Flame Scanners Optimization

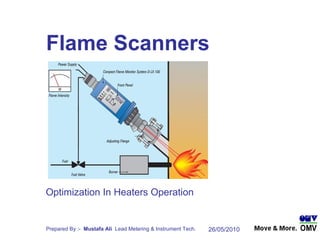

- 1. Flame Scanners Optimization In Heaters Operation

- 2. Introduction Flame whose UV radiation is absorbed by dust, water vapor or other material , may be monitored by these highly sensitive semiconductor UV photo elements, These Flame monitors have also proven themselves in monitoring gas & oil combustion systems employing NOx reduction techniques , Flame scanners are used in burner applications with the widest variety of fuels,

- 3. Flame Scanners Installation at Heaters (Sawan CPP) 6 Scanners 6 Scanners 6 Scanners 6 Scanners 6 Scanners 6 Scanners 2 Scanners 2 Scanners

- 5. Flame Scanners Malfunction Background / History Flame Scanners failure often occurs during Heaters Startup Pilot Flame Lit , but couldn’t recognized by Flame Scanner Several attempts to be made to run a Heater , Specially after S/D or Cold Startup Causing production delays, Causing excessive maintenance work hours utilization The Flame Threshold have adjustable Range of “0” Low Sensitivity to “ 9 “ High Sensitivity in Flame Scanners, These Flame Scanners since Sawan Commissioning always set to “ 9 ” Very low Pulse Frequency Threshold (High Sensitivity) to exposed Pilot Flame, That is to say, Very Narrow Flame Recognition Limit Therefore If the flame image is very intense or deteriorates too much the flame signal (pulse frequency) dips below or go over the shut-off threshold. The safety time programmed into the scanner will then begin to run. After the safety time expires, the flame OFF signal is given and the green LED goes out , fail-safe relay output to the external flame ON signal is open & Flame Failure occurred Flame Scanners Malfunction Cause

- 6. Threshold Rocker Switch Setting Graph

- 7. Threshold Settings Graph ( Conventional Practice Setting @ 9 ) Flame Scanners Rocker Switch set at “ 9 “ at All Sawan Heaters

- 8. 4-20 mA Flame Intensity Feature not Utilized 4 – 20 mA Flame intensity signal wires were cut from cable & kept isolated in JB Every time a malfunction occurs, Flame Scanner cover removes to excess the Flame Scanner & we couldn’t get the problem rectified without it,

- 9. Threshold Settings Graph ( Setting Optimized Recently @ 6 ) Methodology deployed & verified recently at Incinerator Train #1 & Train # 2

- 10. 4-20mA Flame Intensity Feature Utilized Recently 4 – 20 mA Flame intensity signal wires were identified , Tagged & kept in JB for measuring Flame Intensity at Incinerator Train # 1 & Train # 2

- 11. Discuss the observation among Instrument Team & prepare plan for implementation Performed job on Train # 2 Incinerator during S/D on 20 / 05 / 2010 Flame Scanner mA used for Flame Intensity has verified Flame Scanner Threshold Setting Change From “9” to “6” Trouble Free Functionality checked Twice on startup of Incinerator Train # 2 Performed job on Train # 1 Incinerator during S/D on 23 / 05 / 2010 Flame Scanner mA used for Flame Intensity has verified Flame Scanner Threshold Setting Change From “9” to “6” Trouble Free Functionality checked Twice on startup of Incinerator Train # 1 Action Taken

- 12. Way Forward Rocker Switch Threshold Adjustment at all the remaining Flame Scanners i,e “ 6 “ 4 – 20 mA Flame intensity measurement at all the remaining Flame Scanners , Verify the Operation / Functionality of Flame Scanners

- 13. Flame must be visible to the flame scanner at all times, regardless of the load range of the burner. The 6° angle of view should always be oriented toward the root of the flame, that is, the bottom third of the flame. The flame scanner’s purge air connection is responsible for keeping the sighting tube and optics free of particles from the combustion chamber. Installation

- 14. The flame scanner is equipped with a push button switch for adjusting the flame recognition threshold .This threshold may be set to one of ten levels. Programming the Flame Scanner Flame OFF Setting: When burner is shut down, Threshold switch must be set high enough that the flame scanner does not see any ambient light and reliably signals ”Flame OFF”: • the green”Flame” LED is not illuminated, • the current in the flame intensity measurement circuit is less than 8 mA, • the fail-safe relay output to the external flame ON signal is open. Flame ON Setting: If the burner is operating, Scanner must reliably exceed the flame recognition (shut-off) threshold and signal”Flame ON”: • the green”Flame” LED is illuminated, • the current in the flame intensity measurement circuit is greater than 12 mA • the fail-safe relay output to the external flame ON signal is closed.

- 15. If the internal self-check recognizes an error in the safety-related software and hardware components, An error shutdown and internal lockout triggered. The relays for the flame, operational readiness and fault signals are released, and the red LED on the front panel will begin blinking. The contact from K1 signals the present fault. The red LED blinks 5 times by itself. After that, the yellow LED will also begin blinking with the red. Fault Recognition If the cause of the error is a defect in the integrated flame scanner, the red and green LED’s will blink alternately. The number of times that the yellow LED blinks corresponds to the type of error, which allows the operator to precisely analyze the source of the fault.

- 16. Flame Scanners Optimization In Heaters Operation Thanks For Kind Attention