Ge 6757 total quality management (tqm)

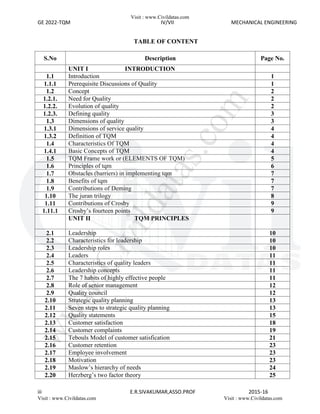

- 1. GE 2022-TQM IV/VII MECHANICAL ENGINEERING iii E.R.SIVAKUMAR,ASSO.PROF 2015-16 TABLE OF CONTENT S.No Description Page No. UNIT I INTRODUCTION 1.1 Introduction 1 1.1.1 Prerequisite Discussions of Quality 1 1.2 Concept 2 1.2.1. Need for Quality 2 1.2.2. Evolution of quality 2 1.2.3. Defining quality 3 1.3 Dimensions of quality 3 1.3.1 Dimensions of service quality 4 1.3.2 Definition of TQM 4 1.4 Characteristics Of TQM 4 1.4.1 Basic Concepts of TQM 4 1.5 TQM Frame work or (ELEMENTS OF TQM) 5 1.6 Principles of tqm 6 1.7 Obstacles (barriers) in implementing tqm 7 1.8 Benefits of tqm 7 1.9 Contributions of Deming 7 1.10 The juran trilogy 8 1.11 Contributions of Crosby 9 1.11.1 Crosby’s fourteen points 9 UNIT II TQM PRINCIPLES 2.1 Leadership 10 2.2 Characteristics for leadership 10 2.3 Leadership roles 10 2.4 Leaders 11 2.5 Characteristics of quality leaders 11 2.6 Leadership concepts 11 2.7 The 7 habits of highly effective people 11 2.8 Role of senior management 12 2.9 Quality council 12 2.10 Strategic quality planning 13 2.11 Seven steps to strategic quality planning 13 2.12 Quality statements 15 2.13 Customer satisfaction 18 2.14 Customer complaints 19 2.15 Tebouls Model of customer satisfication 21 2.16 Customer retention 23 2.17 Employee involvement 23 2.18 Motivation 23 2.19 Maslow’s hierarchy of needs 24 2.20 Herzberg’s two factor theory 25 Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 2. GE 2022-TQM IV/VII MECHANICAL ENGINEERING iv E.R.SIVAKUMAR,ASSO.PROF 2015-16 2.21 Empowerment 28 2.22 Job enrichment vs job empowerment 28 2.23 Teams 29 2.24 Types of teams 30 2.25 Characteristics of successful teams 30 2.26 Recognition and reward 34 2.27 Effects of recognition and reward system 37 2.28 Performance appraisal 37 2.29 Benefits of employee involvement 37 2.30 Continuous process improvement 38 2.31 The pdca cycle 41 2.32 5-s: housekeeping 45 2.33 Implementing 5-s 48 2.34 Kaizen 49 2.35 Kaizen cycle 49 2.36 Supplier partnership 50 2.37 Partnering 52 2.38 Sourcing 52 2.39 Supplier selection 52 2.40 Supplier rating 53 UNIT III TQM TOOLS & TECHNIQUES - I 3.1 Seven tools of quality 55 3.1.1 Prerequisite discussion 55 3.1.2 Concept 55 3.2 Flow charts 55 3.3 Applications 56 3.4 Histogram 56 3.5 Cause and Effect Diagram 57 3.6 Check sheet 58 3.7 Scatter diagram 59 3.8 Control charts 60 3.9 Pareto charts 60 Glossary 61 1. References 61 2. New Seven management Tools 61 3. Concept 62 4. Affinity diagram 62 5. Procedure 62 6. Applications 65 7. Relations diagram 66 8. Tree diagram 66 9 Matrix diagram 68 10 Matrix data analysis diagram 69 11 Process decision programme chart 72 Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 3. GE 2022-TQM IV/VII MECHANICAL ENGINEERING v E.R.SIVAKUMAR,ASSO.PROF 2015-16 12 Arrow diagram 73 13 Six sigma 75 14 Prerequisite discussion 75 15 Concept 76 16 Dmaic 76 17 Dmadv 77 18 Significance 77 19 Application 77 20 Companies which have adopted six sigma 77 21 Glossary 78 22 References 78 23 Benchmarking 78 24 Benchmarking concept 78 25 Reasons to benchmark 79 26 Process of benchmarking 79 26.1 Decide what to benchmark 79 26.2 Understand current performance 79 26.3 Plan 79 26.4 Types of benchmarking 79 26.5 Study others 79 26.6 Learn from the data 79 26.7 Using the findings 80 27 Pitfalls and criticisms of benchmarking 80 27.1 Significance 80 27.2 Application 80 28 Failure mode and effects analysis (fmea) 81 28.1 Types of FMEA 82 28.2 Benefits of fmea 82 28.3 Fmea documentation 84 28.4 Risk priority number (rpn) 10 85 28.5 Significance 85 28.6 Application 85 28.7 Glossary 88 28.8 References Unit IV TQM Tools and Techniques - II 4.1 Prerequesite discussion 90 4.2 Concept 90 4.3 Improve customer satisfaction 90 4.4 Applications 91 4.5 Quality function deployment 91 4.6 Qfd team 91 4.7 House of quality 94 4.8 The steps in building a house of quality are 94 4.9 The qfd process 95 4.10 Application 96 Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 4. GE 2022-TQM IV/VII MECHANICAL ENGINEERING vi E.R.SIVAKUMAR,ASSO.PROF 2015-16 4.11 Taguchi’s quality loss function 96 4.12 Nominal – the – best 97 4.13 Smaller – the – better 98 4.14 Larger – the – better 99 4.15 Total productive maintenance 99 4.16 What is Maintenance and what is Maintenance Management? 100 4.17 Maintenance development stages 100 4.17.1 Break-down (corrective) maintenance 100 4.17.2 Preventive maintenance (1951) 100 4.17.3 Periodic (routine) maintenance (Time based maintenance - TBM) 101 4.17.4 Predictive maintenance 101 4.18 What is Total Productive Maintenance (TPM)? 101 4.19 Why TPM / The objective of TPM 102 4.20 Six core principles of TPM 102 4.21 Direct Benefits of TPM 103 4.22 Indirect benefits of TPM 103 4.23 Steps in introduction of TPM in a organization 103 4.23.1 Preparatory stage 103 4.23.2 TPM introduction in the organization 103 4.23.3 Initial education and propaganda for TPM 103 4.23.4 Setting up TPM and departmental committees 103 4.23.5 Establishing the TPM working system and target 103 4.23.6 A master plan for institutionalizing 104 4.24 Introduction stage 104 4.25 Implementation 104 4.26 Institutionalising stage 104 4.27 Tpm – pillars 105 4.28 Quality costs 110 4.29 Elements of qualitycost 110 4.30 Analysis of quality costs 110 4.30.1 Prevention cost 110 4.30.2 Appraisal cost 111 4.30.3 Internal failure cost 111 4.30.4 External failure cost 111 4.31 Analysis techniques of quality cost 111 4.32 Trend analysis 111 4.33 Pareto analysis 112 4.34 Index numbers 113 4.35 Performance measures 113 4.36 What should be measured? 114 4.36.1 Human resources 114 4.36.2 Customers 114 4.36.3 Production 114 4.36.4 Research and Development 114 4.36.5 Suppliers 114 Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 5. GE 2022-TQM IV/VII MECHANICAL ENGINEERING vii E.R.SIVAKUMAR,ASSO.PROF 2015-16 4.36.6 Marketing / sales 114 4.36.7 Administration 114 4.37 Strategy 114 4.38 Performance measure presentation 115 Unit V Quality Systems 5.1 Iso 9000:2000 116 5.2 Benefits of iso 9000 standards 117 5.3 CLAUSES (ELEMENTS) OF ISO 9000 (During the year 1987) 118 5.4 CLAUSES (ELEMENTS) OF ISO 9000 (During the year 2000) 119 5.5 Implementation of quality management system 120 5.6 Pitfalls of successful implementation 120 5.7 Documentation 120 5.8 Quality auditing 121 5.9 Purpose of quality audit 121 5.10 Types of quality audit 121 5.11 Iso 14000 – environmental management system 122 5.12 Environmental management system (ems) 122 5.13 Requirement of iso 14001 123 5.13.1 General requirements 123 5.13.2 Environmental policy 123 5.13.3 Planning 123 5.13.4 Implementation & operation 123 5.13.5 Checking & corrective action 123 5.13.6 Managenment review 123 5.14 Benefits of environmental management system 124 5.14.1 Global benefits 124 5.14.2 Organizational benefits 124 Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 6. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 1 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 UNIT – I 1.1 INTRODUCTION 1.1.1 PREREQUISITE DISCUSSIONS Quality is in its essence a way of management of the organization. Quality is conformance to customer requirements. The requirements have many dimensions. The number of quality experts also called quality gurus contributed to the evolution of quality. AN INTRODUCTION: A name itself is sufficient to describe everything but a bit more clarification will add to a base for the description. Total quality management is a management’s approach towards the quality, it can be in regard to products, customer satisfaction and employees satisfaction. The concept of TQM was developed by an American W. Edwards Deming and i.e. why it is called as Deming’s concept of TQM .He introduced this concept for improving the quality of various products and services. Earlier it was just related with the quality of products which a organization is producing but now other concepts like marketing, finance design, customer service has also joined the area. Which means that now good numbers of things are there to manage. TQM works on one belief that mistakes can be avoided and defects can be prevented. And management should believe in watching each and every step. TQM is now a day’s called as TPM (total productivity management) and an organization needs to consider ABCD for the effective application of TQM where A stands for accident cure , B stands for breakdown , C stands for cost reduction and D stands for damage. This policy of ABCD is in relation to product and if TQM needs to be introduced a positive attitude from the side of management and employees is required and then a collective effort will come up. TQM should give chance for unleashing employee’s creativity and potential. The aim of TQM is to reduce variations in quality of the products as well as in the working of whole organization. For the successful implementation of TQM, an organization must consider the commitment from all the level of organization. A concept of Six sigma is a part of TQM. It is a strategy developed by Motorola and it helps to detect the defects and to remove them. TQM talks about the satisfaction of customer, supplier, employees etc. and it requires continuous improvement. If the workers of an organization are efficiently working then their morale will go up. TQM works effectively if the organization works in a family manner. Here management is like a father, employees are the children and manager is like mother and as father and mother takes Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 7. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 2 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 care for their home collectively the same way , management and managers are supposed to take care for their organization with the help of tool called TQM. Total quality management is called total because entire organization is involved, Quality means degree of excellence. And management in literal sense means getting things done by others. In a TQM effort, all members of an organization participate in improving processes, products, services and the culture in which they work. The earlier introduced quality management concept is now taken over by Total quality management. To have effective TQM the first requirement is strong internal motivation and emotional involvement for implementation. So the concept of TQM talks about adopting the new policy, creating quality products, eliminate defects, estimate for breakdown, accidents etc . Hence TQM should be purpose driven so first the whole organization should be willing to accept the change then only TQM can actually affect the organization in a positive way. 1.2. CONCEPT 1.2.1. Need for quality: The need for quality was felt, during World War II due to the unprecedented need for manufacture goods. From them on methodologies for assuring quality in products and services evolved continuously finally lead to TQM. 1.2.2. Evolution of quality (or) GURUS OF TQM: SHEWHART - Control chart theory PDCA Cycle DEMING - Statistical Process Control JURAN - Concepts of SHEWHART - Return on Investment (ROI) FEIGANBAUM - Total Quality Control - Management involvement - Employee involvement - Company wide quality control ISHIKAWA - Cause and Effect Diagram - Quality Circle concept CROSBY - “Quality is Free” Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 8. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 3 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 - Conformance to requirements TAGUCHI - Loss Function concept - Design of Experiments 1.2.3. DEFINING QUALITY: Quality is fitness for use Quality is conformance to requirements Quality is the totality of features and characteristics of a product or service that bear on its ability to satisfy stated and implied needs of customer. Quality can be quantified as follows Q = P / E where, Q = Quality P = Performance E = Expectation 1.3. DIMENSIONS OF QUALITY: ------------------------------------------------------------------------------------------------- Dimension Meaning and Example ------------------------------------------------------------------------------------------------- Performance Primary product characteristics, such as the brightness of the picture Features Secondary characteristics, added features, such as remote control Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 9. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 4 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 Conformance Meeting specifications or industry standards, workmanship Reliability Consistency of performance over time, average time of the unit to fail Durability Useful life, includes repair Service Resolution of problems and complaints, ease of repair Response Human – to – human interface, such as the courtesy of the dealer Aesthetics Sensory characteristics, such as exterior finish Reputation Past performance and other intangibles, such as being ranked first 1.3.1 Dimensions of service quality Reliability Refers to the dependability of the service providers and their ability to keep their promises. Responsiveness Refers to the reaction time of the service. Assurance Refers the level of certainty a customer has regarding the quality of the service provided. Empathy Being able to understand the needs of the customer as an individual. Tangibles Similar to the physical characteristics of quality of products. Other Dimensions Time, Courtesy, Timeliness, consistency, accuracy, credibility and security. Total Quality Management (TQM) is an enhancement to the traditional way of doing business. 1.3.2. Definition of TQM Art of managing the whole to achieve excellence. Total - Made up of the whole Quality - Degree of Excellence a Product or Service provides. Management - Art of handling, controlling, directing etc. TQM is the application of quantitative methods and human resources to improve all the processes within an organization and exceed CUSTOMER NEEDS now and in the future. 1.4. CHARACTERISTICS OF TQM The above definitions revealed the following characteristics of TQM : 1. TQM is a customer oriented. 2. TQM required a long term commitment for continuous improvement of all processes. 3. TQM is teamwork. 4. TQM requires the leadership of top management and continuous involvement. 5. TQM is a strategy for continuous improving performance at all levels and in all areas of responsibility. 1.4.1. Basic Concepts of TQM: 1. A committed and involved management. 2. An unwavering focus on the customer both internally and externally. 3. Effective involvement and utilization of entire work force, Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 10. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 5 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 4. Continuous improvement of the business and production process. 5. Treating suppliers as partners. 6. Establish performance measures for the processes. 1.5. ELEMENTS OF TQM A framework summarizing the important elements of TQM discussed in this text. Three elements of TQM include 1. The philosophical elements of TQM stress the operation of the company using quality as the integrating element. 2. The generic tools consist of various statistical process control (SPC) methods that are used for problem solving and continuous improvement by quality teams. Quality function deployment is typically used by managers to drive the voice of the customer into the organization. 3. Tools of the QC department consists of statistical quality control (SQC) methods such as sampling plans, process capability and Taguchi methods. TQM Frame work: 1. Benchmarking 1. Leadership 2. Six sigma 2. Quality statements 3. Seven Traditional Tools 3. Customer focus 4. New seven management tools 4. Employee involvement 5. FMEA 5. Performance appraisal 6. Quality circle 6. PDSA cycle 7. Quality function deployment 7. 5S 8. Taguchi quality loss function 8. Kaizen 9. TPM 9. Supplier partnership. TQM FRAME WORK QUALITY GURUS TOOLS AND TECHIQUES PRINCIPLES AND PRACTICES Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 11. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 6 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 Approach: Continuous improvement process. Measures: Performance Measures 1.6. PRINCIPLES OF TQM Customer’s requirements must be met the first time, every time. There must be agreed requirements, for both internal and external customers. Everybody must be involved, from all levels and across all functions. Regular communication with staff at levels is must. Two way communication at all levels must be promoted. Identifying training needs and relating them with individual capabilities and requirements is must. Quality Improvement Process Team Work Interpersonal Skills Problem Solving Discipline Employee involvement, Structured, Stepwise, Discipline, Consistency. A P S D Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 12. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 7 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 Top management’s participation and commitment is must. A culture of continuous improvement must be established. Emphasis should be placed on purchasing and supplier management Every job must add value. Quality improvement must eliminate wastes and reduce total cost. There must be a focus on the prevention of problems. A culture of promoting creativity must be established. Performance measure is a must at organization, department and individual levels. It helps to asses and meet objectives of quality. There should be focus on team work. 1.7. OBSTACLES (BARRIERS) IN IMPLEMENTING TQM : Lack of Management Commitment Inability to change Organizational culture Improper planning Lack of continuous training and education Incompatible organizational structure and isolated individuals and departments Ineffective measurement techniques and lack of access to data and results Paying inadequate attention to internal and external customers Inadequate use of empowerment and teamwork Failure to continually improve 1.8. BENEFITS OF TQM: Improved quality Employee participation Team work Working relationships Customer satisfaction Employee satisfaction Productivity Communication Profitability Market share 1.9. CONTRIBUTIONS OF DEMING: 1. Create and publish the Aims and Purposes of the organization. 2. Learn the New Philosophy. 3. Understand the purpose of Inspection. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 13. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 8 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 4. Stop awarding business based on price alone. 5. Improve constantly and forever the System. 6. Institute Training. 7. Teach and Institute Leadership. 8. Drive out Fear, Create Trust and Create a climate for innovation. 9. Optimize the efforts of Teams, Groups and Staff areas. 10. Eliminate exhortations for the Work force. 11a. Eliminate numerical quotas for the work force. 11b. Eliminate Management by objectives. 12. Remove Barriers that rob people of pride of workmanship. 13. Encourage Education and Self-improvement for everyone. 14. Take action to accomplish the transformation. 1.10. THE JURAN TRILOGY Juran views quality as fitness for use. Juran Trilogy is designed to reduce the cost of quality over time. 1. QUALITY PLANNING Determine internal & external customers. Their needs are discovered. Develop product / service features. Develop the processes able to produce the product / service features. Transfer plans to operations. 2. QUALITY CONTROL Control is used by operating forces to help meet the product, process and service requirements. It consists of the following steps 1. Determine items to be controlled. 2. Set goals for the controls. 3. Measure actual performance. 4. Compare actual performance to goals. 5. Act on the difference. 3. QUALITY IMPROVEMENT Aims to attain levels of performance that are higher than current levels. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 14. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 9 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 It consists of the following steps Establishment of quality council. Identify the improvement projects. Establish the project teams with a project leader. Provide the team with the resources. 1.11. CONTRIBUTIONS OF CROSBY: The Four absolutes of quality are 1. Quality is defined as conformance to requirements. 2. The system for causing Quality is prevention. 3. The performance standard must be zero defects. 4. The measurement of Quality is the Price of Nonconformance 1.11.1 Crosby’s Fourteen Points: 1. Management Commitment 2. Quality Improvement Team 3. Quality Measurement 4. Cost of Quality Evaluation 5. Quality Awareness 6. Corrective Action 7. Establish an Ad Hoc Committee for the Zero Defects Program 8. Supervisor Training 9. Zero Defects Day 10. Goal Setting 11. Error Cause Removal 12. Recognition 13. Quality Councils 14. Do It Over Again Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 15. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 10 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 UNIT – II 2.1. LEADERSHIP “Leadership is lifting of man’s visions to higher sights, the raising of man’s performance to a higher standard, the building of man’s personality beyond its normal limitations”. Introduction: The success of quality management is to a greater extent is influenced by the quality of the leadership. Peter Drucker, the eminent management thinker and writer quotes: “Leadership is lifting of man’s visions to higher sights, the raising of man’s performance to a higher standard, the building of man’s personality beyond its normal limitations”. Leadership is the process of influencing others towards the accomplishment of goals. Leader triggers the will to do, show the direction and guide the group members towards the accomplishment of the company’s goal. 2.2 CHARACTERISTICS FOR LEADERSHIP The customers first. Value people. Built supplier partnership. Empower people. Demonstrate involvement/commitment. Strive for excellence. Explain and deploy policy. Improve communication. Promote teamwork. Benchmark continuously. Establish system. Encourage collaboration. 2.3 LEADERSHIP ROLES 1. Producer role. 2. Director role. 3. Coordinator role roles. 4. Checker role. 5. Stimulator role. 6. Mentor role. 7. Innovator role. 8. Negotiator role. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 16. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 11 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 2.4 LEADERS Shape the Organization’s value Promote the Organization’s value Protect the Organization’s value and Exemplifies the Organization values 2.5 CHARACTERISTICS OF QUALITY LEADERS 1. They give priority attention to external and internal customers and their needs. 2. They empower, rather than control, subordinates. 3. They emphasis improvement rather than maintenance. 4. They emphasis prevention. 5. They emphasis collaboration rather than competition. 6. They train and coach, rather than direct and supervise. 7. They learn from the problems. 8. They continually try to improve communications. 9. They continually demonstrate their commitment to quality. 10. They choose suppliers on the basis of quality, not price. 11. They establish organizational systems to support the quality effort. 12. They encourage and recognize team effort. 2.6 LEADERSHIP CONCEPTS A leader should have the following concepts 1. People, Paradoxically, need security and independence at the same time. 2. People are sensitive to external and punishments and yet are also strongly self - motivated. 3. People like to hear a kind word of praise. Catch people doing something right, so you can pat them on the back. 4. People can process only a few facts at a time; thus, a leader needs to keep things simple. 5. People trust their gut reaction more than statistical data. 6. People distrust a leader’s rhetoric if the words are inconsistent with the leader’s actions. 2.7 THE 7 HABITS OF HIGHLY EFFECTIVE PEOPLE: 1. Be Proactive 2. Begin with the End in mind 3. Put First Things First 4. Think Win – Win 5. Seek First to Understand, then to Be Understood 6. Synergy 7. Sharpen the Saw (Renewal) Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 17. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 12 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 2.8 ROLE OF SENIOR MANAGEMENT 1. Management by Wandering Around (MBWA). 2. Strategy of problem solving and decision making. 3. Strong information base. 4. Recognition and Reward system. 5. Spending most of the time on Quality. 6. Communication. 7. Identify and encourage potential employee. 8. Accept the responsibility. 9. To play a role model. 10. Remove road blocks. 11. Study TQM and investigate how TQM is implemented elsewhere. 12. Establish policies related to TQM. 13. Establish ‘priority of quality’ and ‘customer satisfaction’ as the basic policy. 14. Assume leadership in bringing about a cultural change. 15. Check whether the quality improvement programmes are conducted as planned. 16. Become coaches and cheer leaders to implement TQM. 17. Generate enthusiasm for TQM activities. 18. Visit other companies to observe TQM functioning. 19. Attend TQM training programme. 20. Teach others for the betterment of society and the surroundings. 2.9 QUALITY COUNCIL A quality council is established to provide overall direction. The council is composed of Chief Executive Officer Senior Managers Coordinator or Consultant A representative from the Union Duties of the council are Develop the core values, vision statement, mission statement and quality policy statement Develop the strategic long term plan with goals and Annual Quality Improvement Program with objectives Create the total education and training plan Determine and monitor the cost of poor quality Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 18. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 13 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 Determine the performance measures Determine projects those improve the process Establish multifunctional project and work group teams Revise the recognition and rewards system A typical meeting agenda will have the following items Progress report on teams Customer satisfaction report Progress on meeting goals New project teams Benchmarking report Within three to five years, the quality council activities will become ingrained in the culture of the organization. 2.10 STRATEGIC QUALITY PLANNING Goals – Long term planning (Eg : Win the war) Objectives – Short term planning (Eg : Capture the bridge) Goals should Improve customer satisfaction, employee satisfaction and process Be based on statistical evidence Be measurable Have a plan or method for its achievement Have a time frame for achieving the goal Finally, it should be challenging yet achievable 2.11 SEVEN STEPS TO STRATEGIC QUALITY PLANNING In order to integrate quality with the strategic planning process, a systematic and sequential procedure has to be adopted. There are seven basic steps to strategic process planning. They are Step 1. Customer Needs PRESENT VISION OF FUTURE STRATEGIC PLAN Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 19. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 14 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 The basic step is the identification of customers and their wants and needs. An organization must seek its customers’ requirements, expectations and assess future trends before developing a strategic plan. Step 2. Customer Position The second step requires the planners to determine its positioning with regards to its customers. Various alternatives such as whether the organization should give up, maintain or expand market position should be considered. In order to become successful, the organization should concentrate and consolidate its position in its areas of excellence. Step 3. Predict the Future Next, the planners must predict future conditions that will affect their product or service: To help predicting the future, the tools such as demographics, economic forecasts, and technical assessments or projections may be used. Step 4. Gap Analysis In this step, the planners must identify the gaps between the current state and the future state of the organization. This concept is also known as value stream mapping. For identifying the gaps, an analysis of the core values and concepts and other techniques may be used. Customer needs Customer Positioning Predict the future Gap Analysis (Comparison of various alternatives) Closing the gap (selection of best alternative) Alignment Implementation Reevaluated and review Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 20. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 15 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 Step 5. Closing the Gaps Now the planners should develop a specific plan to close the gaps. This process is also termed as Process improvement. By assessing the relative importance and relative difficulty of each gap, planners can close the gaps. Step 6. Alignment Now the revised plan should be aligned with the mission, vision, and core values and concepts of the organization. Organization should embrace quality as an essential ingredient in their vision, mission, and objectives. Step 7. Implementation In order to implement the action plan, resources must be allocated to collecting data, designing changes, and overcoming resistance to change. Also the planners should monitor and assess the result of the strategic plan. Since quality is a continuous improvement process, one has to reassess and renew the strategic plans periodically. So it is a cyclic process. Figure summarizes the strategic planning cycle. 2.12 QUALITY STATEMENTS QUALITY STATEMENTS Three elements of quality statements are : a. Vision statement, b. Mission statement, and Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 21. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 16 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 c. Quality policy statement What is Vision Statement? 1. The vision statement is a short declaration of what on organization aspires to be tomorrow. 2. It is the ideal state that might never be reached; but on which one will work hard continuously to achieve. Successful visions provide a brief guideline for decision making. 3. The vision statement should be coined in such a way that the leaders and the employees working in the organization should work towards the achievements of the vision statement. 4. An example of a simple vision statement is : “To continuously enrich knowledge base of practitioners in mobility industry and institutions in the service of humanity”. – Society of Automotive Engineers (SAE) What is Mission Statement? 1. The mission statement, describes the function of the organization. It provides a clear statement of purpose for employees, customers, and suppliers. 2. The mission statement answers the following questions : who we are?; who are our customers? ; what we do?; and how we do it? 3. An example of a simple mission statement is : “Concern for the ultimate customers – millions of customers Concern for the intermediate customers – the trade Concern for the suppliers – the sources of raw materials and ancillaries Concern for the employees – the most valued asset Concern for the competitors – wishing them well as healthy competition ultimately benefits the customers. Concern for the shareholders – the investing public Concern for the national aspiration – India’s future!” - ITC Limited What is Quality Policy Statement? The quality policy is a guide for everyone in the organization as to how they provide products and service to the customers. It should be written by the CEO with feedback from the workforce and be approved by the quality council. A quality policy is a important requirement of ISO 9000 quality systems. An example of a simple quality policy statement is: “Xerox is a quality company. Quality is the basic business principle for Xerox. Quality means providing our external and internal customers with innovative products and services that fully satisfy their requirements. Quality is the job of every employee”. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 22. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 17 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 VISION STATEMENT It is a short declaration of what an organization aspires to be tomorrow. Example : Disney Theme Park - Happiest place on earth Polaroid - Instant photography Successful visions provide a guideline for decision making MISSION STATEMENT It answers the following questions Who we are? Who are the customers? What we do? How we do it? It describes the function of the organization. It provides a clear statement of purpose for employees, customers & suppliers A simpler mission statement is “To meet customers transportation and distribution needs by being the best at moving their goods on time, safely and damage free” - National Railways QUALITY POLICY STATEMENT It is guide for everyone in the organization as to how they should provide products and services to the customers. Common characteristics are Quality is first among equals Meet the needs of the internal & external customers Equal or exceed competition Continuously improve the quality Utilize the entire workforce Ex: Xerox is a quality company. Quality is the basic business principle for Xerox. Quality means providing our external and internal customers with innovative products and services that fully satisfy their requirements. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 23. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 18 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 2.13 CUSTOMER SATISFACTION WHO ARE THE CUSTOMERS? The customers are : 1. The most important people in the business. 2. Not dependent on the organization. The organization depends on them. 3. Not an interruption to work but are the purpose of it. 4. Doing a favour when they seek business and not vice-versa. 5. A part of business, not outsiders. 6. Life blood of the business. 7. People who come with their needs and jobs. 8. Deserve the most courteous and attentive treatment. Types of Customers Customers are two types. They are : 1. Internal customers, and 2. External customers. 1. Internal Customers 1. The customers inside the company are called internal customers. 2. As there is a flow of work, product and service in the organization, each department is dependent on the other. In this, each department or each quality management unit is considered as a customer by the previous department and as a supplier for the next department. Similarly every person in a process is considered as a customer of the preceding operation. This explains the concept of internal customer. 2. External Customers The customers outside the company are called external customers. In other words, an external customer is the one: who uses the product or service ; who purchases the product or service; or who influences the sale of the product or service. Customer – Supplier Chain In order to achieve the total customer orientation, TQM requires the better customer – supplier relationship. Figure shows the model of customer – supplier chain. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 24. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 19 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 All processes require inputs, which are provided by the internal or external suppliers. Similarly all processes delivers outputs, which are used by internal or external customers. Each unit is considered as a customer by the previous unit and as a supplier for the next unit. Customer satisfaction, a business term, is a measure of how products and services supplied by a company meet or surpass customer expectation. It is seen as a key performance indicator within business and is part of the four of a Balanced Scorecard. In a competitive marketplace where businesses compete for customers, customer satisfaction is seen as a key differentiator and increasingly has become a key element of business strategy. 2.14 CUSTOMER COMPLAINTS Satisfied Dissatisfied customer Totally satisfied customer contributes to monitored. FEEDBACK (INFORMATION COLLECTING TOOLS) Feedback enables organization to Discover customer satisfaction Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 25. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 20 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 Discover relative priorities of quality Compare performance with the competition Identify customer needs Determine opportunities for improvement Listening to the voice of the customer can be accomplished by numerous information collecting tools. 1. Comment Card 2. Customer Questionnaire Highly Neutral Highly Satisfied Dissatisfied 1. Trash removal 5 4 3 2 1 2. Personal hygiene 5 4 3 2 1 3. Romance 5 4 3 2 1 4. Thoughtfulness 5 4 3 2 1 5. Listening skills 5 4 3 2 1 6. Faithfulness 5 4 3 2 1 7. Respect for Mother – in - law 5 4 3 2 1 8. Overall,how satisfied are you with your marriage? 5 4 3 2 1 To make surveys more useful, it is best to remember eight points Clients and Customers are not the same Surveys raise customers expectations How you ask a question will determine how the question is answered The more specific the question, the better the answer You have only one chance and only 15 minutes The more time you spend in survey development, the less time you will spend in data analysis and interpretation Who you ask is as important as what you ask Before the data are collected, you should know how you want to analyse and use the data 3. Focus Groups These groups are very effective for gathering information on customer expectations and requirements. 4. Toll – Free Telephone Numbers 5. Customer Visits 6. Report Card Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 26. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 21 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 7. The Internet and Computers 8. Employee Feedback 9. Mass Customization 2.15 Tebouls Model of customer satisfication USING CUSTOMER COMPLAINTS Actions an organization can take to handle complaints are as follows Investigate customers experiences by actively getting feed back, both positive and negative, and then acting on it promptly Develop procedures for complaint resolution that include empowering front – line personnel. Analyze complaints, but understand that complaints do not always fit into neat categories. Work to identify process and material variations and then eliminate the root cause. “More inspection” is not corrective action. When a survey response is received, a senior manager should contact the customer and strive to resolve the concern. Establish customer satisfaction measures and constantly monitor them. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 27. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 22 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 Communicate complaint information, as well as the results of all investigations and solutions, to all people in the organization. Provide a monthly complaint report to the quality council for their evaluation and, if needed, the assignment of process improvement teams. Identify customers’ expectations beforehand rather than afterward through complaint analysis. SERVICE QUALITY Customer service is the set of activities an organization uses to win and retain customer’s satisfaction. It can be provided before, during, or after the sale of the product or exist on its own. Elements of customer service are Organization 1. Identify each market segment. 2. Write down the requirements. 3. Communicate the requirements. 4. Organize processes. 5. Organize physical spaces. Customer Care 6. Meet the customer’s expectations. 7. Get the customer’s point of view. 8. Deliver what is promised. 9. Make the customer feel valued. 10. Respond to all complaints. 11. Over – respond to the customer. 12. Provide a clean and comfortable customer reception area. Communication 13. Optimize the trade – off between time and personal attention. 14. Minimize the number of contact points. 15. Provide pleasant, knowledgeable and enthusiastic employees. 16. Write document in customer friendly language. Front-Line people 17. Hire people who like people. 18. Challenge them to develop better methods. 19. Give them the authority to solve problems. 20. Serve them as internal customers. 21. Be sure they are adequately trained. 22. Recognize and reward performance. 23. Lead by example. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 28. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 23 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 24. Listen to the front-line people. 25. Strive for continuous process improvement. 2.16 CUSTOMER RETENTION It means “retaining the customer” to support the business. It is more powerful and effective than customer satisfaction. For Customer Retention, we need to have both “Customer satisfaction & Customer loyalty”. The following steps are important for customer retention. 1. Top management commitment to the customer satisfaction. 2. Identify and understand the customers what they like and dislike about the organization. 3. Develop standards of quality service and performance. 4. Recruit, train and reward good staff. 5. Always stay in touch with customer. 6. Work towards continuous improvement of customer service and customer retention. 7. Reward service accomplishments by the front-line staff. 8. Customer Retention moves customer satisfaction to the next level by determining what is truly important to the customers. 9. Customer satisfaction is the connection between customer satisfaction and bottom line. 2.17 Employee Involvement Employee involvement is one approach to improve quality and productivity. It is a means to better meet the organization’s goals for quality and productivity. 2.18 MOTIVATION CONCEPT OF MOTIVATION a. Scott defines, “Motivation means a process of stimulating people to accomplish desired goals.” b. Edwin B. Flippo defines, “Motivation is the process of attempting to influence others to do your will through the possibility of reward.” c. In simple words, motivation is the process of inducing people inner drives and action towards certain goals and committing his energies to achieve these goals. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 29. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 24 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 IMPORTANCE OF MOTIVATION a. Motivation improves employee involvement. b. Motivation promotes job satisfaction and thus reduces absenteeism and turnover. c. Motivation helps in securing a high level of performance and hence enhances efficiency and productivity. d. Motivation creates a congenial working atmosphere in the organization and thus promotes interpersonal cooperation. THEORIES OF MOTIVATION Though there are many theories of motivation, the Maslow’s hierarchy of needs theory and Herzberg’s two factor theory are more important from our subject of view. 2.19 MASLOW’S HIERARCHY OF NEEDS EMPLOYEE WANTS ------------------------------------------------------------------------------------------------- Factor Employee Rating Manager Rating Interesting work 1 5 Appreciation 2 8 Involvement 3 10 Job security 4 2 Good Pay 5 1 Promotion/ growth 6 3 Good working conditions 7 4 Loyalty to employees 8 7 Help with personal problems 9 9 Tactful discipline 10 6 Social Security Self - Actualization Esteem Survival Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 30. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 25 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 (OR) 2.20 Herzberg’s Two Factor Theory This theory is also called motivation-hygiene theory. This theory is based on two factors: 1. Motivation factors or satisfiers, and 2. Hygiene factors or dissatisfiers. Various motivation and hygiene factors are listed in Table. Motivation and hygiene factors Motivation Factors Hygiene Factors Achievement Supervisors Recognition Working conditions The work itself Interpersonal relationships Responsibility Pay and security Advancement and growth Company policy and administration According to Herzberg, maintenance or hygiene factors are necessary to maintain a reasonable level of satisfaction among employees. These factors do not provide satisfaction to the employees but their absence will dissatisfy them. Therefore these factors are called dissatisfiers. On the other hand, motivational factors creates satisfaction to the workers at the time of presence but their absence does not cause dissatisfaction. It can be noted that Herzberg’s dissatisfiers are roughly equivalent to Maslow’s lower levels, and the motivators are similar to the Maslow’s upper levels. Self Actualization Needs Esteem Needs Social Needs Safety Needs (or) Security Needs Physiological (or) Basic Needs Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 31. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 26 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 Thus the knowledge of motivation is required for any organization to understand the utilization of employee involvement. ACHIEVING A MOTIVATED WORK FORCE The building of a motivated work force if for the most part an indirect process. Concepts to achieve a motivated work force are as follows: 1. Know thyself. 2. Know your employees. 3. Establish a positive attitude. 4. Share the goals. 5. Monitor progress. 6. Develop interesting work. Job rotation Job enlargement Job enrichment 7. Communicate effectively 8. Celebrate success. EMPLOYEE SURVEYS Employee surveys help managers assess the current state of employee relations, identify trends, measure the effectiveness of program implementation, identify needed improvements, and increase communication effectiveness. STEP 1 The Quality Council to create a multifunctional team STEP 2 The Team will develop survey instrument STEP 3 Administer the survey STEP 4 Results are compiled and analyzed STEP 5 Determine areas for improvement Employee involvement is creating an environment in which people have an impact on decisions and actions that affect their jobs. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 32. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 27 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 Tell: the supervisor makes the decision and announces it to staff. The supervisor provides complete direction. Sell: the supervisor makes the decision and then attempts to gain commitment from staff by "selling" the positive aspects of the decision. Consult: the supervisor invites input into a decision while retaining authority to make the final decision herself. Join: the supervisor invites employees to make the decision with the supervisor. The supervisor considers her voice equal in the decision process. To round out the model, I add the following. Delegate: the supervisor turns the decision over to another party. Seven Rules of Motivation #1 Set a major goal, but follow a path. The path has mini goals that go in many directions. When you learn to succeed at mini goals, you will be motivated to challenge grand goals. #2 Finish what you start. A half finished project is of no use to anyone. Quitting is a habit. Develop the habit of finishing self-motivated projects. #3 Socialize with others of similar interest. Mutual support is motivating. We will develop the attitudes of our five best friends. If they are losers, we will be a loser. If they are winners, we will be a winner. To be a cowboy we must associate with cowboys. #4 Learn how to learn. Dependency on others for knowledge supports the habit of procrastination. Man has the ability to learn without instructors. In fact, when we learn the art of self-education we will find, if not create, opportunity to find success beyond our wildest dreams. #5 Harmonize natural talent with interest that motivates. Natural talent creates motivation, motivation creates persistence and persistence gets the job done. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 27 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 Tell: the supervisor makes the decision and announces it to staff. The supervisor provides complete direction. Sell: the supervisor makes the decision and then attempts to gain commitment from staff by "selling" the positive aspects of the decision. Consult: the supervisor invites input into a decision while retaining authority to make the final decision herself. Join: the supervisor invites employees to make the decision with the supervisor. The supervisor considers her voice equal in the decision process. To round out the model, I add the following. Delegate: the supervisor turns the decision over to another party. Seven Rules of Motivation #1 Set a major goal, but follow a path. The path has mini goals that go in many directions. When you learn to succeed at mini goals, you will be motivated to challenge grand goals. #2 Finish what you start. A half finished project is of no use to anyone. Quitting is a habit. Develop the habit of finishing self-motivated projects. #3 Socialize with others of similar interest. Mutual support is motivating. We will develop the attitudes of our five best friends. If they are losers, we will be a loser. If they are winners, we will be a winner. To be a cowboy we must associate with cowboys. #4 Learn how to learn. Dependency on others for knowledge supports the habit of procrastination. Man has the ability to learn without instructors. In fact, when we learn the art of self-education we will find, if not create, opportunity to find success beyond our wildest dreams. #5 Harmonize natural talent with interest that motivates. Natural talent creates motivation, motivation creates persistence and persistence gets the job done. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 27 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 Tell: the supervisor makes the decision and announces it to staff. The supervisor provides complete direction. Sell: the supervisor makes the decision and then attempts to gain commitment from staff by "selling" the positive aspects of the decision. Consult: the supervisor invites input into a decision while retaining authority to make the final decision herself. Join: the supervisor invites employees to make the decision with the supervisor. The supervisor considers her voice equal in the decision process. To round out the model, I add the following. Delegate: the supervisor turns the decision over to another party. Seven Rules of Motivation #1 Set a major goal, but follow a path. The path has mini goals that go in many directions. When you learn to succeed at mini goals, you will be motivated to challenge grand goals. #2 Finish what you start. A half finished project is of no use to anyone. Quitting is a habit. Develop the habit of finishing self-motivated projects. #3 Socialize with others of similar interest. Mutual support is motivating. We will develop the attitudes of our five best friends. If they are losers, we will be a loser. If they are winners, we will be a winner. To be a cowboy we must associate with cowboys. #4 Learn how to learn. Dependency on others for knowledge supports the habit of procrastination. Man has the ability to learn without instructors. In fact, when we learn the art of self-education we will find, if not create, opportunity to find success beyond our wildest dreams. #5 Harmonize natural talent with interest that motivates. Natural talent creates motivation, motivation creates persistence and persistence gets the job done. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 33. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 28 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 #6 Increase knowledge of subjects that inspires. The more we know about a subject, the more we want to learn about it. A self-propelled upward spiral develops. #7 Take risk. Failure and bouncing back are elements of motivation. Failure is alearning tool. No one has ever succeeded at anything worthwhile without a string of failures. 2.21 EMPOWERMENT CONCEPT OF EMPOWERMENT Empowerment is the opposite of helplessness or dependency. An empowered person does not feel incapable of doing the things that he considers important for the well-being of his organization. There are no constraints that he perceives to be externally imposed. In other words, being empowered implies that the person acts from a state of autonomy, doing what he knows is the right thing to do under a given set of circumstances. It is understood that empowerment is dependent upon two factors: (i) An individual’s personal choices; and (ii) The organization climate, that can either encourage dependency or foster autonomy. EMPOWERMENT DEFINED 1. According to Webster’s Dictionary, the verb empower means ‘to give the means, ability or authority’. Therefore empowerment in work setting involves giving people the means, ability and authority to do something they have not done before. 2. An operation definition of empowerment: “Empowerment is an environment in which people have the ability, the confidence, and the commitment to take the responsibility and ownership to improve the process and initiate the necessary steps to satisfy customer requirements within well-defined boundaries in order to achieve organizational values and goals.” 2.22 Job Enrichment Vs Job Empowerment Job enrichment is aimed at expanding the content of an individual’s job. But job empowerment focuses on expanding on the context of the job such as its interactions and interdependencies to other functions of the organization. Empowerment is investing people with authority. It’s purpose is to tap the enormous reservoir of potential contribution that lies within every worker. The two steps to empowerment are Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 34. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 29 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 1. To arm people to be successful through coaching, guidance and training. 2. Letting people do by themselves. The principles of empowering people are given below. 1. Tell people what their responsibilities are. 2. Give authority. 3. Set standards for excellence. 4. Render training. 5. Provide knowledge and information. 6. Trust them. 7. Allow them to commit mistakes. 8. Treat them with dignity and respect. Three dimensions of empowerment are Capability Alignment and Trust CHARACTERISTICS OF EMPOWERED EMPLOYEES Some important characteristics of empowered employees, identified by Hubert Rampersad, are that: They feel responsible for their own task. They are given a free hand in their work. They balance their own goals with those of the organization. They are well trained, equipped, creative, and customer oriented. They are critical, have self-esteem, and are motivated. They are challenged and encouraged. They monitor and improve their work continuously. They find new goals and change challenges. Therefore, it is important to empower individuals and teams at all levels of the organization to achieve the continuous improvement process. 2.23 TEAMS Employee involvement is optimized by the use of teams. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 35. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 30 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 A team is defined as a group of people working together to achieve common objectives or goals. Teamwork is the cumulative actions of the team during which each member of the team subordinates his individual interests and opinions to fulfill the objectives or goals of the group. WHY TEAMS WORK 1. Many heads are more knowledgeable than one. 2. The whole is greater than the sum of its members. 3. Team members develop a rapport which each other. 4. Teams provide the vehicle for improved communication. 2.24 TYPES OF TEAMS 1. Process improvement team. 2. Cross – functional team. 3. Natural work teams. 4. Self – Directed / Self – Managed work teams. 2.25 CHARACTERISTICS OF SUCCESSFUL TEAMS : 1. Sponsor 2. Team Charter 3. Team Composition 4. Training 5. Ground Rules 6. Clear Objectives 7. Accountability 8.Well-Defined decision procedure 9. Resources 10. Trust 11.Effective Problem Solving 12. Open Communication 13. Appropriate Leadership 14. Balanced Participation 15. Cohesiveness The effective team should have certain characteristics. These are : 1. Sponsor : In order to have effective liason with the quality council, there should be a sponsor. The sponsor is a person from the quality council, he is to provide support to the organization. 2. Team Charter : A team charter is a document that defines the team’s mission, boundaries, the background of the problem, the team’s authority and duties, and resources. It also identifies the members and their assigned roles – leader, recorder, time keeper and facilitator. 3. Team Composition : The size of the team should not exceed ten members except in the case of natural work teams or self-directed teams. Teams should be diversed by having members with different skills, perspective and potential. Wherever needed, the internal and external customers and suppliers should be included as a team member. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 36. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 31 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 4. Training : The team members should be trained in the problem-solving techniques, team dynamics and communication skills. 5. Ground Rules : The team should have separate rules of operation and conduct. Ground rules should be discussed with the members, whenever needed it should be reviewed and revised. 6. Clear Objectives: The objective of the team should be stated clearly. Without the clear objective, the team functions is not to be effective. 7. Accountability: The team performance is accountable. Periodic status report of the team should be given to the quality council. The team should review its performance to determine possible team process weaknesses and make improvements. 8. Well-defined Decision Procedures: The decision should be made clearly at the right time by the team. 9. Resources: The adequate information should be given to the team wherever needed. The team cannot be expected to perform successfully without the necessary tools. 10. Trust : Management must trust the team to perform the task effectively. There must also be trust among the members and a belief in each other. 11. Effective Problem-Solving : Problem-solving methods are used to make the effective decision. 12. Open Communication : Open communication should be encouraged i.e., everyone feels free to speak in the team whatever they are thinking, without any interruptions. 13. Appropriate Leadership: Leadership is important in all the team. Leader is a person who leads the team, motivates the team and guides the team in a proper direction. 14. Balanced Participation : Everyone in a team should be involved in the team’s activities by voicing their opinions, lending their knowledge and encouraging other members to take part. 15. Cohesiveness: Members should be comfortable working with each other and act as a single unit, not as individuals or subgroups. ELEMENTS OF EFFECTIVE TEAM WORK Main elements of effective teamwork are as follows: 1. Purpose 2. Role and responsibilities 3. Activities 4. Effectiveness Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 37. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 32 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 5. Decisions 6. Results, and 7. Recognition. Figure depicts the seven main elements of effective teamwork. (i) STAGES OF TEAM DEVELOPMENT Each term takes sometime to start functioning effectively towards problem solving. Each team goes through six distinct stages in its development. These are farming, storming, norming, performing maintenance and evaluating. 1. Farming stage : When a team is created, it consist of group of individuals and team work does not exist at this stage. Team’s purpose, members’ roles, acceptance of roles, authority and process of functioning are learnt in the formation process. 2. Storming stage : Initial agreements and role allocations are challenged and re-established at this stage of team development. At this stage, hostilities and personal needs often emerge which may be resolved. 3. Norming stage : During norming stage of team development, formal and informal relationships get established among team members. Openness and cooperation have been observed as signs of team’s behaviour. 4. Performing stage : At this stage, the team starts operating in successful manner. Trust, openness, healthy conflict and decisiveness of a group’s performance can be reached at this stage. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 32 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 5. Decisions 6. Results, and 7. Recognition. Figure depicts the seven main elements of effective teamwork. (i) STAGES OF TEAM DEVELOPMENT Each term takes sometime to start functioning effectively towards problem solving. Each team goes through six distinct stages in its development. These are farming, storming, norming, performing maintenance and evaluating. 1. Farming stage : When a team is created, it consist of group of individuals and team work does not exist at this stage. Team’s purpose, members’ roles, acceptance of roles, authority and process of functioning are learnt in the formation process. 2. Storming stage : Initial agreements and role allocations are challenged and re-established at this stage of team development. At this stage, hostilities and personal needs often emerge which may be resolved. 3. Norming stage : During norming stage of team development, formal and informal relationships get established among team members. Openness and cooperation have been observed as signs of team’s behaviour. 4. Performing stage : At this stage, the team starts operating in successful manner. Trust, openness, healthy conflict and decisiveness of a group’s performance can be reached at this stage. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 32 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 5. Decisions 6. Results, and 7. Recognition. Figure depicts the seven main elements of effective teamwork. (i) STAGES OF TEAM DEVELOPMENT Each term takes sometime to start functioning effectively towards problem solving. Each team goes through six distinct stages in its development. These are farming, storming, norming, performing maintenance and evaluating. 1. Farming stage : When a team is created, it consist of group of individuals and team work does not exist at this stage. Team’s purpose, members’ roles, acceptance of roles, authority and process of functioning are learnt in the formation process. 2. Storming stage : Initial agreements and role allocations are challenged and re-established at this stage of team development. At this stage, hostilities and personal needs often emerge which may be resolved. 3. Norming stage : During norming stage of team development, formal and informal relationships get established among team members. Openness and cooperation have been observed as signs of team’s behaviour. 4. Performing stage : At this stage, the team starts operating in successful manner. Trust, openness, healthy conflict and decisiveness of a group’s performance can be reached at this stage. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 38. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 33 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 5. Maintenance stage : Functioning of team does not deteriorate overtime. At this stage, the performance of teamwork at the earlier stage will be maintained for some period of time. 6.Evaluating stage : At this stage, team’s performance is to be evaluated in view of the set targets. Both self-evaluation and management-based evaluation form this stage of team development. TEAM MEMBER ROLES TEAM LEADER Ensures the smooth and effective operation of the team. Facilitates the team process. Serves as a Contact Point. Organizes the implementation of changes. Prepares the meeting agenda. FACILITATOR Supports the leader. Focuses on the team process. Acts as a resource to the team. Provides feedback to the team. RECORDER Documents the main ideas of the team’s discussion, the issues raise, decisions made, action items etc. Presents the documents and distributes the MOM. Participates as a team member. TIMEKEEPER Ensures that the team maintains the schedule. Participates as a team member. TEAM MEMBER Contributes best, without reservation. Respects other people’s contributions. Listens carefully and asks questions. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 39. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 34 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 Works for consensus on decisions. Supports the decision of the team. Understands and is committed to the team objectives. Respects and is tolerant of individual differences. Acknowledges and works through conflict openly. Carries out assignments. DECISION MAKING METHODS 1. Non-decision. 2. Unilateral decision. 3. Handclasp decision. 4. Minority-rule decision. 5. Majority-rule decision. 6. Consensus. COMMON BARRIERS TO TEAM PROGRESS Insufficient training. Incompatible rewards and compensation. First-line supervisor resistance. Lack of planning. Lack of management support. Access to information systems. Lack of Union support. Project scope too large. Project objectives are not significant. No clear measures of success. No time to do improvement work. 2.26 RECOGNITION AND REWARD RECOGNITION AND REWARD. MEANING: Recognition is a process whereby management shows acknowledgement of an employee’s outstanding performance. Recognition is a form of employee positive motivation. Recognition of Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 40. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 35 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 employees is highly essential as people find themselves in a accepted and winning role. To sustain employee’s interest and to propel them towards continuous improvement, it is essential to recognize the people. This acknowledgement may be of financial, psychological or both in nature. Ways to recognize people Send letters to improve team members when they establish a team thanking them for their involvement. 1. Develop a behind the scenes awards specifically for those whose actions are not usually in the lime light, make sure such awards are in the lime light. 2. Create best ideas of the year booklet and include everyone’s picture name and description of their best ideas. 3. Feature the quality team of the month and put their picture in a prominent place. 4. Honor peers who have helped you by recognizing them at your staff meetings. 5. Let people attend meetings, committees etc; in your place when you are not available. 6. Involve teams with external customers and suppliers, sending them on appropriate visits to solve problems and look for opportunities. 7. Invite a team for coffee or lunch at any time, not necessarily when you need them for something. 8. Create a visibility wall to display information, posters, and pictures, thanking individual employees and their teams, and describing their contributions. 9. When you are discussing an individual or group ideas with other people, peers, or higher management make sure that you give them credit. WHY SHOULD ONE RECOGNISE PEOPLE 1. improve employees morale 2. show the company’s appreciation for better performance 3. create satisfied workplace 4. Create highly motivated workplace. 5. Reinforce behavioral patterns. 6. Stimulate creative efforts. REWARD MEANING: Reward is a tangible one, such as increased salaries, commissions, cash bonus, gain sharing, etc; to promote desirable behavior. TYPES OF REWARDS: 1. Intrinsic rewards 2. Extrinsic rewards Intrinsic rewards are related to feelings of accomplishment of self-worth. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 41. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 36 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 Extrinsic reward are related to pay or compensation issues. INTRINSIC REWARDS 1. Non-monetary forms of recognition to acknowledge achievement of quality improvement goals. 2. Celebration to acknowledge achievement of quality improvement goals. 3. Regular expressions of appreciation by managers and leaders to employees to acknowledge achievement of quality improvement goals. 4. 360 degree performance appraisals feedback from co-workers subordinates to customers is incorporated into performance appraisals. EXTRINSIC REWARDS: 1. Profit sharing 2. gain sharing 3. employment security 4. compensation time 5. individual based performance systems 6. quality based performance appraisals Recognition is a process by which management shows acknowledgement of an employee’s outstanding performance. Various ways for Recognition and Rewards are 1. Recognition can be expressed using verbal and written praise. 2. Rewards may be in the form of certificates and plaques. 3. Reward is normally in the form of cinema tickets, dinner for family etc. 4. The financial compensation (for recognition) can be paid in terms of increased salaries, commissions, gain sharing etc. 5. The efforts of employees can be recognized by promotions, special job assignments etc. 6. A letter of appreciation from the CEO or the Top Management will increase the employee’s involvement. 7. Reward may be delayed but recognition should be in a timely basis. 8. Rewards should be appropriate to the improvement level. 9. People like to be recognized than any reward. 10. Special forms of recognition include pictures on the bulletin board, articles in news letters, letter to families etc. 11. Supervisors can give on-the-spot praise for a job which is done well. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 42. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 37 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 2.27 EFFECTS OF RECOGNITION AND REWARD SYSTEM 1. Recognition and reward go together for letting people know that they are valuable members for the organization. 2. Employee involvement can be achieved by recognition and reward system. 3. Recognition and reward system reveals that the organization considers quality and productivity as important. 4. It provides the organization an opportunity to thank high achievers. 5. It provides employees a specific goal to achieve. 6. It motivates employees to improve the process. 7. It increases the morale of the workers. 2.28 PERFORMANCE APPRAISAL The performance appraisal is used to let employees know how they are performing. The performance appraisal becomes a basis for promotions, increase in salaries, counseling and other purposes related to an employee’s future. IMPORTANCE OF PERFORMANCE APPRAISALS 1. It is necessary to prevail a good relationship between the employee and the appraiser. 2. Employee should be informed about how they are performing on a continuous basis, not just at appraisal time. 3. The appraisal should highlight strength and weakness and how to improve the performance. 4. Employee should be allowed to comment on the evaluation and protest if necessary. 5. Everyone should understand that the purpose of performance appraisal is to have employee involvement. 6. Errors in performance evaluations should be avoided. 7. Unfair and biased evaluation will render poor rating and hence should be eliminated. 2.29 BENEFITS OF EMPLOYEE INVOLVEMENT Employee involvement improves quality and increases productivity because Employees make better decisions using their expert knowledge of the process Employees are better able to spot and pin-point areas for improvement. Employees are better able to take immediate corrective action. Employee involvement reduces labour / management friction. Employee involvement increases morale. Employees have an increased commitment to goals because they are involved. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 43. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 38 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 2.30 CONTINUOUS PROCESS IMPROVEMENT Continuous process improvement is designed to utilize the resources of the organization to achieve a quality-driven culture. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 44. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 39 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 Improvement is made by Viewing all work as process. Making all process effective, efficient and adaptable. Anticipating changing customer needs. Controlling in-process performance using measures such as scrap reduction, control charts etc. Eliminating waste and re-work. Eliminating non-value added activities. Eliminating non-conformities. Using Benchmarking. Incorporating learned lessons into future activities. Using technical tools such as SPC, benchmarking, experimental design, QFD etc Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 45. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 40 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 PROCESS Process refers to business and production activities of an organization. Input / Output Process Model There are five basic ways for improvement. Reduce resources. Reduce errors. Meet or exceed expectations of downstream customers. Make the process safer. Make the process more satisfying to the person doing it. INPUT Materials, Money, Information, Data, etc. PROCESS People, Equipment, Method, Procedures, Environment, Materials OUTPUT Information, Data, Product, Service, etc. OUTCOMES FEEDBACK CONDITIONS Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m

- 46. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 41 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 2.31 THE PDCA CYCLE : PROBLEM SOLVING METHOD 1. IDENTIFY THE OPPORTUNITY Identify the Problem Pareto analysis of external alarm signals. Pareto analysis of internal alarm signals. Proposals from key insiders. Proposals from suggestion schemes. Field study of user’s needs. Comments of key people outside the organization. Customer surveys. Employee surveys. Brainstorming by work groups. Form the Team Team should be selected. Goals and milestones are established. Define the Scope. Criteria for a good problem statement is as follows It clearly describes the problem. It states the effect. It focuses on what is known, unknown etc. It emphasizes the impact on the customer. 2. ANALYZE THE CURRENT PROCESS The objective is to understand the process and how it is currently performed. Step 1 : The team to develop a process flow diagram. Step 2 : The target performance measures are defined. Step 3 : Collection of all available data and information. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 41 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 2.31 THE PDCA CYCLE : PROBLEM SOLVING METHOD 1. IDENTIFY THE OPPORTUNITY Identify the Problem Pareto analysis of external alarm signals. Pareto analysis of internal alarm signals. Proposals from key insiders. Proposals from suggestion schemes. Field study of user’s needs. Comments of key people outside the organization. Customer surveys. Employee surveys. Brainstorming by work groups. Form the Team Team should be selected. Goals and milestones are established. Define the Scope. Criteria for a good problem statement is as follows It clearly describes the problem. It states the effect. It focuses on what is known, unknown etc. It emphasizes the impact on the customer. 2. ANALYZE THE CURRENT PROCESS The objective is to understand the process and how it is currently performed. Step 1 : The team to develop a process flow diagram. Step 2 : The target performance measures are defined. Step 3 : Collection of all available data and information. GE 2022 TQM IV/VII MECHANICAL ENGINEERING 41 E.R.SIVAKUMAR ,ASSO.PROF/MECH 2015-2016 2.31 THE PDCA CYCLE : PROBLEM SOLVING METHOD 1. IDENTIFY THE OPPORTUNITY Identify the Problem Pareto analysis of external alarm signals. Pareto analysis of internal alarm signals. Proposals from key insiders. Proposals from suggestion schemes. Field study of user’s needs. Comments of key people outside the organization. Customer surveys. Employee surveys. Brainstorming by work groups. Form the Team Team should be selected. Goals and milestones are established. Define the Scope. Criteria for a good problem statement is as follows It clearly describes the problem. It states the effect. It focuses on what is known, unknown etc. It emphasizes the impact on the customer. 2. ANALYZE THE CURRENT PROCESS The objective is to understand the process and how it is currently performed. Step 1 : The team to develop a process flow diagram. Step 2 : The target performance measures are defined. Step 3 : Collection of all available data and information. Visit : www.Civildatas.com Visit : www.Civildatas.com Visit : www.Civildatas.com w w w . C i v i l d a t a s . c o m