ANPARA THERMAL POWER

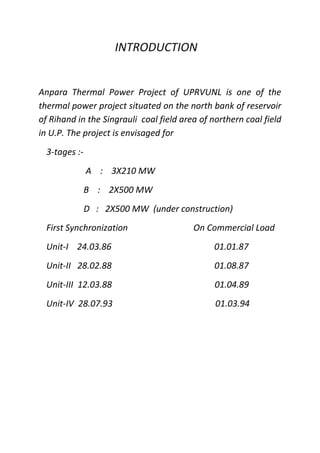

- 1. INTRODUCTION Anpara Thermal Power Project of UPRVUNL is one of the thermal power project situated on the north bank of reservoir of Rihand in the Singrauli coal field area of northern coal field in U.P. The project is envisaged for 3-tages :- A : 3X210 MW B : 2X500 MW D : 2X500 MW (under construction) First Synchronization On Commercial Load Unit-I 24.03.86 01.01.87 Unit-II 28.02.88 01.08.87 Unit-III 12.03.88 01.04.89 Unit-IV 28.07.93 01.03.94

- 2. U.P.R.V.U.N.L. ANPARA SONEBHADRA (U.P.) A PROJECT REPORT ON BOILER MAINTENANCE DIVISION SUBMITTED TO: SUBMITTED BY: Er. SANJAY KUMAR PATEL AJAY KUMAR TIWARI EXECUTIVE ENGINEER B.TECH. (ME),IIIrd year B.M.D.-II B.T.P.S A.E.C,AGRA

- 3. Anpara Thermal Power Station Plant Location The Anpara Power Plant is located near village Anpara on the bank of Rihand reservoir in the district of Sonebhadra (Uttar Pradesh). it is about 34 km from Rihand Dam on Pipri-Singrauli road and about 200 km from Varanasi. Varanasi is connected by air/rail and road route from other major cities. Generating Units at Anpara Thermal Power Station All the units of Anpara TPS are coal-fired thermal power plants, having a total generating capacity of 1630 mw and consists of following units – Stag e Unit No. Original Capacity Derated Capacity Date of First Commissioning Original Equipment Manufacturers 1 1 210 MW 210 MW 24.03.1986 M/S BHARAT HEAVY ELECTRICALS LTD. 2 210 MW 210 MW 28.02.1987 -DO- 3 210 MW 210 MW 12.03.1988 -DO- 2 4 500 MW 500 MW 19.07.1993 M/S MITSUBISHI CORPN. JAPAN 5 500 MW 500 MW 04.07.1994 -DO- The coal to all these units is fed from Kharia, Kakri and Bina open coal mines of NCL, by means of a marry-go-round system, maintained by UPRVUNL.

- 4. UNIT OVERVIEW Following figure is the Unit Overview of ‘B’ Anpara Thermal Power Plant which is unit 4 and unit 5 generates 2 X 500 MW. It means these units two machine of 500 MW. Following figure is the Overview of one unit. Figure of Unit Overview

- 5. IMPORTANT TERM AND THEIR FUNCTION 1). C.E.P.(Conensate Exaction Pump):- It is used to pump the condensate water from condenser to L.P.H.S. through C.P.P. 2). C.P.P.(Condensate Polishing Plant):-It is used to polish the condensate water by the process of ion exchange and filtration of corrosion product. 3). L.P.H.S.(Low Pressure Heater System):- It heat the water at low pressure. The water is in liquid form. 4). Deaerator:- It is used to remove oxygen from the water. 5). B.F.P.(Boiler Feed Pump):- Boiler feed pump is used to feed water to steam generator boiler drum to desired pressure and temperature. i). T.B.F.P.(Turbo Boiler Feed Pump):- It work with the steam from Intermediate Pressure (I.P.) turbine exhast. ii). M.B.F.P.(Motorised Boiler Feed Pump):-It work with the motor as name specifies. 6). H.P.H.S.(High Pressure Heating System):- It feed the heat water at very high pressure. This provide the good mechanical properities at high temperture. 7). Boiler:- It is with the large number of tube running feed water in it and heated with burner. 8). Turbine:- It is parts where steam is flow through blades of turbine and make shaft to move. i).H.P.:- It work with heat pressure steam. ii). I.P.:- It work with Intermediate pressure steam. iii). L.P.:- It work with low pressure steam. 9). Generator:- Moving shaft work as mechnical energy and convert it to electrical energy by generator 10). Condenser:- It than convert the steam to the water. 11). E.S.P.(Electrostatic percipitate):- It used to filter the ash coming from the economizer to the chimney where dust is stick to anode. 12). F.D. Fan (Force Draft Fan):- It is use to provide atmospheric air to furnance. 13). P.A. Fan (Primary Draft Fan):- It is used to transfort coal from the mill to the furnance. 14). I.D. Fan (Induced Draft Fan):- It is used to Push the Flue Gas out from the chimneys.

- 6. DESCRIPTION OF THE CYCLE 1. The energy used to heat the feed water is usually derived from steam extracted between the stages (distance of the one rotor blade and stationary blade is one stage) of the steam turbine. Therefore, the steam that is used to perform the expansion work in the turbine (and therefore generate power) is utilized for that purpose. The percentage of total cycle steam mass flow used for the feed water heater is termed as the Extraction Fraction. Increase in this cause a decrease in turbine power output. 2. Feed water heaters can also be open and close Heat Exchangers. An open feed water is merely a direct contact heat exchanger in which extracted steam is allow to mixed with the feed water. This kind of heater normally required a feed pump at both inlet and the outlet since the pressure in the heater is between the boiler pressure and the surface condenser pressure. A deaeartor is special case of the open feed water heater which is specifically designed to remove non-condensable gases from the feed water. 3. Closed feed water heater are typically shell and tube type heat exchanger where the feed water passes through the tubes and is heated by the turbine extraction steam. This do not require separate pumps before and after the heater to boost the feed water to the pressure of the extracted steam (which is almost fully condensed after heating the feed water) must be throttled to the condenser pressure, an isenthalpic process that results in the some entropy gain with a slight penalty on overall cycle efficiency. 4. Many power plants incorporate a number of feed water heaters and may use both open and closed components. 5. Feed water is also used in both fossil and nuclear fuelled power plant. An economizer serves a similar purpose to a feed water heater, but is technically different. Instead of using actual cycle steam for heating, it uses the lowest temperature Flue gas from the furnace to heat the water before it enters the boiler proper. This allows for the heat transfer between the furnace and feed water to occur across a smaller average temperature gradient (for the steam generator as a whole). System efficiency is therefore further increased when viewed with respect to the actual energy content of the fuel.

- 7. ACKNOWLEDGEMENT A summer project is a golden opportunity for learning and self- development. I consider myself very lucky honoured to have so many wonderful people lead me through in completion of this project. My grateful thanks to Er SANJAY KUMAR PATEL, Executive Engineer and Mr AMIT RANJAN, Assistant Engineer who in spite of being extraordinarily busy with his duties, took time out to hear, guide and keep me on the correct path. I do not know where I would have been without him. A humble ‘Thank you sir’. Last but not the least there were so many who shared valuable information that helped in the successful completion of this project. AJAY KUMAR TIWARI B-TECH (ME), IIIrd year A.E.C. ,AGRA

- 8. CERTIFICATE This is to certify that Mr. AJAY KUMAR TIWARI doing B.Tech. (Mech. Engg.) IIIrd year from ANAND ENGG. COLLEGE ,AGRA (Uttar Pradesh) has completed his vocational training from Anpara Thermal Power Station, Anpara, Sonbhadra (U.P.) from 15.06.2013 to 15.07.2013. His area of training is BMD - II. This training was carried out under the guidance of Mr. SANJAY KUMAR PATEL (Executive Engineer BMD-II). During this period he has been punctual, sincere in his job & has undergone the learning process with responsibility and sense of purpose. He also bears a very good character. We wish him 'All The Best' for his bright future. GUIDED BY: PREPARED BY: Er. SANJAY KUMAR PATEL AJAY KUMAR TIWARI EXECUTIVE ENGG. BTECH(ME)- III YR BMD-II BTPS AEC,AGRA

- 9. CONTENTS 1. Introduction 2. Anpara Power Project (In One Sight) 3. ATPS Achievements 4. Unit Overview 5. Boiler Maintenance Division - I A. Boiler 1.1 Steam Drum 1.2 Furnace Water Wall 1.3 Super heater, Re-heater 1.4 Economizer 1.5 Air Pre-heater 1.6 Boiler Circulation Pump (BCP) 2.1 Maintenance testing of boiler Bottom Ash Disposal 2.2 Furnace Purge Condition B. Electrostatic Precipitator (ESP) C. Submerged Screw Conveyer (SSC) 6. Diagrams

- 10. DECLARATION This is to hereby declare that I studied in B.Tech (Mechanical Engineering) III Year from ANAND ENGG. COLLEGE,AGRA (Uttar Pradesh), that I have completed my summer training from Anpara Thermal Power Station with full dedication & devotion. I have completed my work without using any unfair means. It was a real learning experience gaining partial knowledge. AJAY KR. TIWARI

- 11. UNIT OVERVIEW ‘B’TPS is worked on the modified rankine cycle. In ‘B’TPS there are 2 units namely 4 & 5.The capacity of each unit is 500 MW Here outlet steam of L.P.TBN goes condenser where this steam condense & becomes condensate. Also there is a provision of makeup DM water the level. Condensate is extract from the condenser by CEP. There are three CEP in which one is in reserve & other two are working in position. CEP force the condensate to CPP for improving the quality of the condensate. After that this condensate goes to the LP heaters for initially heat up. There are three LP heaters. The outlet of 3rd LP heater goes to boiler feed, initially to the M-BFP & in running to the T-BFP discharge of T-BFP goes to HP-HTRS. There are four HP heaters and discharge of HP HTR 6B & 5B goes to the economiser which is in the boiler furnace. After economiser, feed water goes to the boiler drum where steam is collect on the upper portion & water on the lower portion which is circulated by BCP (3:1 in reserve). From boiler drum, steam is goes to the super heater where steam becomes super heat & after that goes to the HP TBN which of 4 stages. After that goes it to the re- heater, where it reheat & goes to IP TBN which of 5 stage. From IP TBN, steam goes to the LP TBN inlet where it expands & TBN convert heat energy to mechanical energy which is further converted into electrical energy by generator.

- 12. HIGH PRESSURE HEATER These are placed between the boiler feed water pump and the boiler. The tube material varies depending on your nuclear power plant’s need, although the standard is seamless low alloy carbon steel. This provides good thermal conductivity as well as good mechanical properties at high temperatures. Working of High Pressure Heater There are two trenches of HP heater 5A & 6A are in one trench where HP heater 5B & 6B are in other trench. The feed water flows through the tubes of HP heaters. For changing HP heater from water side one no. filling valve is provided for each trench of heater. For changing of HPH-5 & 6 from steam side at load on machine approximately 20%, extraction steam valve shall be opened gradually and slowly to avoid the hammering. Technical Data:- S.No. Description HPH-5 HPH-6 1. Condensing zone 529 m2 718 m2 2. Overall area 755 m2 915 m2 3. Drain cooling zone 131 m2 88 m2 4. Water velocity in tube 1.96 m/sec 1.96 m/sec 5. Design water flow 7224.48 T/hr 7224.48 T/hr 6. Tube size:ODXTh.mm 15.875X2.11 15.875X2.413 7. No.of tubes 1037 1037

- 13. LOW PRESSURE HEATER These are placed between main condensate extraction pumps and the boiler feed water pumps and consist of a U-Tube bundle heat exchanger mounted in a tube sheet and surrounded by a steam shell. Stainless steel is often used to protect against corrosion and erosion while longitudinal welding allows thin tube wall to produced. Low pressure heater is installed after condensate extraction pump and in the same way it heats the water but it takes the same extraction from the LP turbine. Working of Low Pressure Heater All the heaters are designed for horizontal mounting, surface type, having S.S.U-tube. Condensate water flow inside the tube and heating steam washes the tube system from outside in the shell of LP Heater. LPH-1 is located inside the condenser. LPHS should be charged from water inside by opening of their inlet and outlet valve. For charging of LPH-2 & 3 from steam side at load on machine approximately 20%, extraction steam valve shall be opened gradually and slowly to avoid the hammering Technical Data:- S.No. Description LPH-1 LPH-2 LPH-3 1. Condensing zone 1060 m2 1944 m2 860 m2 2. Overall zone 1060 m2 1060 m2 920 m2 3. Drain cooling zone Not provided 116 m2 60 m2 4. Water velocity in tube 1.98 m/s 1.68 m/s 1.85 m/s 5. Design water flow 1052.43 T/hr 1265.10 T/hr 1265.10 T/hr 6. Tube size ODXTh.mm 16X0.889 19.05X0.889 19.05X0.889 7. No. of tube 931 895 814

- 14. DEAERATOR It is cylindrical, spray and tray type deaerator of adequate capacity for limiting non-condensed gases to 0.005 cc/lit (at storage tank). It acts as a heater in regenerative system. It is in two parts i.e. deaeretion chamber and storage tank. The condensate water sprayed on trays of deaerator through nozzles. In the separate part of steam, so that the saturation temperature is virtually reached. The non-condensable gases accumulated the spray and escape via the discharge in the atmosphere. Initially deaerator is charged from auxiliary steam being kept on auto mode with a pressure of 0.3 kg/cm2 and after approximately 20% load on machine, is changed from turbine extraction. Technical Data:- 1.Deaerator:- Type: Cylindrical, spray & tray Condensate inlet quantity: 1337.7 T/hr , Overall length: 10275 mm, Dia X Thickness:( 3040X20 )mm, Spray valve : 108 nos., Capacity: 15 T/hr. Per valve 2.Feed storage tank:- Horizontal, cylindrical shell, Capacity at operating level: 330 m2 , overall length: 42236 mm, Dia X Thickness:(3600X25) mm, Two nos. Deaerator vent silenser provided of size 250 mm & flow rate 300 kg/hr. 3.Deaerator Recirculation Pump:- Horizontal centrifugal type having capacity: 318 m3 /hr, Total Head: 19 M WC, Speed: 1450 rpm, Suction/Discharge bore: Nb 150/Nb 200mm.

- 15. BOILER FEED PUMP Boiler feed pump is used to feed water to steam generator boiler drum at desired pressure and temperature. Need Of Boiler Feed Pump As the water is feed to the steam generator it has to be at the temperature & pressure that of the steam generator. Process Of Water Flow Boiler feed pump extract water from deaerator and feed it to the boiler drum via HP heater and economizer. General Configuration Of Boiler Feed Pump Generally 2 turbine driven boiler feed pump (1 working & 1 standby) & 2 motor driven boiler feed pump is used for 1 unit. Turbine Driven Boiler Feed Pump:- It works with the steam extraction from intermediate pressure (IP) turbine exhaust. Motor Driven Boiler Feed Pump:- It works with a motor as the name specifies.

- 16. BOILER Boiler wide subject the study of boiler is continue. Boiler Pressure Part & Steam Production Boiler Pressure parts include:- > Economizer > Evaporator > Super heater > Re heater > Boiler drum Drum Type Sub Critical Boiler Feed water heating takes place in economizer to raise its. temperature safely lower than the saturation temperature. Steam generator takes place in furnace water walls. Steam-water separation takes place in the drum. Temperature of separated steam increases in super heaters. After expansion in HP Turbine, steam increases to same temperature in the re heater. Circulation system can also loosely be defined as the combination of equipments and processes for maintaining differential pressure throughout the water/steam path. For a sub critical boiler, the system is consisted of drum, down comers, ACP, Ring Header, Evaporator (water wall), Evaporator outlet Header, Riser tube etc and for a super critical boiler, the system is consider of BFP, Economizer and Super Heater.

- 17. ACHIEVEMENTS Following achievements of Anpara Thermal Power Station Anpara Sonebhadra (U.P) are given bellow:- 1. President of India awarded consecutively for years 1989,1990,1991 & 1992-1993 2. Highest unit P.L.F. unit-1 Dec.1988, 97% with 150.90 M.U. generation. 3. Highest unit power load factor unit-2 Nov.1989, 95.67%, with 144.65 M.U. generation. 4. Highest unit P.I.F. unit-3, Oct.1993, 94.67%, with 148.37 M.U. generation. 5. Highest STN P.L.F. (with two units 2&3) Oct.1993, 61.77% with 289.54 M.U. generation. 6. Highest one day STN P.L.F. on 11.12.1993, 100.07% with 15.1308 M.U. generation. (unit 1,2&3). 7. Highest station P.L.F. on Dec.1993, 90.02% with 421.96 M.U. generation (unit 1,2&3) 8. Min. monthly oil used in Feb.1992, 0.33 KI/M.U. 9. First 500 M.W. load on unit-4 achieved at 10.17 hrs. On 30.12.1993 & full load trial operation completed on 24.02.1994.

- 18. ANPARA THERMAL POWER (IN ONE SIGHT) ‘A’TPS ‘B’TPS Project cost Rs.721 crores Rs.4100 crores Capacity 3X210 MW 2X500 MW Generation per year (M.V) 72% P.L.F 4500 6300 Boiler & its helpful instruments B.H.E.L Mitsuibishi TBN, generator & its helpful instruments K.W.U (B.E.H.L) Toshiba(Japan)& B.H.E.L Coal Plant E.P.J. & M.A.M.C F.C.B.Applewage (france) Ash Disposal B.S.B.K Webcock (UK) Water treatment & chlorification Drislacs & Simplacs P.W.T.(UK) CW & its cooling system Voltas & B.S.T. B.E.H.L Coal used yearly 272 mill.Ton 4 mill.Ton(E-grade) Avg.calorific value of coal 4260 Kcal/kg 4458 Kcal/kg Coal of min grade used 3188 Kcalkg Cal.value 150 It/hr.(F.I) 447 ton/hr.(F.I) Ash storage limit 99.70% 99.876% Height of chimney 220 mt 275 mt Ash disposal/year 0.816 mill.Ton 1.3 mill.Ton

- 19. BOILER MAINTANANCE DEVISION-I Boiler:- A steam generator or boiler is usually a closed vessel made of steel. Its function is to transfer the heat produced by the combustion of fuel (solid, liquid & gaseous) to water and ultimately to generate steam. In this plant boiler is hanged at 79mt. above from bottom with vent house, boiler have two pass. There are used high pressure, vertical, forced circulation water tube boiler in ‘B’TPS. Steam Drum:- Steam drum is cylindrical drum in which steam is collecting at the top portion of water level. There are used one boiler drum. It have diameter of 1780 mm I.D. and overall length between welded line is 21500mm. It have 92 nos of turbo separator. Furnace water wall:- Water wall have no. of bundle of tube (water) in which water circulates. This is of water cooled welded wall hopper bottom type. Dimensions of furnace water is given below such as:- width, depth & volume are 17907mm, 15330mm & 14300 mm3 respectively. Heating surface of FWW have radiant convective type & EPRS (EPRS is including panel, platen super heaters). So dimension of radiant heating surface & convective heating surface are 5120 m2 & 1090 m2 . So total heating surface is 6310 m2 and dimension of EPRS is 7030 m2. Heat loading of BMCR is realising heat from furnace & showing the cooling of furnace. In this furnace heat release rate 92100 Kcal/hrm3 &furnace cooling factor rate 187000 kcal/hrm3 . Description –furnace walls are composed of 50.8 mm O.D reflects tube on 63.5mm centres. The space between fin welded to form a complete gas tight seal.

- 20. Super heater:- A super heater is an important device of steam generating unit. Its purpose is increased the temperature of saturated steam without raising, it is placed in the path of hot flue gases from the furnace. Super heater is design at a pressure of 205 kg/cm2 . Steam temperature control by the spray control method & its range about 60 to 100% BMCR. Roof extended side wall & rear pass wall is of steam cooled type. Primary super heater are of pentant panel type. The amount of heating surface at roof , extend side wall & rear panel wall is 2510 m2 . The amount of heating surface at primary, secondary & tertiary and final super heater are 6550m2 , 2250m2 , 2410m2 & 2540m2 respectively, so total amount of surface is 16260m2 . Re-heater:- The steam goes from outlet of HP TBN to re-heater where it re-heat & goes to IP turbine. Re-heater is designed at pressure 51 kg/cm2 . Steam temperature is controlled by excess air ratio, burner till & spray control method and its range is 60 to 100 % BMCR. Primary re-heater are of pendant space type. The area of heating surface by primary , secondary & tertiary re-heaters are 1040m2 , 3030m2 & 2880m2 , so total heating surface is 6950m2 . Economizer:- It is used to heat the feed water by utilising the heat in the exhaust fuel before leaving the chimney. The economizer improving the efficiency of steam boiler, this is designed at pressure of 208.5 kg/cm2 . Economizer is of base tube in line arrangement horizontal type.

- 21. Air preheater:- 1.primary air preheater- Type of primary air preheater is Ijungstron type with vertical shaft. Size of this is 26-vix-1625 there are used two no. of air preheater heating surface per air preheater is 12520m2 . 2.Secondary air preheater- Type of this Ijungstron type with vertical shaft size this is 30-vix-2300. There are used of no. of air preheater. Heating surface per air preheater is 38190m2 . Boiler circulation pump:- Boiler circulation pump is connected between the suction manifold & water wall bottom header. Boiler circulation pump is pumped the water and increased the pressure by water goes from the suction manifold to water wall bottom header and bottom to steam drum. Since boiler is forced circulation boiler then the BCP is required by the pumping the from suction manifold to water wall bottom header. Maintenance testing of boiler bottom ash disposal system:- Ash hopper- Ash hopper quenching valve(nozzle) should be open. Checkout the leakage of oil with hydraulic system of AHG. Seal Truf- Seal truf make up water valve should be open & over flow water should be fall down with truf. Cleaning of dust of seal truf. Screw conveyor & Clinker Grinder- Checkout tension of chain of screw conveyor. Tightness of bracket boll of flight bar in each shift. For cleaning of conveyor chain, cleaning of spray jet. Cleaning of overall flow tank Testing of segment of clicker grinder.

- 22. For gressing of bearing of SSC & clinker grinder one time in each week. Checkout temperature of SSC, bearing of clinker grinder & hydraulic motor. Hydraulic Power Pack- Checkout level of oil of HPP & temperature of HPP. Cooling water valve should be opened. Removing of leakage of oil from pipe line & machine of HPP. Checkout the reading of all pressure gauge at HPP. Removing leakage of oil with hydraulic oil pumps. Water should not fall down on any electrical instruments. Cleaning of HPP pack & all related instruments daily. Chain tensioner- Pressure oil hydraulic chain tension should not be less than 22 kg/cm2 . Level of oil tank of chain tensioner should not be less than decided sign & oil should not leakage with system. Valve- The leakage of oil & water from all valve of all instruments. Liner plate & nozzle in drain trench should be in good position. Furnace Purge Condition:- BMS power normal. No boiler trip command. Fuel oil shut off valve closed. Fuel oil leak check valve closed. All burner valves closed.

- 23. Fuel oil supply pressure proper. All feeders stopped. All mills stopped. All flame scanner no flame. Any flame scanner fan started. Ail flow (30%). One IDF/FDF running. Any secondary APH started. All aux air dampers modulating. Any BCP pressure normal. Drum level normal. Electro static precipitator:- Electro static precipitator is device used to collecting the ash from the mixture of fuel gas & ash by ID fan, gas induced after that it goes to the chimney by ESP 99.876% ash is removed. Fly ash fall down at bottom of hopper. It goes outside in the form of slury. Submerged Screw Conveyor:- Screw conveyor is rotating part which submerged in water tank 85% of fly ash goes in ESP & 15% of fly ash goes in SCC, which are heavy particles. It makes a from clinker and after that it goes outside.

- 24. MILL In the coal mill, coals breaks into small particles. From coal bunker coal goes in feeder A & B by motorised valve. After that in the screw conveyor & from screw conveyor, it goes in the tube mill. Which have 80 tons coal in the tube mill, ball of 875 gm. The mixture of hot & cold air from primary air fan goes by screw conveyor in the tube mill & all coal small particles goes in the burner 1,2,3,4. The temperature of hot air is 293.90 c. There are connected two sealing air fan for sealing air. LP pumps is also connected to screw conveyor. There are connected two HP pumps such as HP-1 & HP-2 for BRG and ball & sockets. All system of conveyor & tube mill connected to motor of 600 rpm reduced gear is connected to motor for reducing the speed at 120 rpm. And pinion is connected for rotating the screw conveyor at 16 rpm. Parts of mill:- 1. Coal bunker 2. R.C. feeder 3. Screw conveyor 4. Mill drum 5. Ball 6. Motor 7. Reducer 8. Pinion

- 25. Maintenance Testing:- Lubrication system of main bearing of mill. Main reduces lubrication system. Auxiliary reducer lubrication system. Maintenance testing of R.C. feeder & sealing air fans. Used Lubricants:- 1. Main bearing oil (servomas S.P.400 unit 1800 It) 2. Main reducer & auxiliary reducer lubricant oil (servomas S.P.220 unit 180 It & 75 It) 3. Girth gear greesh (servotech-40) 4. Pinion bearing / screw conveyor / seal air fan & R.C. feeder bearing (servo jam EP-2) Running Condition on Mill:- 1. Motor wind temperature R=65o c 2. Motor wind temperature Y=62o c 3. Motor wind temperature B=63o c 4. Motor wind temperature R=165o c

- 26. UNIT ELECTRICAL OVER VIEW From generator we have 21 KV power which goes from transformer and stepup at 400 KV. Current goes by pass bus in the main bus 1 & 2. Scoop tube control system- Scoop tube control system consisting of control drive scoop tube itself fitted to the end of input shaft on the hydraulic coupling casting. The control driver responding to control signal produce 0 to 90 degree rotary angles and these angular change are directly transmitted to scoop tube. Power Transmission Element:- The rotary part is made up of output member and input member. The runner and impeller have flat vanes. The impeller is forced to input shaft and the runner connected to the output shaft by means of flanged joints. Speed Reduction Gear:- The runner is connected to pinion, which engages with wheel at all times. The wheel is connected at its shaft and I.D. fan by way of gear coupling. The main shaft is integral with boss and is fixed to the main boss by means of rivets.