Remove static charges and improve quality and productivity in textile processing!

•

1 recomendación•132 vistas

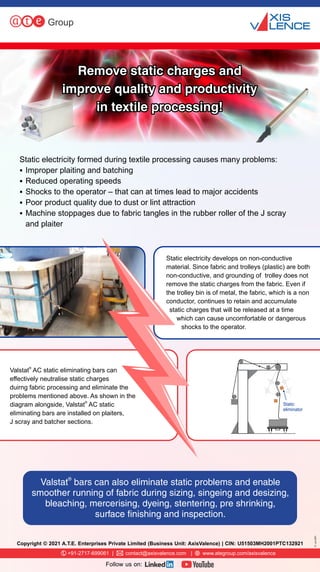

Static electricity formed during textile processing causes many problems including machine stoppages, reduced operating speeds, degradation in product quality, shocks to the operator, improper plaiting and batching, etc. AxisValence's electrostatic solutions remove static charges and improve quality and productivity in textile processing. Here's an infographic that shows how.

Denunciar

Compartir

Denunciar

Compartir

Descargar para leer sin conexión

Recomendados

250kn worm gear screw jack,jtc250 25 ton heavy load screw jack,25 tonnes high...

250kn worm gear screw jack,jtc250 25 ton heavy load screw jack,25 tonnes high...Jacton Electromechanical Co.,Ltd

Más contenido relacionado

Similar a Remove static charges and improve quality and productivity in textile processing!

250kn worm gear screw jack,jtc250 25 ton heavy load screw jack,25 tonnes high...

250kn worm gear screw jack,jtc250 25 ton heavy load screw jack,25 tonnes high...Jacton Electromechanical Co.,Ltd

Similar a Remove static charges and improve quality and productivity in textile processing! (18)

SEISMIC RESILIENCE PERFORMANCE OF CORRUGATED STEEL SLIT SHEAR WALLS

SEISMIC RESILIENCE PERFORMANCE OF CORRUGATED STEEL SLIT SHEAR WALLS

Electrostatic charging elimination in mask manufacturing line

Electrostatic charging elimination in mask manufacturing line

IRJET- Improvement in Drive Mechanism of Guillotine Damper

IRJET- Improvement in Drive Mechanism of Guillotine Damper

IRJET - Feasibility Analysis and Structural Evaluation of Connecting ROD

IRJET - Feasibility Analysis and Structural Evaluation of Connecting ROD

IRJET- Effect of Stiffened Element in Structural Behaviour of Steel Built...

IRJET- Effect of Stiffened Element in Structural Behaviour of Steel Built...

Prysmian JSTCC Low Voltage Universal Cable Joint Kits

Prysmian JSTCC Low Voltage Universal Cable Joint Kits

Thomson Linear RoundRail 2CA Web Universal Carriage Specs

Thomson Linear RoundRail 2CA Web Universal Carriage Specs

Thomson roundrail 2_ca_web_universal_carriage_specsheet

Thomson roundrail 2_ca_web_universal_carriage_specsheet

250kn worm gear screw jack,jtc250 25 ton heavy load screw jack,25 tonnes high...

250kn worm gear screw jack,jtc250 25 ton heavy load screw jack,25 tonnes high...

WELDLINE STRENGTH ANALYSIS THEORETICAL PREDICTIVE MODEL WITH THE USE OF MOLDL...

WELDLINE STRENGTH ANALYSIS THEORETICAL PREDICTIVE MODEL WITH THE USE OF MOLDL...

DESIGN AND DEVELOPMENT OF ELECTRO-MECHANICAL LIFTING JACK

DESIGN AND DEVELOPMENT OF ELECTRO-MECHANICAL LIFTING JACK

Más de A.T.E. Private Limited

KARL MAYER SIM.PLY - High-performance Spreading and Impregnation Line for Con...

KARL MAYER SIM.PLY - High-performance Spreading and Impregnation Line for Con...A.T.E. Private Limited

The Flexi weighting arms – a smart choice to replace pneumatic drafting on ri...

The Flexi weighting arms – a smart choice to replace pneumatic drafting on ri...A.T.E. Private Limited

Más de A.T.E. Private Limited (20)

KARL MAYER SIM.PLY - High-performance Spreading and Impregnation Line for Con...

KARL MAYER SIM.PLY - High-performance Spreading and Impregnation Line for Con...

A.T.E.’s continuous dosing system to eliminate variations in CPB dyeing

A.T.E.’s continuous dosing system to eliminate variations in CPB dyeing

The Flexi weighting arms – a smart choice to replace pneumatic drafting on ri...

The Flexi weighting arms – a smart choice to replace pneumatic drafting on ri...

Smart Sustainability Suite for Water and Wastewater Treatment plants

Smart Sustainability Suite for Water and Wastewater Treatment plants

Weighting arms for short staple and worsted ring frames

Weighting arms for short staple and worsted ring frames

Drafting and spindles for worsted spinning machines

Drafting and spindles for worsted spinning machines

Último

Navigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...

Navigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...Arindam Chakraborty, Ph.D., P.E. (CA, TX)

(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7

(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service9953056974 Low Rate Call Girls In Saket, Delhi NCR

Último (20)

Navigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...

Navigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...

Top Rated Call Girls In chittoor 📱 {7001035870} VIP Escorts chittoor

Top Rated Call Girls In chittoor 📱 {7001035870} VIP Escorts chittoor

(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7

(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7

Call Girls Pimpri Chinchwad Call Me 7737669865 Budget Friendly No Advance Boo...

Call Girls Pimpri Chinchwad Call Me 7737669865 Budget Friendly No Advance Boo...

Block diagram reduction techniques in control systems.ppt

Block diagram reduction techniques in control systems.ppt

Double Revolving field theory-how the rotor develops torque

Double Revolving field theory-how the rotor develops torque

VIP Model Call Girls Kothrud ( Pune ) Call ON 8005736733 Starting From 5K to ...

VIP Model Call Girls Kothrud ( Pune ) Call ON 8005736733 Starting From 5K to ...

Call Girls Wakad Call Me 7737669865 Budget Friendly No Advance Booking

Call Girls Wakad Call Me 7737669865 Budget Friendly No Advance Booking

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

Remove static charges and improve quality and productivity in textile processing!

- 1. Static eliminator Static electricity develops on non-conductive material. Since fabric and trolleys (plastic) are both non-conductive, and grounding of trolley does not remove the static charges from the fabric. Even if the trolley bin is of metal, the fabric, which is a non conductor, continues to retain and accumulate static charges that will be released at a time which can cause uncomfortable or dangerous shocks to the operator. ® Valstat AC static eliminating bars can effectively neutralise static charges duirng fabric processing and eliminate the problems mentioned above. As shown in the ® diagram alongside, Valstat AC static eliminating bars are installed on plaiters, J scray and batcher sections. Static electricity formed during textile processing causes many problems: § Machine stoppages due to fabric tangles in the rubber roller of the J scray and plaiter § Reduced operating speeds § Shocks to the operator – that can at times lead to major accidents § Improper plaiting and batching § Poor product quality due to dust or lint attraction V1, Jun 2021 Copyright © 2021 A.T.E. Enterprises Private Limited (Business Unit: AxisValence) | CIN: U51503MH2001PTC132921 +91-2717-699061 | contact@axisvalence.com | www.ategroup.com/axisvalence Follow us on: ® Valstat bars can also eliminate static problems and enable smoother running of fabric during sizing, singeing and desizing, bleaching, mercerising, dyeing, stentering, pre shrinking, surface finishing and inspection. Remove static charges and Remove static charges and improve quality and productivity improve quality and productivity in textile processing! in textile processing! Remove static charges and improve quality and productivity in textile processing!