Inventory 1213683812410770-9

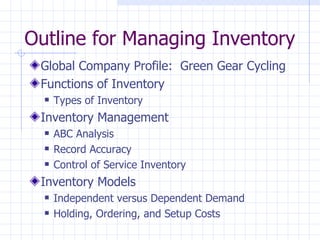

- 1. Outline for Managing Inventory Global Company Profile: Green Gear Cycling Functions of Inventory Types of Inventory Inventory Management ABC Analysis Record Accuracy Control of Service Inventory Inventory Models Independent versus Dependent Demand Holding, Ordering, and Setup Costs

- 2. What is Inventory? Parts and materials Available capacity © 1995 Corel Corp. Human resources © 1984-1994 T/Maker Co. © 1984-1994 T/Maker Co. © 1995 Corel Corp.

- 3. Green Gear Cycling Bike Friday - a bike in a suitcase Mass customization fast throughput low inventory work cells generalized machine (reduce setups) Balance between inventory holding cost and availability Aggressive attention to reducing cycle time of whole process

- 4. The Functions of Inventory To ”decouple” or separate various parts of the production process To provide a stock of goods that will provide a “selection” for customers To take advantage of quantity discounts To hedge against inflation and upward price changes

- 5. Inventory Classifications Inventory Process Number Demand Other stage & Value Type Raw Material A Items Maintenance Independent WIP & Finished B Items Dependent Dependent Goods C Items Operating

- 6. Types of Inventory Direct Inventory Raw material Work-in-progress (WIP) Finished goods Indirect Inventory Stored capacity Maintenance/repair/operating supply

- 7. The Material Flow Cycle and WIP Other Wait Move Queue Setup Run Input Time Time Time Time Time Output Cycle Time Run time: Job is at machine and being worked on Setup time: Job is at the work station, and the work station is being "setup." Queue time: Job is where it should be, but is not being processed because other work precedes it. Move time: The time a job spends in transit Wait time: When one process is finished, but the job is waiting to be moved to the next work area. Other: "Just-in-case" inventory.

- 8. Sources of Waste JIT “fights” seven types of waste Waste of motion --excessive or unnecessary human activity Waste of waiting --jobs waiting to be processed Waste of inventory --building up unnecessary inventory stocks Waste of conveyance --jobs being unnecessary moved Waste of processing --excessive or unnecessary operations Waste of overproduction --producing more than demanded Waste of correction (defective products) --waste due to scrap, rework, repair, etc.

- 9. Independent vs. Dependent Demand Independent demand - demand for item is independent of demand for any other item EOQ Models Dependent demand - demand for item is dependent upon the demand for some other item MRP Systems

- 10. Disadvantages of Inventory Higher costs Ordering (or setup) cost Costs of processing, clerks’ wages etc. Holding (or carrying) cost Building lease, insurance, opportunity, taxes etc. Difficult to control Hides production problems

- 11. Inventory Tracking JIT and mass customization requires knowledge of location of all goods in order to precisely control the production plan Requires ERP data, barcode technology, RF and electronic communications to track inventory in transit, on the shop floor, and in the warehouse In JIT system, warehouse is less a warehouse than a “pass through facility.” Inaccurate inventory tracking is worse than no information

- 12. Holding Costs Breakdown (Approximate Ranges) Category Cost as a % of Inventory Value 6% Housing costs (3 - 10% Material handling costs 3% (1 - 3.5%0 Labor and administration 3% cost (3 - 5%) Investment costs 11% (6 - 24%) Pilferage, scrap, and 3% obsolescence (2 - 5%)

- 13. EOQ Model: Minimize the overall Costs Cost e t Curv otal Cos Curve T ost C ing Hold Ordering & Setup Costs Curve Optimal Order Quantity Order Quantity (Q*)

- 14. Inventory Holding Costs Obsolescence Insurance Extra staffing Interest Pilferage Damage Warehousing Etc.

- 15. Ordering Costs & Setup Costs Order processing Clerical support Clean-up costs Re-tooling costs Relocation or adjustment costs

- 16. Objective: Why holding cost increase? Why order cost decrease? Two underlying inventory question How much to order (e.g. finding EOQ) When to order (e.g. finding ROP)

- 17. Underline Decisions Supported by EOQ Models Objective: Minimizing the total inventory costs How much to order (Economic Order Quantity) When to order? (Reorder Point) How often should we place orders (Ordering Period) Others How to Take advantage of quantity discount What if the lead time and demand are not constant? Heuristics: Fixed Period Systems

- 18. Basic EOQ Model (Constant Demand and Lead Time) Inventory Level Optimal Average Order Inventory Quantity (Q*/2) (Q*) Reorder Point (ROP) Time Lead Time

- 19. Derive the EOQ: Finding Q* that Minimizes the Total Costs Total inventory cost = Order (Setup) cost + Holding cost D Q TC = S + H Q 2 To minimize TC, we set the derivative of TC with respect to Q* equal to 0 d (TC ) − DS H = ( 2 )+ = 0 dQ Q 2 Thus, 2DS Q* = H

- 20. EOQ Model Equations: How much to Order Optimal Order Quantity 2 ×D ×S = Q* = H Expected Number of Orders = N = D Q* Expected Time Between Orders Working Days / Year =T = N D = Demand per year S = Setup (order) cost per order H = Holding (carrying) cost

- 21. Reorder Point: When to Order? When there is lead time between order and delivery, we need to identify the reorder point to avoid out of stock. This provides answer for the second inventory “When to order?” ROP = (Demand per day)(Lead time for a new order in days) = d × L D d= Working Days / Year

- 22. EOQ Example Electronic Assembler, Inc. has to order 2920 TX5 circuit boards per year. The ordering cost is $80 per order; and the holding cost per unit per year is $50. The purchase price is $28. The items can be delivered in 5 days. The company would like to reduce its inventory costs by determining the optimal number of circuit boards to obtain per order. The conditions of ordering and inventory handling satisfy the assumptions of the EOQ model. Annual demand D = 2,920 units Daily demand d = 2,920/365=8 units Holding cost H = $50 per unit per year Ordering cost S = $80 per order Purchase price P = $28 per unit Lead time LT = 5 days Answer the following questions with detailed calculations and explanation: 1. Optimal quantity per order (EOQ): 2. Annual total relevant costs (optimal): 3. Annual total costs (optimal): 4. Number of orders per year: 5. Inventory cycle time (Nd=365 working days per year): 6. Reorder Point (ROP):

- 23. Production Order Quantity Model Allows partial receipt of material Other EOQ assumptions apply Suited for production environment Material produced, used immediately Provides production lot size Lower holding cost than EOQ model

- 24. POQ Model Inventory Level Optimal Average Order Inventory Quantity (Q*) Reorder Point (ROP) Time Lead Time

- 25. POQ Model Inventory Levels Inventory Level Production portion of cycle Demand portion of cycle with no supply Supply Supply Time Begins Ends

- 26. POQ Model Inventory Levels Inventory Level Inventory level with no demand Production Max. Inventory Portion of Cycle Q·(1- d/p) Q* Time Supply Supply Demand portion of cycle Begins Ends with no supply

- 27. POQ Model Equations = Q* = 2*D*S Optimal Order Quantity p H* 1 - ( ) d p Maximum inventory level = Q * ( 1 - d p ) D Setup Cost = * S D = Demand per year Q S = Setup cost Holding Cost = 0.5 * H * Q ( ) 1- d p H = Holding cost d = Demand per day p = Production per day

- 28. Quantity Discount Model Answers how much to order & when to order Allows quantity discounts Reduced price when item is purchased in larger quantities Other EOQ assumptions apply Trade-off is between lower price & increased holding cost

- 29. Quantity Discount Model How Much to Order? Total Cost Discount 1 Discount 2 Initial Price Price Price or t1 TC f ount Dis coun sc or N o Di TC f t2 c oun Di s for TC Quantity which would be ordered Order Quantity to Quantity to Quantity Lowest cost not in earn earn discount range Discount 1 Discount 2

- 30. Probabilistic Models Allow demand and lead time to vary Follows normal distribution Other EOQ assumptions apply Consider service level & safety stock Service level = 1 - Probability of stockout Higher service level means more safety stock More safety stock means higher ROP

- 31. Probabilistic Models When to Order? Frequency Service Inventory Level Level P(Stockout) Optimal Order X Quantity SS ROP Reorder Point (ROP) Safety Stock (SS) Place Receive Time order Lead Time order

- 32. ABC Classification: Pareto Principle (Critical few and trivial many) % Annual $ Usage Class % $ Vol % Items 100 A 80 15 B 15 30 80 C 5 55 60 40 A B 20 C 0 0 50 100 % of Inventory Items

- 33. Heuristics: Fixed Period Model Orders placed at fixed intervals Inventory brought up to target amount Amount ordered varies No continuous inventory count Possibility of stockout between intervals Useful when vendors visit routinely Example: P&G representative visits every 2 weeks

- 34. Heuristics: Fixed Period Model Inventory Level Target maximum Time Period Period Period

- 35. Implementing JIT via Agile Inventory Management Traditional: inventory exists in case problems arise JIT objective: Eliminate redundant inventory JIT requires Small lot sizes Low setup time Containers for fixed number of parts JIT inventory: Minimum inventory to keep system running (lean but agile)

- 36. Lowering Inventory Reduces Waste Work in process inventory level (hides problems) Unreliable Capacity Scrap Vendors Imbalances

- 37. Lowering Inventory Reduces Waste Reducing inventory reveals problems so they can be solved. WIP Unreliable Capacity Scrap Vendors Imbalances

- 38. To Lower Inventory, Reduce Lot Sizes Inventory Level Average Lot Size 200 inventory = 40 Average inventory = 100 Lot Size 80 Average inventory = (Lot size)/2 Time

- 39. …Which Increases Inventory Costs Cost otal Co s t T ost i ng C Ho l d Setup Cost Smaller Optimal Lot Size Lot Size Lot Size

- 40. Unless Setup Costs are Reduced Cost l Cost Tota Cos t Ho l di ng Setup Cost New optimal Original optimal Lot Size lot size lot size

- 41. Steps to Reduce Setup Time (Honda Assembly Line) 90 min Initial Setup Time Separate setup into preparation, and actual Step 1 setup, doing as much as possible while the machine/process is running (save 30 minutes) 60 min Move material closer and improve Step 2 material handling (save 20 minutes) 45 min Standardize and Step 3 improve tooling (save 15 minutes) 25 min Use one-touch system to eliminate adjustments (save 10 Step 4 15 min minutes) Step 5 13 min Training operators and standardizing work procedures (save 2 minutes)

- 42. Reducing Lot Sizes Increases the Number of Lots Small lots increase flexibility to meet customer demands Strategies for eliminating waste and for eliminating waiting

- 43. Freeze Part of the Schedule JIT Small Lots A A B B B C A A B B B C Time Flexibility between Nissan plant and Dealers Five day before delivery: 100% flexibility Four day before: Freeze number of each model Three day before: Freeze change color Two day: Freeze major options One day before: Freeze minor options

- 44. JIT Scheduling Involves timing of operations JIT requires Communicating schedules to suppliers Level schedules Arrange flexible schedule for small lots (jelly bean scheduling) Freeze part of schedule nearest due date Kanban techniques

- 45. Kanban Japanese word for card Pronounced ‘kahn-bahn’ (not ‘can-ban’) Authorizes production from downstream operations ‘Pulls’ material through plant May be a card, flag, verbal signal, empty container, real time message (stock broker, football player) etc. Most common example: use fixed-number containers or work permits to coordinate actions Add or remove containers to change production rate

Notas del editor

- While most students recognize inventory as a “stock of material,” the notion of inventory as a “stored capacity” probably merits explicit discussion.

- This slide provides a more detailed view of the material flow cycle. Students might be asked to comment on the impact of each element on the overall time. Questions such as: - why do we need these times? - how can they be reduced? - would we wish to eliminate these elements entirely? might be helpful.

- Of the items listed on this slide, the least obvious to most students is the manner in which inventory can be used to hide production problems.

- Note that this slide suggest holding costs are, on average, about 26% of the inventory value

- You might ask students if they can identify an industry for which the cost of obsolescence is particularly important. Is the number of such industries likely to grow or decline? The same question could be asked regarding pilferage. The question could be asked in a more general manner: Are there industries for which one or another of the areas listed is of particular or unusual importance?

- One should link this model to the assumptions. You should also explore, at least briefly, how this picture would change if the assumptions were not met.

- For some students, it is most important at this point to explain in detail the meaning and significance of each equation. It might be helpful to actually work through a numerical example.

- One way to approach this is as an EOQ model with the instantaneous replenishment assumption relaxed. The following slide (EOQ Model modified to show changes for POQ) allows you to do this if you wish. Otherwise, skip it and move on.

- Given that students recognize that production takes place for only a portion of the cycle, you might ask how one determines the appropriate length of the production period. If they understand the model, they will perceive that the production period is determined by the POQ.

- Here again, it may be helpful to actually go through a numerical example, but it will probably be necessary to explain in detail the meaning and significance of each equation

- Students will probably need help interpreting this slide. The overlays do, however, allow you to step through your argument. It is important to stress that after one identifies the quantities which would actually be ordered, there remains the task of calculating total cost for each quantity.

- One point to stress here is that this is simply an extension of the original EOQ model where we are now allowing the demand to vary. Students should become accustomed to seeking such extensions as the need arises. The next slide presents a graphical view of this model.

- 32

- Are we back to Pareto analysis?

- This represents a model in which orders are based upon time, not the quantity needed. The following slide provides a graphical representation.

- Students should be asked to draw their own connection between inventory and problems. Given that inventory exists in case of problems, if we wish to eliminate inventory, we also must eliminate problems. Again the notion that JIT is not simply an inventory methodology.

- The analogy presented in this and the next four slides may help to illustrate the action of inventory in hiding problems.

- The next several slides look at the process and consequences of reducing inventory.

- In discussing this slide, it is helpful to stress the caveat that JIT works given that other problems are solved. JIT not only requires the solution of other problems, it also helps in diagnosis.

- Students should be asked what problems they would expect to encounter when trying to introduce schedules appropriate to JIT.