Resume

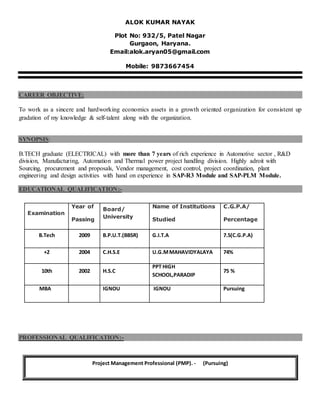

- 1. ALOK KUMAR NAYAK Plot No: 932/5, Patel Nagar Gurgaon, Haryana. Email:alok.aryan05@gmail.com Mobile: 9873667454 CAREER OBJECTIVE: To work as a sincere and hardworking economics assets in a growth oriented organization for consistent up gradation of my knowledge & self-talent along with the organization. SYNOPSIS: B.TECH graduate (ELECTRICAL) with more than 7 years of rich experience in Automotive sector , R&D division, Manufacturing, Automation and Thermal power project handling division. Highly adroit with Sourcing, procurement and proposals, Vendor management, cost control, project coordination, plant engineering and design activities with hand on experience in SAP-R3 Module and SAP-PLM Module. EDUCATIONAL QUALIFICATION:- PROFESSIONAL QUALIFICATION:- Project Management Professional (PMP). - (Pursuing) Examination Year of Passing Board/ University Name of Institutions Studied C.G.P.A/ Percentage B.Tech 2009 B.P.U.T.(BBSR) G.I.T.A 7.5(C.G.P.A) +2 2004 C.H.S.E U.G.MMAHAVIDYALAYA 74% 10th 2002 H.S.C PPT HIGH SCHOOL,PARADIP 75 % MBA IGNOU IGNOU Pursuing

- 2. PROFESSIONAL WORK EXPERIENCE 1. Organization : Giesecke & Devrient Group, Gurgaon Established in 1852, G&D is one of the world's largest German based Company having 31 worldwide Affiliates in the field of bank note printing, Cash center automation, Cash counting machine etc. Role : Deputy Manager- Strategic Purchase (R&D division) Duration : Aug 2016 – Till date Key Responsibilities: Strategic procurement , LCCS(low cost country sourcing), Best cost country sourcing(BCCS). Support R&D team throughout PLM cycle . Managing Contracts like NDA, Business compliance questionnaire , QA Agreement, SLA, MSA,ABG,PBG etc.. Support R&D team in ongoing product development which includes sourcing, procurement, product certification(RoHs, CE, GS etc.) etc. Manages the sourcing deals, contracts, delivery and quality for a complete procurement cycle, ensuring the commercial and cost saving benefits are realized at the development level and ensuring on time delivery with the suppliers.. Identifies opportunities for operational excellence and cost saving in the areas of subcontracting jobs. Deliver significant Monthly cost saving and cost avoidance report , which positively impact net profit margin to the organization. Cross functional discussions to understand the budget requirement and allocation and drive the procurement chain in line to this. Review and assess total supply chain risk and identify opportunities to minimize and eliminate risk . Interview, select, train, manage, and appraise the performance of associated personnel , Design and implement team building exercises Supplier key account management(SKAM).

- 3. 2. Organization : AVL India Pvt Ltd ,Gurgaon Established in 1948, AVL is the world's largest independent Automotive Austria based Company having 45 worldwide Affiliates for the development of powertrain systems with internal combustion engines as well as instrumentation and test systems. AVL is acting in the following scopes of business: Development of Powertrain Systems: AVL develops and improves all kinds of powertrain systems and is a competent partner to the engine and automotive industry. Simulation: In addition AVL develops and markets the simulation methods which are necessary for the development work. Engine Instrumentation and Test Systems: The products of this business area comprise all the instruments and systems required for engine and vehicle testing.Utility projects for Automobile Industries. Role : Assistant Manager- Purchase (ITS/Materials) Duration : July 2014 –July 2016 Key Responsibilities: AVL India key user for SAP – MM module and EBP system. Implement procurement strategy and policies. Forecast procurement needs. New product development as per PPAP & APQP guidelines. Setting up the weekly, monthly and quarterly procurement plan according to the project & production requirement, by coordinating with relevant team. Support engineering in new product development process which includes order processing until pilot production. Cost Saving initiatives through alternate sourcing, negotiation and value engineering. Regularly update and follow Cost intelligent report. Conduct negotiation with Local and international suppliers in regard to prices, quality, volume, lead time, contract and payment term, framework agreement and etc. Optimize purchasing sources by continuously vetting selected suppliers. Order goods and services as per negotiated and approved budget. Review quotations. Prepare Price comparisons, approve and issues purchase orders in accordance with company policy and negotiated terms and conditions. Maintain procurement files. Track Purchasing activity and measurements.

- 4. Effective & proactive liaison with other departments as necessary to forecast, plan to meet purchase deadline and to maintain optimum inventory. Deliver significant Monthly cost saving and cost avoidance report , which positively impact net profit margin to the organization Maintain SRM portal for suppliers globally i.e. New supplier registration, maintaining supplier Docs like Non-disclosure Agreement (NDA), Q&A Agreement, ABG,PBG etc. Conduct frequent supplier Audit like quality audit, performance audit and finance audit, Manage and develop the existing and potential supplier pool and update the Approved Vendor List. Update Supplier Evaluation and Performance rating on Quarterly basis. Update Records in compliance to ISO Audit. Manage vendor relationships and assist in building effective partnerships. Assist department in developing and implementing purchasing strategies for goods. Responsible for planning, developing and buying goods, parts, supplies and equipment in a timely and cost effective way; timely manner while maintaining appropriate quality standards and specifications. Knowledge of Basic accounting like Taxation, Inco terms, Contracts etc. Contract management and E-tendering process through SRM portal. Working with SAP and EBP system. Attend Seminars and meets globally to get update with latest products, technologies and solutions. Regularly follow sources like Indian product finder (IPF) ,Yellow pages etc. Key Item Categories: All major categories of electrical and instrument system from reputed OEMs like Lapp, Polycab, KEI, Belden, Rittal, Siemens, Schneider, L&T, Phoenix, connectwell, Wago ,GE, Honeywell, Advantech, Dell, Axis, HP, Flexicon, Hummel, Commet, ABB, CG, Emerson, APC, IDEC, Profab, OBO, Kappa, Bajaj, Bussman, Yokogawa, Wika, Baumer, Kaycee, Tyco, Te-connectivity etc. Electrical switchgears, PLC modules, VFDs, all types cables and its accessories, Motors, Transmitters, Sensors,RTDs and Thermocouple, Scada, Control Transformers, CT and PT. Firefighting and fire detection systems, Security solutions like CCTV, Chillers, and Lighting Packages. Electrical panels like MCC panel, PCC panel, Instrumentation panels, Utility panels etc. Finalizing electrical &other utility installation work contract to sub-contractor IT products like Monitor modules, Networking equipment, Ups etc. Other electrical materials as when required.

- 5. Electronic items like PCB, components. 3. Organization : ACB(India)Ltd, Gurgaon, Haryana Role : Senior Engineer Electrical- Material planning and Procurement Duration : March 2010 to July 2014 For Purchase management: Adequate Knowledge in ERP-MM Module (Navision) Development of alternative sources for raw material which helps in cost saving. Planning and budgeting of purchase functions, involving cost estimation, contract negotiations. Inviting and allotting tenders. . Implementing systems to avoid situation like over stocking or out of stock which cause production and financial losses. Developing reports on procurement and usage of material for top management. Co-ordination with internal department from the receipt of materials till the dispatch. Supplier base management / rationalization. Inventory control. Getting quotations & Samples, costing and finalization. Regular Interaction with Design Dept. for any design change/improvement Cost Saving initiatives through alternate sourcing, negotiation and value engineering. Experience on lining up long term supply contract (LTA)/rate agreements/Blanket orders with different vendors. Releasing purchase orders using ERP module. Contract management and E-tendering process. Knowledge of Basic accounting like Taxation, Inco terms, Contracts etc. For Vendor management: Effective management of vendor database. ABC classification of vendors on the basis of criteria like cost, quality, time delivery etc. Development of new vendors through vendor registration, Evaluating vendors and negotiating the price, delivery schedule and other terms and conditions with them. Timely clearing of payments and handling vendor enquiries. Running programs to evaluate vendors, based on the feedback from internal stake holders. Preparation of vendor comparison report for reference. Major projects handled: EPC for complete coal handling plant(CHP) including DSS and DES for 30 MW,270 MW,300 MW thermal power plant at Chhattisgarh.

- 6. Job Responsibilities: Prepare project vendor list, submit prequalification documents and review for company approval where necessary. Receive company approved M.R. Compile RFQ. Issue to qualify Bidders. Receive Bids, Distribute Bids and Evaluate Bids. Assess need for Pre –Award clarifications meetings. Award Recommendation; obtain approval for purchase from company. Prepare LOI/PO, procure spares as per SPIR procedure. Distribute PO copies and notify unsuccessful bidders. Establish contact with vendors; monitor/Report any PO changes. Ensure In time delivery of Materials. Procurement of Major Equipment and Materials like: Electrical switch gears like ACB, MCCB, MCB, contactors, relays, Bus coupler etc. for manufacturing of Electrical MCC , LT panels and PLC panels. Mechanical items like MS and SS plate, EN-8,9 shaft, MS round bars, Gear box and Motor, Bearings and sleeves, ERW pipe, Seam less pipe, MS angels and channels, Reinforcement steel bars etc. and also every type of consumable items for our manufacturing process of complete conveyor system. Machineries and heavy equipment like Electric and manual hoist, CNC Lathe ,Power press machine, Special purpose Machines, Electric Actuators, Compressor, conveyor belt, safety switches, Power and control cable , Lightings, VFDs, crusher, transformer, DG sets, capacitor bank, UPS and Battery ,Auto sampler, Belt weigher etc. for Coal handling plant(CHP) project. Procurement of GI pipes, Nozzles, Bag filter, sequential timer, solenoid valves, dampers, cages, ID Fan etc. for DSS and DES system for project. Work Experience:In Project& Engineering department 4. Organization : ACB(India)Ltd. Gurgaon, Haryana Role : Engineer Electrical- Project & Engineering Duration: Sept 2009 to March 2010 Project Name EPC for complete coal handling plant(CHP).Erection and commissioning of CHP (Coal handling plant) for 30 MW ,270 MW, 300 MW thermal power plant Environment & Technologies Power supply to CSEB(Chhattisgarh electrical Board)

- 7. Location Chhattisgarh Project Description: CHP is a pre-subsidiary unit which ensures supply of proper sizes of coal to the thermal power plant which ensures the supply of the coal from its receipt to transporting it to Boiler and store in Bunkers which is further utilized in thermal power plant. It also processes the raw coal to make it suitable for Boiler Operation. it includes the process like weighing of coal, crushing, ash monitoring, dust extraction, metal detection, magnetic separation etc. and transferring it to the thermal unit through different conveyors. Job Responsibilities: Understanding the building plans, elevations, sections and layout drawings. Gathering specific data from the utilities (Electricity board). Assessment of the type of installation like outdoor/indoor substation(Point of supply) Preparation of basis of designs i.e. SLD which should include the cost estimate. Preparation of Load calculation to arrive maximum peak demand Sizing of all equipment like transformer, DG sets, capacitor bank, UPS and Battery etc. and their installation. Electrical design calculations like Load and Maximum demand calculation, Short circuit calculation, Voltage drop calculation, Cable sizing, Earthing, Lighting Preparation of single line schematic of electrical distribution system with metering options. Drawing finalization for LT electrical power distribution system, CHP MCC, PCC and PLC based control, Instrumentation and Automation system. Preparation of Control Schematics for Power Feeder, Motor Feeder, Transformer Feeder, conveyor protection system including safety switches (ZSS, PCS, Belt sway switch etc.) Preparation of Cable schedule, Cable layout and routing drawing. Preparation of DBR for Dust suppression system and relevant electrical power and control circuit design. Operation and maintenance of complete coal handling plant i.e. MCC panel, PLC panel etc. Erection and maintenance of travelling tripper, crusher, Plough discharger, Rack and pinion gates, Rod gates, Flap gate etc. Control and instrumentation of complete Belt conveyor protection system. Man power management, cost Management, Spare parts management of coal handling plant. Preventive Measures and Break down handling of complete coal handling plant. In charge of Complete Automation system of Coal Handling Plant. TRAINING PROGRAMES : Completed two months training on industrial automation and PLC programming (Allen Bradley). Completed one month training on CNC programming for Turning and milling (G code, M code).

- 8. One month training at SAIL (ROURKELA). Completed one month training on Software languages i.e. C, C++ MANAGEMENT SKILLS Knowledge about 5’S, TQM, TPM. IT EXPOSURE: Design tools familiar with: Operating systems: Windows 2000, 2007,2008, XP. Packages: SAP(R3) ,EBP, Navision (ERP), FSL (ERP), MS Word, Excel, MS Project, Power point presentation. AWARDS AND RECOGNITION: Awarded with 2nd position in performance assessment test during GET period. 1st Prize in Mathematics Olympiad. College level award in Cricket. School level award in essay competition. INTEREST AREAS BUT NOT LIMITED: Industrial Automation Mobile Communication Mathematics Market research PERSONAL DETAILS:- Name: Alok Kumar Nayak Date of Birth: 12-May-1987 Sex: Male Nationality: Indian Marital Status: Married Religion: Hindu Area of Interest: Mathematics, Sports (Cricket, carom) & internet surfing. Languages known: English, Hindi and Oriya Declaration: I hereby declare that the above details furnished by me are true to my knowledge. Alok kumar nayak. Gurgaon