6 s – guideline for the lean practitioner

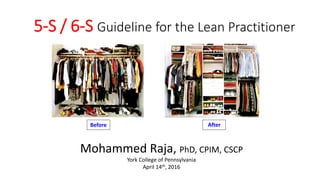

- 1. 5-S / 6-S Guideline for the Lean Practitioner Mohammed Raja, PhD, CPIM, CSCP York College of Pennsylvania April 14th, 2016 Before After

- 2. AGENDA What is 5-S / 6-S Visual Control Role of the Leader 6-S Number’s Game Benefits of 6S Mohammed Raja, PhD, CPIM, CSCP York College of Pennsylvania

- 3. What is 5-S 6-S Visual Control Henry Ford’s CANDO program: Cleaning up, Arranging, Neatness, Discipline, Ongoing Improvement Step # Japanese 5-S 1 Seiri 2 Seiton 3 Seiso 4 Seiketsu 5 Shitsuke Sort Set in Order Sweep/Shine Standardize Sustain Description Identify what’s needed and what’s not needed Organize what is needed Clean everything inside and out Establish policies and procedures Ingrain 5S culture through Training Safety Create a safe working environment A series of steps and procedures used to arrange work areas in the best manner to enhance Safety, Performance, and Cleanliness. 6-S Word

- 4. 6S Supply List Pegboard Peg Anchors Paint Paint Pens Label Maker/Cartridges Digital Camera Scissors Floor Tape Clipboards Box Cutters Tape Measure (100 feet) Velcro Tape Glue Gun Stencils (A-Z and 1-10) Red Tags Cleaning Supplies Cleaning Gloves Large Dry Erase Board

- 5. Purpose of 6-S Visual Control Drive cultural change within the organization through ……. Behavioral modifications Structured process improvements Empowered Employees Sustain Sustain Sustain Sustain Safety Safety Safety Safety Foundation for a Lean Transformation To solve problems in their work area Build knowledge and capability Minimize/eliminate wasteful activities

- 6. 8 Deadly Wasteful Activities TIMWOOD(S) Poor Layout Widely Spaced Equipment Large Safety Stock Inconsistent work methods Poor workplace organization Long setup times Unplanned maintenance Lack of communication Customer requirement not clearly defined Unclear goals Weak process control Poor Quality Culture Lack of Investment in training

- 7. 6-S Number’s Game This sheet represents our current work place. Our job during a 20 second shift, is to strike out the numbers 1 to 49 in correct sequence (e.g. 1, 2, 3,……., 48, 49) Record your individual score, along with the best and worst score from the group. The original game was developed by RWD Technologies Ltd.

- 9. 6-S Number Game How do you feel about your score??? What appeared to get in the way of achieving a higher score?

- 10. Sort (Seiri) Is everything here really needed? Why Sort ?? Remove un-needed inventory which occupies space

- 11. Leaders Role in Implementing “Sorting” Define what’s necessary and unnecessary? Item Tagged by: ________________________ Name of Item: __________________________ Date: _________________________________ Location of Item: ________________________ Reason for Red tagging (Check One) For Office Use Only: Item No. ___________________________ Disposition:_________________________ __________________________________ Obsolete Defective Scrap Trash Unneeded Used once/day Used once/week Used < once/month Seldom Used Use Unknown Red Tagging Identify unnecessary items that need to be either thrown out, recycled, sold or relocated Allocate a central Red Tag area. Include disposal instructions. Appoint a review board for questionable items. Leave items in the workplace Set their final location later in the 6S process Allocate an area close to workplace Review on specific date Store occasionally used items in out of way locations

- 12. 6-S Number’s Game STEP 1: SORT Our initial analysis shows numbers 50 – 90 are not essential to our daily tasks. Hence they are removed from the work area Same rule apply: Strike out numbers 1 to 49 in sequence during a 20 second shift. Record your individual score, along with the best and worst score from the group.

- 14. 6-S Number’s Game How do you feel about your score??? What appeared to get in the way of achieving a higher score?

- 15. Why Set in Order Set in Order (Seiton) Is there a place for everything and is everything in its place? Before After

- 16. Leaders Role in Implementing “Set-in-Order” Determine location for all items Calculate quantities of each item Shelving and racking system Items have specific locations Shadow boards Label storage locations Labelling and Signboards, Floor Taping, Color Coding Usage levels Location Frequently used Place near point of use Used Sometimes Place distant from point of use Rarely Used Placed separately (marked and labeled clearly for later use)

- 17. 6-S Number’s Game STEP 2: Set in Order We have installed some racking on the job site using a 3 x 3 grid. We have organized the numbers such that number 1 is located in the bottom left hand corner and the numbers are sequenced from bottom to top and left to right. For example: #1 in the bottom left, #2 in the middle left, #3 in the top left #4 in the bottom middle, #5 in the middle middle, …. And so on. Same rule apply: Strike out numbers 1 to 49 in sequence during a 20 second shift. For each specific step in the 6S process, record your individual score, along with the best and worst score from the group.

- 19. 6-S Number’s Game How do you feel about your score??? What appeared to get in the way of achieving a higher score?

- 20. Sweep / Shine (Seiso) Is your workplace clean from dirt, grease, and dust from the floor, machine, and material? Why Sweep / Shine ?? Before After End of Shift

- 21. Leaders Role in Implementing “Sweep/Shine” Map of the area and divide into cleaning zones Checklist of cleaning activity per person per zone Cleaning Schedule Sheet (Planned v/s Actual) Establish min. requirements/standards for cleaning Provide cleaning supplies (e.g. brooms, dust pans, garbage cans, rags, degreasers, and floor cleaners) Cleaning Zones Mopping work area Plan for Cleaning - Who, What, How

- 22. 6-S Number’s Game STEP 3: Sweep / Shine We have initiated a cleaning system to sweep the work area on a daily basis. We have organized the numbers such that number 1 is located in the bottom left hand corner and the numbers are sequenced from bottom to top and left to right. Same rule apply: Strike out numbers 1 to 49 in sequence during a 20 second shift. Record your individual score, along with the best and worst score from the group.

- 24. 6-S Number’s Game How do you feel about your score??? What appeared to get in the way of achieving a higher score?

- 25. Standardize (Seiketsu) Is there one right way to do the work? Why Standardize Danger Stop, Emergency Stop, electrical panels Caution Potential Danger of serious injury Warning Energized equipment, proceed with caution Safety First Aid and Safety Equipment Facility and Safety Signage (OSHA compliant) X-Ray X-Ray, Alpha, Beta, Gamma, Photon Radiation Floor and Aisle Marking (OSHA compliant) Defect, Scrap, Red Tag Area Aisleways, Traffic lanes Material or product inspection Raw material, WIP, Finished goods Present special physical or health risk (use caution) Keep clear for operational purpose (non safety related) Keep clear safety reasons (emergency access, firefighting equipments etc) Storage System

- 26. Leaders Role in Implementing “Standards” Update documentation to reflect changes – Defined audit requirements – Description/picture of the defined standard for the work area Make sure all stake holders are aware of the new standard Clearly labelled Nuts/Bolts storage bins

- 27. 6-S Number’s Game STEP 4: Standardize After in-depth Work Flow Analysis, we have installed a more detailed racking system. This allows us to re-organize the numbers in a standard fashion which will ease the completion of the task Same rule apply: Strike out numbers 1 to 49 in sequence during a 20 second shift. Record your individual timing, along with the best and worst timing from the group.

- 29. 6-S Number’s Game How do you feel about your score??? What appeared to get in the way of achieving a higher score?

- 30. Safety Is safety a universal responsibility of all employees? Why Safety??

- 31. Leaders Role in Implementing “Safety” Provide Basic Safety Awareness Training Identify Hazard locations Provide counter measures Install Machine guards Wear personal protective equipment Conduct periodic safety audits and evaluations Develop incident tracking and investigate process(es) to eliminate root cause No Job is so important or so urgent that we cannot take the time to Do it SAFELY

- 32. 6-S Number’s Game STEP 5: Safety After a review of the resources used in the process, we have provided safer writing instruments. Same rule apply: Strike out numbers 1 to 49 in sequence during a 20 second shift. Record your individual timing, along with the best and worst timing from the group.

- 34. 6-S Number’s Game How do you feel about your score??? What appeared to get in the way of achieving a higher score?

- 35. Sustain Is there an habit of properly maintaining procedures? Why Sustain ??

- 36. Leaders Role in Implementing “Sustainability” SMARTS approach Awareness: Time: Management Support: Recognition: Satisfaction: Structured Plan: 6S Audit plan monitored and modified where necessary Full and continuing support in terms of leadership, resources and recognition Understand the 6S steps and the importance of sustaining them Efforts of the 6S team must be recognized by management Employees must be given time in their work schedules for 6S related activities Execution of 6S initiatives and benefits must be measured and shared with the organization

- 37. 6-S Number’s Game STEP 6: UnSustain We have recently discovered that two numbers necessary for the completion of the project are missing. Identify the two missing numbers as quickly as possible. Record your individual timing, along with the best and worst timing from the group.

- 39. 6-S Number’s Game STEP 6: Sustain We have recently discovered that two numbers necessary for the completion of the project are missing. Identify the two missing numbers as quickly as possible. This time let’s identify the two missing numbers in a workshop that has implemented Sort – Set in Order – Shine – Standardize - Safety

- 41. 6-S Number’s Game STEP 6: Implement Sustain practice to another work area This sheet represents our newly improved work place. Our job during a 20 second shift, is to strike out the numbers 51 to 99 in correct sequence (e.g. 51, 52, …., 98, 99) The team score will be represented by the lowest individual score achieved. Same rule apply: Strike out numbers 51 to 99 in sequence during a 20 second shift. Record your individual timing, along with the best and worst timing from the group.

- 43. What’s the benefit of 6-S Visual Control Benefits to the Employee Provides opportunity to deliver creative inputs Work place is made cleaner, safer and simpler Increases job satisfaction Improves communication Benefits to the Organization Reduces Waste Downtime Defects Changeover time Delays Improves Safety Visual Control Process Control Standardization Delivery Performance

- 44. Quantifiable Improvements using 6-S Visual Control 96% decrease in defects 80% decrease in flow distance 70% cut in material handling 68% reduction in rack storage 60% in floor space 50% decrease in annual physical inventory 45% decrease in number of forklifts 15% increase in throughput 12% decrease in engineering cycle times Source: www.visualworkplace.com, QMIVisual-Lean Institute

Notas del editor

- Humans struggle with parting ways with things……look at the self-storage industry. Organized approach to sorting. Keeps track of what is being removed. Eliminate wasted transportation and motion due to extra parts Reduce time to find what is needed by reducing the clutter These tags are used to identify unnecessary items that need to be either thrown out, recycled, sold or relocated. They are especially useful as a visual management tool as they easily communicate visually to other staff members that the tagged items are unneeded/unwanted. Remove all the items from the company within 45-60 days Do not create piles for removal Clears the confusion that clutter creates

- Removal Procedure Do not move pile from one part of the plant to another Items removed from company within 45-60 days Actively look for best customers Sell items to employees, Sell items through local and web based ads Conduct an auction for the public Donate to local colleges or trade schools

- How quickly can you get things when you need them and how quickly can you put it away Necessary tools and equipment are easily accessible Decide how many of each item will be stored in a given location (set height, size, and min/max inventory limits) Make it obvious when they are not in their correct place.

- Paint lines 2 to 4 inches thick All movable equipment must have a home location Provide an address for items (Items in rack are labeled) Place “Keep Clear” designations in places where safety is a concern Tool Check Card - Effective way to keep track of tools and person using the tool in the different work areas Color coding the card Communicate the status of the tool Tool broken Tool on order Tool upgrade Work from the floor up – focusing on the layout of the area first. (e.g. Work areas, aisle ways, and floor locations are established)

- Facilitate inspection and early detection of problems Identify and eliminate sources of contamination Contributes to improved morale, safety, breakdown and defect prevention

- Shine process should not be left for a special janitorial staff. It should be every associates responsibility. Paint equipment, tables, dollies, shelves – Creates showroom like appearance and help make labels, stencils, and other designation stand out Cleaning and degreasing equipment Refill fluids as needed Wipe down work surfaces Wipe out storage bins Wipe shelves and racks Clean tools Wipe down garbage cans Sweep and mop the floor

- Provide training so that all employees can implement the best practice/standard Determine standard procedures (based on best practices) and make them visible Sort - Standardize Red tag procedures and Red tag holding area rule Set in Order - Standardize location, number and position of all items (standardize colors, shapes, symbols, etc.) Shine - Standardize cleaning schedules and procedures Roles and responsibilities need to be clear and consistently applied To encourage Simplicity, Repeatability, minimize/eliminate Variability, Accountability

- All tool boards are painted the same color Boards have shadows and tool labels Boards are identified with an address

- Reduced injuries and work-related illness Safety and Quality go hand in hand Improvements in productivity and morale Cost savings – medical insurance and emergencies All safety equipment is present and is regularly maintained e.g. fire extinguishers, Personal Protective Equipment (PPE), First Aid kit All required signage is in place e.g. exits, hazards All trip hazards are eliminated All electrical cabling is safely routed All equipment and lighting is in working order All floor surfaces are in good condition All walkways and stairways are clearly marked and free from material and other obstacles

- Cost savings – medical insurance and emergencies All safety equipment is present and is regularly maintained e.g. fire extinguishers, Personal Protective Equipment (PPE), First Aid kit All required signage is in place e.g. exits, hazards All trip hazards are eliminated All electrical cabling is safely routed All equipment and lighting is in working order All floor surfaces are in good condition All walkways and stairways are clearly marked and free from material and other obstacles

- Ensue that employees understand that maintaining the levels of workplace organization is top priority Use self discipline, develop good habits, develop visual controls, Maintain the momentum generated during the initial implementation of 6S Ensure that Routines and Schedules specified in the standardized phase is properly maintained Build a continuous improvement culture which recognizes standards and invests in maintaining and developing them (through audits)

- Ingrain 5S as a culture through training and ongoing discipline – control, communication, train, monitor, improve Pocket Manual – Act as reminders Slogans – Help communicate the message Displays – “before” and “after” pictures Newsletter – Provide updates on ongoing projects Suggestion box – Provide opportunities to suggest improvement 6S audit sheet 6S corrective action tracking sheet