multi-modal interactions

•Descargar como PPS, PDF•

1 recomendación•614 vistas

Complete details of multi-modal interactions

Denunciar

Compartir

Denunciar

Compartir

Recomendados

Recomendados

Más contenido relacionado

La actualidad más candente

La actualidad más candente (18)

Tool wear & Tool life / Machinability / Surface roughness

Tool wear & Tool life / Machinability / Surface roughness

Theory of metal cutting MG University(S8 Production Notes)

Theory of metal cutting MG University(S8 Production Notes)

Design of Stage Progressive Die for a Sheet Metal Component

Design of Stage Progressive Die for a Sheet Metal Component

Destacado

Destacado (18)

Incremental sheet metal forming - Incremental Single Point

Incremental sheet metal forming - Incremental Single Point

Ch6 sheetmetw proc (1) Erdi Karaçal Mechanical Engineer University of Gaziantep

Ch6 sheetmetw proc (1) Erdi Karaçal Mechanical Engineer University of Gaziantep

Sheet metal forming processes Erdi Karaçal Mechanical Engineer University of ...

Sheet metal forming processes Erdi Karaçal Mechanical Engineer University of ...

Similar a multi-modal interactions

Similar a multi-modal interactions (20)

Punching and Blanking Process (Sheet Metal Forming)

Punching and Blanking Process (Sheet Metal Forming)

Último

https://app.box.com/s/7hlvjxjalkrik7fb082xx3jk7xd7liz3TỔNG ÔN TẬP THI VÀO LỚP 10 MÔN TIẾNG ANH NĂM HỌC 2023 - 2024 CÓ ĐÁP ÁN (NGỮ Â...

TỔNG ÔN TẬP THI VÀO LỚP 10 MÔN TIẾNG ANH NĂM HỌC 2023 - 2024 CÓ ĐÁP ÁN (NGỮ Â...Nguyen Thanh Tu Collection

https://app.box.com/s/x7vf0j7xaxl2hlczxm3ny497y4yto33i80 ĐỀ THI THỬ TUYỂN SINH TIẾNG ANH VÀO 10 SỞ GD – ĐT THÀNH PHỐ HỒ CHÍ MINH NĂ...

80 ĐỀ THI THỬ TUYỂN SINH TIẾNG ANH VÀO 10 SỞ GD – ĐT THÀNH PHỐ HỒ CHÍ MINH NĂ...Nguyen Thanh Tu Collection

Último (20)

Basic Civil Engineering first year Notes- Chapter 4 Building.pptx

Basic Civil Engineering first year Notes- Chapter 4 Building.pptx

TỔNG ÔN TẬP THI VÀO LỚP 10 MÔN TIẾNG ANH NĂM HỌC 2023 - 2024 CÓ ĐÁP ÁN (NGỮ Â...

TỔNG ÔN TẬP THI VÀO LỚP 10 MÔN TIẾNG ANH NĂM HỌC 2023 - 2024 CÓ ĐÁP ÁN (NGỮ Â...

On National Teacher Day, meet the 2024-25 Kenan Fellows

On National Teacher Day, meet the 2024-25 Kenan Fellows

HMCS Vancouver Pre-Deployment Brief - May 2024 (Web Version).pptx

HMCS Vancouver Pre-Deployment Brief - May 2024 (Web Version).pptx

80 ĐỀ THI THỬ TUYỂN SINH TIẾNG ANH VÀO 10 SỞ GD – ĐT THÀNH PHỐ HỒ CHÍ MINH NĂ...

80 ĐỀ THI THỬ TUYỂN SINH TIẾNG ANH VÀO 10 SỞ GD – ĐT THÀNH PHỐ HỒ CHÍ MINH NĂ...

Beyond_Borders_Understanding_Anime_and_Manga_Fandom_A_Comprehensive_Audience_...

Beyond_Borders_Understanding_Anime_and_Manga_Fandom_A_Comprehensive_Audience_...

HMCS Max Bernays Pre-Deployment Brief (May 2024).pptx

HMCS Max Bernays Pre-Deployment Brief (May 2024).pptx

Jual Obat Aborsi Hongkong ( Asli No.1 ) 085657271886 Obat Penggugur Kandungan...

Jual Obat Aborsi Hongkong ( Asli No.1 ) 085657271886 Obat Penggugur Kandungan...

Fostering Friendships - Enhancing Social Bonds in the Classroom

Fostering Friendships - Enhancing Social Bonds in the Classroom

Kodo Millet PPT made by Ghanshyam bairwa college of Agriculture kumher bhara...

Kodo Millet PPT made by Ghanshyam bairwa college of Agriculture kumher bhara...

Python Notes for mca i year students osmania university.docx

Python Notes for mca i year students osmania university.docx

multi-modal interactions

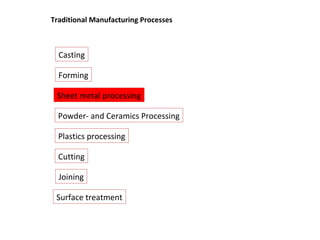

- 1. Traditional Manufacturing Processes Casting Forming Sheet metal processing Cutting Joining Powder- and Ceramics Processing Plastics processing Surface treatment

- 2. Sheet Metal Processes Raw material: sheets of metal, rectangular, large Raw material Processing: Rolling (anisotropic properties) Processes: Shearing Punching Bending Deep drawing Hydroforming

- 3. Shearing A large scissors action, cutting the sheet along a straight line Main use: to cut large sheet into smaller sizes for making parts.

- 4. Shearing • Shearing is a process for cutting sheet metal to size out of a larger stock such as roll stock. Shears are used as the preliminary step in preparing stock for stamping processes. • Material thickness ranges from 0.125 mm to 6.35 mm (0.005 to 0.250 in). The dimensional tolerance ranges from ±0.125 mm to ±1.5 mm (±0.005 to ±0.060 in). • The shearing process produces a shear edge burr, which can be minimized to less than 10% of the material thickness. The burr is a function of clearance between the punch and the die (which is nominally designed to be the material thickness), and the sharpness of the punch and the die.

- 5. Blanking / Punching • Blanking and punching are similar sheet metal cutting operations that involve cutting the sheet metal along a closed outline. • If the part that is cut out is the desired product, the operation is called blanking and the product is called blank. If the remaining stock is the desired part, the operation is called punching.

- 7. Cutting tool is a round/rectangular punch, that goes through a hole, or die of same shape F ∝ t X edge-length of punch X shear strength Punch die sheet crack (failure in shear) clearance die piece cut away, or slug t F ∝ t X edge-length of punch X shear strength Punch die sheet crack (failure in shear) clearance die piece cut away, or slug t

- 8. Punching Main uses: cutting holes in sheets; cutting sheet to required shape typical punched part nesting of parts Exercise: how to determine optimal nesting?

- 9. Bending Body of Olympus E-300 camera component with multiple bending operations [image source: dpreview.com] component with punching, bending, drawing operations

- 16. Typical bending operations and shapes (a) (b)

- 17. Sheet metal bending Planning problem: what is the sequence in which we do the bending operations? Avoid: part-tool, part-part, part-machine interference

- 18. Bending mechanics R = Bend radius Neutral axis α L = Bend length This section is under extension This section is in compression Bend allowance, Lb = α(R + kT) T = Sheet thickness R = Bend radius Neutral axis α L = Bend length This section is under extension This section is in compression Bend allowance, Lb = α(R + kT) T = Sheet thickness Bending Planning what is the length of blank we must use? Ideal case: k = 0.5 Real cases: k = 0.33 ( R < 2T) ~~ k = 0.5 (R > 2T)

- 19. Bending: cracking, anisotropic effects, Poisson effect Bending plastic deformation Bending disallow failure (cracking) limits on corner radius: bend radius ≥ 3T Engineering strain in bending = e = 1/( 1 + 2R/T) effect of anisotropic stock Poisson effect Exercise: how does anisotropic behavior affect planning?

- 21. Bending: springback 134 3 + − = ET YR ET YR R R ii f i How to handle springback: (a) Compensation: the metal is bent by a larger angle (b) Coining the bend: at end of bend cycle, tool exerts large force, dwells coining: press down hard, wait, release Initial Final R i Rf i f αf αi T

- 22. Deep Drawing die die die die die punch punch punch punch blank part blank holder (a) (b) (c) (d) (e) Examples of deep drawn parts die die die die die punch punch punch punch blank part blank holder (a) (b) (c) (d) (e) die die die die die punch punch punch punch blank part blank holder (a) (b) (c) (d) (e) Examples of deep drawn parts Tooling: similar to punching operation, Mechanics: similar to bending operation Common applications: cooking pots, containers, …

- 24. Sheet metal parts with combination of operations Body of Olympus E-300 camera component with multiple bending operations [image source: dpreview.com] component with punching, bending, drawing operations