50727481 checklist-for-site-works

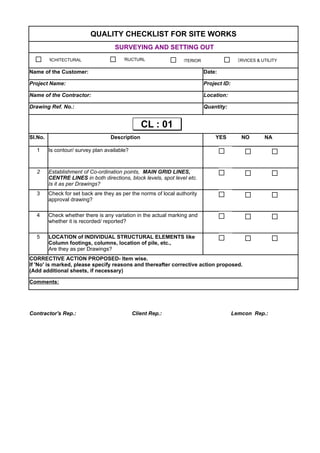

- 1. QUALITY CHECKLIST FOR SITE WORKS SURVEYING AND SETTING OUT Name of the Customer: Date: Project Name: Project ID: Name of the Contractor: Location: Drawing Ref. No.: Quantity: Sl.No. Description YES NO NA 1 Is contour/ survey plan available? 2 3 4 5 Comments: Contractor's Rep.: Client Rep.: Lemcon Rep.: Establishment of Co-ordination points, MAIN GRID LINES, CENTRE LINES in both directions, block levels, spot level etc. Is it as per Drawings? Check for set back are they as per the norms of local authority approval drawing? Check whether there is any variation in the actual marking and whether it is recorded/ reported? LOCATION of INDIVIDUAL STRUCTURAL ELEMENTS like Column footings, columns, location of pile, etc., Are they as per Drawings? CORRECTIVE ACTION PROPOSED- Item wise. If 'No' is marked, please specify reasons and thereafter corrective action proposed. (Add additional sheets, if necessary) ARCHITECTURAL STRUCTURL INTERIOR SERVICES & UTILITY CL : 01CL : 01

- 2. QUALITY CHECKLIST FOR SITE WORKS EARTH WORK/ BACKFILLING Name of the Customer: Date: Project Name: Project ID: Name of the Contractor: Location: Drawing Ref. No.: Quantity: Sl.No. Description YES NO NA 1 Is format CL: 01 for Surveying complied with? 2 3 4 Is adequate shoring, strutting done? 5 Check for DEWATERING. Is it O.K.? 6 Is the excavation done up-to the level as per drawing. A. NATURAL EXISTING GROUND LEVEL : B. FOUNDING LEVEL : C. DEPTH OF EXCAVATION : BACKFILLING 1 Is the earth used for filling as per specification? 2 3 Contractor's Rep.: Client Rep.: Lemcon Rep.: Whether suitable arrangements for re-routing the service lines done? Is the LAYOUT, ALIGNMENT and SIZE of Excavation marked on the ground as per drawings? Check for the approved method of compaction, ie. (Roller, plate compactor, etc.,) Whether Proctor compaction test carried out satisfactorily as per the requirement? CORRECTIVE ACTION PROPOSED- Item wise. If 'No' is marked, please specify reasons and thereafter corrective action proposed. ARCHITECTURAL STRUCTURAL SITE DEVELOPMENT SERVICES & UTILITY CL : 02CL : 02 $ $

- 3. QUALITY CHECKLIST FOR SITE WORKS CONCRETE POUR CARD Name of the Customer: Date: Project Name: Project ID: Name of the Contractor: Location: Drawing Ref. No.: Grade & Quantity : Sl.No. Description YES NO NA A. FORM WORK: 1 Level 2 Plumb 3 Cutouts B. Reinforcement: 1 As per bar bending schedule 2 Dowel bars 3 Links 4 Binding/ Welding C. Services: 1 Position 2 Size 3 Trimming bars D. General 1 Embedments 2 Water proofing 3 Construction Joint E. Sampling: 1 Mix as per design : 2 No. of sample & Identity Comments: Contractor's Rep.: Client Rep.: Lemcon Rep.: IF 'YES', THEN SITE ENGINEER SHALL TAKE SUITABLE CORRECTIVE ACTION in consultation with PRT/ AST/ PRM AND RECHECK . CORRECTIVE ACTION PROPOSED- Item wise. If 'No' is marked, please specify reasons and thereafter corrective action proposed. (Add additional sheets, if necessary) ARCHITECTURAL STRUCTURAL INTERIOR SERVICES & UTILITY CL : 03CL : 03

- 4. QUALITY CHECKLIST FOR SITE WORKS WATER PROOFING Name of the Customer: Date: Project Name: Project ID: Name of the Contractor: Location: Drawing Ref. No.: Quantity: Sl.No. Description YES NO NA 1 2 Check for surface preparation. Is it o.k.? 3 Check for Plastering before coating. Is it o.k.? 4 Check for coating of chemical. Is it o.k.? 5 Check for Plastering after coating. Is it o.k.? 6 Check for fixing of nozzles and spacing. Is it o.k.? 7 Check for grouting. Is it o.k.? 8 Check for brickbatcoba thickness & slopes. 9 Check for curing. Is it o.k.? Comments: Contractor's Rep.: Client Rep.: Lemcon Rep.: Whether approved / specified materials used as per specification? CORRECTIVE ACTION PROPOSED- Item wise. If 'No' is marked, please specify reasons and thereafter corrective action proposed. (Add additional sheets, if necessary) ARCHITECTURAL STRUCTURAL INTERIOR SERVICES & UTILITY 1. Raft slab 2. Retaining wall 3. Toilet sunken 4. Terrace CL : 04CL : 04

- 5. QUALITY CHECKLIST FOR SITE WORKS EXTERNAL & PARTITION WALL/ RR MASONRY Name of the Customer: Date: Project Name: Project ID: Name of the Contractor: Location: Drawing Ref. No.: Quantity: Sl.No. Description YES NO NA Thickness 1 2 Check for placing reinforcement RC bands as per specification. 3 4 INTERIOR - (PARTITION / WALL PANELLING FRAME WORK) 1 Type of Partitions/ Frame etc., Frame work materials used. a) Aluminum frames b) Timber frames c) G.I /M.S frames 2 3 Height of Partition. b) Half height 4 5 6 Comments: Contractor's Rep.: Client Rep.: Lemcon Rep.: Check for ALIGNMENT & LOCATION of wall. Is it as per drawing? Check for MORTAR MIX PROPORTION is ok? Check for SIZES OF OPENINGS for Doors & Windows? / Any other sevices. AC duct, Cable tray, chilled water pipe, etc. If it is wooden partition, check for Anti-termite/ wood borer preventing treatment provided? Whether the frame work sufficiently anchored in the floor & true ceiling? Check provisions made in the frame work for fixing conduits for electrical, Data lines etc., as per drawings. Check for approved make of finishing materials as per specification. CORRECTIVE ACTION PROPOSED- Item wise. If 'No' is marked, please specify reasons and thereafter corrective action proposed. (Add additional sheets, if necessary) : ARCHITECTURAL STRUCTURAL INTERIOR SERVICES & UTILITY 9. Glazed Hollow 1. Brick 2. Solid Block 4. R . R 5. C. R 10. Others6. Aerocon Block 7. Gypsum 3. Hollow Block 8. Wooden CL : 05CL : 05

- 6. QUALITY CHECKLIST FOR SITE WORKS PLASTERING/ PAINTING Name of the Customer: Date: Project Name: Project ID: Name of the Contractor: Location: Drawing Ref. No.: Quantity: Sl.No. Description YES NO NA 1 2 3 4 PAINTING 1 DURING & AFTER PAINTING 1 2 Check for Number of Coats. Comments: Contractor's Rep.: Client Rep.: Lemcon Rep.: Check for COMPLETION OF PRECEDING ACTIVITIES like fixing of service Conduits, Water Supply & sanitation lines, etc. Whether chicken mesh, Corner beads used as per specifications? Check for MORTAR MIX PROPORTION & Check for Surface of mortar mixing and addition of water profing compond if required. Check for THICKNESS & NUMBER OF COATS of Plaster and required finish for further activities. PRIOR TO PAINTING Check whether approved make & shade are used? Check for APPLICATION of paint. Is it uniform? CORRECTIVE ACTION PROPOSED- Item wise. If 'No' is marked, please specify reasons and thereafter corrective action proposed. (Add additional sheets, if necessary) ARCHITECTURAL STRUCTURAL INTERIOR SERVICES & UTILITY CL : 06CL : 06

- 7. QUALITY CHECKLIST FOR SITE WORKS JOINERIES - (FIXING DOORS/ WINDOWS/ VENTILATOR) Name of the Customer: Date: Project Name: Project ID: Name of the Contractor: Location: Drawing Ref. No.: Quantity: Sl.No. Description YES NO NA 1 Whether specified material and approved sample are used? 2 3 4 Check for fixing and grouting of frames with hold fasts. Is it o.k.? 5 Check whether architrave is specified for door frames? 6 7 Locks/ Latches 8 Handle 9 Weather stripping / Stoppers Comments: Contractor's Rep.: Client Rep.: Lemcon Rep.: Check for the correct size of frames/ shutters as per drawing. Is it o.k? Check for the proper primer painting, powder coating, Anodizing coating and other finishes to frames before fixing. Is it o.k.? Check vision panel, door closers, floor spring, Access card , whether provision made. CORRECTIVE ACTION PROPOSED- Item wise. If 'No' is marked, please specify reasons and thereafter corrective action proposed. (Add additional sheets, if necessary) ARCHITECTURAL STRUCTURAL INTERIOR SERVICES & UTILITY CL : 07CL : 07

- 8. QUALITY CHECKLIST FOR SITE WORKS FLOORING/ DADOING Name of the Customer: Project Name: Name of the Contractor: Drawing Ref. No.: Sl.No. Description I Prior to Tiling: 1 2 3 4 5 6 7 LAYING PAVER BLOCKS 1 All pipe line/ Conduiting/ Sleeve work completed. 2 Check formation level ie. Bottom of sand bedding 3 Check thickness, shape, colour, pattern of paver blocks. Comments: Contractor's Rep.: Client Rep.: Lemcon Rep.: Check for COMPLETION OF PRECEDING ACTIVITIES like fixing of Door, Frames, Partitions, etc. A. Check for Provision of Service Conduits, junction Boxes, plumbing, etc. Is the SAMPLE OF TILES approved?. Check for MORTAR MIX/ ADHESIVE PROPORTION. Is it as specified? Check for THICKNESS OF MORTAR BED. Is it o.k? Check for PATTERN OF LAYING. Is it ok? Check for TOP LEVEL. Is it o.k? CORRECTIVE ACTION PROPOSED- Item wise. If 'No' is marked, please specify reasons and thereafter corrective action proposed. (Add additional sheets, if necessary) ARCHITECTURAL INTERIOR 1. Ceramic tile 2. Vitrified tile 3. Marble 5. Cement based tile 6. Mosaic DADOINGFLOORING SKIRTING 7. Paver block CL : 08CL : 08

- 9. FOR SITE WORKS ADOING Date: Project ID: Location: Quantity: YES NO NA Lemcon Rep.: orrective action proposed. 4. Granite 8. Others EXTERNAL CLADDING 7. Paver block

- 10. QUALITY CHECKLIST FOR SITE WORKS INTERIOR (FALSECEILING) Name of the Customer: Date: Project Name: Project ID: Name of the Contractor: Location: Drawing Ref. No.: Quantity: Description YES NO NA 1 Check the type of falseceiling as per specification. 2 3 4 5 6 Comments: Contractor's Rep.: Client Rep.: Lemcon Rep.: Sl.N o. If it is Grid type, Check whether grids are marked as per drawing so as to locate the service points. Check whether the frame work and hanger rods are as per specification. Before fixing/ laying of boards check all service works such as electrical, AC ducting, fire alarm, sprinkler, speakers, smoke detector, heat detector, etc, Whether cutout/ opening provided. Check for any cornices, trap door provision as per the drawing. Check for painting of ceiling ( If it is board) - is it as per specification. CORRECTIVE ACTION PROPOSED- Item wise. If 'No' is marked, please specify reasons and thereafter corrective action proposed. (Add additional sheets, if necessary) ARCHITECTURAL STRUCTURAL INTERIOR SERVICES & UTILITY CL : 09CL : 09

- 11. QUALITY CHECKLIST FOR SITE WORKS ROAD & DRAINS WORKS Name of the Customer: Date: Project Name: Project ID: Name of the Contractor: Location: Drawing Ref. No.: Quantity: Sl.No. Description YES NO NA PREPARATION OF SUBGRADE 1 SAND - GRAVEL MIX FOR ROAD WORK. 1 Check the formation of subgrade with specified camber. 2 3 W.B.M: 1 Check for proper grading of aggregates. 2 3 4 5 6 ASPHALT/ BT FOR ROAD WORKS 2 Check Whether tack coat application is done properly. 3 Check for Uniform spread thickness of premix. Is it o.k.? 4 Drain work: 1 Marking layout line level of R.C.C drain. 2 Making R.C.C. drain all as per drawing in line, level & slope. Comments: PREPARATION OF SUBGRADE to specified lines and Camber. Check for Cleaning and Making up of Soft spots & other irregularities. Check for spreading in layers as specified and watering has been done on prior to the required proctor density to the required compaction. Check for finished surfaces, compacted thickness, camber, gradient lines and slope. Are they acceptable? Check for Underground trenches / Hume pipes / Drain crossing / road crossing LAYOUTS, GRADES & CROSS - SECTIONS OF COMPACTED SUBGRADE prior to spreading of aggregates. Check for UNIFORM SPREAD THICKNESS of Aggregates. Check for DRY ROLLING, using proper road roller. Check for WET ROLLING of Aggregates and COMPACTION. Check for FINISHED SURFACES, COMPACTED THICKNESS, CAMBER, LINES AND SLOPE.Are they acceptable? Check for finished surfaces,compacted thickness. gradient lines and slope: Are they acceptable. CORRECTIVE ACTION PROPOSED- Item wise. If 'No' is marked, please specify reasons and thereafter corrective action proposed. (Add additional sheets, if necessary) SERVICES & UTILITY CL : 10CL : 10

- 12. Sl.No. Description YES NO NA CL : 10CL : 10 Contractor's Rep.: Client Rep.: Lemcon Rep.:

- 13. QUALITY CHECKLIST FOR SITE WORKS Name of the Customer: Date: Project Name: Project ID: Name of the Contractor: Location: Drawing Ref. No.: Quantity: Sl.No. Description YES NO NA 1 Check the setting out is line with drawing/ layout 2 3 Check the type of finish : a) Laminate b) Veneer with melamine polish c) ACP 4 INTERIOR (STORAGE UNIT) 1 b) 1200 mm height c) 2100/ 2400 mm height 2 3 4 Check is it modular/ Custorm built. 1 2 3 4 Check type of skirting. 5 Check location of switch boxes, is it ok? INTERIOR (FURNISHING WORKS) 1 2 Check whether chair is of specified make colour and shade. INTERIOR - (FURNITURES/ STORAGE UNIT/ PARTITION/ PANELLING/ FURNISHING WORKS) Check the provisions are made for such as pencil drawer, Key board drawer, storage units attached with the table. Check the Approved make and thickness of materials as per specifications and drawings. Type of storage unit: a) 750 mm Low height Check the Hardware such as lock, hinges, handles are provided with as per specifications / drawings. Check the plywood thickness, finishing of material whether with Laminate or Veneer. Check type of internal frame work (work/ Aluminium box sections) Check type of partition (Fully solid/ Fully glazed/ combination of glass and opaque) Check before fixing of plywood electrical civil access, other services consul Check whether the carpet is of specified make colour and shade. ARCHITECTURAL STRUCTURAL INTERIOR SERVICES & UTILITY CL : 11CL : 11

- 14. Sl.No. Description YES NO NA CL : 11CL : 11 3 4 Check about etching designs in glass partition. Comments: Contractor's Rep.: Client Rep.: Lemcon Rep.: Check the Fabric Pinup board.Is the fabric, colour, size of board as per drawing / Specification. CORRECTIVE ACTION PROPOSED- Item wise. If 'No' is marked, please specify reasons and thereafter corrective action proposed. (Add additional sheets, if necessary)

- 15. QUALITY CHECKLIST FOR SITE WORKS PLUMBING & SANITARY/ SANITARY FIXTURES Name of the Customer: Project Name: Name of the Contractor: Drawing Ref. No.: Sl.No. Description Water supply: 1 2 3 4 5 Sewer Line: 1 2 3 4 5 Whether leak tests conducted? SANITARY FIXTURES & FITTINGS 1 Comments: Contractor's Rep.: Client Rep.: Lemcon Rep.: Check whether all pipe joints and method of jointing are done as per specification and conforming to relevant IS codes and standards. Whether the samples of pipes and fittings are as per approved specification? Whether the concealed pipe lines are painted and protected as per the specification? Whether connected pipe lines and fittings are satisfactorily tested for leaks before covering? Ceiling suspended lines adequately supported by suitable dia of rod/ anchor fastener with suitable spacing. Check the approved pipes are used for the sewer lines. Is it o.k.? Check for the levels and alignment of sewer line as per drawing / specifications. Is it o.k.? Check whether the jointing of pipes are as per specifications/ drawing. Is it o.k.? Check whether for the inspection chambers are at the correct location shape and to the correct invert level as per drawings/ specifications. Whether the fixtures are fixed in correct position and level as per the drawings/ specifications? ARCHITECTURAL STRUCTURAL INTERIOR CL : 12CL : 12

- 16. FOR SITE WORKS ANITARY FIXTURES Date: Project ID: Location: Quantity: YES NO NA Lemcon Rep.: INTERIOR SERVICES & UTILITY

- 17. C.R. Narayana Rao Architects & Engineers Rev.1 dtd. 13.01.2006 17 of 18 QUALITY CHECKLIST FOR SITE WORKS ELECTRICAL INSTALLATION WORKS Name of the Customer: Date: Project Name: Project ID: Name of the Contractor: Location: Drawing Ref. No.: Quantity: The following Indian Standard Codes are adopted for Installing the equipments at site Sl. No. Description YES NO NA I.S No. 1 CODE OF PRACTICES 2 732/1989 - Code of Practice for Electrical wiring installation. 3 4 5 6 7 Comments: Contractor's Rep.: Client Rep.: Lemcon Rep.: 8884/1976 - Code of Practice for the installation of electric bell and call system. 10028 Part 1 1985 - Code of Practice for selection installation and maintenance of transformers Part 2 Installation. 10118 Part 3 1982 - Code of Practice for selection, installation and maintenance of switchgear and control gear Part 3- Installation. 5613 Part 2 Selection 1 1985 - Code of Practice for design installation and maintenance of overhead power lines Part 2 lines upto and including 11KV section 1 Installation. 1255 (1983) - Code of Practice for Installation and Maintenance of Power Cables upto and inlcuding 33 KV rating. CORRECTIVE ACTION PROPOSED- Item wise. If 'No' is marked, please specify reasons and thereafter corrective action proposed. (Add additional sheets, if necessary) CL : 13CL : 13 SERVICES & UTILITY

- 18. C.R. Narayana Rao Architects & Engineers Rev. 0 dtd. 13.01.2006 18 of 18 QUALITY CHECKLIST FOR SITE WORKS FABRICATION WORK Name of the Customer: Date: Project Name: Project ID: Name of the Contractor: Location: Drawing Ref. No.: Quantity: Sl. No. Description YES NO NA BEFORE FABRICATION: Check for the following PRECEDING ACTIVITIES: 1 2 Approval obtained for the fabrication drawing 3 Check for the approved welding rods used 4 AFTER FABRICATION: 1 Material section used as per drawing. 2 Whether welding length as per drawing. 3 4 Fabricated material is ready for sand blasting Comments: Contractor's Rep.: Client Rep.: Lemcon Rep.: Check for the quality of materials / Test certificates of materials submitted. Check for fabrication material free from mud stains/ other materials. Whether all the interconnection section welded/ holes drilled to assemble other members. CORRECTIVE ACTION PROPOSED- Item wise. If 'No' is marked, please specify reasons and thereafter corrective action proposed. (Add additional sheets, if necessary) CL : 14CL : 14 ARCHITECTURAL STRUCTURAL INTERIOR SERVICES & UTILITY