests: o Dyed fabric. o Shade check. o Wash fastness. o Water fastness. o Crocking fastness. Responsibility of OFF-Line Quality Control: To check the following things: • Inspection of fabric in the inspection M/C under 4-point system. • Yarn count and lot no. • Buyer. • Design. • Stitch length of grey fabric. • Shade of grey fabric with in one order. Off-Line Tests: Off-Line tests for finished fabrics are divided into two groups. These are as follows: o Physical tests o Chemical tests Physical Tests: o GSM of Fabric. o Abrasion resistance / Pilling. o Dimensional stability test. o Spirality test. o Color fastness to rubbing test (Dry / wet). o Bursting strength test (For Knitted fabric). o Tensile Strength test (For Woven fabric). Chemical Tests: o Color Fastness to washing. o Color Fastness to light. o Color Fastness to heat. Color Fastness to actual laundering

- 60. 60 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t o Color Fastness to Chlorinated water. o Color Fastness to water spotting. o Color Fastness to perspiration. o Color Fastness to Seawater. o Flammability test. o Fibre analysis. o PH test. o Spray test (water repellency). o Phenolic yellowing. Color Fastness Test Procedure Color Fastness: The “color fastness” of a colored textile is defined as its resistance to these changes when subjected to particulates of conditions. It follows that color fastness must be specified in terms of these changes and expressed in terms of the magnitude. Color Fastness to Rubbing (Dry & Wet) Test Sample Size: • Dyed fabric – 15 cm × 5 cm • White Test Cloth - 5 cm × 5 cm Procedure: • White test cloth is put on to the grating and stag by steel wire. • The sample is run twenty times manually for ten seconds and the rubbing fastness of the sample cloth and degree of staining is accessed. • For rubbing fastness (Wet), the rubbing cloth is placed in the water and socked and squeeze. The wet rubbing cloth is placed on to the grating and stag with stainless steel wire and run ten times manually then assesses the staining on to the rubbing cloth and the rubbing fastness of the sample cloth is accessed. Report: Change of shade of the sample is measured with grey scale and degree of staining of the white test cloth is measured by Staining Scale.

- 61. 61 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Color Fastness to Wash Required materials: 1. Sample size 40 × 100 mm 2. Multifiber at 40 × 100 mm 3. ECE detergent (WOB) – 4g/L 4. Sodium Perborate (Na2BO3.H2O2.3H2O2) - 1g/L 5. Distilled water 6. Normal cold water 7. Steel balls Required instrument: 1. Rota Wash 2. Scissor 3. Stitch machine Procedure: 1. Cut sample & multifibre at 100 × 400 mm and then stitch. 2. 50 ml ECE detergent (WOB) & 50 ml Sodium per borate is taken with the sample. For Marks & Spencer, the solution is taken by the following formula: (Sample fabric + Multifibre weight) × 50 ml 3. The sample is kept in 600 C for 30 minutes in Rota Wash Machine 4. Rinse the sample twice with cold water. 5. Dry at 60°C by hanging or by Flat iron pressing but temperature should not be more than 150°C. Report: Dry the specimen and the change of shade & degree of staining is measured by Grey Scale & Staining Scale. Grading of staining: Grade Rating 01 Very poor 02 Poor 03 Moderate 04 Good 05 Excellent

- 62. 62 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Color Fastness to Water Test Test specimen: • Sample fabric – 50 mm × 50 mm • Multifibre fabric – 50 mm × 100 mm • Cut the multifibre into two piece • Sandwich the test specimen between two piece of multifibre Testing Solution: • Water is taken as required Method: • The composite specimen is put in a peri dish (2 specimen of a sample). • Water is taken in the peri dish as required. • Bubble is made out from the specimen by tapping. • The specimen is put for 30 minutes. • A glass plate is placed on the composite specimen for 15 minutes at room temperature. • Excess solution is poured off. • Peri dish with composite specimen & glass plate is placed into the incubator at (37±2) 0 C for 4 hours. • The specimen is dried (Temp ≤ 600 C) Report: • Change of shade & degree of staining is measured by the Grey Scale & Staining Scale.

- 63. 63 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Color Fastness to Perspiration Test Test specimen: • Sample fabric – 50 mm × 50 mm • Multifibre fabric – 50 mm × 100 mm • Cut the multifibre into two piece • Sandwich the test specimen between two piece of multifibre Testing Solution: 1. Alkaline Solution: Histidine monohydro chloride monohydrate (C6H10ClN3O2.H2O) : 5.00 g/L NaCl : 5.00 g/L Disodium hydrogen orthophosphate (Na2HPO4.2H2O) :2.5 g/L PH (Adjust by 0.1 N NaOH) : 8 2. Acidic Solution: Histidine monohydro chloride monohydrate (C6H10ClN3O2.H2O) : 5.00 g/L NaCl : 5.00 g/L Disodium hydrogen orthophosphate (Na2HPO4.2H2O) :2.2 g/L PH (Adjust by 0.1 N NaOH) : 5.5 Method: - The composite specimen is put in a peri dish (2 specimen of a sample). - Solution (Alkaline & Acidic) is taken in the two peri dish. Here, M:L is taken 1:20. - Bubble is made out from the specimen by tapping. - The specimen is put for 30 minutes. - A glass plate is placed on the composite specimen for 15 minutes at room temperature. - Excess solution is poured off. - Peri dish with composite specimen & glass plate is placed into the incubator at (37±2) 0 C for 4 hours. - The specimen is dried (Temp ≤ 600 C) Report: Change of shade & degree of staining is measured by the Grey Scale & Staining Scale.

- 64. 64 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t PH of a Dyed Fabric Test Test specimen: • 2 gm of dyed fabric is taken. • The fabric is cut into pieces of (0.5 cm × 0.5 cm) Procedure: 1. The sample is taken into conical flax. 2. 100 ml distilled water (slightly warm) is taken into the conical flax. 3. The conical flax is put on the Magnetic Stirrer for 30 minutes. Report: The PH of the conical flax is measured by Digital PH meter. G.S.M TEST Procedure: GSM is the most important factor. There is a GSM cutter. The sample cut by the GSM cutter is weighted in the electronic balance. The reading (in gm) from the balance is multiplied by 100 to get the value of GSM. Another way of G.S.M test: Where, CPI = Course Per Inch WPI = Wales Per Inch SL = Stitch Length Ne = English Cotton Count . 9158.0 )( × ×× = Ne mmSLWPICPI GSM

- 65. 65 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Shrinkage & Spirality test Buyer’s requirements: Template size : 50cm & 35cm, 25.5cm &18cm (use after quick wash). Shrinkage : Length wise- 5% Width wise-5% Spirality : Left - 5% Right - 5% Procedure: At first take two ply of fabric & put the template (50cm) on to the fabric. The template has 8 holes. Both length & width wise the template holes can measure 35cm at 3 places. Then we mark the 8 holes by permanent marker & also at the edges of the template. Then sewn the fabric & it is given to the washing m/c for run at 60°C for 60minutes with water. After that dry the sample & then measure the fabric: Spin speed - 500 rpm Drum speed -500 rpm Calculation: Shrinkage Test: Lengthwise: After wash – Before wash ×100 Before wash Width wise: After wash – Before wash ×100 Before wash Spirality test: = M)&HforthLength(wid 2 sideRightsideLeft + × 100 %

- 66. 66 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Pilling test Procedure: • Cut the fabric 12.5 x 12.5cm & balance mark should be 10cm by using template. • Then sewn the fabric so that it can be firmly fit in the tube moulded polyurethane tubes. • Then four tubes are placed in a box & start 60±2 rev/min for 5 hrs or according to buyer requirement. • Here mainly used 3hrs (1100 cycle). • Then assess the pilling by putting tested specimen on the viewing cabinet & compare with standard photographs

- 67. 67 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t

- 68. 68 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Process Flow Chart of Final Inspection:(Q.A.D) After completing finishing process here firstly check the shade as per buyer standard with dimensional stability from lab. Secondly check dia / width fabric weight or G.S.M Thirdly check fabric surface or appearance as per buyer standard. The every roll with every meter check as per four (04) point system. Make a report. If OK then ready for delivery. If not OK then identify the fault. If it is knitting fault then inform the knitting department by job card and mail, & requested the fabric for replacement. If it is dyeing fault & If make sure that it is reprocess able then give job card to dyeing department correction. And if is not reprocess able then reject the fabric & inform the dyeing department to replace the rejected quantity.

- 69. 69 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Final Inspection Final inspection is necessary to find out any type of fault which may produced in different work procedure of knitting, dyeing or finishing. Identification of batch to batch shade variation is also an important task of this section. In Dalas Fashion Ltd. the inspection department follows four points system. Four point system for Inspection: Inspection procedure for the system: • At the beginning of each roll, a 6″ full width cutting ( Head end) should be taken as a • Color reference and checked for side to center and side to side shading. • Measure useable edge to edge width of fabric. • For direction of fabric fault the rating of 4 point should be as follows: Flows up to 3″ in length : 1 Point Flows up to 6″ in length : 2 Point Flows up to 9″ in length : 3 Point Flows over 9″ in length : 4 Point Note: • No linear yards to be penalized more than 4 points. • All holes, regardless of size will be penalized 4 points. • Determine fault rate per piece when actual fabric width is less than 36″. • Minimum length of the roll 25 yards. • Accepted range 28 point per 100square yards. Calculation of fault per 100 square yards: Actual point counted 36″ = * * 100 Actual roll length in yards Actual width in inch = Points per 100sq. Yards Note: • Acceptable points for final inspection- 28. • After inspection fabrics are packed and send to the store.

- 70. 70 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t

- 71. 71 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Production Planning and Control This department plays an important role in any production related plant. In DALAS FASHION LTD. the total operation of order receives to final product delivery has planned by this section. The concern departments of production perform their processing works on the basis of the instruction of this department. Planning section made a proper schedule of operation to ensure the required delivery time schedule. The costing of any product has done here. The sections of this department are- - Planning - Marketing - Inspection & - Maintenance. Human Resource & Administration: The sections of Human Resource department are- - Accounts - Store & procurement. - Civil & Construction. - IT. Administration: The responsibilities of this department are- - Maintain rules & regulation of the company. - Maintain welfare & participation committee. - Ensure different facility of the employee like increment, bonus, leave etc. - Logistic support of the company. - Workers salary payment. - First aid & medical facility. - Transport of the factory.

- 72. 72 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t

- 73. 73 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t MAITENANCE Maintenance is a procedure by which we can maintain active functioning in operation according to the behavior and utility of a particular element. In engineering, we use this terminology for maintaining smooth and uninterrupted performance of machines, tools and metallurgical characteristics in practical uses. Objective of maintenance: ♦ To keep the factory plants, equipments, machine tools in an optimum working condition. ♦ To ensure specified accuracy to product and time schedule of delivery to customer. ♦ To keep the downtime of machines to the minimum thuds to have control over the production program. ♦ To keep the production cycle within the stipulated range. ♦ To modify the machine tools to meet the need for production. Three types of maintenance are performed in Dalas Fashion Ltd. 1. Preventive Maintenance. 2. Routine/ Schedule Maintenance. 3. Breakdown Maintenance. Preventive Maintenance: When a problem occurred the operator informed the supervisor, then the supervisor informed the production officer, then the production officer called the maintenance officer. The maintenance officer visits the problem and takes necessary steps to solve the problem. Schedule maintenance: It is time-based maintenance and pre-planned to perform on machine and equipments. This plan usually made on monthly basis. Breakdown maintenance: In this type of maintenance when the machine remains stop that time the maintenance is done.

- 74. 74 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Maintenance Tools, Equipments & their functions: Name of Tools Function Hammer To give shape Slide Wrench Tightening and opening bolt Spanner Tightening and opening bolt Pliers Cutting, Holding, Joining, wire, Gripping Hacksaw Cutting Pipe Wrench Tightening, opening, gripping pipe Chisel Shaping, Cutting File Shaping Clamp Gripping Vice Name of Equipments Function Grinding m/c Grinding Cutting m/c Cutting Drill m/c Drilling Shaping m/c Shaping Lathe m/c To make something Bending m/c Bending Flow chart of maintenance Problem occurred Operator Supervisor Production officer Maintenance officer Solution Remarks: Their maintenance procedure is very good & effective as a result they have good efficiencies.

- 75. 75 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t UTILITY

- 76. 76 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Utility facilities: The following utility facilities are available in Dalas Fashion Ltd. Gas Electricity Water Steam Compressed Air GENERATOR The only one source of electricity of DALAS FASHION LTD. is the gas generator. They had two gases Generator to overcome the required electricity of the DFL. Name of Generator : Gas Generator Capacity : • 750 KVA (02) • 350 KVA (01) Origin : China Company Name : SHENGLY POWER BOILER The equipment used for producing steam from water is called steam generator or boiler. The boiler used for producing steam in GKL is Cochran boiler which is a fire tube type boiler. This produced steam is supplied by the steam line in different section. Simple vertical boiler of fire tube type is mainly used in small plant requiring small quantity of steam and where floor area is limited. Boiler Specification: Boiler Type : Fire Tube Boiler Brand Name : DAELIM ROYAL Max. Steam Output : 6 t /h Test Pressure : 20.5 bar Volume : 12540 L Year of Manufacture : 2005 Country Name : Korea

- 77. 77 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t COMPRESSOR Basically Compressor generate the compress air which distributed in the knitting, dyeing & finishing section and this air is used for following reasons- - To clean the m/c parts in knitting zone. - To open different type of valves in dyeing m/c during dozing, water feeding, drainage time. - Squeezer needed compress air for balloon form. - Turning M/C’s needed compress air for batch preparation. Compressed air is produced by air compressor. There are six air compressors and three dryers in FAKIR Knitwear’s Limited. For producing compressed air. Name of the compressor : Air Compressor Origin : TAIWAN Brand : PUMA Model : 20HP, 15HP No. Of Compressor : 01

- 78. 78 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t WATER TREATMENT PLANT (W.T.P) Natural water quality: Water for a textile plant may come from various sources. These include surface water from rivers and lakes, and subterranean water from wells. In DALAS FASHION LTD.they collect water from Under ground. Natural and pretreated water may contain a variety of chemical species that can influence textile wet processing in general, and dyeing in particular. There are two deep tubeweel by the two side of the treatment plant. There are also two submersible pumps in the deep tubeweel one is 100 ft deep and another is 140 ft deep. The submersible pump transfer raw water in the water tank by creates force. The formation of oxidation of the water by showering with the help of another two pimps in the water tank. Iron content removes by the oxidation. Two circular transfer raw water in the (vessel no-1) Multigrade filter unit. The large size plastic, iron that means solid content are removed in the multigrade filter unit. The water is transferred to the (vessel No-2) Activated carbon filter unit. In the (vessel No-2) Activated carbon unit to remove chlorine that means bad smell. The water then transfer in to the (vessel No-3) softener unit from the activated carbon unit at the presence of cationic resin (Zeolite) is reacted with water to remove the hardness of water. The water is transferred in to the reserve tank from the softener unit. The soft water is supplied from the reserve tank by the 7 Boosting pump in the different section of the factory. The various salts present in water depend on the geological formations through which the water has flowed. These salts are mainly the carbonates (CO3 2-) , hydrogen carbonates or bi-carbonates ( HCO3 -) , Sulphates ( SO4 2- ) and chlorides (Cl- ) of calcium ( Ca2+ ), magnesium (Mg2+ ) . Although calcium and magnesium carbonates in limestone are relatively insoluble in water. This water hardness causes some serious consequences in a textile dyeing and finishing industries and these are • Precipitation of soaps. • Redeposit ion of dirt and insoluble soaps on the fabric being washed , this can cause yellowing and lead to uneven dyeing and poor handle. • Precipitation of some dyes as calcium and magnesium salts. • Scale formation on equipment and in boilers and pipelines. • Reduction of the activity of the enzymes used in washing. • Incompatibility with chemicals in finishing recipes and so on. Hardness expressed by parts per million (ppm) of CaCO3 which is standard hardness scale and it is also called American hardness. The hardness of raw water is 100 ppm or more. To use it in dyeing and in boiler this water must need to soft & foreign materials needs to remove

- 79. 79 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t The flow chart of water treatment plant is given below Fig: Water treatment plan Water hardness test Necessary equipments & chemicals: • Buffer soln . • Indicator. • Liquid EDTA soln . • Beaker. Procedure: • Take 50 ml water in a beaker which treated by WTP-plant. • Take 4/5 drops buffer soln in a beaker . • Take 1 drop indicator in a beaker and form the violet color. • Now EDTA soln is dropped until the pink color is not form a crystal color. Here, 1 drop EDTA soln = 3 ppm . Result: Industrial Soft-water std. range is 5 ppm but it is very difficult to control. So in this industry, water hardness scale maintains 7 to 8 ppm of CaCO3. Hard Water Store Tank Stone Filter Carbon Filter Resin Filter Dele- Very Pump Soft Water Store Tank

- 80. 80 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t The Back wash & Regeneration process The back wash process to clean the vessel no-1,2 & 3. The back wash process should be done after 8-12hrs. After 40-48 hrs later the regeneration process should be done. It should be done after back wash process. After back wash the common salt dissolved with water in to the STT (salt saturated tank) the solution of common salt is ringing the resin by the injector. The use of 18% salt in the total solution. (Suppose, 5000 lit of solution the amount of salt 600kg). The resin is activated by the salt rising. Here used cationic resin (NaHSO3). If the PH of the water increase or decrease it should be control by the dosing chemical (Sodium Hypochlorite) from the chemical tank. Figure: Water treatment plant Where, A=Hard water storage tank B=Stone filter C=Carbon filter D=Resin filter E=Soft water storage tank F= Pump Hardness check: The hardness should be checked after every 6 hrs. It should be checked by the hardness test kits. The using hardness test kits are Hanna Instrument. Made in Italy. If the hardness is going to be 0.5 on the syringe scale. Then have to do the regeneration process. The capacity of the vessel 115m3 / hr or 115 ton/hr. A B C D E

- 81. 81 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t EFFLUENT TREATMENT PLANT Effluents and effluent treatment: “Effluent is the stream of excess chemical liquor extracted from an industry after using in original operation. For example the excess dye liquor extracted from textile industry after dyeing in an effluent of that dyeing industry.” Effluent treatment can be explained as below: Industrial effluent generated from different processes are treated with various chemicals to remove or neutralize the environmentally toxic materials present in it, before discharging it to surface or ground water. This is called effluent treatment. The main objects of effluent treatment are: 1. To control PH 2. To remove coloring matter 3. This process is provided for treating the effluents of dyeing, printing, finishing, weaving & thus allow to discharge effluent as per by World Bank dept of environment of Bangladesh. The effluent generated from different sections of a textile mill must be treated before they are discharged to environment. Various chemicals & physical means are introduced for this purpose. The effluent treatment plant in DALAS FASHION LTD. is under installation work.

- 82. 82 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Effect of impurities or effect of effluents on environment: Name of impurities Effect Bacteria Diseases Algae, Protozoa, Fungi Diseases, odor color, turbidity Clay and colloids Turbidity Salts of calcium and magnesium Carbonates Hardness, alkalinity, taste, corrosiveness, scale formation Bicarbonates Hardness, alkalinity, taste, corrosiveness, scale formation Sulphate Hardness, taste Chlorides Hardness corrosiveness, taste. Salts of sodium Carbonates Alkalinity Bicarbonates Alkalinity Sulphate Foaming and scaling Chlorides Taste Fluorides Tooth decay Iron oxides Taste, red water hardness, corrosiveness Manganese Black or brown water Vegetable dyes Color, acidity Radioactive impurities Diseases Gases O2 Corrosive to metals CO2 Acidity, corrosive to metals H2S Odor, acidity, corrosive to metals N2 Child disease, algal growth Chemical used in effluent treatment: The following chemicals are used in effluent treatment: • FeSO4 approximately 600-700 PPM, it is used for removing color. • polyelectrolyte, it is used to increase precipitation rate • H2SO4 , up to PH neutralizations for controlling PH of liquor • Lime approximately 450-550 PPM used to remove coloring matters in alkaline medium • Alum, alum is used to sediment residual matters • DREWFLOC 270 polymer, about 0.05-.25%

- 83. 83 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Requirement of discharge effluent as per World Bank: PH : 6 – 8 BOD : < 50 COD : < 250 SS : < 100 TDS : Not stated Color : Clear Typical Output of the Plant: Raw effluent colour : Black Raw effluent pH : 01 Treated effluent colour : Light greenish Treated Effluent pH : 6-6.5 Treated Effluent Temp : 380 C Sketch of the ETP is given below: Effluent water from dyeing Equalization tank Flocculation tank Primary clarifier Sludge bed Chlorination tank Secondary clarifier Aeration tank Multi filter Discharged effluent Sodium hydrochloride Acid solution Poly electrolyte & alarm dosing

- 84. 84 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Flow Chart of Effluent Treatment: Raw effluent Equalization Tank Flocculation tank Primary Clarifier Aeration tank Secondary c larifier Chlorinaiton tank Multi filter Sludge Separation: Sludge of Tube Satalor Sludge thickening plant Sludge drying

- 85. 85 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t

- 86. 86 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t COSTING Costing is a process by which the setting price of a product is calculated. It is a very important task for a factory which runs for business purposes. And it is also strictly followed in the DALAS FASHION LTD. Costing of the products considering the raw materials expenditure, salary and wages of officers and workers, distributions and advertisement expenses etc. all direct and indirect expenses is done in this factory. It is determined by a troop of accountants with advice and consultancy of executive director. Costing Of the Product The following points are considered for costing any dyed product in DALAS FASHION LTD. 1. Total dyes & chemical cost 2. Total utility cost 3. Salary 4. Payment 5. Transport cost 6. Lunch 7. Entertainment cost 8. Miscellaneous cost 9. Government cash incentive Price of the Product: Generally price of product is determined by the required profit adding to the total expenses. So, Price of products= (Direct expenses + Indirect expenses + Factory Overhead) + Required profit

- 87. 87 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Price Range of Different Products: T-Shirt = $0.75 - $4.50 /Pcs Polo Shirt =$2.00 - $6.50 /Pcs Kids Wear ==$0.75- $2.15 /Pcs Knitting Charge of Different Fabrics: Fabric name Charge per kg(Tk) 1. Single Jersey 09 2. Single Jersey with Lycra 30 3. Single locust PK 16 4. Double lacost PK 16 5. Single PK 16 6. Double PK 16 7. Rib 17 8. Rib with Lycra 30 9. Interlock 25 10. Auto striper 80 11. Auto striper with Lycra 100 12. Fleece 22-25 Dyeing Charge of Different Fabrics: Name of fabric process Charge per kg(Tk) 1. White with Enzyme 35 2. White without Enzyme 30 3. Avg. color with Enzyme 85 4. Avg.color without Enzyme (Light& med.) 75 5. Deep shed with Enzyme (Black) 110 6. Deep shed without Enzyme (Black) 95 7. Only wash (Tubular) 25 8. Only wash (Open) 45 9. Double dyeing (Face & Back) 115

- 88. 88 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Finishing Charge of Different Fabrics: Name of fabric process Charge per kg(Tk) 1. Slitting only 5 2. Stenter only 25 3. Compacting only 15 4. Stenter + Compacting 35 5. Stenter + Compacting+ wash 50 6. Tube Compacting 10 Costing Of the Product: Let price of yarn is $ 3.00/ kg. +Process loss of yarn for knitting (10%) = $0.30 Knitting fabric cost = $3.30 Cost of dyes & chemicals = $2.50 +Process loss for dyeing (12%) = $0.30 Dyed fabric cost = $ 6.10 +Packing cost = $0.05 Production cost of fabric=$6.15 Fabric price (with 25% margin) =$7.79 Fabric consumption/ doz. = (Body length + Sleeve length) x Chest length x 2 x GSM x12 /100, 00000

- 89. 89 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Garments specification: Body length=78 cm Sleeve length=33 cm Chest length=62 cm GSM=210 Fabric consumption/ doz. = {(78+33) x62x2x210x12}/ 100, 00000 = 3.469 kg Fabric consumption/dozen (with 10% wastage) = 3.816 kg Body fabric cost / doz. =$(7.79x 3.816) = $29.73 Cost of collar& cuff/doz = $ 4.00 Cost of Trims=$ 2.25 Cost of Trims (with 5% Process loss) = $2.36 Production Cost of Garments/ doz=$36.09 Garments Price/doz (with 25% Profit) =$45.12 L/C vat 5% add = 869.93 Fabric cost per kg = dollar 0.2067 93.869 = 0.421 dollar Remarks: Costing is very important for a productive factory. Without proper costing all production curriculums will go to vain. Because a factory cannot reach to its goal without achieving good profit and good profit is not possible without skillful costing. In DALAS FASHION LTD. there are some skillful personnel to do this job.

- 90. 90 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t

- 91. 91 | P a g e I n d u s t r i a l T r a i n i n g R e p o r t Conclusion We have completed our Industrial Training successfully by the grace of Allah. Industrial Attachment provides us to the expected destiny of practical life. DALAS FASHION LTD.DALAS FASHION LTD.DALAS FASHION LTD.DALAS FASHION LTD. is a well known factory in the textile field of Bangladesh. The completion of the Eight (08) weeksEight (08) weeksEight (08) weeksEight (08) weeks industrial attachment at DALAS FASHION LTD.DALAS FASHION LTD.DALAS FASHION LTD.DALAS FASHION LTD. gave us the inspiration that factory is one of the appropriate destiny to implement the theoretical knowledge. From this industrial attachment we got the details idea about the factory environment, production process, total management, store & inventory process, maintenance, utility etc. DALASDALASDALASDALAS FASHION LTD.FASHION LTD.FASHION LTD.FASHION LTD. is well equipped and the working environment is excellent. The relation between top management to bottom level is so nice.We are lucky to get the opportunity of having training in this mill. The factory runs by a number of efficient Textile Engineers, Skilled technical & Non-technical persons. All the Textile Engineers, technical & Non- technical persons are very sincere, co-operative and helpful. It was really a productive practical learning besides our four year academics, so we wish we will be able to implement our learning and methodological knowledge successfully in the textile industry and the betterment of the economy of our country.