Presentation

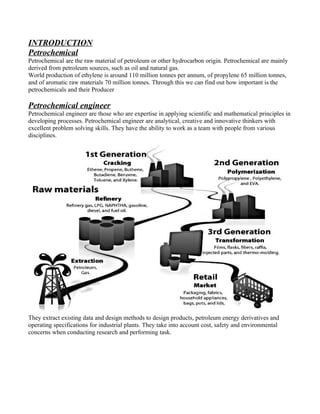

- 1. INTRODUCTION Petrochemical Petrochemical are the raw material of petroleum or other hydrocarbon origin. Petrochemical are mainly derived from petroleum sources, such as oil and natural gas. World production of ethylene is around 110 million tonnes per annum, of propylene 65 million tonnes, and of aromatic raw materials 70 million tonnes. Through this we can find out how important is the petrochemicals and their Producer Petrochemical engineer Petrochemical engineer are those who are expertise in applying scientific and mathematical principles in developing processes. Petrochemical engineer are analytical, creative and innovative thinkers with excellent problem solving skills. They have the ability to work as a team with people from various disciplines. They extract existing data and design methods to design products, petroleum energy derivatives and operating specifications for industrial plants. They take into account cost, safety and environmental concerns when conducting research and performing task.

- 2. ROLE OF PETROCHEMICAL ENGINEER IN PETROCHEMICAL INDUSTRY The role of petrochemical engineer may focus on one or more of the following; Researching new products from trial through to commercialization; managing scale-up processes from plant to full industrial-scale manufacturing; improving product lines; modifying the processing plant that produces the products; and designing and commissioning new plants. Some of their detailed work is given below:- Design and operating process for commercial product A Petrochemical engineer develops economical industrial processes to make the huge range of products on which modern society depends, including: fuel; artificial fibres; pharmaceuticals; chemicals and plastics. From different process petrochemical engineer made a very wide range of chemicals and other materials to regenerate them used in industry - monomers, solvents, detergents, and adhesives. Process that takes place in a petrochemical engineering Cacking Mainly is the cracking process use in industy which means to break a larger molecule into smaller ones and byproduct. Some cracking process are: • Fluid catalytic cracking Fluid catalytic cracking is a process of breaking down the larger, heavier and more complex hydrocarbon molecules into single and lighter molecule using fluid bed catalyst. It is commonly used process where gasoline is required. • Hydro cracking Hydro cracking is a catalytic cracking process assisted by the presence of an elevated partial pressure of hydrogen gas. The function of hydrogen is the purification of the hydrocarbon stream from sulphur. It is mainly used where the demand of diesel is larger. • Steam cracking

- 3. Steam cracking is a petrochemical process in which saturated hydrocarbons are broken using steams. It is commonly used for producing the lighter alkenes including ethene and propene. In steam cracking, a gaseous or liquid hydrocarbon feed like naphtha, LPG or ethane is diluted with steam and briefly heated in a furnace without the presence of oxygen. • Thermal Cracking Thermal cracking is a process used to break up heavy oil molecules into lighter more valuable fraction by the use of high temperature without the aid of catalyst. A Petrochemical engineer works in the process field on various different stages, i.e. • reviewing data to see if more research and information needed; • designing and installing new production unit, monitoring and upgrading the processes; • preparing reports, flow diagrams and charts; Management of industrial plant and sizing of equipment Engineer work on the field localizing the space for plant and instrument to be shifted according to their need and use the equipment as per required. Basically in every industry there is a cost management process to overcome the capital cost in the return of interest and for it the engineer surpress the need of solvent by usig different equipments. A petrochemical engineer select the appropriate techniques and sequence of events for a particular project in sizing the equipment and plantation. Heat Exchanger Distillation Tower

- 4. Fuel Tanks Pipe and Valve Instrumentation of equipments Petrochemical engineer is responsible for designing, developing, installing, managing and/or maintaining equipment which is used to monitor and control engineering systems, machinery. The main objective of the work of petrochemical engineer is to ensure that these systems and processes operate effectively, efficiently and safely. Designs plants and equipments configuration so that they can be readily adapted to suit the product range and the process technologies involved, taking environmental and economic aspects into account;

- 5. Maintaining machines and plant operation Petrochemical engineers plan the routine maintenance of equipment and machinery. They work on-site or remotely diagnosing faults and overseeing time-critical repairs. Petrochemical engineers use sophisticated, computerized systems to schedule the work. The activities of a Petrochemical engineer are, • controlling maintenance tools, stores and equipment; • monitoring and controlling maintenance costs; • designing maintenance strategies, procedures and methods; • diagnosing breakdown problems;

- 6. Economic evaluation of project and labour A petrochemical engineer, • Generates a set of projects or purchases for investment consideration, • Establish the planning horizon for economic analysis, • Estimate the cash flow profile for each project, • Accept or reject a proposal on the basis of the established criterion. A petrochemical engineer’s job is to organize his/her department and employees, visualize future impacts and needs, energize the employees to get their tasks done Although economic evaluations approach costs in a common format, they differ in the way they approach benefits. These differences play a critical role in developing criteria in petrochemical industry. Design and operate of environmental control system Environmental control engineering may be defined as the use of engineering and scientific principles for the improvement of the built and natural environment. Petrochemical engineers practice the science of environmental sustainability. Petrochemical engineers understand the environmental impact of many pollutions sources such as Carbon dioxide (CO2) and industrial emissions Gases from manufacturing. Quality assurance for process and products Quality assurance (QA) aims to ensure that the product or service an industry provides is fit for its purpose and meets customer expectations. A Petrochemical engineer co-ordinate the activities required to meet this aim. The Petrochemical engineer monitors and advises on how the quality management system is performing and publishes data and reports regarding company performance against set indicators. •ensuring compliance with national and international standards and legislation; •promoting quality achievement and performance improvement throughout the process;

- 7. Supervising the operation A petrochemical engineer as a supervisor is first and foremost an overseer whose main responsibility is to ensure that a group of subordinates get out the assigned amount of production, when they are supposed to do it and within acceptable levels of quality, costs and safety. In particular, the supervisor can have a significant effect on how effectively their staff perform as a team. general operations; general house keeping and continual improvement activities; reallocating tasks or rescheduling production, where necessary. The responsibility they carry varies with the situation. In some cases they may have to take technical decisions on a regular basis, whereas in others they may call upon maintenance or other technical staff for backup when necessary. Conducting surveys A Petrochemical engineer investigates, plans and manages proposals to either build new developments or organise the regeneration of existing plant. Surveying and development takes into account both the physical and social impact of the built environment and the commercial viability of any proposals. The exact nature of a engineer is their working activities as surveyor i.e. • ensuring that the production is cost effective. • advising on procurement strategy; • understanding the implications of health and safety regulations; CONCLUSION This is a petrochemical engineer who works in the petrochemical industry perform various tasks and operation with his/her staff and faculty members, without it the valuable and useful product from Raw material can’t be in progress. A Petrochemical engineer has a precise nature. Anything that is scientific warrants preciseness by those working in this field. A petrochemical engineer is no different. Since the engineers are using various types of sciences to complete their job, it is important that they are precise. Not only will this make their job easier but it will also make it less likely that they make a mistake in the calculations and the final product as a result thereof. The industry has made great strides in controlling unwanted emissions; compared with other resource industries due to a petrochemical engineer, its emissions are low per unit of output.