Assessment and reinforcement of the 20 existing bridges in the Bozoum-Bossangoa road in Central African Republic. Presentation to the Ministry of Works.

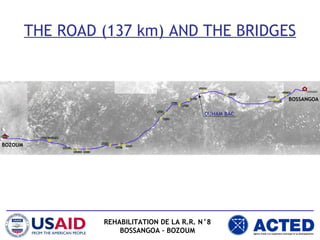

- 1. THE ROAD (137 km) AND THE BRIDGES REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM BOSSANGOA BOZOUM OUHAM BAC

- 2. EXISTING BRIDGES - DESCRIPTION REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM STEEL GIRDERS TIMBER DECKING STONE MASONRY ABUTMENTS • THERE ARE 20 BRIDGES ON THE BOSSANGOA-BOZOUM ROAD • THE CONSTRUCTION METHOD IS THE SAME FOR ALL THE BRIDGES: TIMBER DECKING ON 4 STEEL GIRDERS WITH STONE MASONRY ABUTMENTS

- 3. EXISTING BRIDGES - CONSERVATION STATE • TIMBER DECKING – ON THE BOSSANGOA SIDE, THE TIMBER DECKING IS STILL IN POSITION, BUT GENERALLY IN POOR CONDITION. – ON THE BOZOUM SIDE THE ORIGINAL DECKING HAS COLLAPSED AND HAS BEEN REPLACED BY WOODEN BRANCHES. • STEEL GIRDERS – THE CONDITION IS GOOD. • MASONRY ABUTMENTS – THE CONSERVATION IS GENERALLY GOOD, EXCEPT FOR 7 BRIDGES WITH CRACKS THAT REQUIRE REINFORCING. REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM

- 4. EXISTING BRIDGES - CONSERVATION STATE PONT N° 16 (BOSSANGOA SIDE) – THE TIMBER DECKING REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM

- 5. EXISTING BRIDGES - CONSERVATION STATE PONT N° 17 (BOSSANGOA SIDE) – THE TIMBER DECKING REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM

- 6. EXISTING BRIDGES - CONSERVATION STATE PONT N° 19 (BOSSANGOA SIDE) – THE TIMBER DECKING REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM

- 7. EXISTING BRIDGES - CONSERVATION STATE PONT N° 8 (BOZOUM SIDE) – THE TIMBER DECKING REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM

- 8. EXISTING BRIDGES - CONSERVATION STATE PONT N° 10 (BOZOUM SIDE) – THE TIMBER DECKING REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM

- 9. EXISTING BRIDGES - CONSERVATION STATE PONT N° 12 (BOZOUM SIDE) – THE TIMBER DECKING REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM

- 10. EXISTING BRIDGES - CONSERVATION STATE PONT N° 20 (BOZOUM SIDE) – THE STEEL GIRDERS REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM

- 11. EXISTING BRIDGES - CONSERVATION STATE PONT N° 4 (BOZOUM SIDE) – THE STEEL GIRDERS REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM

- 12. EXISTING BRIDGES - CONSERVATION STATE PONT N° 7 (BOZOUM SIDE) – THE STEEL GIRDERS REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM

- 13. EXISTING BRIDGES - CONSERVATION STATE PONT N° 4 (BOZOUM SIDE) – THE ABUTMENTS REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM

- 14. EXISTING BRIDGES - CONSERVATION STATE PONT N° 16 (BOSSANGOA SIDE) – THE ABUTMENTS REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM

- 15. EXISTING BRIDGES - CONSERVATION STATE PONT N° 20 (BOZOUM SIDE) – THE ABUTMENTS REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM

- 16. EXISTING BRIDGES - CONSERVATION STATE PONT N° 3 (BOZOUM SIDE) – THE ABUTMENTS REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM

- 17. EXISTING BRIDGES - CONSERVATION STATE PONT N° 18 (BOSSANGOA SIDE) – THE ABUTMENTS REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM

- 18. THE DESIGN • GOAL OF THE DESIGN: – REOPEN THE ROAD AND THE BRIDGES TO TRAFFIC IN A SAFE, FAST AND COST-EFFECTIVE WAY. WE HAVE TRIED TO CONSERVATE AND REUSE TO THE MAXIMUM THE EXISTING BRIDGES, IDENTIFYING THE ALLOWABLE LOAD OF THE STRUCTURES AND REINFORCEING THEM WHERE NEEDED. • METHOD OF WORK: – FOR ALL THE BRIDGES WE HAVE CONDUCTED A STRUCTURAL ANALYSIS WITH COMPUTER FINITE ELEMENT MODELS TO DEFINE THE MAXIMUM LOAD THAT THE BRIDGES CAN SUPPORT AND THEREFORE THE ALLOWABLE LOAD OF THE ROAD. THE CALCULATIONS HAVE BEEN DONE ACCORDING TO EUROCODES AND AASHTO “STANDARD SPECIFICATIONS FOR HIGHWAY BRIDGES”. REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM

- 19. THE DESIGN – THE STRUCTURAL ANALYSIS • DESIGN LOAD: (FROM AMERICAN AASHTO CODES) • THE MATERIALS: – TIMBER: MUKULUNGU – STEEL: ? FOR THE EXISTING GIRDERS WE HAVE NO INFORMATION ON THE GRADE OF THE STEEL AND ITS RESISTANCE. WE HAVE CONSERVATIVELY ASSUMED THAT THE GIRDERS ARE MADE OF S235 STEEL (yielding strength = 235 MPa) WHICH IS THE LOWEST OF THE 3 COMMERCIAL STEEL GRADES (235, 275 O 355 MPa) REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM

- 20. THE DESIGN – THE STRUCTURAL ANALYSIS REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM FINITE ELEMENT MODEL (2D) FINITE ELEMENT MODEL (3D) BENDING MOMENT CALCULATED DEFLECTION MAXIMUM CALCULATED DEFLECTION

- 21. THE DESIGN – CONCLUSIONS • REPLACE THE TIMBER DECKING FOR ALL BRIDGES • REINFORCE THE ABUTMENTS OF 7 BRIDGES • MAINTAIN THE STEEL GIRDERS FOR ALL BRIDGES EXCEPT BRIDGE N° 18 WHICH HAS A LOWER LOAD CAPACITY: 2 NEW GIRDERS WILL BE ADDED FOR THIS BRIDGE. REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM

- 22. THE DESIGN – REPLACEMENT OF THE DECKING REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM MUKULUNGU TIMBER FOR TRANSVERSE MADRIERS AND LONGITUDINAL ELEMENTS: RESISTANT AND DURABLE

- 23. THE DESIGN – REPLACEMENT OF THE DECKING REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM CLOSER MADRIERS (25 cm INSTEAD OF 30 cm) TO INCREASE RESISTANCE AND SAFETY OF PEDESTRIANS RECONSTRUCTION OF THE SAFETY POSTS ON EACH SIDE OF THE ABUTMENTS TO ENSURE THAT VEHICLES TRAVEL ON THE CENTER OF THE BRIDGE

- 24. THE DESIGN – REPLACEMENT OF THE DECKING REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM RUNNING SURFACE MADE WITH 8 cm MADRIERS INSTEAD OF 3 cm PLANKS TO INCREASE DURABILITY

- 25. THE DESIGN – REPLACEMENT OF THE DECKING REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM LAG SCREWS INSTEAD OF NAILS TO INCREASE DURABILITY RUNNING SURFACE MADE WITH 8 cm MADRIERS INSTEAD OF 3 cm PLANKS TO INCREASE DURABILITY

- 26. REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM THE DESIGN – REINFORCEMENT OF THE ABUTMENTS • SIMPLE AND EFFECTIVE REINFORCEMENT TECHNIQUES (FOR EXAMPLE CONCRETE COATING) HAVE BEEN CHOSEN FOR THE ABUTMENTS EXAMPLE OF THE REINFORCEMENT FOR BRIDGES 1, 2, 14 AND 20:

- 27. REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM THE DESIGN – ALLOWABLE LOAD • THE CALCULATIONS HAVE SHOWN THAT, ASSUMING A STEEL RESISTANCE OF 235 MPa, ALL OF THE BRIDGES (EXCEPT ONE) CAN SUPPORT AN AXLE LOAD OF AT LEAST 100 kN (10 tons) • THE EXCEPTION IS BRIDGE n° 18 (pk 32.5) WHICH CAN SUPPORT AN AXLE LOAD OF JUST 70 kN (7 tons) • THEREFORE, BRIDGE N° 18 WILL BE REINFORCED BY ADDING 2 NEW GIRDERS BESIDES THE EXISTING ONES, INCREASING ITS LOAD CAPACITY TO 100 kN (10 tons). • TO ACCOUNT FOR POSSIBLE OVERLOADED TRUCKS, WE WILL CONSIDER AN ADDITIONAL 15% SAFETY FACTOR, THEREFORE THE ALLOWABLE AXLE LOAD ON THE ROAD WILL BE: 85 kN (8.5 tons)

- 28. REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM BRIDGE n° 18 – REINFORCEMENT • TWO NEW GIRDERS WILL BE ADDED BESIDES THE EXISTING ONES, INCREASING THE LOAD CAPACITY

- 29. REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM TEST LOADS – DURING CONSTRUCTION • DURING CONSTRUCTION IT WILL BE IMPORTANT TO CHECK THAT THE BENDING RESISTANCE OF THE MUKULUNGU TIMBER ISN’T LOWER THAN THE VALUE CONSIDERED IN THE DESIGN (30 MPa) • SIMPLE RESISTANCE TESTS WILL HAVE TO BE MADE ON THE TIMBER MADRIERS

- 30. REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM TEST LOADS – DURING CONSTRUCTION • TEST LOADS ON THE TIMBER MADRIERS

- 31. REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM TEST LOADS – AFTER CONSTRUCTION • AFTER CONSTRUCTION IT WILL BE IMPORTANT TO CHECK THAT THE RESPONSE OF THE BRIDGE CORRESPONDS TO THE EXPECTED PERFORMANCE. • LOAD TESTS WILL BE MADE ON THE BRIDGES TO CHECK THAT THE REAL DEFLECTION CORRESPONDS TO THE CALCULATED DEFLECTION. A TRUCK WITH THE SAME WEIGHT AS THE DESIGN LOAD WILL STAY ON THE BRIDGE WITH THE AXLE PLACED IN MIDSPAN, AND THE MAXIMUM DEFLECTION WILL BE MEASURED WITH A DIAL GAUGE.

- 32. REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM MAINTENANCE AND MONITORING IN ORDER TO ENSURE THE DURABILITY OF THE BRIDGES IT IS NECESSARY TO REGULARLY MAINTAIN AND MONITOR THEM. • TIMBER RUNNING SURFACE: IT IS ONE OF THE MOST EXPOSED PARTS TO WEAR AND DEGRADATION, AND SHOULD BE CHECKED EVERY 4 MONTHS TO IDENTIFY DAMAGED PARTS THAT SHOULD BE REPLACED. • TRANSVERSE MADRIERS: THE TRANSVERSE MADRIERS SHOULD BE INSPECTED EVERY 4 MONTHS TO FIND DAMAGED OR BROKEN ELEMENTS THAT SHOULD BE IMMEDIATELY REPLACED. • TIMBER CONNECTIONS: THE CONNECTIONS BETWEEN THE TIMBER ELEMENTS ARE PARTICULARLY SENSITIVE TO VIBRATIONS AND TRAFFIC. THEY SHOULD BE CHECKED EVERY 4 MONTHS; THEY SHOULD BE TIGHTENED WHEN NECESSARY, AND REPLACED IMMEDIATELY IF FOUND TO BE MISSING. • SAFETY POSTS: THE SAFETY POSTS ON THE ABUTMENTS ARE ESSENTIAL FOR THE SAFETY OF THE BRIDGES: THEY SHOULD BE CHECKED EVERY 2 MONTHS AND IMMEDIATELY REPLACED IF BROKEN. • ABUTMENTS: ABUTMENTS SHOULD BE CHECKED REGULARLY FOR CRACKS, DISPLACED STONES, SCOUR ON FOUNDATIONS, ETC. AND APPROPRIATE RECONSTRUCTION/REINFORCEMENT SHOULD BE DONE. A COMPLETE INSPECTION SHOULD BE DONE EVERY SIX MONTHS. • VEGETATION: VEGETATION SHOULD BE CLEARED FROM THE BRIDGE ANNUALLY. VEGETATION SHOULD ALSO CAREFULLY BE REMOVED FROM THE ABUTMENTS WITHOUT DAMAGING THE MASONRY.

- 33. REHABILITATION DE LA R.R. N°8 BOSSANGOA – BOZOUM THANKYOU FOR YOUR ATTENTION

Notas del editor

- 1.5 Safety factor for yielding (according to Eurocodes) + approx. 30% for dynamic impact factor + aprox. 25% for eccentric loading