Shangkar Venugopal - Commercial CV updated 061116 - Linkedin

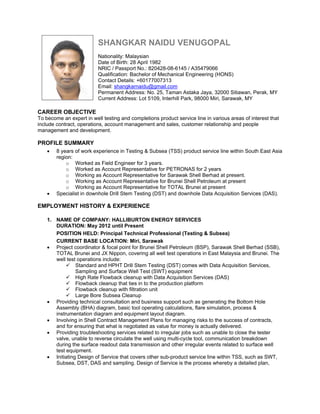

- 1. SHANGKAR NAIDU VENUGOPAL Nationality: Malaysian Date of Birth: 28 April 1982 NRIC / Passport No.: 820428-08-6145 / A35479066 Qualification: Bachelor of Mechanical Engineering (HONS) Contact Details: +60177007313 Email: shangkarnaidu@gmail.com Permanent Address: No. 25, Taman Astaka Jaya, 32000 Sitiawan, Perak, MY Current Address: Lot 5109, Interhill Park, 98000 Miri, Sarawak, MY CAREER OBJECTIVE To become an expert in well testing and completions product service line in various areas of interest that include contract, operations, account management and sales, customer relationship and people management and development. PROFILE SUMMARY 8 years of work experience in Testing & Subsea (TSS) product service line within South East Asia region: o Worked as Field Engineer for 3 years. o Worked as Account Representative for PETRONAS for 2 years o Working as Account Representative for Sarawak Shell Berhad at present. o Working as Account Representative for Brunei Shell Petroleum at present o Working as Account Representative for TOTAL Brunei at present Specialist in downhole Drill Stem Testing (DST) and downhole Data Acquisition Services (DAS). EMPLOYMENT HISTORY & EXPERIENCE 1. NAME OF COMPANY: HALLIBURTON ENERGY SERVICES DURATION: May 2012 until Present POSITION HELD: Principal Technical Professional (Testing & Subsea) CURRENT BASE LOCATION: Miri, Sarawak Project coordinator & focal point for Brunei Shell Petroleum (BSP), Sarawak Shell Berhad (SSB), TOTAL Brunei and JX Nippon, covering all well test operations in East Malaysia and Brunei. The well test operations include: Standard and HPHT Drill Stem Testing (DST) comes with Data Acquisition Services, Sampling and Surface Well Test (SWT) equipment High Rate Flowback cleanup with Data Acquisition Services (DAS) Flowback cleanup that ties in to the production platform Flowback cleanup with filtration unit Large Bore Subsea Cleanup Providing technical consultation and business support such as generating the Bottom Hole Assembly (BHA) diagram, basic tool operating calculations, flare simulation, process & instrumentation diagram and equipment layout diagram. Involving in Shell Contract Management Plans for managing risks to the success of contracts, and for ensuring that what is negotiated as value for money is actually delivered. Providing troubleshooting services related to irregular jobs such as unable to close the tester valve, unable to reverse circulate the well using multi-cycle tool, communication breakdown during the surface readout data transmission and other irregular events related to surface well test equipment. Initiating Design of Service that covers other sub-product service line within TSS, such as SWT, Subsea, DST, DAS and sampling. Design of Service is the process whereby a detailed plan,

- 2. verified internally by Halliburton and formally accepted by customer, is developed to realize customer’s requirements. Involving in Business Acquisition Process (BAP) that include several phases such as Identifying the Opportunity, Pursuit the Opportunity, Tender, Negotiation & Award and Execution. The following are the tenders participated over the past 2 years: Brunei Shell Petroleum – Provision of CTU & Stimulation Services HESS – Supply of Well Testing & Equipment Services for North Malay Basin Petronas Carigali Brunei Limited – Provision of Well Testing Equipment & Services TOTAL Brunei – Well Cleanup Equipment & Services Note: The Business Acquisition Process (BAP) is Halliburton’s methodology for business development. 2. NAME OF COMPANY: HALLIBURTON ENERGY SERVICES DURATION: June 2008 until May 2012 POSITION HELD: Technical Professional (Testing & Subsea) BASE LOCATION: Kuala Lumpur, Malaysia Project coordinator & focal point for PETRONAS CARIGALI, covering all well test operations in Malaysia water. Provided technical consultation and business support to customers concerning Testing & Subsea (TSS) products and services. Initiated Design of Service that covers other sub-product service line within TSS, such as Surface Well Testing (SWT), Subsea, Drill Stem Testing (DST), data acquisition and sampling. Design of Service is the process whereby a detailed plan, verified internally by Halliburton and formally accepted by customer, is developed to realize customer’s requirements. Managed resources to ensure all the equipment and personnel needed are provided in timely manner. Identified, assessed and managed well testing hazards by conducting Hazard & Operability (HAZOP) studies, compilation of Hazard Identification (HAZID) worksheet and risk analysis. Performed downhole data acquisition at the wellsite by running Electronic Memory Recorder (EMR) and Surface Readout (SRO) system using E-Line and wireless deployment. SRO provides real time and historical data acquisition at surface during well testing operation. Qualified as a TSS assessor to train mentor junior personnel in the area of expertise. Routinely conduct Field Service audits to ensure the processes are in compliance with Halliburton Management System. Applied technical knowledge to solve unanticipated situations and consult with Halliburton Global as needed. Involved in Pan Malaysia tender and proposal submission. Developed tender response strategy based on relationship, tender factors and market conditions. WELLSITE JOB HISTORY No Rig / Well Position Customer Job Description 1 Randolph Yost / D18-301 DST Assistant PETRONAS Casing test by using RTTS Packer Storm Valve job Overbalanced shoot & pull 2 Offshore Courageous / St Joseph 701 DST Assistant Shell Underbalanced shoot & pull 3 Rig 136 / Desaru 4C Gauge Specialist Petrofac Run DynaMem TM Gauges for well testing job 4 DD3 / Kinabalu E4 Gauge / DynaLink TM Specialist PETRONAS Run DynaMem TM Gauges and involved in wireless deployed DynaLinkTM trial First successful wireless deployed DynaLink TM in the world

- 3. 5 Naga-1 / F12-2 Gauge / DynaLink TM Specialist PETRONAS Run DynaMem TM Gauges and wireless deployed DynaLinkTM trial across subsea on semisubmersible The wireless trial across subsea served the purpose of performing a wireless acoustic communication test across the subsea test tree for future wireless deployed DynaLink TM on semisubmersible rigs 6 GSF 134 / Bergading-2 Gauge / DynaLinkTM Specialist PETRONAS Run DynaMem TM Gauges and first wireless deployed DynaLink TM commercial job in Malaysia Buildup period was extended for 3 hours after reviewing the surface readout (SRO) data to achieve a satisfactory Horner plot (value added service) 7 Sedco 601 / Melawati-1 Gauge / DynaLinkTM Specialist PETRONAS Run DynaMem TM Gauges and wireline deployed DynaLink TM The objective of this job is to determine the boundaries of the reservoir in which buildup period was estimated up to 72 hours. The buildup period was shortened upon achieving the satisfactory data. 8 Energy Searcher / 113-BV-3X Gauge / DynaLinkTM Specialist VGP (Vietnam) Run DynaMem TM Gauges and wireline deployed DynaLink TM No. of DST performed = 4 9 Topaz Driller / 16- 2-HMX-1X DynaLink TM Specialist Phu Quy (Vietnam) Run wireless deployed DynaLink TM 10 Nabor 503 (Land) Engineer in Charge JX Nippon Oversee the well test operation Note: DynaLinkTM is a registered trademark of Halliburton surface readout system DynaMemTM is a registered trademark of Halliburton electronic memory recorder HALLIBURTON COURSES ATTENDED No Training Course Description 1 Technical Training Program (TTP) Phase 1 Provided basic understanding of the industry that included familiarity with each of the upstream technologies and operations. 2 DynaMemTM Gauge Training Covered the fundamentals of memory gauge operations including gauge programming, data retrieval, running, reporting and maintenance procedure. 3 Hazard Identification Training (Shell) Basic understanding and fundamentals of Risk Management processes 4 Production Logging & Well Testing (Petronas) Introduction to well testing operations, well test analysis, description of surface well test equipment, downhole tools, perforation techniques and sampling. 5 Front Line Field Supervisor 6 Supervisor 101 (Shell) 7 DynaLinkTM DynaLinkTM is a registered trademark of Halliburton Surface Readout System (System) used to gather downhole data in real-time. This course is for data acquisition engineers to provide the insight of the SRO operational and data gathering. 8 Service Tools II Retrievable packer applications, operations and specifications

- 4. 9 Test Tools Application DST tools applications, operations and specifications. 10 Surface Well Test (Intermediate) Designed to give the job tested and experienced Surface Well Testing personnel operational and practical training on required flow rate calculations, operational requirements, data gathering, and analysis interpretation. 11 Business Leadership Development This course was given to selected candidates to be part of Halliburton Management Program 12 Halliburton Academy (HalAcademy) HalAcademy is the Company’s prestigious annual conference where the top performers will be recognized, the Company’s vision will be discussed, and the latest Technology & Innovation will be presented 13 Subsea Applications This course provided the understanding of Subsea applications with completions and drill stem testing, operations, maintenance and specifications HALLIBURTON AWARDS & ACHIEVEMENTS Awarded Maximizing Value-added Performance (MVP) award in February 2010 for being the instrumental to the deployment of the first successful wireless DynaLinkTM telemetry system in Malaysia and for TSS Halliburton globally. Authored a technical paper title – “Operational & Safety Aspects of Drill Stem Testing – Getting it Right” and presented the paper in APPEA conference in Brisbane, Australia during May 2010. Note: APPEA is the Australian Petroleum, Production & Exploration Association and recognized as Australia’s number one energy body. The APPEA conference has established itself as THE leading event for both networking and learning for the oil and gas sectors. Awarded MVP award in May 2011 for the outstanding performance representing Halliburton with PETRONAS in APPEA 2011 conference in Perth, Australia and presented a joint project technical paper title – “Advanced Wireless Telemetry System for Real-time Surface Readout during Drill Stem Testing”. Awarded MPV award in June 2014 in recognition for my contribution towards successful deliver of Large Bore Subsea intervention work for Shell. Represented Halliburton and presented a technical paper title – “Case History: First Isochronal Reservoir Test Successfully Performed Worldwide at a BHT more than 430 degF” in SPE’s Applied Technical Workshop – HPHT Wells in Phuket, Thailand during September 2011. Appointed as a HSE Lead Central Asia in 2011 to lead the Central Asia Country Management Team in pursuing ZERO Health & Safety incidents, ZERO environmental incidents and ZERO nonproductive time. Selected through region’s Succession Management process as one of the individuals chosen to participate in Halliburton Hi-Potential Program and Development Process. 3. NAME OF COMPANY: KEPPEL FELS (Kazakhstan) DURATION: March until May 2008 POSITION HELD: Dimension Control / QA Engineer BASE LOCATION: Aktau Port, Kazakhstan Involved in fabrication and erection of barges and platforms for an Oil & Gas project which is known as Kashagan Experimental Project in Caspian Sea. Performed Dimension Control survey upon fit up and subsequently after welding for pipe racks and barges structures throughout the project phases by using various precision instruments, namely Total Station (Nikon DTM-522), Auto Level (Nikon AS-2C) and Theodolite. Performed Dimension Control survey, specifically flange facing alignment, rotation of flanges, pipe straightness and pipe elbow radius upon fit up and subsequently after welding for various

- 5. materials and sizes of fabricated pipe spools by using Spirit Level, Piano Wire, L-Squares and Plumb Bobs. Issued acceptance / rejection surveillance reports C/W drawing generated by using AutoCAD reflecting actual dimensions against approved tolerances as stipulated in client (Agip KCO) specifications. Conducted periodical leveling surveillance on partially existing and wholly erected structures to ensure levelness is sustained. Prepared the Dimension Control reports before and after welding at initial, middle and final stages for structural erection and submitted to client for endorsement Liaised with production to ensure all critical work points as per engineering drawing are fully adhered to and maintained. Conducted Dimension Control training to junior engineers. 4. NAME OF COMPANY: Industrias Metalurgicas Pescarmona S.A (IMPSA) DURATION: June 2007 until February 2008 POSITION HELD: Quality Control Engineer BASE LOCATION: Lumut, Malaysia Assigned to carry out Magnetic Particle Inspection (MPI), Visual Inspection (VI) and Bolt Torque Inspection for Ship to Shore (STS) crane manufacturing project in Batam, Indonesia. Witnessed and monitored the adhesion test, painting progress and pressure test for Rubber Tired Gantry (RTG) cranes components as per the documented requirement. Performed Dimension Control (DC) survey upon fit-up and subsequently after welding for crane structures throughout the project phases by using various sophisticated instruments, namely Total Station and Theodolite. Prepared the DC reports before and after welding at initial, middle and final stages for structural erection and submitted to client representatives for endorsement. Supported manufacturing operations by ensuring that inspections and documentation of results are carried out in a timely and efficient manner. Liaised with client representatives and suppliers to ensure a positive working relationship. Surveillances of welding parameters such as preheat, interpass temperatures and preheat maintenance. Rotating equipment testing by using feeler gauge and micrometer dial. EDUCATION 2007: University of Technology (UTM), Johor Bahru, Malaysia Bachelor of Mechanical Engineering (HONS) 2000: Malaysian Certificate of Education (MCE/SPM) - First Grade with aggregate of 9 1998: Lower Certificate of Education (LCE/PMR) - 7As PERSONAL INTEREST Sports Books Adventurous activity REFEREES Referees can be provided upon request