dhi.resume 2017

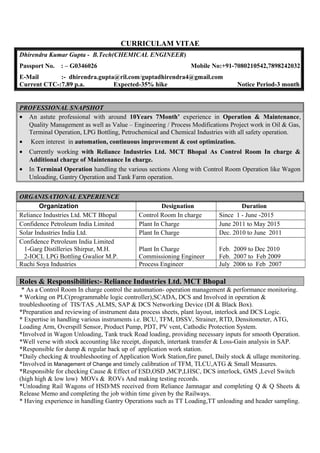

- 1. CURRICULAM VITAE Dhirendra Kumar Gupta - B.Tech(CHEMICAL ENGINEER) Passport No. : – G0346026 Mobile No:+91-7080210542,7898242032 E-Mail :- dhirendra.gupta@ril.com/guptadhirendra4@gmail.com Current CTC-:7.89 p.a. Expected-35% hike Notice Period-3 month PROFESSIONAL SNAPSHOT • An astute professional with around 10Years 7Month’ experience in Operation & Maintenance, Quality Management as well as Value – Engineering / Process Modifications Project work in Oil & Gas, Terminal Operation, LPG Bottling, Petrochemical and Chemical Industries with all safety operation. • Keen interest in automation, continuous improvement & cost optimization. • Currently working with Reliance Industries Ltd. MCT Bhopal As Control Room In charge & Additional charge of Maintenance In charge. • In Terminal Operation handling the various sections Along with Control Room Operation like Wagon Unloading, Gantry Operation and Tank Farm operation. ORGANISATIONAL EXPERIENCE Organization Designation Duration Reliance Industries Ltd. MCT Bhopal Control Room In charge Since 1 - June -2015 Confidence Petroleum India Limited Plant In Charge June 2011 to May 2015 Solar Industries India Ltd. Plant In Charge Dec. 2010 to June 2011 Confidence Petroleum India Limited 1-Garg Distilleries Shirpur, M.H. 2-IOCL LPG Bottling Gwalior M.P. Plant In Charge Commissioning Engineer Feb. 2009 to Dec 2010 Feb. 2007 to Feb 2009 Ruchi Soya Industries Process Engineer July 2006 to Feb 2007 Roles & Responsibilities:- Reliance Industries Ltd. MCT Bhopal * As a Control Room In charge control the automation- operation management & performance monitoring. * Working on PLC(programmable logic controller),SCADA, DCS and Involved in operation & troubleshooting of TIS/TAS ,ALMS, SAP & DCS Networking Device (DI & Black Box). *Preparation and reviewing of instrument data process sheets, plant layout, interlock and DCS Logic. * Expertise in handling various instruments i.e. BCU, TFM, DSSV, Strainer, RTD, Densitometer, ATG, Loading Arm, Overspill Sensor, Product Pump, PDT, PV vent, Cathodic Protection System. *Involved in Wagon Unloading, Tank truck Road loading, providing necessary inputs for smooth Operation. *Well verse with stock accounting like receipt, dispatch, intertank transfer & Loss-Gain analysis in SAP. *Responsible for dump & regular back up of application work station. *Daily checking & troubleshooting of Application Work Station,fire panel, Daily stock & ullage monitoring. *Involved in Management of Change and timely calibration of TFM, TLCU,ATG & Small Measures. *Responsible for checking Cause & Effect of ESD,OSD ,MCP,LHSC, DCS interlock, GMS ,Level Switch (high high & low low) MOVs & ROVs And making testing records. *Unloading Rail Wagons of HSD/MS received from Reliance Jamnagar and completing Q & Q Sheets & Release Memo and completing the job within time given by the Railways. * Having experience in handling Gantry Operations such as TT Loading,TT unloading and header sampling.

- 2. * Having Knowledge of all Tanks, Tank Truck and Rail Wagon Safety fittings. *Responsible for timely completion of PM & CM order via SAP, work permit creation & closure. *Issuing of all types of work permits as an Issuer and maintaining Reliance HSE Management System. *Maintenance and Calibration of MOV’s, Overspill Sensor, Turbine flow meters (TFM), Batch Control Units (BCU), Access Control Devices (ACD) and Loading Arm. * Maintenance of tanks, pipelines, pumps and allied equipment. *Operation & maintenance of fire fighting system viz. sprinklers, hydrants, monitors & foam pourer system. * Ensuring proper functioning and timely calibration/proving/maintenance of instrument like densitometer, TFM, PDT, over spill sensor and pressure guage. *Monthly checking of Emergency Shutdown Switches (ESD), Heat Detectors, Optical Smoke Detectors (OSD), Manual Call Points (MCP) and Linear Heat Sensing Cables on tanks installed in terminal. *Responsible for preparation of MIS, alarm analysis, control room report and inventory management. *Responsible for fully automated TT loading in time & its effective manpower utilization. *Participated in various Internal Audit - Operation, IMS, OISD,OMS & PSM. *Participated in various External Audit like BSC , IMS, ISO, FSM, PNGRB, PSSR, OISD, OMS and Resop. *Comply to all ISO requirements, undertake internal ISO audits and achieve nil non conformities in audit. *Expertise in implementing statutory & legal compliances and renewal of all statutory licence laisonining with government department, submitted all returns on time. *Good knowledge of Spare Management, AMC services & payments, material/engineering procurement, purchase requisition creation, help to converting purchase order and work order. *Keep abreast of fire order and onsite emergency plan and ensure ender tank farm team are fully framed on the same and perform roles as defined in the documents for Mock drill & DCMP drill. *Participated in MB Lal committee recommendation like ROSOV, hydrocarbon detector, MEFG, Dyke valve indicator, TSV & domeroof erection in floating roof tank commissioning. Safety-Well verse with Health,Safety &Environment aspects & timely report of all incidents & its analysis. Training - 15 Day Intensive Training MCT Rewari Terminal ,5 Day IMS Training in RCP Mumbai , 2 Days TIS/TAS training in jamnagar & 5 Day Fire Fighting Training in IOCL Mathura & RIL Vadodara. PROJECTS -: * Good knowledge of oil & gas operation codes, API codes & standard. * Handling project of TAS Up gradation & installation of new (PLC,DCS,ESD,ALMS,TAS DB & TIS) installation of newly supplied TAS/DCS and Expediting the SAP/TIBCO vs Registration ACD system interface with new TA-SQL server in RIL MCT Bhopal. *Interface test between new TAS/DCS and PLC, integration of new TAS Database/Web Server. *Establishing & testing of BCU, ATG, FCU, PACSCAN & GUI *Performed pre-commissioning & commissioning of floating/fixed roof tank and pipelines work in RIL. *Performed quality Inspection, leak test, hydrotest and pneumatic test at site. * Involved as a part of team in reviewing PFD’S and P&ID’S and Basic Engineering Process Design. *Basic of Fabrication, Erection, Welding, NDT, Hydro testing, Leakage Testing, Card Board Blasting. * Executed commissioning test flushing, hydro jetting, air blowing, purging, blanketing etc. *Factory acceptance tests (FAT), site acceptance tests (SAT) and supported qualification and validation. * Routinely troubleshoot operational problems with systems. Provide engineering for development of optimization strategies, upgrades, replacements, and modifications in the manufacturing plant. *Driving strategic corporate initiatives like TPM, SAFETY and maintain all records as per desired system. JOB RESPONSIBILITIES (Previous Organization) * Preparation of process flow diagrams, piping & instrumentation diagrams of equipment, process plant and also involved in shutdown and start up activities in plant. *Interdisciplinary co-ordination with other department like civil, electrical, mechanical for finalizing the job.

- 3. * Preparation of Line List, Instrument Data Sheets, Piping Item data. * Preparation of Process Data Sheets for Tanks, Vessels, Columns, Separators etc. * Preparation of specification for process Pumps, Compressor & its performance optimization, * Process Calculations such as Mass & Energy Balance, Line sizing, Heat exchanger, Pressure drop, line sizing, Pump Calculations, Relief System as PSV, TSV. * Ability to work with well-established policies procedure of standards and HSE . * Designing Heat Exchanger, Super heater, Cooling Tower and Utility P&ID Preparation. * Involved in Preparation of Utility Summary and in estimation of Utility Consumption. * Actively participated in Hazop Study and Good knowledge of Safety system design. * Handling Hydraulic motor, Pump & System. Handling Man, Material Management and lab equipment. *LPG Operations - taking Necessary Actions to control the same. * Sampling and storage of various products such as LPG, MS, HSD, Alcohal, FO &Solvent. * Loading of LPG TTs, Wagon, LPG bullets & gantry Mercaptane additives system. * Handling operation and maintenance of Fire Water Engines Various Pipe Line For LPG , Centrifugal, Reciprocating Pumps, Compressors, Control Valve like ROV, MOV & SRV. *In Solar Industries -Manufacture of Bulk Emulsion of High Density Ammonium Prills & Furnace Oil and also involved in different pattern of blasting in different mining area in WCL Chandrapur. KEY DELIVERABLES-: * Erection & Commissioning or project work (piping, tank installation & design equipment for IOCL,HPCL,BPCL LPG Bottling Plant& Refinery.) * Analyze process performance of OIL&GAS and Petrochemical Operation. * Energy & Heat saving in process by correcting process & equipment design. * Operating & Handling various problems in processing Petrochemicals product Fuel Oil, Furnace Oil, Used/Waste Oil, Glycerine, Ethanol, Methanol, Biodiesel, Resin & Solvents units in Garg Distilleries. *Erection, fabrication and commissioning of SEP (Extractor ,Distillation ,Desolventizer) & Edible Oil Refining equipments (Separator, Bleacher, Deodorizer, Filter) in Ruchi Soya Industries . *Expansion Project of 1500MT Capacity in Ruchi Soya Industries & Capacity enhancement of exiting plant & improving their efficiency. *Overall responsibility for Plant Operation and Safety and Quality (BPCL Asst. LPG Bottling). *Preparation of work instruction and execution daily, weekly, monthly production Plan and Implementing Shift wise Production Plan and achieving the Targets. OPERATION & MAINTENANCE PURVIEW • Pumps (Rotary, Centrifugal, gear, Screw, Vacuum), Compressor, Boiler, Cooling tower and ETP. • Equipments handled –Distillation Column, Absorber, Heat Exchangers, CSTR/PFR Reactor, Vessels (Vertical, horizontal, Mounded), Vaporizer, Pneumatic Equipments, Separator and Filters ACADEMIC CREDENTIALS B.TECH. (2002-06) in CHEMICAL ENGG. From MEERUT INSTITUTE OF ENGINEERING AND TECHNOLOGY, MEERUT. (U.P.) with 63.2%. (Approved by AICTE, New Delhi and Affiliated to U.P. Technical University, Lucknow) INDUSTRIAL TRAINING: 1-: Oswal Chemicals Fertilizer Ltd, Shahajahanpur. U.P. (Urea Plant) 2-: SOFCON INDIA PVT. LTD., Training- Automation Engineering IT SKILLS

- 4. Programming Skills:- C, Oracle/SQL, MS-Office, MS-word, MS-Excel, PowerPoint, Networking & SAP. PERSONAL DETAILS Date of Birth : 7th June 1982 Address : Dhirendra Kumar Gupta,S-16,Kakda Abhinav Homes Ayodhya Byepass Road,Bhopal (M.P.) 462041 Languages known : English & Hindi Extra Achievement:- First prize in REDCROSS COMPETITION(Regional and District) at intermediate level - Active participation in various college level cultural programs and quiz competitions. MAJOR ATTRIBUTES: Professional- 1. Fast Learner- Always eager to learn new systems and techniques whether technical or managerial. 2. Strengths - Have good interpersonal skills, have good level of persuasiveness, leadership quality. 3. Hands On- Strongly believe in hands on working, as it is the only way to learn. 4. Team Man- Always believe in the virtue of working as a team, have always formed a team and performed with team spirit. 5. Ability to perform under pressure and challenging circumstances. Personal- 1. Adaptable- Always open to change and adapt easily to changing environment. 2. Fighting Spirit- Has never bogged down by odds and believes that if we try hard no hurdle is insurmountable. 3. Sociable- Love to meet and make new friends. Have always been able to blend with people of different background and culture. Declaration –I hereby declare that the information furnished above is given with full sincerity and honesty. Date : Dhirendra Kumar Gupta My reporting matrix:- Terminal Manager Org Unit Chief Unit Head HR-Business Partner Head HR Group HR Head EC Sponsor Overseas Travel Approver REFERENCE:-

- 5. 1- Rajendra.R.Chauhan-7869910319 2- Rakesh.C.Srivastav -9589195714 3- Eknath Magar -9755023463

- 6. 1- Rajendra.R.Chauhan-7869910319 2- Rakesh.C.Srivastav -9589195714 3- Eknath Magar -9755023463