Foundry Lectures

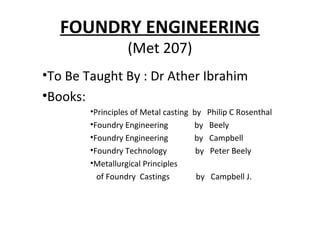

- 1. FOUNDRY ENGINEERING (Met 207) •To Be Taught By : Dr Ather Ibrahim •Books: •Principles of Metal casting by Philip C Rosenthal •Foundry Engineering by Beely •Foundry Engineering by Campbell •Foundry Technology by Peter Beely •Metallurgical Principles of Foundry Castings by Campbell J.

- 2. Traditional Manufacturing Processes Casting Forming Sheet metal processing Cutting Joining Powder- and Ceramics Processing Plastics processing Surface treatment

- 3. Casting mold pour liquid metal solidify, remove finish Casting is a manufacturing process in which molten/liquid material is poured into a mold containing a cavity of specific shape, and then allowed to solidify. The solid casting is then taken out and cleaned to complete the process

- 4. • VERSATILE: •complex geometry, internal cavities/ external shapes, hollow sections •Wide range of Weight and size •small (~10 grams) very large parts (100 tones) •Teeth Zipper (few mm) Ocean Liner Propeller (10 m) •Net Shape, Near Net Shape •Any Metal (that can be melt) •Some metal can only be cast •Simplified Construction •Some Engineering properties are only possible in casting •Isotropic •Machinability •Damping capacity •Good Bearing qualities •Strength and Lightness • ECONOMICAL: •little wastage (extra metal is re-used) Low cost •Suitable for mass production Advantages

- 5. Limitations Depend upon casting method • Mechanical Properties •Porosity •Poor Dimensional Accuracy •Surface Finish •Safety Hazard

- 6. History Casting is a 6000 year old process. Earliest castings include the 11 cm high bronze dancing girl found at Mohen-jo-daro(dated about 3000 BC). The remains of the Harappan civilization contain kilns for smelting copper ingots, casting tools, stone moulds, cast ornaments and other items of copper, gold, silver and lead. Iron pillars, arrows, hooks, nails, bowls dated 2000 BC Another oldest casting is a copper frog dated 3200 BC discovered in Mesopotamia The Iron Pillar of Delhi, standing 23 feet, weighing 6 tonnes and containing iron, is a remarkable example of metallurgical science in 5th century AD

- 7. Types of Foundries •Based on material • Ferrous , Non ferrous, gray Iron, Steel, Brass, Light metal •Based on nature and Organisational Framework •Jobbing foundry(A foundry that creates a wide variety of castings, in small quantities for a range of customers) •Production foundry •Semi Production foundry •Captive foundry(A foundry operation that is wholly incorporated into a larger manufacturing operation) •Independent foundry

- 8. Casting Process • Preparing a mold cavity of the desired shape with proper allowances and provided with means for the escape of air or gases. • Melting the metal with acceptable quality and temperature. • Pouring the metal into the cavity. • Solidification process designed and controlled to avoid defects. • Casting removal. • Finishing, cleaning and inspection operations.

- 9. Process Selection Design and Specification Determination of Casting Technique Pattern MakingMoulding Material Preparation Furnace Charge Preparation Moulding & Core making Metal Melting Casting Fettling Heat Treatment & Finishing Inspection & Testing Black Casting Flow Diagram for Casting Production

- 10. Classification of Casting Processes

- 11. Different Casting Processes Process Advantages Disadvantages Examples Sand many metals, sizes, shapes, cheap poor finish & tolerance engine blocks, cylinder heads Shell mold better accuracy, finish, higher production rate limited part size connecting rods, gear housings Expendable pattern Wide range of metals, sizes, shapes patterns have low strength cylinder heads, brake components Plaster mold complex shapes, good surface finish non-ferrous metals, low production rate prototypes of mechanical parts Ceramic mold complex shapes, high accuracy, good finish small sizes impellers, injection mold tooling Investment complex shapes, excellent finish small parts, expensive jewellery Permanent mold good finish, low porosity, high production rate Costly mold, simpler shapes only gears, gear housings Die Excellent dimensional accuracy, high production rate costly dies, small parts, non-ferrous metals gears, camera bodies, car wheels Centrifugal Large cylindrical parts, good quality Expensive, few shapes pipes, boilers, flywheels

- 12. Types of Mould Open Mould Closed Mould

- 14. Sand Casting

- 15. [ )]()( 0 mplfms TTCHTTCVH −++−= ρ Where H = Total heat Required to raise the temperature of the metal to the pouring temperature, J (Btu) ρ = Density g/cm3 Cs= Weight Specific Heat for the Solid Metal J/g-o C Hf = Heat of Fusion J/g Cl= Weight Specific Heat for the Liquid Metal J/g-o C Tm, Tp, To = Melting, pouring and ambient temperature respectively V = Volume A Good Approximation! Why? Heating of Metal

- 16. • Specific Heat and other Thermal Properties of a Solid Metal Vary with Temperature Especially if the Metal Undergoes a Change of Phase During Heating • A Metal Specific Heat may be Different in the Solid and Liquid States • Most Casting Metals are Alloys; Thus Heat of Fusion Cannot be Applied so Simply • The Property Values Required may not be Available for All Alloys • There are Significant Heat Losses to the Environment During Heating

- 17. Factors Affecting the Pouring Operation Pouring Temperature (Super Heat) Pouring Rate (Slow excessive) Turbulence Re = Vd/v V = mean velocity d = Linear dimension of the mould channel section v = kinematic viscosity of the liquid

- 18. 2 2 22 21 2 12 1 22 F g vP hF g vP h +++=+++ ρρ Where h= Head cm P = Pressure on the liquid N/cm2 ρ = Density g/cm3 v = Flow velocity cm/s g = Gravitational Acceleration Constant Bernoulli’s Theorem Continuity Law Q = V1A1=V2A2 Mould Filling Time MFT = V/Q

- 21. Nucleation • Homogeneous Nucleation (Self Nucleation) •Heterogeneous Nucleation

- 27. Solidification • During solidification process a series of events occur which affect – Size & shape of grains formed – Influences overall properties • In general casting results in reasonably uniform grain structure • Some difference between – Pure metals – alloys

- 28. Solidification – Pure Metals • Solidifies at constant temperature – Must give off latent heat of fusion before phase change • Rapid cooling at mold edge – Skin/shell – fine grains – Slower in the middle – columnar grains

- 29. Characteristics of Molten Metal • Viscosity – How runny is it when hot • Surface Tension – Development of film

- 30. Casting Parameters • Mold Design – Risers, runners, gates, etc. • Mold Material – Thermal conductivity – Roughness of its surface • Rate of Pouring • Degree of superheating – How far above melting point

- 31. Fluidity of Molten Metals • Fluidity – capability of molten metal to fill mold cavity • Two basic factors – Characteristics of molten metal – Casting parameters

- 32. Factor Affecting Fluidity Pouring Temperature Metal Composition Viscosity Heat Transfer to Surroundings Volume Specific Heat Latent Heat Of Fusion Thermal Conductivity of the Alloy

- 33. a = Crucible b= Electric resistance furnace c= Fluidity test channel d= Pressure reservoir e= Manometer f= Cartesian manostat Vacuum Fluidity Test Apparatus

- 34. Influence of Superheat on fluidity • Super heat • Duration of flow depends upon the amount of heat to be removed before onset of solidification

- 35. Composition and Fluidity • Pure Metal High fluidity • Alloys • Solid solution with long freezing range poor fluidity • Eutectic High fluidity

- 36. Model of Solidification in flow channel

- 37. • A pure metal solidifies at a constant temperature equal to its freezing point (same as melting point)

- 38. Cooling and Solidification Pure metal

- 39. Critical Radius Vs Under cooling

- 41. Solidification - Alloys • Solidify with a temperature range – Produces a mushy or pasty state • Cooling rate effects – Slow – coarse structures/grains – Fast – fine structures/grains • In general as grain size decreases – Strength and ductility increase – Shrinkage voids decrease – Cracking during solidification decreases

- 42. Solidification of Alloys • Most alloys freeze over a temperature range • Phase diagram for a Cu Ni alloy system and‑ cooling curve for a 50%Ni 50%Cu composition‑

- 43. Development of columnar grain structure

- 44. Schematic representation of temperature distribution in plane front solidification Thermal conditions suitable for production of columnar structure Positive thermal gradient at the solid liquid interface Interface advancing as the TG (growth) is reached Flat plane is formed when cooling rate is slow and temp gradient is steep Latent heat is insufficient

- 45. Thermal conditions with reversal of temperature gradient in liquid adjoining interface Latent heat is sufficient to reverse the temperature gradient at the interface in such lowest temperature in the liquid is no longer adjacent to the interface therefore growth mode changes from plane front advancement to deposition in regions of greater undercooling and thus microscopic heat flow becomes important

- 46. Thermal equilibrium diagram for two metals forming a continuous range of solid solutions

- 47. Equilibrium distribution of solute between solid and liquid phases at successive stages of unidirectional freezing

- 48. Concentration of solute in liquid ahead of advancing interface- non equilibrium conditions a)Solute distribution CL b)Equilibrium liquidus temperature TE corresponding to solute content at distance D from solidification interface

- 49. Relation of temperature gradient in liquid to equilibrium freezing temperature profile Constitutional undercooling Temperature and compositional gradients in the liquid are the important influencing factors on both grain and substructure of casting

- 50. Dendritic growth cored structure Cellular substructure formed by undercooling

- 52. Independent nucleation Influence of temperature gradient in liquid on crystallization, TE= eq freezing temp TN= nucleation temp depending upon heterogeneous nuclei T1-3= temperature gradients producing increasing undercooling and associated changes in morphology planar-cellular-dendritic-independently nucleated

- 53. The Structure of Casting Three major influences •Alloy constitution • mode of crystallization, single/ multiphase eutectic or both • Level of constitutional undercooling •Thermal conditions • Temperature distribution, rate of cooling are determined based on initial temperature and thermal properties of metal and mold •Inherent nucleation and growth conditions in the liquid • Homogeneous and heterogeneous nucleation stimulation in liquid metal

- 54. Interaction of temperature and compositional gradients in determining structure (a)Influence of a temperature gradient (T) (b)Influence of a liquidus temperature profile (TE) (i) conditions favoring plane front solidification, (ii) conditions producing undercooling

- 55. Influence of undercooling on interface morphology and mode of growth. (a)Planar interface (b)Cellular interface (c)Dendritic growth (d)Independent nucleation

- 56. Influence of temperature gradient G and freezing rate R on solidification morphology

- 57. Influence of solute concentration, temperature gradient and freezing rate on solidification phenomena in unidirectional cooling (a)Formation of cellular interface (b)Cellular-dendritic transition in Sn-Pb alloys (c)Onset of equiaxed growth in Al-Mg alloys

- 58. Thermal explanation of mixed structures in castings (a) columnar growth stage (b) central equiaxed region

- 60. • Characteristic grain structure in a casting of a pure metal, showing randomly oriented grains of small size near the mold wall, and large columnar grains oriented toward the center of the casting Solidification of Pure Metals

- 61. ©2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e • Characteristic grain structure in an alloy casting, showing segregation of alloying components in center of casting Solidification of Alloys

- 62. Three Cast Structures of Solidified Metals •FIGURE 5.8 Schematic illustration of three cast structures of metals solidified in a square mold: •(a) pure metals; •(b) solid-solution alloys; and •(c) the structure obtained by heterogeneous nucleation of grains, using nucleating agents.

- 63. Ken Youssefi Mechanical Engineering Dept., SJSU 63 Solidification Time Solidification time = C(volume/surface area)2 Where C is a constant that depends on mold material and thickness, metal characteristics and temperature.

- 64. The mold constant C depends on the properties of the metal, such as Density, Heat Capacity, Heat of Fusion and superheat, and the mold, such as initial temperature, density, Thermal conductivity, heat capacity and wall thickness. The metric units of the mold constant C are min/ cm2 According to Askeland, the constant n is usually 2, however Degarmo claims it is between 1.5 and 2. The mold constant of Chvorinov's rule, C, can be calculated using the following formula: Where Tm = melting or freezing temperature of the liquid (in Kelvin) To = initial temperature of the mold (in Kelvin) ΔTs = Tpour − Tm = superheat (in Kelvin) L = latent heat of fusion (in [J.Kg-1 ]) k = thermal conductivity of the mold (in [W.m-1 .K-1 )]) ρ = density of the mold (in [Kg.m-3 ]) c = specific heat of the mold (in [J.Kg-1 .k-1 ]) ρm = density of the metal (in [Kg.m-3 ]) cm = specific heat of the metal (in [J.Kg-1 .k-1 ]) C

- 65. Ken Youssefi Mechanical Engineering Dept., SJSU 65 Solidification Time Sphere, cube and a cylinder with the same volume

- 66. • Cooling rate depends on casting material and configuration. It also depends on volume and surface area of the casting. • The pouring rate should be such that solidification does not start and the cavity is completely filled without eroding mould surface and undue turbulence. • On the basis of experience following empirical relations are developed for pouring time K: Fluidity factor W: Weight In kg Tp: Poring time in sec Pouring Rate

- 67. Mould Fcators in Metal Flow • Fluidity is the property of metal alone • The flow of metal under given pressure head is also strongly influenced by the nature of mould • Metal flow is arrested through solidification, mould condition can effect flow duration directly (thermal properties) or indirectly (velocity) • Reduction in velocity-> increased time for heat loss/length of passage wall -> final arrest in shorter distance

- 68. Thermal properties D = (kcρ) ½ K = thermal conductivity c= Specific heat ρ = density • Rate of cooling depends upon the heat diffusivity on mould material • Rapid cooling result from the use of high heat diffusivity mould materials, chills etc • Cooling is accelerated by water in green sand moulds, this effect retards metal flow in thin sections Mould Surface Effect • Roughness of mould surface (grain size dependent) slows down the flow • Moud coatings are used to increase flow characteristics • e.g. hexachloroethane in aluminum alloy casting

- 69. Air Pressure Effect • Inadequate vents and channels for the escape of rapidly expanding air/gases can result in loss of fluidity due to reduced flow as result of back pressure • Mould conditions affecting flow are inherent in the moulding process and material • Successful filling of mould depends primarily on the use of suitable gating techniques

- 70. The path of molten metal during casting process comprises mainly four parts: 1. Pouring of molten metal from ladle to the cup in the mould 2. Flow within the gating channels, from pouring basin to ingate 3. Jet of molten metal emerging from ingate and entering the mould cavity 4. Filling of mould cavity by liquid movements in the bulk as well as near the surface.

- 71. Gating of Castings • The rate and direction of metal flow must be such as to ensure complete filling of the mould before freezing • Flow should be smooth and uniform with minimum turbulence, entrapment of air, metal oxidation and mould erosion • It should promote ideal temperature distribution within the completely filled mould cavity so that the pattern of subsequent cooling is favourable to feeding • The systems should have traps and filters for the separation of inclusions Gating system should be designed as per the •Weight and shape of each casting •Fluidity of metal •Metal susceptibility to oxidation • and ensure Minimum cost, molding time, fettling time, metal consumption The main objective of a gating system is to lead clean molten metal poured from ladle to the casting cavity, ensuring smooth, uniform and complete filling.

- 72. (a) Bush/basin (b) Sprue or down runner (c) Runner (d) Ingates Separators/filters

- 73. Top Gating Bottom Gating Side Gating Top Gating Open pour, edge gate, pencil gates

- 74. Normal horn gate reverse horn gate

- 75. Multiple ingate systems (a),(b) parallel finger ingates (c) Circumferentially placed ingates

- 76. Flow behavior in horizontal gating systems (a) Central spure (b) End sprue

- 77. Multiple finger ingate systems designed to induce uniform flow (a)Pool in system (b)Backswept runner (c)Tapered runner

- 78. Horizontal gating systems (a)Streamlined system with progressively diminishing cross-sectional area of passages (b)System using parallel runner with angled ingates

- 79. Step gating system (a)Simple system (b)Inclined Steps with common junction (c)Reversed down runner

- 80. Some Devices for separation of non metallic inclusions (a)Trap in gate member (b)Underslung gates (c)Baffle core (d)Ball plug

- 81. Strainer cores and screens (a)Strainer core (b)System with metal screen

- 88. Shrinkage • Most metals shrink during solidification & cooling process • Causes dimension changes and sometimes cracking – Molten metal contracts as it cools prior to solidification – Metal contracts during solidification process – Metal contracts further as it cools to room temperature

- 89. Shrinkage Metal Percent Contraction (-) Expansion(+) Aluminum Zinc Gold Copper Brass Carbon Steel Lead Gray Cast Iron -7.1% -6.5% -5.5% -4.9% -4.5% -2.5-4% -3.2% +2.5%

- 90. ©2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e Shrinkage during Solidification and Cooling • (0) starting level of molten metal immediately after pouring; (1) reduction in level caused by liquid contraction during cooling

- 91. ©2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e Shrinkage during Solidification and Cooling • (2) reduction in height and formation of shrinkage cavity caused by solidification; (3) further reduction in volume due to thermal contraction during cooling of solid metal

- 92. ©2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e Solidification Shrinkage • Occurs in nearly all metals because the solid phase has a higher density than the liquid phase • Thus, solidification causes a reduction in volume per unit weight of metal • Exception: cast iron with high C content – Graphitization during final stages of freezing causes expansion that counteracts volumetric decrease associated with phase change

- 93. ©2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e Shrinkage Allowance • Patternmakers correct for solidification shrinkage and thermal contraction by making the mold cavity oversized • Amount by which mold is made larger relative to final casting size is called pattern shrinkage allowance • Casting dimensions are expressed linearly, so allowances are applied accordingly

- 94. ©2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e Directional Solidification • To minimize effects of shrinkage, it is desirable for regions of the casting most distant from the liquid metal supply to freeze first and for solidification to progress from these regions toward the riser(s) – Thus, molten metal is continually available from risers to prevent shrinkage voids – The term directional solidification describes this aspect of freezing and methods by which it is controlled

- 95. ©2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e Achieving Directional Solidification • Directional solidification is achieved using Chvorinov's Rule to design the casting, its orientation in the mold, and the riser system that feeds it – Locate sections of the casting with lower V/A ratios away from riser, so freezing occurs first in these regions, and the liquid metal supply for the rest of the casting remains open – Chills internal or external heat sinks that cause‑ rapid freezing in certain regions of the casting

- 96. ©2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e External Chills • (a) External chill to encourage rapid freezing of the molten metal in a thin section of the casting; and (b) the likely result if the external chill were not used

- 97. Use of chills

- 99. ©2010 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e Riser Design • Riser is waste metal that is separated from the casting and re-melted to make more castings • To minimize waste in the unit operation, it is desirable for the volume of metal in the riser to be a minimum • Since the shape of the riser is normally designed to maximize the V/A ratio, this allows riser volume to be reduced to the minimum possible value

- 100. Pattern allowances • Shrinkage allowance • Draft allowance • Machining allowance • Distortion allowance

- 101. MANUFACTURING MATERIAL PATTERN WORKING DRAWING

- 103. MANUFACTURING MATERIAL CAST PART WORKING DRAWING

- 105. Challenges with Casting • Several defects can develop in castings • Most can be avoided with proper design and processing techniques

- 106. Challenges with Casting • Metallic Projections - fins, flash, rough surface – Too high pressure – Improper mating mold pieces • Cavities - pockets caused by shrinkage or gases – Can be controlled by adding flux • Discontinuities – includes cracks, cold/hot tearing, and cold shunts – Constrained cooling – Molten metal too low temperature

- 107. Challenges with Casting • Defective Surface – scars(marks), adhering sand layers, oxide scale – Design of gate may improve • Incomplete Casting – premature solidification – Insufficient volume of metal poured • Incorrect Dimensions/Shape – improper shrinkage allowance, warped( benting) casting, etc. • Inclusions – form during melting, solidification, and molding – Usually a result of chemical reactions – Reduce strength of casting – Can/should be filtered out

- 108. Sand Casting • Most prevalent form of casting • 15 million tons of metal cast by this method annually in the US • Typical sand casting applications – Machine bases – Large turbine impellers – Propellers – Plumbing fixtures – Agricultural and railroad equipment components

- 109. Sand Casting • Utilizes gravity to feed molten metal into a non- reuseable mold • Sand contains binding materials • Requires a reuseable mold pattern • Produces a parting line on the work piece • Requires drafts and fillets on pattern • Produces rough textured(roughness) surfaces • Sprues, risers, and runners must be removed

- 110. Green Sand Casting Pouring Basin Sprue Runner Gate Mold Cavity Riser Drag Cope

- 111. Green Sand Casting

- 112. Green Sand Casting • Wall Thickness – Typical 0.25 - 1.0 in. – Feasible 0.30 - 3.0 in. • Casting Weight – Typical 1 – 50 lb. – Feasible few oz. – several hundred lb.

- 113. Green Sand Casting • Tolerances – Typical ±0.125 in. – Feasible ±0.0625 in. • Surface Finish – Typical 300-600 μin. – Feasible 200-1000 μin.

- 114. Factors Affecting Tolerance and Surface Finish • Accuracy of pattern • Dimensional stability of pattern • Casting shrinkage • Pattern smoothness • Pattern wear • Sand compaction • Dimensional stability of casting alloy • Gating and rising system

- 115. Four Main Components For Making A Sand Casting Mold: • Base Sand • Binder • Additives • Parting Compound SAND MOLD

- 116. MOLDING SAND CHARACTERSTICS • Chemical inertness • Refractoriness • Permeability • Cohesiveness (or bond) • Surface finish • Collapsibility • Flowability • Availability/cost

- 117. GENERAL PROPERTIES OF MOLDING SANDS • Molding sand must be readily moldable and produce defect-free castings. • AFS – sets forth the standard condition of testing the sand properties. 1. GREEN STRENGTH: • Adequate strength and toughness for making and handling the mold. 2. DRY STRENGTH: • Dry sand must have strength to resist erosion and also the metallostatic pressure of the molten metal or else the mold may enlarge.

- 118. 3. HOT STRENGTH: • Hot molten metal • Metallostatic pressure of the liquid metal bearing against the mold walls may cause mold enlargement, or if the metal is still flowing, erosion, cracks, or breakages may occur unless the sand posses adequate hot strength. 4. PERMEABILITY: • Steam and other gases • The mold must be permeable, i.e. , porous to permit the gases to escape.

- 119. 5. THERMAL STABILITY: • Heat from the casting causes rapid expansion of the sand surface at the mold-metal interface. • The mold surface may crack, buckle(twisted), or flake off (scab) unless the molding sand is relatively stable dimensionally under rapid heating. 6. REFRACTORINESS: • The absence of melting, softening, or adherence of the sand to the casting makes for better casting surface and easier cleaning of the casting. • Ferrous alloys ---- sand with high refractoriness.

- 120. 7. FLOWABILITY: • The sand should pack well/flow under load. • Sands of low flowability may result in non- uniform hardness. • Soft molds --- enlargement of the casting or roughness of the casting surfaces. 8. PRODUCE GOOD CASTING FINISH: • Finer sands ----- a smoother casting surface.

- 121. 9. COLLAPSIBILITY: • Heated sands -------- hard and rocklike. • Difficult to remove from the casting • May cause the contracting metal to tear or crack. 10. THE SAND SHOULD BE REUSABLE. 11. EASE OF SAND PREPARATION AND CONTROL. ** Economic production of good casting.

- 122. SAND DEFINATIONS Silica Sand: White, washed and dried, silica sand grains of high purity, 99.8+ percent SiO2. Bank Sand: Sand from glacial or sedimentary deposits occurring in banks or pits usually containing less than 5 % clay. Lake Sand: A sub-angular sand, from lake areas. System Sand: employed in a mechanical sand preparation and handling system. Heap Sand: Sand thought of as being heaped on the floor when it is prepared for use. Facing Sand: A specially prepared sand used next to the pattern and backed up with heap or system sand.

- 123. Backing Sand: Molding sand used to back up facing sand and not used next to the pattern. Bonding Sand: Sand high in clay content used to add clay to a molding sand. Sharp Sand: A sand substantially free of bond. Lake sands Sand Additive: Any material added to molding sands for a special effect. Loam: A mixture of sand, silt and clayey particles in such a proportions as to exhibit about 50 % sand grains and 50 % silt and clay.

- 124. Types of Sands SILICA (Sio2) Sand Olivine Sand Chromite Sand Zircon Sand Chamotte Sand

- 127. Grain Shape is defined in terms of • Angularity and • Sphericity Sand Grains Vary from • Well Rounded to Rounded • Sub rounded • Sub Angular • Angular • Very Angular With in each angularity band grains may have • High • Medium • Low Sphericity Angularity is estimated through low power microscope examination and comparison with published charts The Best foundry sand grains are Rounded with medium to high Sphericity giving rise to Good Flowability and Permeability with high strength at low binder additions More Angular and low sphericity sand require higher binder additions have lower packing density and poor flowability Grain Shape

- 136. Binders • Clay and water • Oil • Resin • Sodium silicate

- 137. Additives To improve surface finish, dry strength, refractoriness, and "cushioning(mechanical damping) properties of the casting following: additives may be added upto •Reducing Agents (5%) Coal Powder, Creosote, Pitch, Fuel Oil •Cushioning Material (3%) Wood Flour, Saw Dust Powdered Husks(shell), Peat, And Straw • Cereal Binders (2%) Starch, Dextrin, Molasses Sulphite Lye(strong solution of sodium or potassium hydroxide), •2% Iron Oxide Powder Disadvantage they greatly reduce permeability

- 138. Parting Compounds Common Powders include •Talc •Graphite •Dry Silica Common Liquids include •Mineral Oil •Water-Based Silicon Solutions

- 139. Requirements of molding sand are: (a) Refractoriness (b) Cohesiveness (c) Permeability (d) Collapsibility The performance of mould depends on following factors: (a) Permeability (b) Green strength (c) Dry strength

- 140. Effect of moisture, grain size and shape on mould quality

- 141. Patterns • Variety of patterns are used in casting and the choice depends on the configuration of casting and number of casting required – Single-piece pattern – Split pattern – Follow board pattern – Cope and drag pattern – Match plate pattern – Loose-piece pattern – Sweep pattern – Skeleton pattern

- 142. Pattern geometry Solid Split Match plate‑ Cope and Drag pattern

- 143. (a)Split pattern (b) Follow-board (c) Match Plate (d) Loose-piece (e) Sweep (f) Skeleton pattern

- 144. TABLE 11.3 Ratinga Characteristic Wood Aluminum Steel Plastic Cast iron Machinability E G F G G Wear resistance P G E F E Strength F G E G G Weightb E G P G P Repairability E P G F G Resistance to: Corrosionc E E P E P Swellingc P E E E E aE, Excellent; G, good; F, fair; P, poor. bAs a factor in operator fatigue. cBy water. Source : D.C. Ekey and W.R. Winter, Introduction to Foundry Technology. New York. McGraw-Hill, 1958. Pattern Material Characteristics

- 146. Use of chaplets to avoid shifting of cores Possible chaplet design and casting with core

- 148. 148 And more… Figure 7.2.32 Omit outside bosses and the need for cores. (Courtesy of Meehanite Metal Corp.) Figure 7.2.35 Avoid using ribs which meet at acute angles. (Courtesy of Meehanite Metal Corp.)

- 150. MANUFACTURING MATERIAL COOLING EFFECTS ON MOLD CAVITIES FILLED WITH MOLTEN METAL

- 151. General design rules • Casting soundness-feeder heads can be placed to offset liquid shrinkage • Fillet or round all sharp angles • Bring the minimum number of adjoining sections together • Design all sections as nearly uniform in thickness as possible • Avoid abrupt section changes-eliminate sharp corners at adjoining sections: not exceed a 2:1 ratio • Design ribs for maximum effectiveness-increase stiffness and reduce mass • Avoid bosses & pads unless absolutely necessary

- 152. General design rules continued • Use curved spokes-less likely to crack • Use an odd number of spokes-more resilient to casting stresses • Consider wall thicknesses – Gray-iron & aluminum: .16 in minimum – Malleable iron & steel: .18 in minimum – Bronze,brass,magnesium: .10 minimum Parting lines: a line along which the pattern is divided for molding or along which sections of the mold separate (consider shape of casting, elimination of machining on draft surfaces, methods of supporting cores, location of gates & feeders) Drill holes in castings: small holes are drilled and not cored

- 153. MANUFACTURING MATERIAL DESIGN MEMBERS SO THAT ALL PARTS INCREASE PROGRESSIVELY TO FEEDER RISERS

- 154. MANUFACTURING MATERIAL FILLET ALL SHARP ANGLES

- 155. Other Considerations • Draft angle – Facilitate the removal of the part from the mold – Typically 1º-5º • Shrinkage Allowance – Added to the pattern size so the desired tolerances can be maintained on the part

- 156. Production steps in sand casting including pattern making and mold making

- 158. Squeeze Heads Figure 11.9 Various designs of squeeze heads for mold making: (a) conventional flat head; (b) profile head; (c) equalizing squeeze pistons; and (d) flexible diaphragm. Source: © Institute of British Foundrymen. Used with permission.

- 159. Vertical Flaskless Molding Figure 11.10 Vertical flaskless molding. (a) Sand is squeezed between two halves of the pattern. (b) Assembled molds pass along an assembly line for pouring.

- 160. • A core is a preformed baked sand or green sand aggregate inserted in a mold to shape the interior part of a casting which cannot be shaped by the pattern. • A core box is a wood or metal structure, the cavity of which has the shape of the desired core which is made therein. • A core box, like a pattern is made by the pattern maker. • Cores run from extremely simple to extremely complicated. • A core could be a simple round cylinder form needed to core a hole through a hub of a wheel or it could be a very complicated core used to core out the water cooling channels in a cast iron engine block along with the inside of the cylinders. • Dry sand cores are for the most part made of sharp, clay-free, dry silica sand mixed with a binder and baked until cured; the binder cements the sand together. • When the metal is poured the core holds together long enough for the metal to solidify, then the binder is finely cooked, from the heat of the casting, until its bonding power is lost or burned out. If the core mix is correct for the job, it can be readily removed from the castings interior by simply pouring it out as burnt core sand. This characteristic of a core mix is called its collapsibility. Cores

- 161. • The size and pouring temperature of a casting determines how well and how long the core will stay together. • The gases generated within the core during pouring must be vented to the outside of the mold preventing gas porosity and a defect known as a core blow. Also, a core must have sufficient hot strength to be handled and used properly. • The hot strength refers to its strength while being heated by the casting operation. Because of the shape and size of some cores they must be further strengthened with rods and wires. • A long span core for a length of cast iron pipe would require rodding to prevent the core from sagging or bending upward when the mold is poured because of the liquid metal exerting a strong pressure during pouring.

- 162. BINDERS •There are many types of binders to mix with core sand. A binder should be selected on the basis of the characteristics that are most suitable for particular use. •Some binders require no baking becoming firm at room temperature such as rubber cement, Portland cement and sodium silicate or water glass. • In large foundry operations and in some small foundries, sodium silicate is a popular binder as it can be hardened almost instantly by blowing carbon dioxide gas through the mixture. •The sodium silicate/CO2 process hardens through reaction. The silica gel that is formed binds individual sand grains together. •Oil binders require heating or baking before they develop sufficient strength to withstand the molten metal. • Sulfite binders also require heating. The most popular of the sulfite binders is a product of the wood pulp industry. • There are many liquid binders made from starches, cereals and sugars. They are available under a countless number of trade names.

- 163. A good binder will have the following properties; •Strength •Collapse rapidly when metal starts to shrink. •Will not distort core during baking. •Maintain strength during storage time. •Absorb a minimum of moisture when in the mould or in storage. •Withstand normal handling. •Disperse properly and evenly throughout the sand mix. •Should produce a mixture that can be easily formed MANUFACTURING OF CORE •Core sand mixes can be mixed in a Muller or paddle type mixer and in small amounts on the bench by hand. •The core is made by ramming the sand into the core box and placing the core on a core plate to bake.

- 164. Three Part Core

- 165. Pasted Core

- 166. Core Making: Cores are made of foundry sand with addition of some resin for strength by means of core boxes Core box, two core halves ready for baking, and the complete core made by gluing the two halves together

- 167. Balance Core This is when the core is supported on one end only and the other unsupported end extends a good way into the mold cavity. CHAPLETS • Chaplets consist of metallic supports or spacers used in a mold to maintain cores, which are not self-supporting, in their correct position during the casting process. • They are not required when a pattern has a core print or prints which will serve the same purpose. • The pattern is drilled, wherever a chaplet is needed.

- 168. CORE BAKING AND CORE OVENS •The cores are baked in order to set the binder. •The usual temperature range for oil bonded cores is from 300 to 450 degrees Fahrenheit. The time required varies with the bulk of the core. •A large core might take several days to bake or a small core might bake out in an hour or less. •When an oil core is completely baked the outside is a rich dark brown not black or burned. The core must be cured completely through with no soft centres. •Another factor which relates to the time and temperature required to properly dry a core, is the type and amount of binder used. Oil binders require hotter and quicker baking. •The core oven, which is usually a gas fired oven with temperature controls, is equipped with shelves on which to set the core plates and cores for baking. •The core oven can consist of a square or rectangular brick oven with doors. The bottom of the oven is floor level. The ores are placed on racks which, when full, are rolled into the oven, the oven closed and the cores baked.

- 170. Types of Permanent Pattern Casting TechniquesGreen Sand Molds The most common type consisting of forming the mold from damp molding sand (silica, clay and moisture) Skin-dried Molds It is done in two ways; (1) The sand around the pattern to a depth of about 1/2 in(10 mm) is mixed with a binder so that when it is dried it will leave a hard surface on the mold. (2) Entire mold is made from green sand, but a spray or wash, which hardens when heat is applied, is used. (3) The surface is then dried upto a depth of 12-25 mm by means of hot air, infrared lamp etc. Dry Sand Molds These molds are made entirely from fairly coarse molding sand mixed with binders (linseed oil or gelatinized starch). They baked before being used. A dry sand mold holds its shape when poured and is free from gas troubles due to moisture.

- 171. Floor and Pit Mold Loam sand Mold High Pressure Mold

- 172. Resin Bond : Shell Molding Casting process in which the mold is a thin shell of sand held together by thermosetting resin binder Steps in shell molding: (1) a match plate or cope and drag metal‑ ‑ ‑ ‑ pattern is heated and placed over a box containing sand mixed with thermosetting resin.

- 173. Steps in shell molding: (2) box is inverted so that sand and‑ resin fall onto the hot pattern, causing a layer of the mixture to partially cure on the surface to form a hard shell; (3) box is repositioned so that loose uncured particles drop away;

- 174. Steps in shell molding: (4) sand shell is heated in oven for‑ several minutes to complete curing; (5) shell mold is stripped from the pattern;

- 175. Steps in shell molding: (6) two halves of the shell mold are‑ assembled, supported by sand or metal shot in a box, and pouring is accomplished; (7) the finished casting with sprue removed. From www.janfa.com

- 176. Advantages and Disadvantages • Advantages of shell molding: – Smoother cavity surface permits easier flow of molten metal and better surface finish – Good dimensional accuracy - machining often not required – Mold collapsibility minimizes cracks in casting – Can be mechanized for mass production • Disadvantages: – More expensive metal pattern – Difficult to justify for small quantities

- 177. Resin Bond Cold Box – synthetic liquid resin mixed with sand. – Cold-setting process- bonding of mold takes place without heat Hot Box organic and inorganic binders added. greater dimensional accuracy. greater cost.

- 178. Schematic of the V-process or vacuum molding. A) A vacuum is pulled on a pattern, drawing a heated shrink-wrap plastic sheet tightly against it. b) A vacuum flask is placed over the pattern and filled with dry unbonded sand, a pouring basin and sprue are formed; the remaining sand is leveled; a second heated plastic sheet is placed on top; and a mold vacuum is drawn to compact the sand and hold the shape. c) With the mold vacuum being maintained, the pattern vacuum is then broken and the pattern is withdrawn. The cope and drag segments are assembled, and the molten metal is poured. V Process- No Bond

- 179. Advantages and Disadvantages of the V-Process • Advantages – Absence of moisture-related defects – Binder cost is eliminated – Sand is completely reusable – Finer sands can be used – Better surface finish – No fumes generated during the pouring operation – Exceptional shakeout characteristics • Disadvantages – Relatively slow process – Used primarily for production of prototypes – Low to medium volume parts – More than 10 but less than 50,000

- 180. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Plaster Mold Casting Similar to sand casting except mold is made of plaster of Paris (gypsum CaSO‑ 4 2H‑ 2O) • In mold-making, plaster and water mixture is poured over plastic or metal pattern and allowed to set – Wood patterns not generally used due to extended contact with water • Plaster mixture readily flows around pattern, capturing its fine details and good surface finish

- 181. Engr 241 181 Plaster–mold casting(cont.) • Mold dried in oven • Poured in vacuum or under pressure due to low permeability • Low permeability (gas cannot escape)

- 182. Plaster-Mold Casting Antioch Process • Plaster of paris with talc and silica flour. • Mixed with water • Poured over pattern • Plaster sets – pattern removed Engr 241 182

- 183. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Advantages and Disadvantages • Advantages of plaster mold casting: – Good accuracy and surface finish – Capability to make thin cross sections‑ • Disadvantages: – Mold must be baked to remove moisture, which can cause problems in casting – Mold strength is lost if over-baked – Plaster molds cannot stand high temperatures, so limited to lower melting point alloys (Mg, A, Zn)

- 184. Slip Casting

- 185. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Ceramic Mold Casting Similar to plaster mold casting except that mold is made of refractory ceramic material zircon, aluminum oxide and fused silica that can withstand higher temperatures than plaster • Can be used to cast steels, cast irons, and other high temperature alloys‑ • Applications similar to those of plaster mold casting except for the metals cast • Advantages (good accuracy and finish) also similar but expansive

- 186. Unicast and Shaw Process a mixture of refractory aggregate, hydrolyzed ethyl silicate, alcohol, and a gelling agent to create a mold. The slurry hardens almost immediately to a rubbery state . The flask and pattern is then removed. Then a torch is used to ignite the mold, which causes most of the volatiles to burn-off and the formation of ceramic microcrazes (microscopic cracks). These cracks are important, because they allow gases to escape while preventing the metal from flowing through; they also ease thermal expansion and contraction during solidification and shrinkage. After the burn-off, the mold is baked at 1,800 °F (980 °C) to remove any remaining volatiles. Prior to pouring metal, the mold is pre-warmed to control shrinkage

- 188. A typical ceramic mold (Shaw process) for casting steel dies used in hot forging. Source: Metals Handbook, vol. 5, 8th ed.

- 189. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Expanded Polystyrene Process Expanded polystyrene casting process: pattern of polystyrene is coated with refractory compound; Uses a mold of sand packed around a polystyrene foam pattern which vaporizes when molten metal is poured into mold Other names: lost foam process, lost pattern process,‑ evaporative foam process, and full mold process‑ ‑ Polystyrene foam pattern includes sprue, risers, gating system, and internal cores (if needed) Mold does not have to be opened into cope and drag sections From www.wtec.org/loyola/casting/fh05_20.jpg

- 190. Expanded Polystyrene Process Foam pattern is placed in mold box, and sand is compacted around the pattern; Molten metal is poured into the portion of the pattern that forms the pouring cup and sprue. As the metal enters the mold, the polystyrene foam is vaporized ahead of the advancing liquid, thus the resulting mold cavity is filled.

- 192. Full Mold

- 193. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Advantages and Disadvantages • Advantages of expanded polystyrene process: – Pattern need not be removed from the mold – Simplifies and speeds mold making, because two mold‑ halves are not required as in a conventional green sand‑ mold • Disadvantages: – A new pattern is needed for every casting – Economic justification of the process is highly dependent on cost of producing patterns

- 194. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Expanded Polystyrene Process • Applications: – Mass production of castings for automobile engines – Automated and integrated manufacturing systems are used to 1. Mold the polystyrene foam patterns and then 2. Feed them to the downstream casting operation

- 195. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Investment Casting (Lost Wax Process) A pattern made of wax (plastic) is coated with a refractory material to make mold, after which wax is melted away prior to pouring molten metal • "Investment" comes from a less familiar definition of "invest" - "to cover completely," which refers to coating of refractory material around wax pattern • It is a precision casting process - capable of producing castings of high accuracy and intricate detail

- 196. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Investment Casting Figure 11.8 Steps in investment casting: (1) wax patterns are produced, (2) several patterns are attached to a sprue to form a pattern tree

- 197. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Investment Casting Figure 11.8 Steps in investment casting: (3) the pattern tree is coated with a thin layer of refractory material, (4) the full mold is formed by covering the coated tree with sufficient refractory material to make it rigid

- 198. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Investment Casting Figure 11.8 Steps in investment casting: (5) the mold is held in an inverted position and heated to melt the wax and permit it to drip out of the cavity, (6) the mold is preheated to a high temperature, the molten metal is poured, and it solidifies

- 199. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Investment Casting Figure 11.8 Steps in investment casting: (7) the mold is broken away from the finished casting and the parts are separated from the sprue

- 200. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Investment Casting Figure 11 9 A one piece compressor stator with 108 separate‑ airfoils made by investment casting (photo courtesy of Howmet Corp.).

- 201. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Advantages and Disadvantages • Advantages of investment casting: – Parts of great complexity and intricacy can be cast – Close dimensional control and good surface finish – Wax can usually be recovered for reuse – Additional machining is not normally required this is a‑ net shape process • Disadvantages – Many processing steps are required – Relatively expensive process

- 202. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Permanent Mold Casting Processes • Economic disadvantage of expendable mold casting: a new mold is required for every casting • In permanent mold casting, the mold is reused many times • The processes include: – Basic permanent mold casting – Die casting – Centrifugal casting

- 203. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e The Basic Permanent Mold Process Uses a metal mold constructed of two sections designed for easy, precise opening and closing •Molds used for casting lower melting point alloys are commonly made of steel or cast iron •Molds used for casting steel must be made of refractory material, due to the very high pouring temperatures

- 205. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Permanent Mold Casting Figure 11.10 Steps in permanent mold casting: (1) mold is preheated and coated

- 206. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Permanent Mold Casting Figure 11.10 Steps in permanent mold casting: (2) cores (if used) are inserted and mold is closed, (3) molten metal is poured into the mold, where it solidifies.

- 207. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Advantages and Limitations • Advantages of permanent mold casting: – Good dimensional control and surface finish – More rapid solidification caused by the cold metal mold results in a finer grain structure, so castings are stronger • Limitations: – Generally limited to metals of lower melting point – Simpler part geometries compared to sand casting because of need to open the mold – High cost of mold

- 208. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Applications of Permanent Mold Casting • Due to high mold cost, process is best suited to high volume production and can be automated accordingly • Typical parts: automotive pistons, pump bodies, and certain castings for aircraft and missiles • Metals commonly cast: aluminum, magnesium, copper base alloys, and cast iron‑

- 209. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Die Casting A permanent mold casting process in which molten metal is injected into mold cavity under high pressure •Pressure is maintained during solidification, then mold is opened and part is removed •Molds in this casting operation are called dies; hence the name die casting •Use of high pressure to force metal into die cavity is what distinguishes this from other permanent mold processes

- 210. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Die Casting Machines • Designed to hold and accurately close two mold halves and keep them closed while liquid metal is forced into cavity

- 213. Process Capabilities and Machine SelectionProcess Capabilities and Machine Selection – Dies are rated according to their clamping force that is needed – Factors involved in selection of die cast machines are • Die size • Piston stroke • Shot pressure • Cost – Die-casting dies • Single cavity • Multiple-cavity • Combination-cavity • Unit dies – Ratio of Die weight to part weight is 1000 to 1 – Surface cracking is a problem with dies due to the hot metal that is poured in to them – Has ability to produce strong high- quality parts with complex shapes – Good dimensional accuracy and surface details

- 214. Various types of cavities in a die casting die.Various types of cavities in a die casting die. a) Single – cavity die b) Multiple – cavity die c) Combination die d) Unit die

- 215. Die CastingDie Casting • Molten metal is forced into the die cavity at pressures ranging from .7MPa – 700MPa • Parts made from here range from: – Hand tools – Toys – Appliance components • There are two basic types of die casting machines – Hot-chamber - involves the use of a piston to push molten metal in to the die cavity – Cold-chamber – molten metal is poured in to the injection chamber & the shot chamber is not heated

- 216. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Hot-Chamber Die Casting Metal is melted in a container, and a piston injects liquid metal under high pressure into the die •High production rates - 500 parts per hour not uncommon •Applications limited to low melting point metals that do not chemically attack plunger and other mechanical components •Casting metals: zinc, tin, lead, and magnesium

- 217. Hot-Chamber Die Casting Cycle in hot chamber casting: (1) with die closed and plunger‑ withdrawn, molten metal flows into the chamber (2) plunger forces metal in chamber to flow into die, maintaining pressure during cooling and solidification.

- 218. Die Casting in Hot-Chamber Process • FIGURE 5.28 Sequence of steps in die casting of a part in the hot-chamber process. Source: Courtesy of Foundry Management and Technology.

- 219. Hot chamber Die-casting processHot chamber Die-casting process • 1. The die is closed and the piston rises, opening the port and allowing molten metal to fill the cylinder. • 2. The plunger moves down and seals the port pushing the molten metal through the gooseneck and nozzle into the die cavity, where it is held under pressure until it solidifies.

- 220. • 3. The die opens and the cores, if any, retract. The casting remains in only one die, the ejector side. The plunger returns, allowing residual molten metal to flow back through the nozzle and gooseneck. • 4. Ejector pins push the casting out of the ejector die. As the plunger uncovers the filling hole, molten metal flows through the inlet to refill the gooseneck, as in step (1).

- 221. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Cold Chamber Die Casting Machine‑ Molten metal is poured into unheated chamber from external melting container, and a piston injects metal under high pressure into die cavity •High production but not usually as fast as hot chamber machines because of pouring step‑ •Casting metals: aluminum, brass, and magnesium alloys •Advantages of hot chamber process favor its use‑ on low melting point alloys (zinc, tin, lead)‑

- 222. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Cold Chamber Die Casting‑ Cycle in cold chamber casting: (1) with die closed and ram‑ withdrawn, molten metal is poured into the chamber

- 223. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Cold Chamber Die Casting‑ Cycle in cold chamber casting: (2) ram forces metal to flow into die,‑ maintaining pressure during cooling and solidification.

- 224. Cold-Die casting processCold-Die casting process • 1. The die is closed and the molten metal is ladled into the cold-chamber shot sleeve. • 2. The plunger pushes the molten metal into the die cavity where it is held under pressure until solidification.

- 225. • 3. The die opens and the plunger advances, to ensure that the casting remains in the ejector die. Cores, if any, retract. • 4. Ejector pins push the casting out of the ejector die and the plunger returns to its original position.

- 226. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Molds for Die Casting • Usually made of tool steel, mold steel, or maraging steel • Tungsten and molybdenum (good refractory qualities) used to die cast steel and cast iron • Ejector pins required to remove part from die when it opens • Lubricants must be sprayed into cavities to prevent sticking

- 227. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Advantages and Limitations • Advantages of die casting: – Economical for large production quantities – Good accuracy and surface finish – Thin sections are possible – Rapid cooling provides small grain size and good strength to casting • Disadvantages: – Generally limited to metals with low metal points – Part geometry must allow removal from die

- 228. Low Pressure Die Casting Process

- 229. Pressure-Casting Process • FIGURE 5.27 The pressure-casting process uses graphite molds for the production of steel railroad wheels. Source: Griffin Wheel Division of Amsted Industries Incorporated.

- 230. (a) The bottom-pressure casting process utilizes graphite molds for the productin of steel railroad wheels. (b) Gravity pouring method of casting a railroad wheel. Note that the pouring basin also serves as a riser. Pressure CastingPressure Casting

- 231. Slush CastingSlush Casting • Molten metal is poured into the metal mold • A desired thickness of the solidified skin is obtained • The remaining metal is poured out • The mold halves are then opened and the casting is removed • Used a graphite or metal mold • Molten metal is forced into the mold by gas pressure • The pressure is maintained until the metal solidifies in the mold • Used for high-quality castings Pressure CastingPressure Casting

- 232. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Centrifugal Casting A family of casting processes in which the mold is rotated at high speed so centrifugal force distributes molten metal to outer regions of die cavity •The group includes: – True centrifugal casting – Semi centrifugal casting – Centrifuge casting

- 233. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e True Centrifugal Casting Molten metal is poured into rotating mold to produce a tubular part •In some operations, mold rotation commences after pouring rather than before •Parts: pipes, tubes, bushings, and rings •Outside shape of casting can be round, octagonal, hexagonal, etc , but inside shape is (theoretically) perfectly round, due to radially symmetric forces

- 234. Centrifugal Casting Process FIGURE 5.30 Schematic illustration of the centrifugal casting process. Pipes, cylinder liners, and similarly shaped parts can be cast by this process.

- 236. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Semicentrifugal Casting Centrifugal force is used to produce solid castings rather than tubular parts • Molds are designed with risers at center to supply feed metal • Density of metal in final casting is greater in outer sections than at center of rotation • Often used on parts in which center of casting is machined away, thus eliminating the portion where quality is lowest • Examples: wheels and pulleys

- 237. Semicentrifugal Casting Process •FIGURE 5.31 (a) Schematic illustration of the semicentrifugal casting process. (b) Schematic illustration of casting by centrifuging. The molds are placed at the periphery of the machine, and the molten metal is forced into the molds by centrifugal forces.

- 238. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Centrifuge Casting Mold is designed with part cavities located away from axis of rotation, so that molten metal poured into mold is distributed to these cavities by centrifugal force •Used for smaller parts •Radial symmetry of part is not required as in other centrifugal casting methods

- 239. Vacuum CastingVacuum Casting1. Mixture of fine sand and urethane is molded over metal dies a cured with amine vapor 2. The mold is partially immersed into molten metal held in an induction furnace 3. The metal is melted in air or in a vacuum 4. The molten metal is usually 55 C above the liquidus temperature – begins to solidify within a fraction of a second 5. Alternative to investment, shell- mold, and green-sand casting 6. Relatively low cost

- 241. Squeeze-Casting Process • FIGURE 5.32 Sequence of operations in the squeeze-casting process. This process combines the advantages of casting and forging.

- 244. Plaster Molds Plaster or plaster-bonded molds are used for casting certain aluminum or copper base alloys. Dimensional accuracy and excellent surface finish make this a useful process for making rubber tire molds, match plates, etc. A variation of this method of molding is the Antioch process, using mixtures of 50 percent silica sand, 40 percent gypsum cement, 8 percent talc, and small amounts of sodium silicate, portland cement, and magnesium oxide. These dry ingredients are mixed with water and poured over the pattern. After the mixture is poured, the mold is steamtreated in an autoclave and then allowed to set in air before drying in an oven. When the mold has cooled it is ready for pouring. Tolerances of 0.005 in (0.13 mm) on small castings and 0.015 in (0.38 mm) on large castings are obtained by this process. A problem presented by plaster molds lies in inadequate permeability in the mold material consistent with the desired smooth mold cavity surface. A closely related process, the Shaw process, provides a solution

- 245. In this process, a refractory aggregate is mixed with a gelling agent and then poured over the pattern. Initial set of the mixture results in a rubbery consistency which allows it to be stripped from the pattern but which is sufficiently strong to return to the shape it had when on the pattern. The mold is then ignited to burn off the volatile content in the set gel and baked at very high heat. This last step results in a hard, rigid mold containing microscopic cracks. The permeability of the completed mold is enhanced by the presence of the so-called microcrazes, while the mold retains the high-quality definition of the mold surface. Two facts are inherent in the nature of sand molds: First, there may be one or few castings required of a given piece, yet even then an expensive wood pattern is required. Second, the requirement of removal of the pattern from the mold may involve some very intricate pattern construction. These conditions may be alleviated entirely by the use of the full mold process, wherein a foamed polystyrene pattern is used. Indeed, the foamed pattern may be made complete with a gating and runner system, and it can incorporate the elimination of draft allowance. In actual practice, the pattern is left in place in the mold and is instantly vaporized when hot metal is poured. The hot metal which vaporized the foam fills the mold cavity to the shape occupied previously by the foam pattern. This process is ideal for casting runs of one or a few pieces, but it can be applied to production quantities by mass-producing the foam patterns. There is extra expense for the equipment to make the destructible foam patterns, but often the economics of the total casting process is quite favorable when compared with resorting to a reusable pattern. There are particular instances when the extreme complexity of a casting can make a hand-carved foam pattern financially attractive.

- 246. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e True Centrifugal Casting Setup for true centrifugal casting.

- 247. Die casting - a type of permanent mold casting - common uses: components for rice cookers, stoves, fans, washing-, drying machines, fridges, motors, toys, hand-tools, car wheels, … HOT CHAMBER: (low mp e.g. Zn, Pb; non-alloying) (i) die is closed, gooseneck cylinder is filled with molten metal (ii) plunger pushes molten metal through gooseneck into cavity (iii) metal is held under pressure until it solidifies (iv) die opens, cores retracted; plunger returns (v) ejector pins push casting out of ejector die COLD CHAMBER: (high mp e.g. Cu, Al) (i) die closed, molten metal is ladled into cylinder (ii) plunger pushes molten metal into die cavity (iii) metal is held under high pressure until it solidifies (iv) die opens, plunger pushes solidified slug from the cylinder (v) cores retracted (iv) ejector pins push casting off ejector die

- 248. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Furnaces for Casting Processes • Furnaces most commonly used in foundries: – Cupolas – Direct fuel fired furnaces‑ – Crucible furnaces – Electric arc furnaces‑ – Induction furnaces

- 249. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Cupolas Vertical cylindrical furnace equipped with tapping spout near base • Used only for cast irons – Although other furnaces are also used, the largest tonnage of cast iron is melted in cupolas • The "charge," consisting of iron, coke, flux, and possible alloying elements, is loaded through a charging door located less than halfway up height of cupola

- 250. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Direct Fuel Fired Furnaces‑ Small open hearth in which charge is heated by‑ natural gas fuel burners located on side of furnace • Furnace roof assists heating action by reflecting flame down against charge • At bottom of hearth is a tap hole to release molten metal • Generally used for nonferrous metals such as copper base alloys and aluminum‑

- 251. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Crucible Furnaces Metal is melted without direct contact with burning fuel mixture • Sometimes called indirect fuel fired furnaces‑ • Container (crucible) is made of refractory material or high temperature steel alloy‑ • Used for nonferrous metals such as bronze, brass, and alloys of zinc and aluminum • Three types used in foundries: (a) lift out‑ type, (b) stationary, (c) tilting

- 252. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Crucible Furnaces Figure 11.19 Three types of crucible furnaces: (a) lift out crucible, (b)‑ stationary pot, from which molten metal must be ladled, and (c) tilting- pot furnace.

- 253. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Electric Arc Furnaces‑ Charge is melted by heat generated from an electric arc • High power consumption, but electric arc furnaces can be designed‑ for high melting capacity • Used primarily for melting steel

- 254. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Induction Furnaces Uses alternating current passing through a coil to develop magnetic field in metal • Induced current causes rapid heating and melting • Electromagnetic force field also causes mixing action in liquid metal • Since metal does not contact heating elements, environment can be closely controlled to produce molten metals of high quality and purity • Melting steel, cast iron, and aluminum alloys are common applications in foundry work

- 255. ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Ladles • Moving molten metal from melting furnace to mold is sometimes done using crucibles • More often, transfer is accomplished by ladles

- 256. Die Casting in Cold-Chamber Process • FIGURE 5.29 Sequence of operations in die casting of a part in the cold- chamber process.

Notas del editor

- Like water to ice